-

Posts

695 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by ChrisLBren

-

Hey Group, I am finally about to buy a bandsaw - keep in mind I have my cabinet maker cuts my wood to spec - so I am not cutting more than 1 inch thick nor am I resawing. I have narrowed it down to these two models - both under 600 dollars. I do like the flexibility of the Jet for other non ship building projects and the 1/2 HP with a solid fence. However the Rikon has less horsepower with 1/3 HP but is 200 dollars cheaper. It does get better reviews though. Any feedback is appreciated. Jet® JWB-10 Open Stand 10'' Bandsaw | Rockler Woodworking and Hardware RIKON 10-305 Bandsaw With Fence, 10-Inch - Power Band Saws - Amazon.com

-

Hi Group, Hoping to get some tips here. I know this saw is designed very well, however I am having problems. I recently replaced both the blade and the belt, and I am still barely able to cut 1/4 inch pear wood with it. 6 inches into the cut it stalls. I am sure I am doing something wrong here. Any advice is appreciated. Thanks to everyone's tips on the thickness sander it now works like a dream - hoping I can figure out the saw.

-

Hi Mark, Please share what blade you bought from Martindale for standard ripping of planks and also for stock thicker than 1/4. I have adjusted my fence quite a bit per instruction and still get stalling in anything much over 1/4 depending on the length of the cut. This is one of the main reasons I want to buy a band saw. Thanks Chris

-

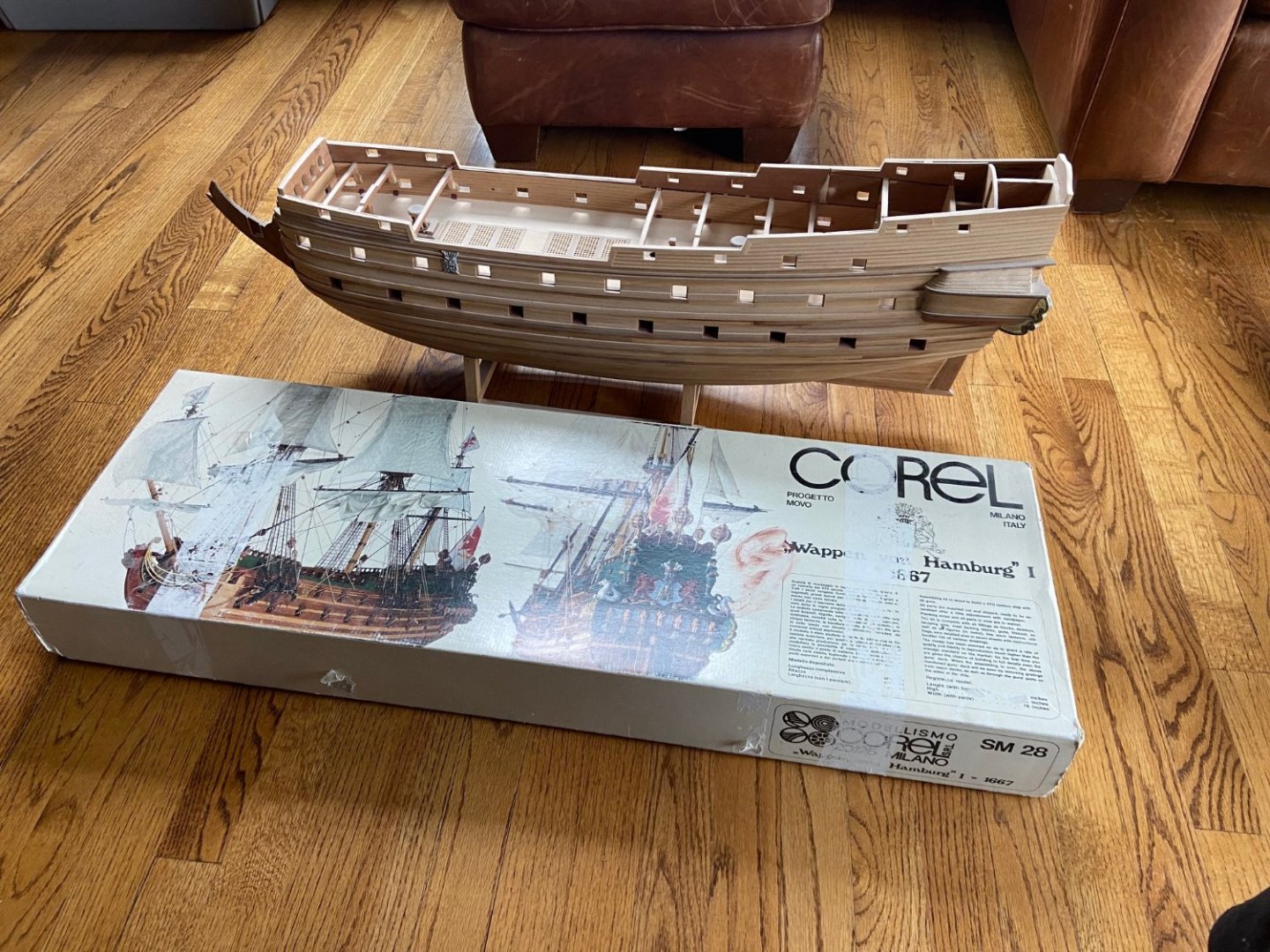

Gentleman - clearing the decks for the next project along with my LGV and I will never get to these. They are looking for a home. You pay for the shipping from Illinois and make a donation to the NRG and they are yours. Wappen hull is complete as are the kits contents and Chucks Winnie is ready for the gunport framing with the cherry included in stage 2 along with the boxwood carvings. Contact me with any questions.

-

Hey Group, I found a new hardwood dealer in the Northwest Suburbs offering dimensioned Black Cherry with the hope of having a local source/easy access. Here are the results of two samples, the Pear lumber I currently own and Cherry sample sanded and finished with one coat of pure tung oil. The Cherry is pretty but much darker and figured - more appropriate for furniture than ship building in my opinion. I decided to order another flitch of Pear for 300 dollars and have my cabinet maker break it down into 1/2 inch billets for 100 dollars for the hours worth of work. I really don't want to resaw boards and worry about the dust and floor space of a larger 14 inch bandsaw - so I will probably go ahead and buy the 10 inch Grizzly or Jet which should be sufficient for my needs cutting 1 inch thick or less hardwood. Send me a PM if anyone is interested in the Hardwood Dealer here in Chicagoland. They also offer Walnut, Cherry and Hard Maple. Nice guys.

-

F4U-1A Corsair by DocRob - FINISHED - Tamiya - 1/32

ChrisLBren replied to DocRob's topic in Non-ship/categorised builds

Simply amazing - one of the best aircraft models I've ever seen. Congrats -

Band Saw Recommendations

ChrisLBren replied to ChrisLBren's topic in Modeling tools and Workshop Equipment

Thanks for all of the replies - I will check out all of the recommendations. Merry Xmas to everyone. As far as the Bandsaw requirements I'm interested in ripping boards into 1/2 and 9/32 billets for a certain French Frigate in 1/36. Because of the amount of wood required (a monster at 5 feet 7 inches unrigged) - I want to be able to do this in house. I believe a good band saw in conjunction with my DeWalt Table saw should do the trick. The TAIG Mill is a dream machine to work with - much more accurate than the Proxxon MF70. Part of me wishes I could re do all of the keel and frame parts on the Big Belly with it. I want a Bandsaw of the same quality as the TAIG and Byrnes tools - you do get what you pay for. Best, Chris -

Hello Group, With the addition of my Taig Mill, Emco Unimat 3 as my metal lathe, I am thinking I need one more tool - a bandsaw to reduce lumber before final dimensioning with my Brynes tools. Thoughts please - ideally I would like to be able to reduce 1 inch thick board to dimensions needed for our hobby. My local cabinet maker is great - however I would like the ability to do this in house in my basement. Christmas is a great time to buy more tools Happy Holidays everyone !!!!

-

La Palme by Tobias - 1:36 - POF

ChrisLBren replied to Tobias's topic in - Build logs for subjects built 1501 - 1750

Looks really nice Tobias !!!! -

F4U-1A Corsair by DocRob - FINISHED - Tamiya - 1/32

ChrisLBren replied to DocRob's topic in Non-ship/categorised builds

This looks fantastic - I can't believe what some of you guys can do with plastic models. Awe inspiring !!!! -

ancre Le Gros Ventre by ChrisLBren - 1/36

ChrisLBren replied to ChrisLBren's topic in - Build logs for subjects built 1751 - 1800

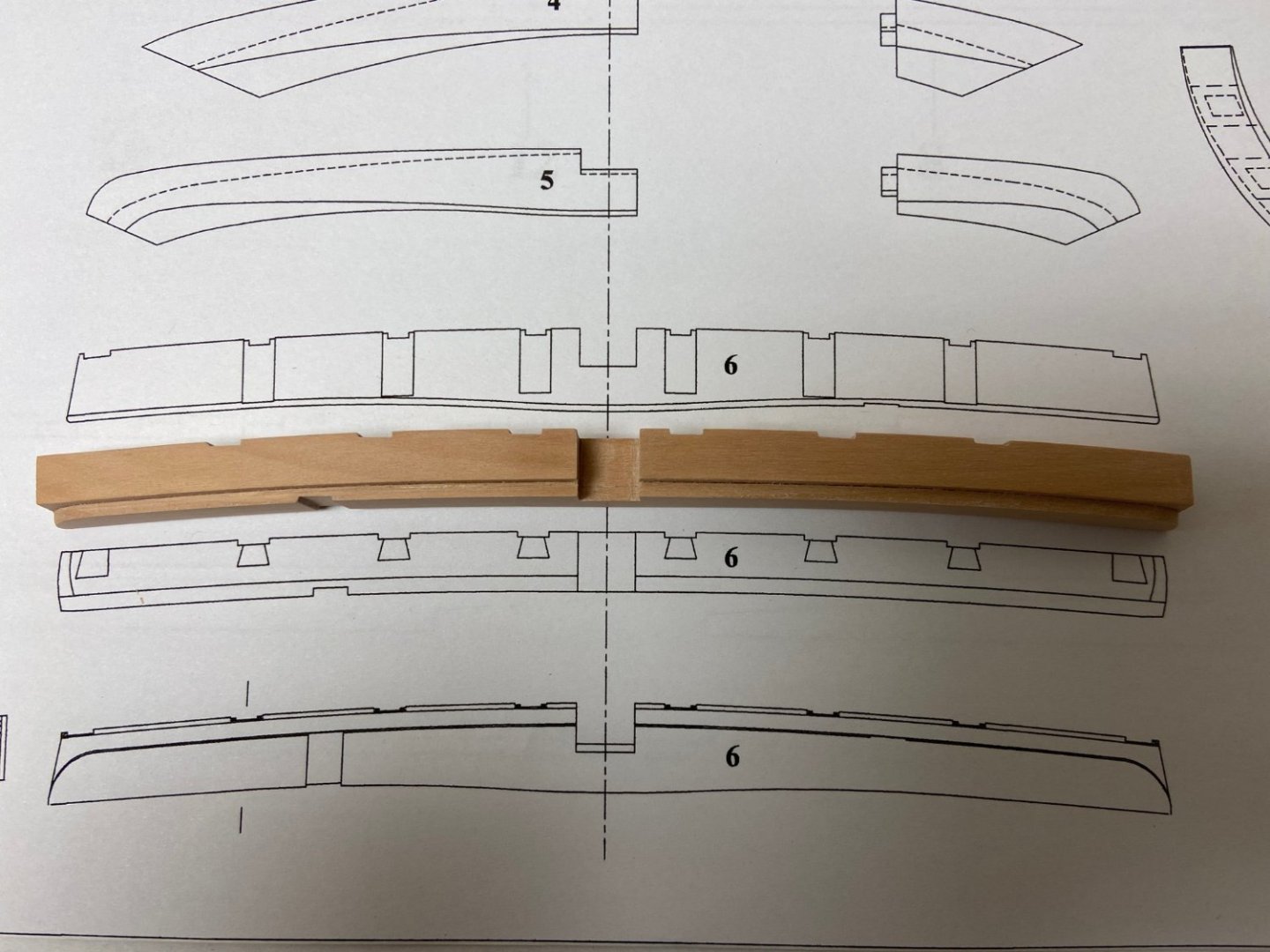

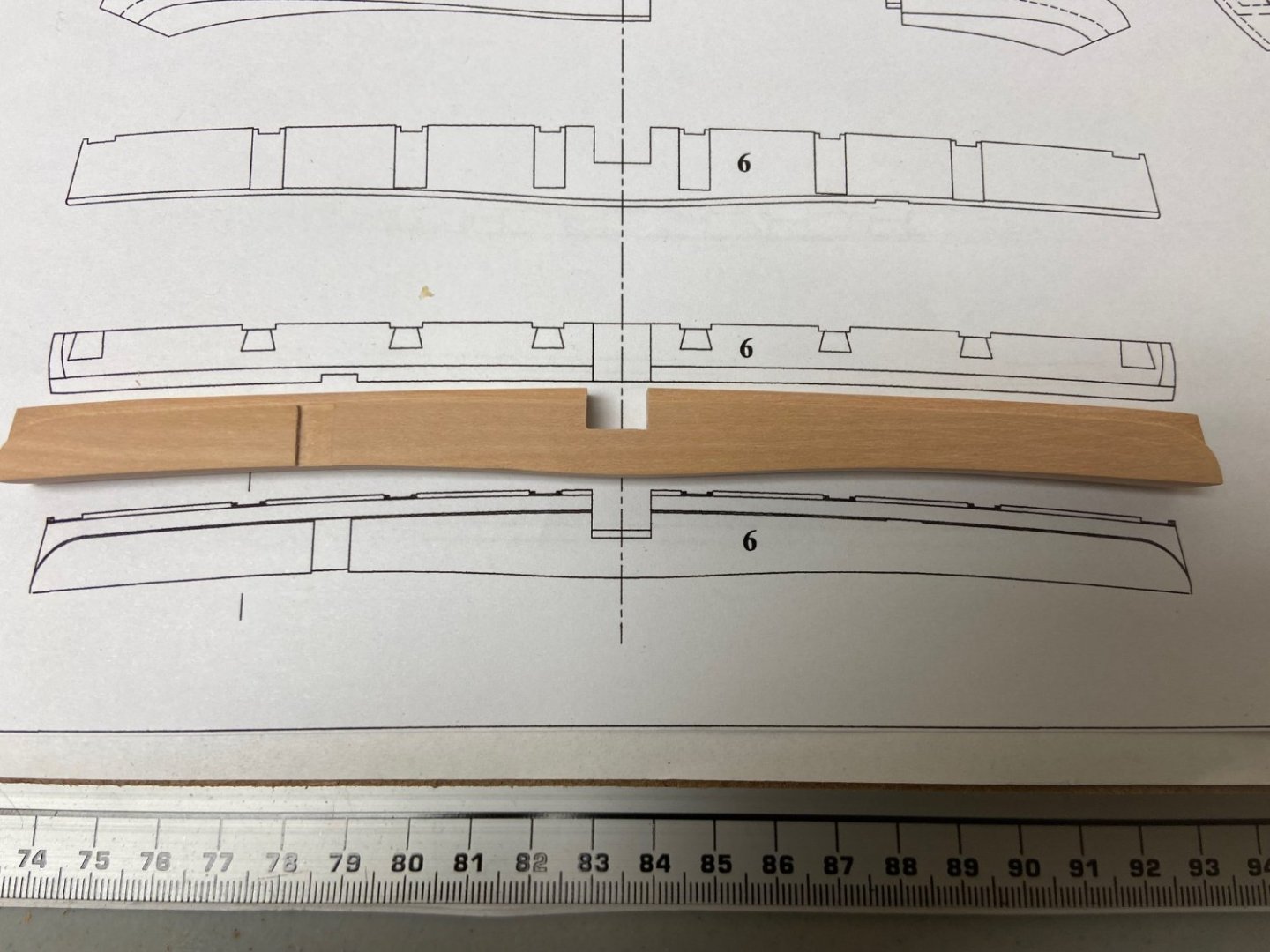

Probably the most difficult part to produce so far - Wing Transom. I used every tool in my shop (mill, all the sanders and chisels). I left off the dove tails in the rear of the part as it may make aligning the legs of the stern trickier later. They really aren't necessary for the structure and the risk of screwing up my third attempt at this part isn't worth it ! -

ancre Le Gros Ventre by ChrisLBren - 1/36

ChrisLBren replied to ChrisLBren's topic in - Build logs for subjects built 1751 - 1800

Thanks Greg ! Yes I am - my schedule is grab some coffee and work 430am-630am while everyone else in the family is asleep (my workshop is in the basement which helps with the noise) I really treasure this time doing a little everyday and just enjoying the process to begin my day.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.