-

Posts

450 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by *Hans*

-

A little bit late from my side, but yes, it is available!

-

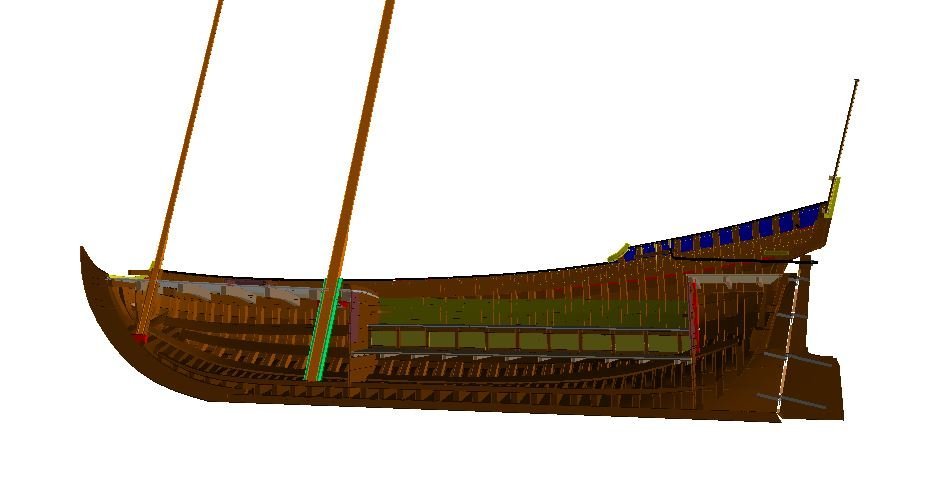

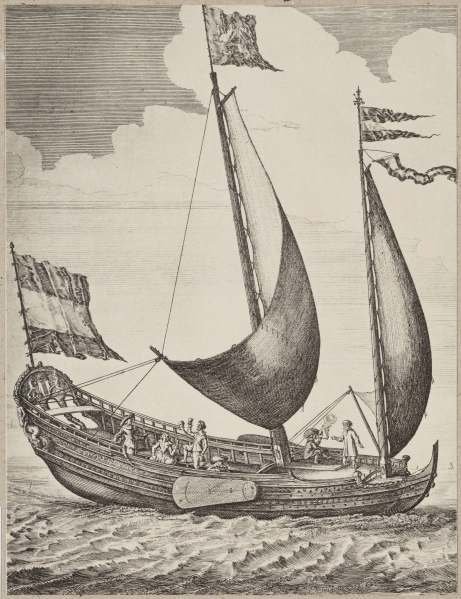

I do have a few images, one made by René Hendricx, on behalf of Ab Hoving (who has worked out the original charter, made by the 17th century writer van Yk, into this model) and some paintings from around 1640 which have been an inspiration for me for this particular model. But they don't really give a clue how the inside of the Speel-jaght was fitted out. Hans

-

Hello Syhobbs, Could you please send some photos to kolderstok at gmail.com? I will have a look at them and see if I can find a solution for you. Hans Kolderstok Edit: in the meantime I did have contact with Syhobbs. It turned out he had an old batch of ornaments, where the kit nowadays has newly sculpted and formed ones. A new set is in the make for him. Hans

-

Why do some manufacturers make single plank kits?

*Hans* replied to Meriadoc Brandybuck's topic in Wood ship model kits

I did give a reaction on this, but unfortunately it has been deleted 😞 There is an article (in English) which explains how the toll on the sound was measured and calculated, and it was not in the way as decribed here above. Those who are interested please pm me so I can give the link. -

Hello Melissa, Thank you for this nice introduction. I will follow your build, but shall not give constant comments on what you have done so far. However - if you face any problems, difficulties or have other questions - please feel free to ask - by pm, or via your build log. Succes!

- 84 replies

-

- Statenjacht

- Kolderstok

-

(and 1 more)

Tagged with:

-

Hello mercdaddy27, Please ask your questions - here, or via kolderstok@gmail.com 🙂 Hans van Nieuwkoop Kolderstok Modelbouw.

-

Why do some manufacturers make single plank kits?

*Hans* replied to Meriadoc Brandybuck's topic in Wood ship model kits

Rumours spread fast 🙂 No, I am actually working on a Dutch fluit, and have the hull more or less finished. However, sales of the other models went up due to the pandemic and I can't hardly find the time to proceed on this new model. Further, maybe important for you: she isn't an easy model. The bulky shape of the hull is very difficult to make, and (how ironical) I am considering to offer a second layer of planking for this model, as the first layer (basswood) could come out quite battered.... Hans -

Just had a look at the finished model in the gallery. You did a great job in quite a short time. Kudos to you as well 🙂

- 136 replies

-

- kolderstok

- batavia

-

(and 1 more)

Tagged with:

-

It worked out very well, and is in fact not even that hard to do (or so it seems....)

- 136 replies

-

- kolderstok

- batavia

-

(and 1 more)

Tagged with:

-

...which is clearly visible! They align perfectly 👍

- 136 replies

-

- kolderstok

- batavia

-

(and 1 more)

Tagged with:

-

David, I'd like to make a small comment: the wood for the masts is beech wood 🙂 Hope you don't mind me saying this.

- 136 replies

-

- kolderstok

- batavia

-

(and 1 more)

Tagged with:

-

Well, I think you did a very fine job over here. 👍

- 136 replies

-

- kolderstok

- batavia

-

(and 1 more)

Tagged with:

-

You might have noticed the bulwarks are pretty solid now, after you have glued the ribs in place. 🙂

- 136 replies

-

- kolderstok

- batavia

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.