-

Posts

110 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by MD11pilot

-

Howdy John, and welcome to the Syren club. I'm looking forward to following along.

- 90 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Congrats! Beautiful little ship.

- 194 replies

-

- armed virginia sloop

- model shipways

-

(and 1 more)

Tagged with:

-

I’m really enjoying your build. I agree with the others - I’m going to follow your lead and make wood cleats. The metal ones just won’t cut it. Love the little plane. How in the world did you find it.

- 1,306 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

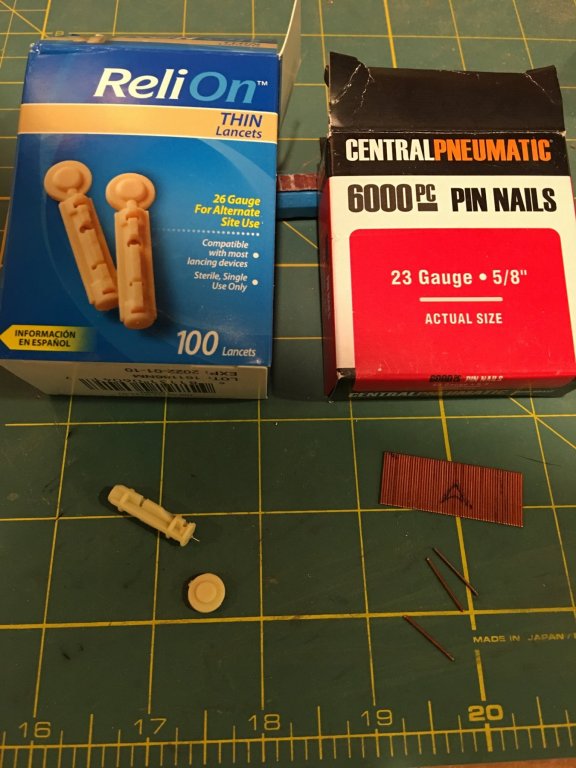

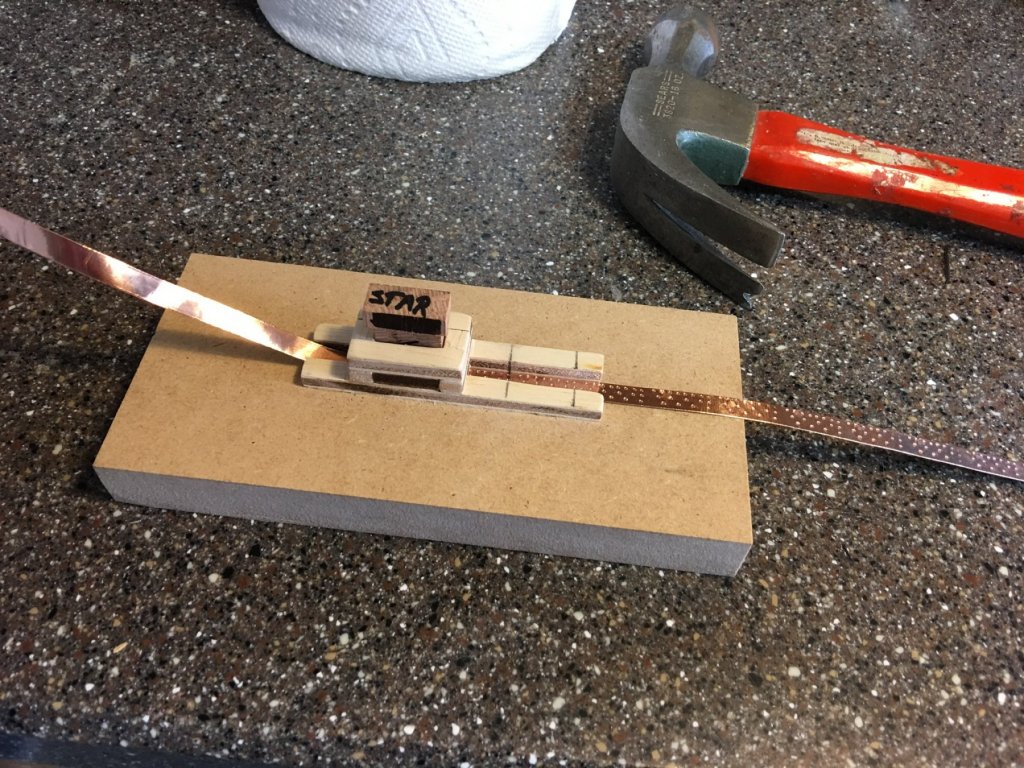

I started with the 26 gauge lancets that are becoming popular for this project. They produce a nice, small nail pattern. However, removing the plastic sleeve is a bit of a pain. You can use nippers to get most of the plastic off. I then set up a candle in a bowl to heat and remove the plastic part that is adhered to the lancet. When I was remaking the second stamp, I remembered that I had a 23 gauge pin driver out in my shop. These finish nailers are becoming quite popular with finish carpenters for holding moldings (and other stuff) together while the glue dries. So I switched to the 23 gauge nails. Worked great without the hassle of removing plastic.

-

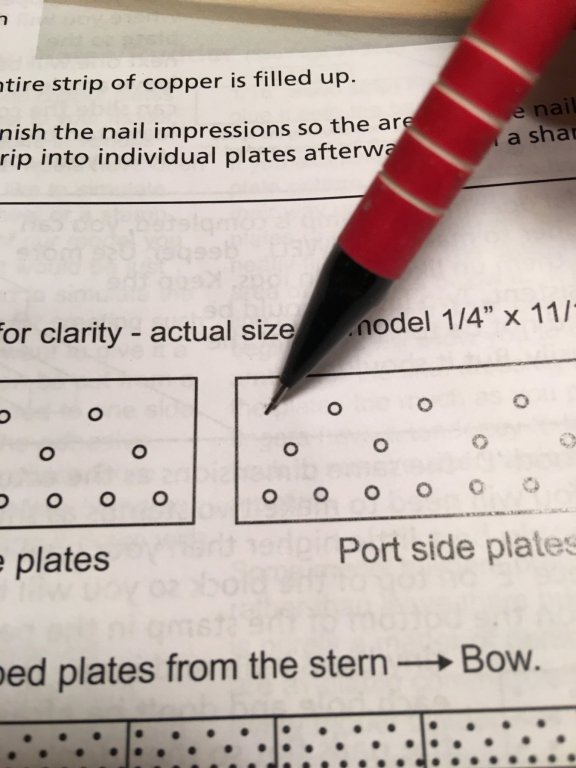

Good afternoon Floyd. Chuck's copper jig tutorial is imbedded in the instruction manual. Chapter 8. I’d highly recommend using a drill press to pre-drill the pin holes. I tried to do it with a hand held pin vise the first time. One stamp came out okay, but the second stamp was a complete mess. You’re drilling so close to the edge of the wood that it’s easy for the drill bit to come out the side of the block - either by poor control, or because the very fine bit is following the grain of the wood. Had to start all over again. And that’s when I figured out that I could chuck my pin vise in my full size drill press as mentioned earlier.

-

Just curious. When did you buy the kit? We've seen some kits recently with poor quality plywood. The plywood in your kit looks good.

- 242 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Howdy Peter! Welcome to the Syren club. Even though you're just a few steps into the project, it's easy to see that you do high quality work. I'm looking forward to watching another beautiful Syren take shape. I like that plank bender. Seems easier than the pin boards.

- 242 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Thanks Floyd, it’s good to be back in the saddle. I’m going to need my stamping jig for the Surprise that’s sitting on my shelf, but thanks for the offer. I only made Port and Starboard stamps as per the instructions. I know some of the advanced guys make a third one for the belt line, but I didn’t think it was necessary. I could go back and add one more nail hole to each plate, by hand, at the position shown in this picture.... I’ll give it it some consideration.

-

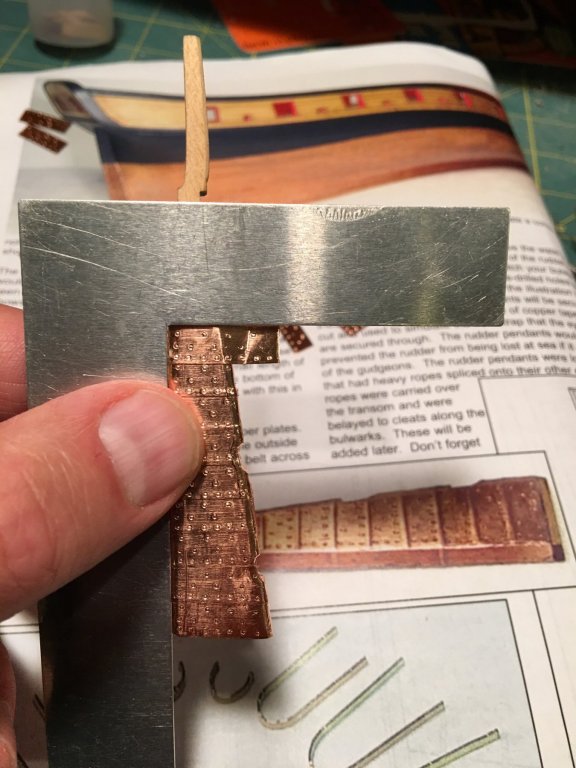

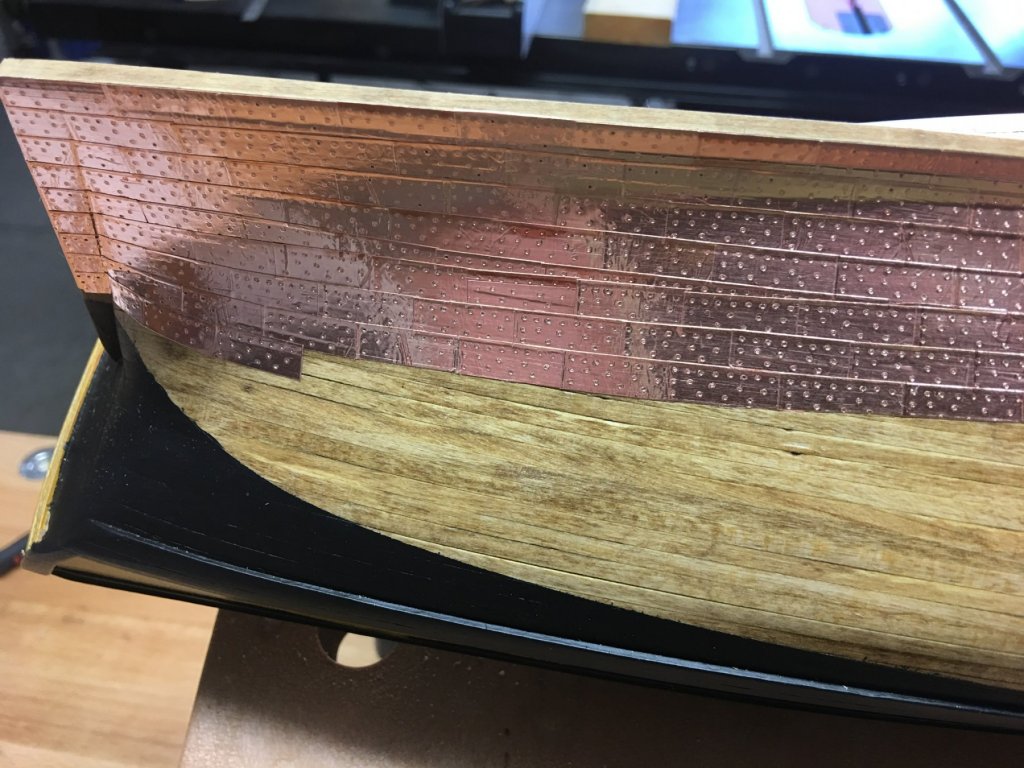

Now for copper bottom. I didn’t do anything creative. Pretty much stuck with instructions. First, I made a mount so could attach the ship upside down in my deskmate. Made the stamp jig and and dies. I don’t have a mini drill press but I was able to secure my pin vise in the chuck of my full size drill press. It actually worked pretty well.

-

Glad to see that there are still folks building the Syren. I’ve been on such a long break that I feared I might be the only one left. I shared your fear of this kit being too advanced for a beginner, but with the excellent instructions and the very detailed build logs on this site, you'll do fine. Have fun! Looking great so far. Eric

-

Really enjoying your build Sal. Getting many great ideas for my project.

- 659 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

I don't often stray into the "scratch build" side of the site, but I just wanted to check out what the "sensei" is up to. Amazing work Chuck. I swear I'd pay good money just to sit quietly in your shop and watch you create one of those amazingly precise scarf joints.

- 1,048 replies

-

- syren ship model

- cheerful

-

(and 1 more)

Tagged with:

-

Love the case, Rod. Your finishing technique makes the case look like something you'd find sitting in the library of an English estate. Nice!

- 127 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.