-

Posts

661 -

Joined

-

Last visited

-

Obormotov reacted to a post in a topic:

HMS Victory by guraus - scale 1:48 plank on frames

Obormotov reacted to a post in a topic:

HMS Victory by guraus - scale 1:48 plank on frames

-

Obormotov reacted to a post in a topic:

HMS Victory by guraus - scale 1:48 plank on frames

Obormotov reacted to a post in a topic:

HMS Victory by guraus - scale 1:48 plank on frames

-

Obormotov reacted to a post in a topic:

HMS Victory by guraus - scale 1:48 plank on frames

Obormotov reacted to a post in a topic:

HMS Victory by guraus - scale 1:48 plank on frames

-

DaveRow reacted to a post in a topic:

HMB Endeavour by DaveRow - FINISHED - Corel - Scale 1:60 - First Build Kit

DaveRow reacted to a post in a topic:

HMB Endeavour by DaveRow - FINISHED - Corel - Scale 1:60 - First Build Kit

-

DaveRow reacted to a post in a topic:

HMB Endeavour by DaveRow - FINISHED - Corel - Scale 1:60 - First Build Kit

DaveRow reacted to a post in a topic:

HMB Endeavour by DaveRow - FINISHED - Corel - Scale 1:60 - First Build Kit

-

rvchima reacted to a post in a topic:

HMB Endeavour by DaveRow - FINISHED - Corel - Scale 1:60 - First Build Kit

rvchima reacted to a post in a topic:

HMB Endeavour by DaveRow - FINISHED - Corel - Scale 1:60 - First Build Kit

-

rvchima reacted to a post in a topic:

HMB Endeavour by DaveRow - FINISHED - Corel - Scale 1:60 - First Build Kit

rvchima reacted to a post in a topic:

HMB Endeavour by DaveRow - FINISHED - Corel - Scale 1:60 - First Build Kit

-

rvchima reacted to a post in a topic:

HMB Endeavour by DaveRow - FINISHED - Corel - Scale 1:60 - First Build Kit

rvchima reacted to a post in a topic:

HMB Endeavour by DaveRow - FINISHED - Corel - Scale 1:60 - First Build Kit

-

DaveRow reacted to a post in a topic:

HMCSS Victoria 1855 by Banyan - 1:72

DaveRow reacted to a post in a topic:

HMCSS Victoria 1855 by Banyan - 1:72

-

DaveRow reacted to a post in a topic:

HMB Endeavour by shipaholic - Eaglemoss - 1/51

DaveRow reacted to a post in a topic:

HMB Endeavour by shipaholic - Eaglemoss - 1/51

-

DaveRow reacted to a post in a topic:

HM Bark Endeavour by dashi - Caldercraft - scale 1:64 - 1768-71 - bashed kit

DaveRow reacted to a post in a topic:

HM Bark Endeavour by dashi - Caldercraft - scale 1:64 - 1768-71 - bashed kit

-

dashi reacted to a post in a topic:

HM Bark Endeavour by dashi - Caldercraft - scale 1:64 - 1768-71 - bashed kit

dashi reacted to a post in a topic:

HM Bark Endeavour by dashi - Caldercraft - scale 1:64 - 1768-71 - bashed kit

-

DaveRow reacted to a post in a topic:

DKM Graf Zeppelin by RGL - FINISHED - Trumpeter - 1/350 - PLASTIC

DaveRow reacted to a post in a topic:

DKM Graf Zeppelin by RGL - FINISHED - Trumpeter - 1/350 - PLASTIC

-

DaveRow reacted to a post in a topic:

DKM Graf Zeppelin by RGL - FINISHED - Trumpeter - 1/350 - PLASTIC

DaveRow reacted to a post in a topic:

DKM Graf Zeppelin by RGL - FINISHED - Trumpeter - 1/350 - PLASTIC

-

DaveRow reacted to a post in a topic:

HMCSS Victoria 1855 by Banyan - 1:72

DaveRow reacted to a post in a topic:

HMCSS Victoria 1855 by Banyan - 1:72

-

DaveRow reacted to a post in a topic:

HMB Endeavour by shipaholic - Eaglemoss - 1/51

DaveRow reacted to a post in a topic:

HMB Endeavour by shipaholic - Eaglemoss - 1/51

-

DaveRow reacted to a post in a topic:

HMB Endeavour by DaveRow - FINISHED - Corel - Scale 1:60 - First Build Kit

DaveRow reacted to a post in a topic:

HMB Endeavour by DaveRow - FINISHED - Corel - Scale 1:60 - First Build Kit

-

dashi reacted to a post in a topic:

HMB Endeavour by DaveRow - FINISHED - Corel - Scale 1:60 - First Build Kit

dashi reacted to a post in a topic:

HMB Endeavour by DaveRow - FINISHED - Corel - Scale 1:60 - First Build Kit

-

dashi reacted to a post in a topic:

HMB Endeavour by DaveRow - FINISHED - Corel - Scale 1:60 - First Build Kit

dashi reacted to a post in a topic:

HMB Endeavour by DaveRow - FINISHED - Corel - Scale 1:60 - First Build Kit

-

dashi reacted to a post in a topic:

HM Bark Endeavour by dashi - Caldercraft - scale 1:64 - 1768-71 - bashed kit

dashi reacted to a post in a topic:

HM Bark Endeavour by dashi - Caldercraft - scale 1:64 - 1768-71 - bashed kit

-

Shipyard Closing Down Well for a time being to refurbish the Entertainment Room for the Display Case to reside. And to explain, the Admiral, as my next project wants me to repaint a room and refurnish appropriately with a side bench_table for the display case to reside on. A few pictures of the Endeavour taking centre spot in the display case. Queensland Western Red Cedar Base with a Acrylic Case over. I learnt so, so much over the 5 year period constructing the H.M.B. Endeavour. I must say thanks to all those who followed the build, those who I/we shared information, and the general encouragement during the period. It would be a lonely life constructing a model without this fantastic Web Site "The NRG Model Ship World" and the members on it. To those other fellas currently constructing the H.M.B. Endeavour, good luck with the rest of build. Enjoy the final home run as I did. That's all Folks....

-

Hi John, Industrial Plastics Pty Ltd They were over at Murarrie, however moved end of January to new location. May of kept their phone no. 1300 465 888 projects@industrialplastics.com.au I emailed them for new location as well.

-

HMCSS Victoria 1855 by Banyan - 1:72

DaveRow replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

Enjoy the UK holiday Pat. Well earned break from the shipyard.- 973 replies

-

- screw

- gun dispatch vessel

- (and 5 more)

-

Shipyard Update Display Case - Base Below is picture of the base to mount the Endeavour on. I had a plaque engraved and located on the corner on the base. Next step to clean dust off the model, a final check over and Place the acrylic case over the top and lock it in place. Nearly finished.

-

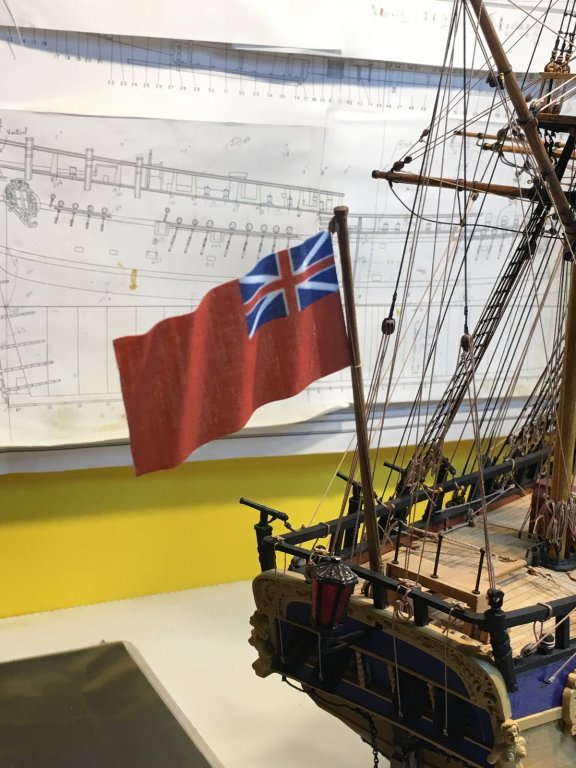

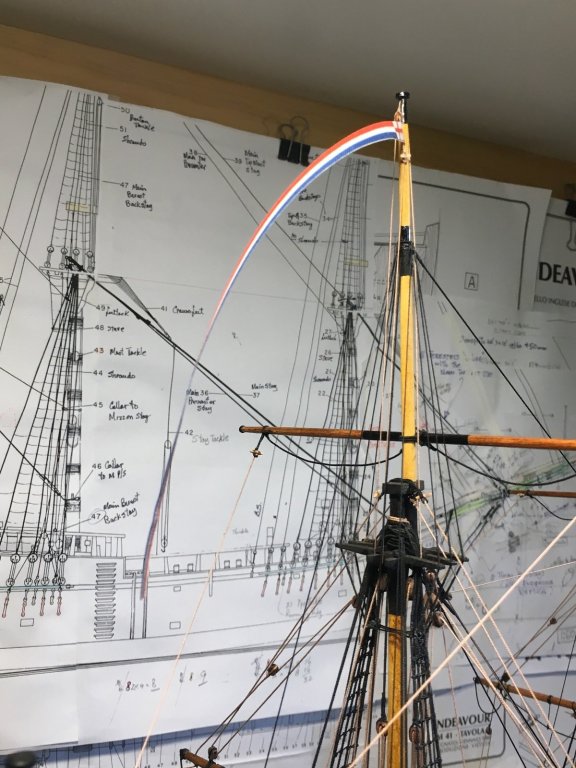

Shipyard Update Flags and Felt on the cradle frames Added Flags to the boat over the last couple of days. Put halyards on each. Bowsprit: Union Jack Stern: Red Ensign. On Main Top-Gallant Mast: Tri-Colour Pennant Felt added to the cradle frames: I am keeping the 2 x black cradle frames to mount on the Display Case Base. Still to trim the felt then screw these two frames into the keel. You can just see the screw in the middle of the stern frame. So close to finishing this build, I can feel the calm and solitude when she's done. Soon to be replaced with "what next".

-

Shipyard Update Stern Figurines, Counter and Window Decorations. I have been procrastinating about how to do these for months(probably years). But the time came to make a decision, as my kit did not have these items included. After an attempt to engrave a figurine(failed) I bashed 2 cast figurines I had bought a couple of years ago(basically cut the legs off) I hand crafted from Pear Wood the Counter decorations under the figurines, and the Window Mullion Deco's. Many hours to decide on the overall shape and cut the patterns in. As an amateur at carving, fairly happy with the outcome. So how did they end up. Counter decorations for under the figurines, ready for fitting. Starboard Figurine Port Figurine Window Mullion decorations (4 off) Note: I do realise the Figurines are short in height and not ideal. The height restriction came about by the Taffarel being turned down either side(P&S) too far ?, thus shortening the height(length) for the Figurines to fit into. Now looking at it, I could of cut into the rail and raised the Figurines up. All a bit too late I'm afraid, as the shipyard is closing down on this build very soon. Not much to go now to finish off what started in April 2014 as a Birthday Present.

-

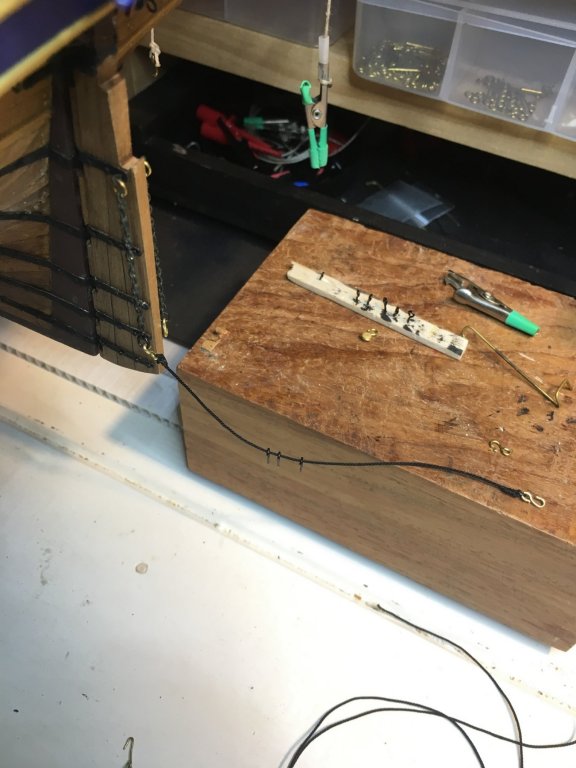

Shipyard Update Gangway Ropes Made the Gangway Ropes off line and tied to either side, as per pictures below. Starboard Ropes Above Port Ropes above

-

Back in the Shipyard Had a really nice trip to the USA. NYC, Washington, New Orleans and Aloha Island - Hawaii. So back to finish of this build. Added the Rudder Pendants according to James Lees “The Masting and Rigging of English Ships of War” Section on Rudder Pendants "Chains were shackled to eyes in the rudder, coming up each side of the rudder to under the transom. To the end of the chains large rings were fitted and into these rings were hooked the rudder pendants. These Pendants had a thimble in each end with the hooks set round the thimbles. The hooks were moused. The pendants were seized to eyes or hooks set under the transom – one by the side of the rudder post, one half way along, and one under the quarter gallery. The end of the pendants were seized to the aft end of the Mizzen channels." So below are a few pictures of the pendants attached to the stern. I wasn't sure if I should use a "Ships of War" detail on the Endeavour. But it all makes sense to have a means to secure and retrieve if the Rudder went adrift from the Gudgeon. I know the replica has a chain/rope from either side of the rudder, going up onto the transom top rail. This configuration I believe looks more realistic. I attached the end hook to the mizzen channel anchor point, assuming it was a solid point to take the load "if the rudder went astray" The chain with "that big ring" Another pic, the pendant running down the port side. Little prep shot laying out the pendant before attaching to the stern. One of the last things is do, is create the stern quarter figures. My kit didn't come with such figures, so scratch build.

-

Will be on shore leave in a few days. The Admiral and I are off to the Big Apple to watch some of the St Patrick's Day March on 16th March. Apparently it goes for 6hrs and we're not standing for that long in the 0 deg, but sure will be spectacular to watch. Afterwards, heading south(to warm up) via Washington, New Orleans, over the pacific via Hawaii too, what become famous through the lyrics from the band "Men At Work" The Land Down Under.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.