-

Posts

694 -

Joined

-

Last visited

About ChrisLBren

- Birthday 11/08/1969

Profile Information

-

Gender

Male

-

Location

Barrington

Recent Profile Visitors

-

ChrisLBren reacted to a post in a topic:

HMS EURYALUS by Matiz - FINISHED - scale 1:56

ChrisLBren reacted to a post in a topic:

HMS EURYALUS by Matiz - FINISHED - scale 1:56

-

ChrisLBren reacted to a post in a topic:

LˇAmarante by marsalv - 1:36 - POF

ChrisLBren reacted to a post in a topic:

LˇAmarante by marsalv - 1:36 - POF

-

ChrisLBren reacted to a post in a topic:

HMS PEGASUS by giampieroricci - Scale 1:36 - Swan-Class Sloop from plans by David Antscherl & Greg Herbert

ChrisLBren reacted to a post in a topic:

HMS PEGASUS by giampieroricci - Scale 1:36 - Swan-Class Sloop from plans by David Antscherl & Greg Herbert

-

Knocklouder reacted to a post in a topic:

OcCre HMS Victory Limited edition

Knocklouder reacted to a post in a topic:

OcCre HMS Victory Limited edition

-

Ondras71 reacted to a post in a topic:

Le Gros Ventre by ChrisLBren - 1/36

Ondras71 reacted to a post in a topic:

Le Gros Ventre by ChrisLBren - 1/36

-

GrandpaPhil reacted to a post in a topic:

Le Gros Ventre by ChrisLBren - 1/36

GrandpaPhil reacted to a post in a topic:

Le Gros Ventre by ChrisLBren - 1/36

-

No Idea reacted to a post in a topic:

Bonhomme Richard by Blockplane - Scale 1/48 - ANCRE

No Idea reacted to a post in a topic:

Bonhomme Richard by Blockplane - Scale 1/48 - ANCRE

-

mtaylor reacted to a post in a topic:

Bonhomme Richard by Blockplane - Scale 1/48 - ANCRE

mtaylor reacted to a post in a topic:

Bonhomme Richard by Blockplane - Scale 1/48 - ANCRE

-

tadheus reacted to a post in a topic:

Le Gros Ventre by ChrisLBren - 1/36

tadheus reacted to a post in a topic:

Le Gros Ventre by ChrisLBren - 1/36

-

tadheus reacted to a post in a topic:

Le Gros Ventre by ChrisLBren - 1/36

tadheus reacted to a post in a topic:

Le Gros Ventre by ChrisLBren - 1/36

-

BlockPlane reacted to a post in a topic:

Bonhomme Richard by Blockplane - Scale 1/48 - ANCRE

BlockPlane reacted to a post in a topic:

Bonhomme Richard by Blockplane - Scale 1/48 - ANCRE

-

Nice work Chris - I know what you mean Ancre plans. They are so accurate - I made the same mistake leaving too much fat on the stern part assemblies on my Le Gros Ventre build and after a half dozen failed attempts I learned - the more accurate your parts are to the plans including the bevels/bias - the better the results. And less sanding !!! Chris

-

ChrisLBren reacted to a post in a topic:

Bonhomme Richard by Blockplane - Scale 1/48 - ANCRE

ChrisLBren reacted to a post in a topic:

Bonhomme Richard by Blockplane - Scale 1/48 - ANCRE

-

woodrat reacted to a post in a topic:

Le Gros Ventre by ChrisLBren - 1/36

woodrat reacted to a post in a topic:

Le Gros Ventre by ChrisLBren - 1/36

-

ChrisLBren reacted to a post in a topic:

HMS PEGASUS by giampieroricci - Scale 1:36 - Swan-Class Sloop from plans by David Antscherl & Greg Herbert

ChrisLBren reacted to a post in a topic:

HMS PEGASUS by giampieroricci - Scale 1:36 - Swan-Class Sloop from plans by David Antscherl & Greg Herbert

-

ChrisLBren reacted to a post in a topic:

Sloop Speedwell by Chuck - Ketch Rigged Sloop, 1752 - POF

ChrisLBren reacted to a post in a topic:

Sloop Speedwell by Chuck - Ketch Rigged Sloop, 1752 - POF

-

ChrisLBren reacted to a post in a topic:

HMS PEGASUS by giampieroricci - Scale 1:36 - Swan-Class Sloop from plans by David Antscherl & Greg Herbert

ChrisLBren reacted to a post in a topic:

HMS PEGASUS by giampieroricci - Scale 1:36 - Swan-Class Sloop from plans by David Antscherl & Greg Herbert

-

ChrisLBren reacted to a post in a topic:

Le Rochefort by No Idea - 1/24th Scale - First POF Build

ChrisLBren reacted to a post in a topic:

Le Rochefort by No Idea - 1/24th Scale - First POF Build

-

ChrisLBren reacted to a post in a topic:

HMS PEGASUS by giampieroricci - Scale 1:36 - Swan-Class Sloop from plans by David Antscherl & Greg Herbert

ChrisLBren reacted to a post in a topic:

HMS PEGASUS by giampieroricci - Scale 1:36 - Swan-Class Sloop from plans by David Antscherl & Greg Herbert

-

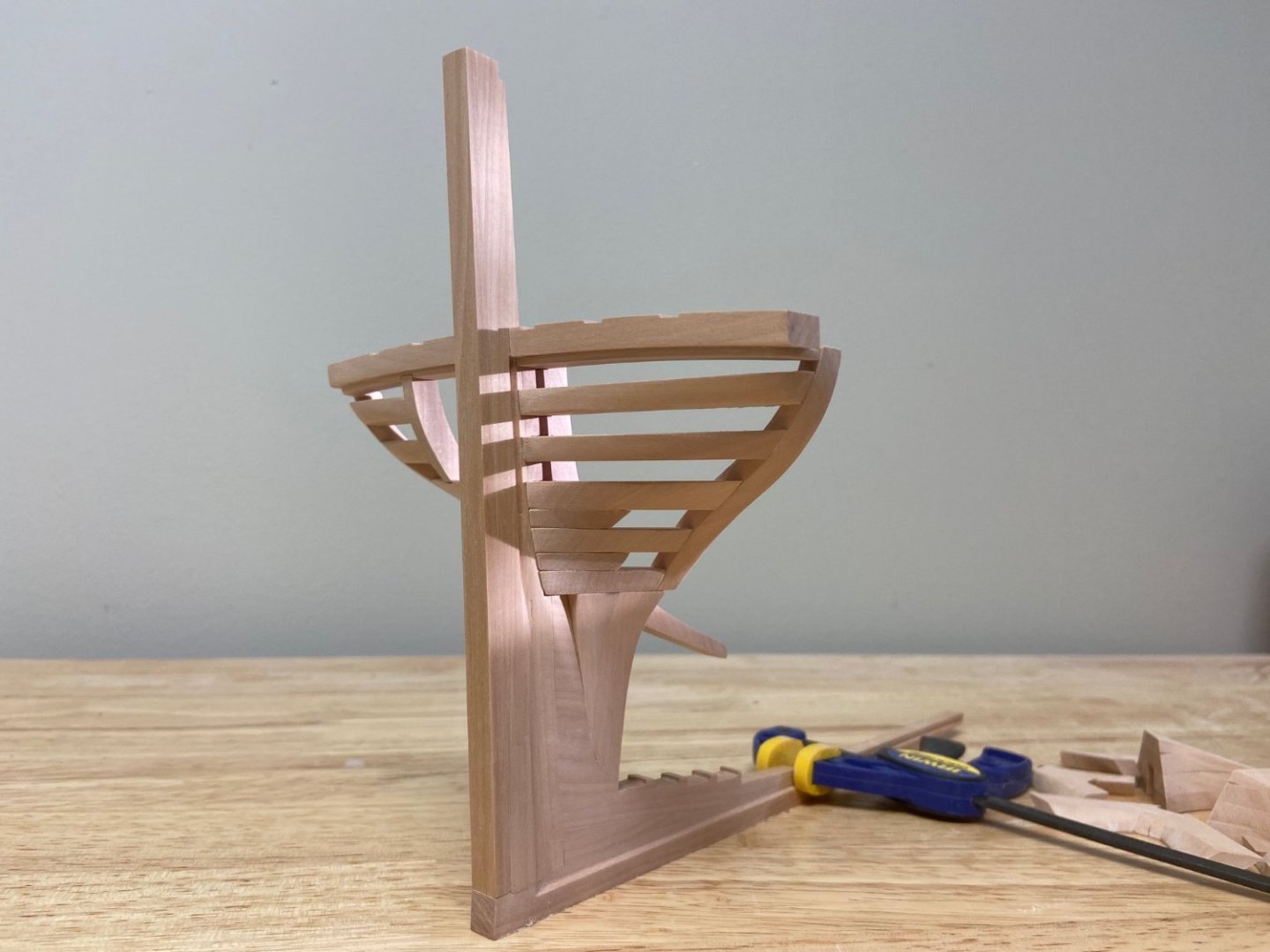

ancre Le Gros Ventre by ChrisLBren - 1/36

ChrisLBren replied to ChrisLBren's topic in - Build logs for subjects built 1751 - 1800

No dovetails for me on the wing transom. They're not necessary and posed way too much of a risk when creating that part - and now even riskier now the assembly is complete ! Thanks for the advice on the extensions Mark. -

ancre Le Gros Ventre by ChrisLBren - 1/36

ChrisLBren replied to ChrisLBren's topic in - Build logs for subjects built 1751 - 1800

Thanks everyone - I will attempt the hawse extensions next. Im just trying to wrap my head around the approach and understanding the plans here. I believe one must plane the blanks to the proper angle first, then cut out the pattern. The biases are then added once the pieces are in a jig that depicts the tops of the extensions and their positions on the curve. -

ancre Le Gros Ventre by ChrisLBren - 1/36

ChrisLBren replied to ChrisLBren's topic in - Build logs for subjects built 1751 - 1800

Good morning Group, After some spending some time in the doldrums, I have restarted Le Gros Ventre and spent the past month working on this assembly. I probably built each part a half dozen times... Decisions, do I begin the installation of the frames or tackle the other really tough part of the build, the hawse extensions? -

Love it Chuck - so simple but effective !!!!

- 786 replies

-

- speedwell

- syren speedwell

-

(and 1 more)

Tagged with:

-

Hey Group, I am wondering if there is a full proof way to avoid this. I am notching pearwood using a mill and sometimes experience chipping on the cut. Right now my mill is set at a high speed at 10000 RPM and I am using new mill bits. Do I need to reduce speed here or just making many small passes at a time for each notch ? Thanks !

-

So far after two coats of 1lb blonde shellac on some scraps Im not happy with it - I think I will mix up to a 2lb cut. Its almost a "non finish" at this point after buffing in between coats with steel wool. I do like the pure tung oil finish better at this point however dont want to give up yet. I also understand many modelers use a wax finish as an alternative. I am a fan of more natural finishes than a poly finish. Any tips are appreciated as always.

-

Hi Group, I bought some blonde shellac flakes at Rockler to experiment with on Black Friday. I am wondering for those of you who use this finish what sort of cut rate you use. Many recommend a two lb cut rate however I wonder if this is too thick. I created my first batch at a 1lb cut rate and would rather build up a finish than lay on one that is too thick. Any advice is appreciated ! Chris

-

OcCre HMS Victory Limited edition

ChrisLBren replied to modeller_masa's topic in Wood ship model kits

That model looks terrible in my opinion - a bastardized attempt at accurate construction. Build the Caldercraft model or Chris's design with Amati if it ever sees the light of day -

Jim Byrnes Saw Rattling Vibration

ChrisLBren replied to ChrisLBren's topic in Modeling tools and Workshop Equipment

Problem solved - the belt guard was causing the issues. I removed it - with the new motor the saw cuts better than ever. Belt guard is probably bent - will need to straighten it out before re - installing -

Jim Byrnes Saw Rattling Vibration

ChrisLBren replied to ChrisLBren's topic in Modeling tools and Workshop Equipment

Thanks Kurt - will check this out and get back -

Jim Byrnes Saw Rattling Vibration

ChrisLBren posted a topic in Modeling tools and Workshop Equipment

Hey Group, I am wondering if any of you have a tip for me here. Recently I had the saw's motor replaced by Jim and it was shipped back to me. Once I turn the power I noticed a rattling vibration noise where the motor plugs into the rear belt gear of the saw under the guard. After maybe no more than 10 or 15 seconds if I touch the belt guard its red hot. Something is causing friction back here obviously. The belt guard does look properly seated on the unit. I have an email into Jim - I know he's trying to take some time off right now. Any ideas are appreciated - I do not want to operate the saw until I can solve this issue. Chris

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpg.4c972e7c6351ce6ecccb529d11e1c4b1.jpg)