-

Posts

55 -

Joined

-

Last visited

About rjones726

- Birthday May 19

Profile Information

-

Gender

Male

-

Location

Port Orchard, Washington

Recent Profile Visitors

-

Pitan reacted to a post in a topic:

Captain John Smiths shallop 1608 by rjones726 - Ships of Pavel Nikitin - 1:32

Pitan reacted to a post in a topic:

Captain John Smiths shallop 1608 by rjones726 - Ships of Pavel Nikitin - 1:32

-

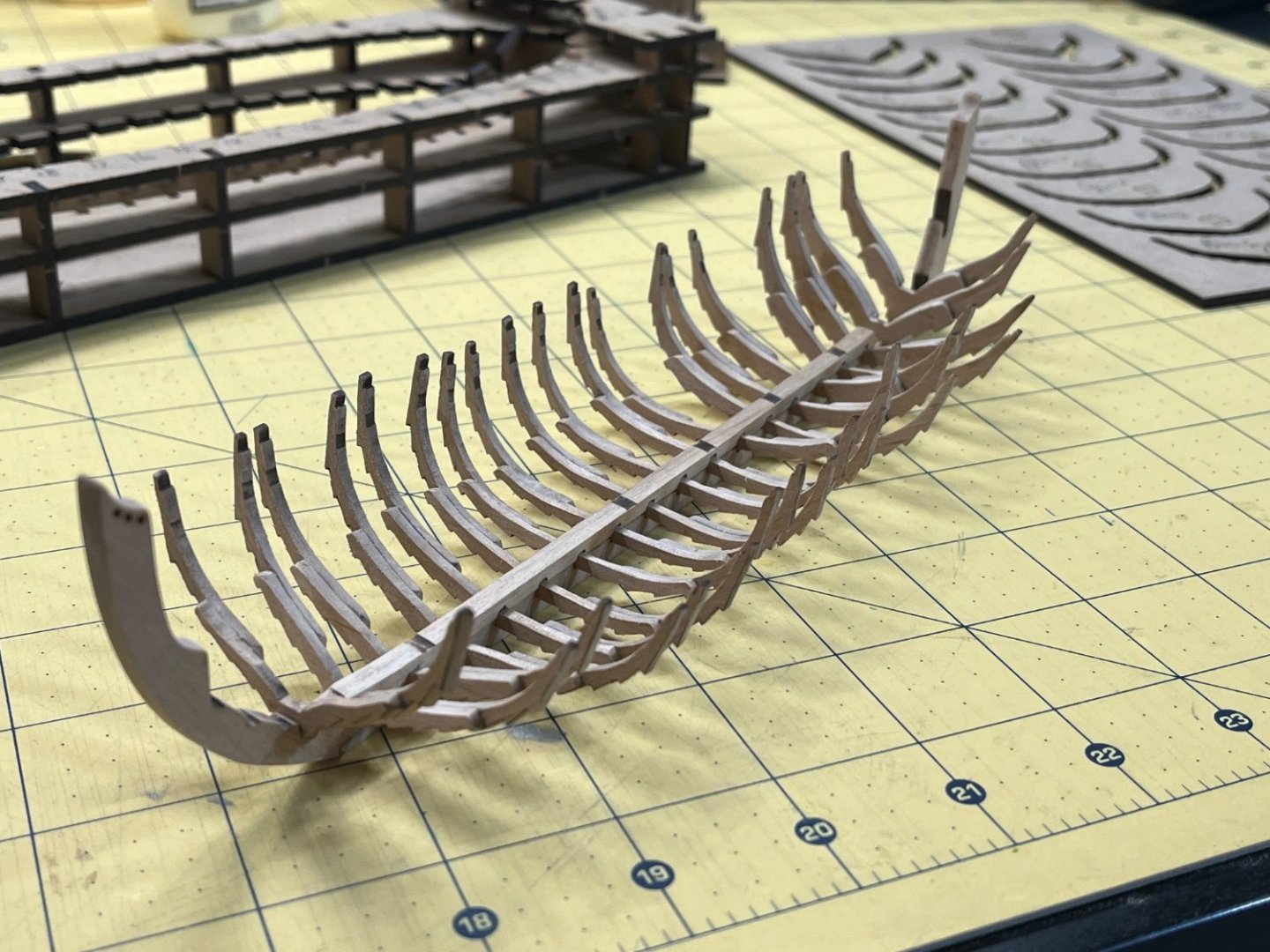

Today I completed the initial fairing of the frames ( minus the fore/aft cant frames). I took it out of the building jig to admire my work and realized how difficult it would be (for me) to properly align everything without it. I'm going to fine tune the fairing and remove any remaining char, then on Friday my lovely wife and I will be boarding a cruise ship in Seattle and heading to Alaska for a week of relaxation. Sort of like shore leave but...not ashore

-

rjones726 reacted to a post in a topic:

Captain John Smiths shallop 1608 by rjones726 - Ships of Pavel Nikitin - 1:32

rjones726 reacted to a post in a topic:

Captain John Smiths shallop 1608 by rjones726 - Ships of Pavel Nikitin - 1:32

-

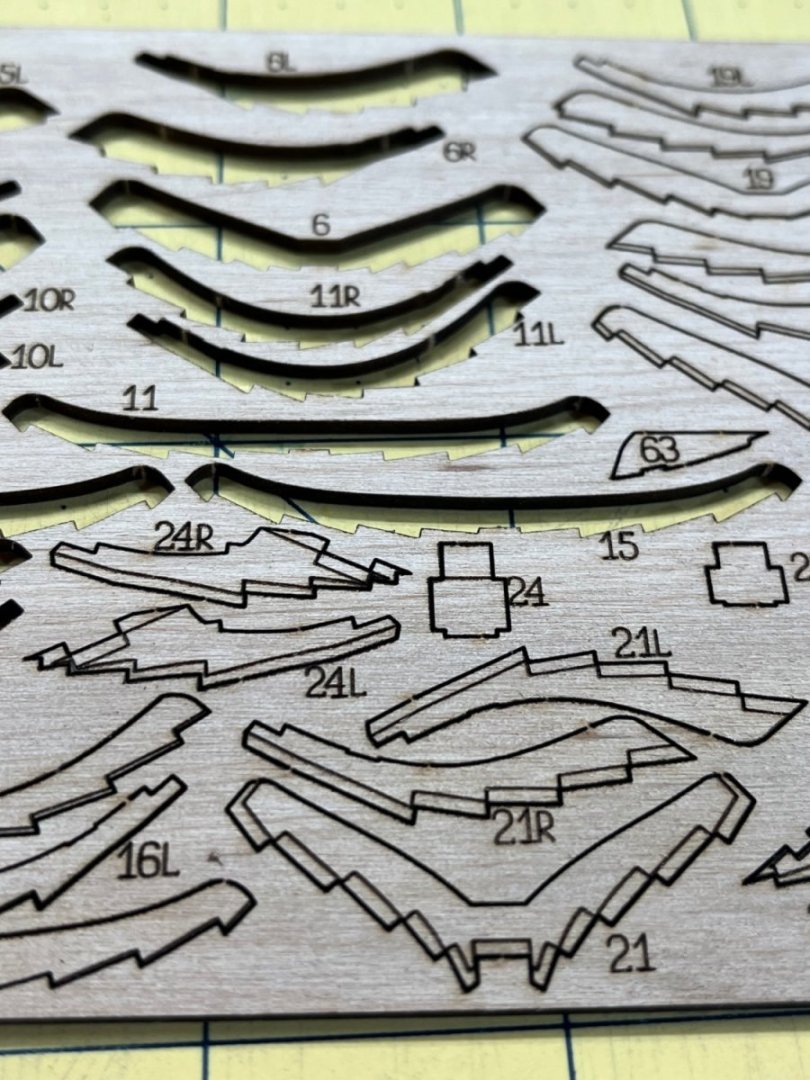

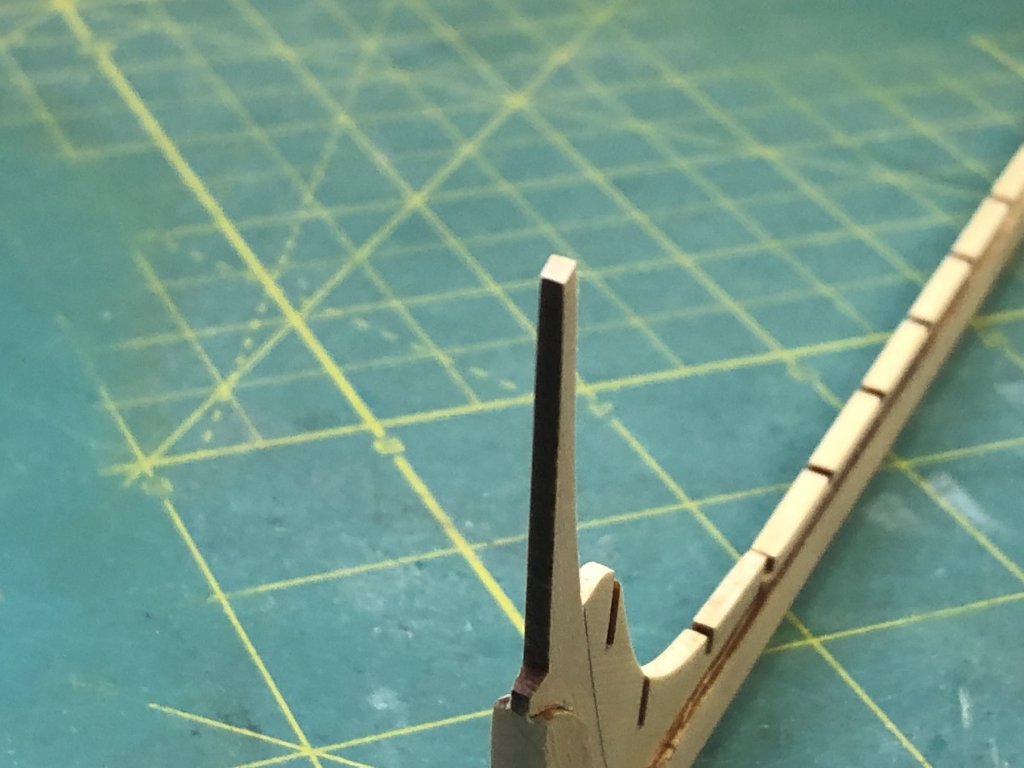

Good day all, After watching a you tube build series of the shallop (Thank you Olha)I decided that this was the kit for me. It seems to be challenging, but not so difficult that I'll give up in disgust (time will tell) I posted a photo in the "At a glance" topic this morning and then decided, "What the heck, I might as well start a build log as well". As you can see, construction is already underway. One of the things that drew me in was the use of jigs. Keeping things in alignment is critical and has caused me fits in the past. Once the jig was built and the 3 piece keel was together I began working on the frames. another jig is provided to ensure proper alignment during their construction. The pieces have a laser line that shows how much fairing is needed. I took my time to look at the instructions and to rewatch the video to ensure the pieces were placed correctly in the jig before gluing with PVA. I wrote "bow" and "stern" on the jig to remind me which way to insert the pieces. The instructions, while very clear, contain no text. Once the glue had dried I removed them and used files and sandpaper to remove the char and begin fairing. I stopped a bit short of the mark and will finish the fairing once the frames are glues and I can check them with a plank. Looking forward to your comments and questions, v/r, Rob

-

rjones726 reacted to a post in a topic:

Medway Longboat 1742 by fluffybunny - 1:24 - by Richard Glatter

rjones726 reacted to a post in a topic:

Medway Longboat 1742 by fluffybunny - 1:24 - by Richard Glatter

-

Lookin' good Rusty. I'm right there with you. The cold, wet weather has moved into the PNW today so I came home from work and finished gluing the keel to the frames. I'm sitting down with a glass of wine and a fire. Eventually I will take some photos and update my build log. Have fun! Rob

- 152 replies

-

- medway longboat

- syren ship model

-

(and 1 more)

Tagged with:

-

rjones726 reacted to a post in a topic:

Medway Longboat 1742 by Doug McKenzie

rjones726 reacted to a post in a topic:

Medway Longboat 1742 by Doug McKenzie

-

I haven't posted in a week or so- it's time for an update. I sanded the stern keel sections to achieve a 1/32" rabbit to accommodate the width of the planks, Everything went great until I decided to dry fit the transom. I sanded the entire stern keel section such that it didn't fit snugly in the laser notch of the transom any more. Of course I waited to check this until after I had glued the stern keel section onto the keel. I debated trying to use alcohol or some other method to try to get it off but in the end I decided to start over using the simplified keel. This time I was careful to only sand the lower portion and leave the upper part alone. The transom fit the way it was supposed to and I am pretty happy with the result. I have been taking my time assembling the frames and working on getting them to fit snugly into the build board. Next task is to get a good fit of all frames in the keel notches. I am sure there are other folks here who are as inexperienced as I am. Hopefully by talking about my mistake, someone reading this will avoid my error. v/r, Rob

-

rjones726 reacted to a post in a topic:

Medway Longboat 1742 -1/2" scale by Rustyj - FINISHED

rjones726 reacted to a post in a topic:

Medway Longboat 1742 -1/2" scale by Rustyj - FINISHED

-

Jeff, I have had the same problems you describe. I used an exact with a sharp #11 blade and a file. The key for me was to take a little off with the blade, file it smooth, and repeat until I removed enough material. I took my time and it came out better than I expected. Having a plan B really took the pressure off. I knew that if I screwed it up I would still be able to complete the project. Have fun!!! v/r, Rob

-

rjones726 reacted to a post in a topic:

Medway Longboat 1742 -1/2" scale - by Jeff

rjones726 reacted to a post in a topic:

Medway Longboat 1742 -1/2" scale - by Jeff

-

rjones726 reacted to a post in a topic:

Medway Longboat - 1742 - FINISHED - 1:24 Scale - by Ryland Craze

rjones726 reacted to a post in a topic:

Medway Longboat - 1742 - FINISHED - 1:24 Scale - by Ryland Craze

-

Well I guess my build is underway. I began by using a set of digital calipers to measure the width of the keel. I then divided by 2, set the calipers and made a faint mark on the charred sides of the keel pieces at the scarf joints. Using those marks as a gage I began to cut and file my way down. As I got close I began using the calipers themselves to check for high spots. I'll glue them up once I run to the store and grab some titebond. I followed Chucks advice to take my time and not settle-make it fit. I'm pretty happy with the way they turned out. For anyone following along I'll warn you, my photography skills are rudimentary at best and all I have is an iPhone. Maybe that's another area I can improve as the build progresses. Any and all comments and critique is welcome. v/r, Rob

-

It makes perfect sense Rusty. My idea was similar-to take a piece of 1/32" scrap attach it to something thicker/longer and set it against the keel as a gage to set the correct spacing. The 1/32" piece will set the rabbit and the thicker piece will rests against the keel. I hadn't thought of using rubber cement to hold it in place. I will probably make a couple and space them out. I need to find a piece of glass or marble as well. Thanks, Rob

-

rjones726 reacted to a post in a topic:

Medway Longboat - Keel, Frames and build board discussion

rjones726 reacted to a post in a topic:

Medway Longboat - Keel, Frames and build board discussion

-

While waiting for my kit to arrive out here in the Pacific NW I've been reading Chucks build log and thinking about how I intend on assembling the keel. I am curious as to how you insure the keel has a 1/32" rabbit on each side (i.e. centering the four 3/32" pieces). I have some ideas but I'd like to hear what more experienced builders have to say.

-

rjones726 reacted to a post in a topic:

Medway Longboat 1742 by Doug McKenzie

rjones726 reacted to a post in a topic:

Medway Longboat 1742 by Doug McKenzie

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.