Search the Community

Showing results for tags 'Scroll saw'.

-

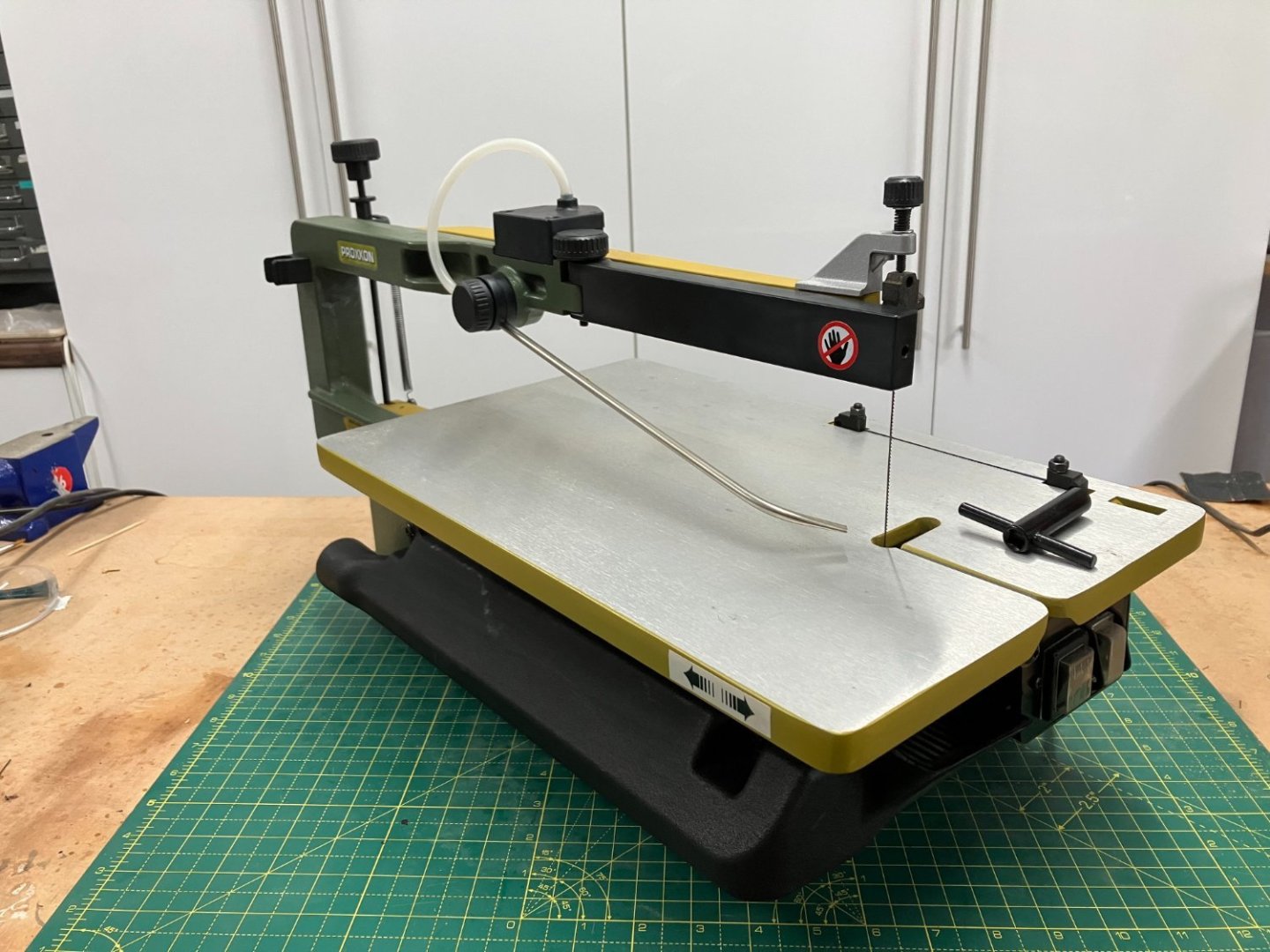

We are planning to move to a retirement village later this year and I won't be taking my larger workshop tools with me. I've already put my larger lathe and mill on ebay, but would much rather my modelling equipment went to a Forum member (I'm also listing my oscillating bobbin sander). I'm hanging on to smaller tools and in a funny sort of way I'm looking forward to going back to a simpler way of modelling. This is Proxxon's top of the range scroll saw and does everything you could want such a machine to do. I've used it quite a bit but it's still in perfect working order and comes with a set of coarse, medium and fine blades. I particularly like the handy slot on the table that keeps the blade holders exactly the right distance apart as you fit the blade. The saw currently retails for around £450 and I would be happy for it to go to a Forum member for £300. The saw is heavy (20kgs) so will need to be collected in person, from Worksop in North Nottinghamshire. Derek

-

Hello, I thought about buying a saw. The work I do will not require cuts of more than 1 cm. thick (scale 1:96 or 1:72 no more). For the space that I have and the budget the options are two: Dremel Moto Saw or Proxxon DS 230. My only doubt regarding the Proxxon is the possibility, or not, of finding blades in the local market, here it is possible to find Dremel blades but in Proxxon. I await your comments to remove the doubt as to which saw to buy. Thank you very much and greetings.

-

Hi all I have read all the posts about scroll saws, band saws, etc. I have a rather specific set of requirements and would like some advice and directions from owners. I will be cutting some pieces for my next build from holly for the bow pieces, and my micromark microliux mini scroll saw isn't up to the job. I also don't like that it doesn't have a vacuum port or blade dust blower. Looking for a replacement that is more capable and higher quality. . I have a Byrnes table saw so no need for ripping or straight cuts. Would like it to have vacuum port but not a deal-breaker. Unlikely to be cutting more than 1/4 or perhaps 3/8 inch woods including boxwood, cherry, holly, and ply. No metal or plastics. Will be doing a cross section in the future so capability to cut frame pieces inside and outside curves essential. I don't have the patience or dexterity to do this work with a coping saw. Modeling work only and space is constrained so don't want or need a "full sized " tool. A footprint similar to the micromark saw would be ideal. Willing to pay for a good tool but realistically $500 tops would prefer less. Is the similar sized and priced Proxxon an upgrade? Other suggestions feom users with similar tasks? Bruce

-

So, I've made the decision to spile all the planks for my upcoming build, as I love the look and fit of spiled planks. I'll basically be cutting each plank from a piece of sheetwood, by hand. While I will be using masking tape to trace the curve of the last plank in order to trace out my spiled plank, I'm still going to need a way to smoothly connect the dots that mark the widths of the proposed plank at each bulkhead on the other side, to complete the outline of the plank. Many people use's a set of ship's curves for this purpose, but I've been looking at the ACU-ARC adjustable curve ruler as an alternative. It looks like this: Basically, it consists of a number of flexible plastic strips bunched together. You can flex the ruler to meet the points you've marked and it will hold its shape due to the friction between the strips. You then simply trace along the flat edge to make your line. I'm wondering if this might be a better choice, since it will provide a nice smooth curve from start to finish, rather than using the traditional method of finding the best fit for a portion of the points with a ship's curve and repeating the process until the line is complete. What do you guys think? Also, one of the things I'm worried about is not currently owning a scroll saw... As it is, my only option seems to be cutting the rough shape of each plank out of the thin sheetwood using an X-Acto blade, then filing/sanding to the final shape. How easy do you think this will be with basswood and walnut sheetwood ranging from 1/32" to 1/16" thick? If I do decide to purchase a scroll saw, what type of blade should I get to smoothly cut sheetwood in this thickness range? I'm assuming I'd be looking for one with a high number of teeth-per-inch. Do you guys have any suggestions for the proper TPI range? My last question refers to the method of laying the tape in order to trace the correct curve of the last plank. I've read some descriptions of this process (and seen a few pictures), but I want to make sure I have this right. The correct method, as I understand it, is to lay the tape so that the portion of the tape that is laying on the existing plank is smooth, with no wrinkles or bends. The other edge of the tape (i.e., the portion that's hanging over the edge of the existing plank) can be a little wrinkled without affecting the accuracy of the curve you're tracing. Is that right? I've tested this method on the rim of a glass that is wider at the mouth than at the base, and I ended up with a nice curved strip that wrapped around the glass and was perfectly parallel to the rim of the glass, so it seems to be a good way of doing it. What do you guys think? As always, thanks for your advice, opinions, and assistance!

-

after a long time thinking and going back and forth , my first power tool I want to buy is a scroll saw. I can use this for scratch building in the future , but also for cutting out scroll saw patterns (which I have heaps off) I had a look at the cheap models but beside worrying how accurate they would cut they all have pinned blades which cant be used when you have very small interior cuts. so I have narrowed it down to 4 which are available in Oz : 1) proxxon DS 230/E : the cheapest which also comes with a fence and mitre guide. no tilting table but not sure if I would use this feature. it has the smallest throath size and needs a tool to change blade. 2) Makita sj401 : pinned and pinless blades, need tools to change. but seems there a lot of negative comments about this model 3) carba-tec 18" scroll saw : cant find much about this one and it seems to have all the features I need 4) carba-tec excallibur 16, 21 or 30" : seems a very good one and the saw tilts instead of the table . easy to switch blades because the arm swings up , very handy for interior cuts. but at over $1000 its a lot of money to invest. i haven't included hegner because just too expensive for what i need any info comments would be appreciated

-

I'm moving to scratch building with the Echo cross section and buying a scroll saw to cut frames. Lots of choices there but my question is what blade (size, type, model - not manufacturer) for what purpose. Specifically what blade to use to cut frames from boxwood for the Echo, which one to use for small pieces of wood and very precise cuts without splintering, how to augment my Byrnes saw with precise cuts, curves, 90 degree turns etc. I've never owned a scroll saw. I'm sure it's a different experience than all the othe model and big boy power tools I have.

- 10 replies

-

- Scroll saw

- blades

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.