-

Posts

145 -

Joined

-

Last visited

About dewalt57

- Birthday 01/31/1947

Profile Information

-

Gender

Male

-

Location

No Hope, Alabama, USA

-

Interests

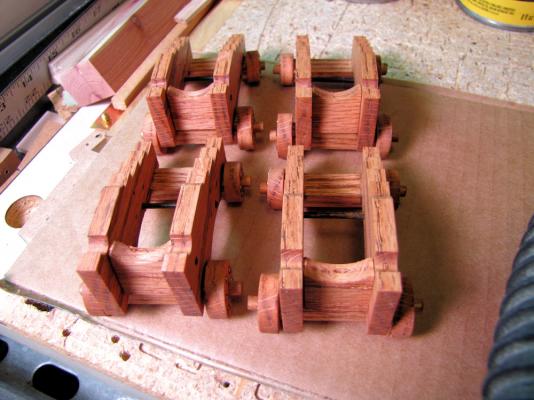

Cnc wood mill, computers, model ship building, wood working..... etc.

Contact Methods

-

Yahoo

dewalt57@yahoo.com

Recent Profile Visitors

-

GrandpaPhil reacted to a post in a topic:

H.M.S. Triton (Cross Section) 1:18 Scale, started by AL

GrandpaPhil reacted to a post in a topic:

H.M.S. Triton (Cross Section) 1:18 Scale, started by AL

-

Jolley Roger reacted to a post in a topic:

H.M.S. Triton (Cross Section) 1:18 Scale, started by AL

Jolley Roger reacted to a post in a topic:

H.M.S. Triton (Cross Section) 1:18 Scale, started by AL

-

Jolley Roger reacted to a post in a topic:

H.M.S. Triton (Cross Section) 1:18 Scale, started by AL

Jolley Roger reacted to a post in a topic:

H.M.S. Triton (Cross Section) 1:18 Scale, started by AL

-

Jolley Roger reacted to a post in a topic:

H.M.S. Triton (Cross Section) 1:18 Scale, started by AL

Jolley Roger reacted to a post in a topic:

H.M.S. Triton (Cross Section) 1:18 Scale, started by AL

-

dewalt57 reacted to a post in a topic:

HMS Bounty Launch by mattsayers148 - FINISHED - Model Shipways - scale 1:16 - SMALL

dewalt57 reacted to a post in a topic:

HMS Bounty Launch by mattsayers148 - FINISHED - Model Shipways - scale 1:16 - SMALL

-

dewalt57 reacted to a post in a topic:

HMS Bounty Launch by mattsayers148 - FINISHED - Model Shipways - scale 1:16 - SMALL

dewalt57 reacted to a post in a topic:

HMS Bounty Launch by mattsayers148 - FINISHED - Model Shipways - scale 1:16 - SMALL

-

dewalt57 reacted to a post in a topic:

HMS Bounty Launch by mattsayers148 - FINISHED - Model Shipways - scale 1:16 - SMALL

dewalt57 reacted to a post in a topic:

HMS Bounty Launch by mattsayers148 - FINISHED - Model Shipways - scale 1:16 - SMALL

-

dewalt57 reacted to a post in a topic:

HMS Bounty Launch by mattsayers148 - FINISHED - Model Shipways - scale 1:16 - SMALL

dewalt57 reacted to a post in a topic:

HMS Bounty Launch by mattsayers148 - FINISHED - Model Shipways - scale 1:16 - SMALL

-

dewalt57 reacted to a post in a topic:

HMS Bounty Launch by mattsayers148 - FINISHED - Model Shipways - scale 1:16 - SMALL

dewalt57 reacted to a post in a topic:

HMS Bounty Launch by mattsayers148 - FINISHED - Model Shipways - scale 1:16 - SMALL

-

dewalt57 reacted to a post in a topic:

Triton Cross Section by Snowmans

dewalt57 reacted to a post in a topic:

Triton Cross Section by Snowmans

-

dewalt57 reacted to a post in a topic:

3D Printing - Not Just Yet!

dewalt57 reacted to a post in a topic:

3D Printing - Not Just Yet!

-

dewalt57 reacted to a post in a topic:

3D Printing - Not Just Yet!

dewalt57 reacted to a post in a topic:

3D Printing - Not Just Yet!

-

dewalt57 reacted to a post in a topic:

3D Printing - Not Just Yet!

dewalt57 reacted to a post in a topic:

3D Printing - Not Just Yet!

-

egkb reacted to a post in a topic:

Wire Ga size chart

egkb reacted to a post in a topic:

Wire Ga size chart

-

dewalt57 reacted to a post in a topic:

U-576 Work-in-Progress

dewalt57 reacted to a post in a topic:

U-576 Work-in-Progress

-

fatih79 reacted to a post in a topic:

H.M.S. Triton (Cross Section) 1:18 Scale, started by AL

fatih79 reacted to a post in a topic:

H.M.S. Triton (Cross Section) 1:18 Scale, started by AL

-

fatih79 reacted to a post in a topic:

H.M.S. Triton (Cross Section) 1:18 Scale, started by AL

fatih79 reacted to a post in a topic:

H.M.S. Triton (Cross Section) 1:18 Scale, started by AL

-

fatih79 reacted to a post in a topic:

H.M.S. Triton (Cross Section) 1:18 Scale, started by AL

fatih79 reacted to a post in a topic:

H.M.S. Triton (Cross Section) 1:18 Scale, started by AL

-

fatih79 reacted to a post in a topic:

H.M.S. Triton (Cross Section) 1:18 Scale, started by AL

fatih79 reacted to a post in a topic:

H.M.S. Triton (Cross Section) 1:18 Scale, started by AL

-

fatih79 reacted to a post in a topic:

H.M.S. Triton (Cross Section) 1:18 Scale, started by AL

fatih79 reacted to a post in a topic:

H.M.S. Triton (Cross Section) 1:18 Scale, started by AL

-

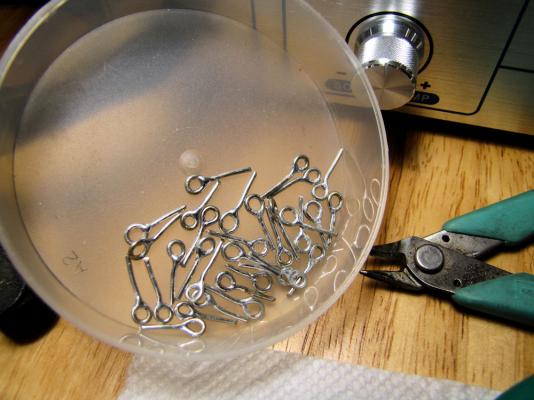

Only one problem with that Ray........ the eyelets are soft soldered (low heat) to close the loop!!! Thanks for thinking on it!! Me thinks this wire is not pure copper, it must be tin coated or something like that, it solders well enough but doesn't take to chemical baths too well it seems. I'm going with what I've got for now with paint on it. AL

-

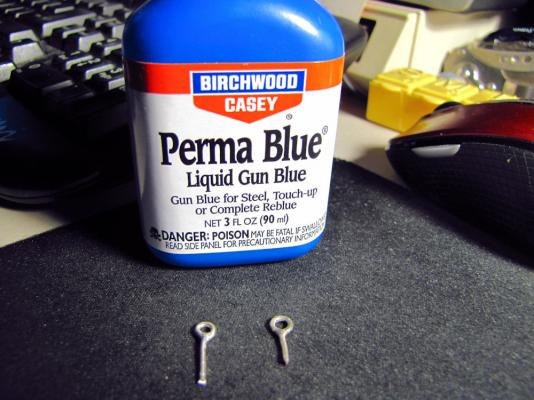

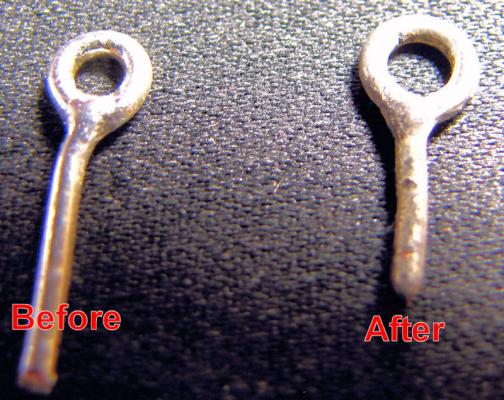

Hey Ray!!! Great to hear from you also!! Yes, I'm still working in the shipyard, haven't given up yet.... LOL Just doing a lot of thinking on ways to deal with each new build session as it comes along. Making very slow progress at it due to back pain problems but making some headway on this ship cross section. Working now on getting these eyelets painted and inserted into the cannon frames, one at a time while trying not to chip the flat black paint off the eyelets as I push them in the tiny holes I've drilled. So far I'm not 100% happy with the results, very hard to not chip the paint as you can see in these close up pictures. Yes.... I've thought of the gun blueing liquid and tried it but not happy with it either, not dark enough on this wire I'm using. I'll more then likely just do some touch up with a paint brush where I nicked the paint. AL

-

Finally got those last 3 cannons painted!!! Been working on the Admirals newly acquired used flagship ( 1995 Ford Aerostar mini van ) and had to sneak in the paint job while taking a break from it.... LOL She says I've done such a nice job on her flagship that I may get a promotion out of it..... LOL

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.