-

Posts

694 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by ChrisLBren

-

Workshop Set Up Question

ChrisLBren replied to ChrisLBren's topic in Modeling tools and Workshop Equipment

Actually Ive got a ton of wall space down there - I just want to have a safe environment to work in good lighting, benches for my tools, a desk to work on, and dust collection Is the priority so I can start modeling again. -

Workshop Set Up Question

ChrisLBren replied to ChrisLBren's topic in Modeling tools and Workshop Equipment

Good question - I've got a contractor visiting to give me an estimate. I'm just wondering can I leave the ceiling as is - for now if I get a dust collection system ? Obviously I've got a lot of expenses right now between the new house and the twins. -

Workshop Set Up Question

ChrisLBren replied to ChrisLBren's topic in Modeling tools and Workshop Equipment

Is this what you guys are talking about as far as dust filtration ? http://jdstools.com/product/air-tech-hp-2/ -

Workshop Set Up Question

ChrisLBren replied to ChrisLBren's topic in Modeling tools and Workshop Equipment

Hey Everyone, Thanks for the ideas - our basement is does not leak so far (we've had a lot of rain in Chicago) and it stays relatively cool in the summer and warm in the winter. There is also double paned glass on the windows. I think I need about 300 square feet of drywall - the tricky thing is dealing with the pipes and wires that protrude -so Id rather hire a professional - shouldnt be more than 550 dollars or so. Dust filtration is a priority for sure. -

Hey Group, Some of you know we just bought a new house with a finished basement (kids playroom with a bathroom and bedroom for our nanny) and a locked door which goes to storage area and partially finished basement for this area of the house. Our house has a basement 50 percent below grade and the walls nearest the finished heated basement are dry walled (code for our city) - the other walls outer walls are insulated above ground and not finished. Im not sure if I want to breathe it or spread saw dust around here. Then again Im not an expert. Is this a suitable setting for a workshop without drywalling the rest of the basement - Ive attached photos. I'd do it myself but there are several pipes and fixtures directly mounted on the studs - which will make this tough unless I hire someone (which may be my best choice). The other option is I mount the work bench in the garage - bring the heavy duty tools up there as I need them for milling and lock them up from the kids (not ideal) - and use a lighter work desk and chair in my office upstairs. Your thoughts and advice are appreciated - a bit bummed - my fathers day gifts were two new work benches and a wheeled storage unit for my tools - which is not ideal now.

-

Come on Ben - you should have carved it yourself....(smile). Looks fantastic - wow....

- 885 replies

-

Fiebing's Leather Dye

ChrisLBren replied to JohnB40's topic in Painting, finishing and weathering products and techniques

You can work with Fiebings with some advance planning. It does bleed easily so I would suggest scribing a line and then mask with Tamiya tape between the areas you dont want the dye to bleed into and be careful not to flood it. Make sense ? And then I've used danish oil as a top coat. Check out my Confederacy log to see the results. I'd probably just use water based paint next time though - as Gaetan said - its much easier to control. -

Hey Gaetan I just noticed your wales are now black ? Did you paint, stain or dye them ? Chris

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

A ship that big might be my last - but I do have plenty of room in our new house to display a few models - I still have Confederacy to finish and a Wappen Von Hamburg hull laying in wait as well...

- 290 replies

-

- frigate

- confederacy

-

(and 1 more)

Tagged with:

-

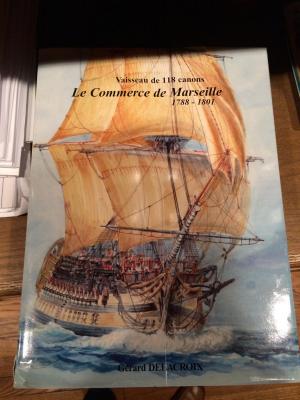

Hey Group I've moved into our new house - I've attached photos of my new workspace (which needs to be set up - I also have a three car garage and a large deck for workspace) and my study where I have a big wall to house a ship model (you can see the profile of the plans of the 118 Commerce de Marseille which would easily fit in this space at 1/48). Its either this ship or the 74 - funny aside - I bought a smaller Weber gas grill this past weekend - the Spirit - and I'm trading up for the Genesis because the wife said it was too small. So maybe I should go for the 118 built as the 120 L'Orient - since she says go big or go home ! Chris

- 290 replies

-

- frigate

- confederacy

-

(and 1 more)

Tagged with:

-

Hey Ben, I think 150 is fine above the wales where you will plank - but I would sand at 320, then 400 and finish at 600 grit below the wales for optimum finish. Sorry to be Mr Miyagi here from Karate Kid (LOL). Its looking good !!! Chris

- 885 replies

-

Gaetan, The sculptures look wonderful ! I'm also a huge fan of the look of using one wood exclusively for a build. I had no idea you could realize sculptures of this quality with cherry - goes to show it all has to do with the skill of the artist. Chris

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

Wow - love it Gaetan - what wood are you using? Im a huge fan of your 74s and you've surpassed them with these carvings. Well done !!!!

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

Only the forward most head timbers left - and then its on to installing the rail and hopefully some pictures. The Byrnes disc sander has come in big time for making these rapidly (as my scrap pile grows). Id advise anyone building her to use a hardwood for these - I'm amazed Chuck was able to pull it off with basswood considering how fragile this structure is. Trial and error is the only way I've found to make these vs using templates etc... This is by far the most challenging part of this build - Confederacy builders you are warned...LOL

- 290 replies

-

- frigate

- confederacy

-

(and 1 more)

Tagged with:

-

I received mine last week - they're great ! I'm studying these intently right now along with book 1 of the 74 Gun ship. And actually the author makes a very valid case for both of these alternate 74s to Boudriots generic vessel - i think the total difference being about 4 feet in length. I lay out his findings in more detail if there is interest, Chris

-

I've got both a Byrnes table saw and disc sander on way...... Cant wait to use the sander on those head timbers that have been giving me fits - pics soon !!!

- 290 replies

-

- frigate

- confederacy

-

(and 1 more)

Tagged with:

-

Wow - that looks great ! What a stunning figurehead for a gorgeous model. Chris

- 1,477 replies

-

- essex

- model shipways

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.