-

Posts

991 -

Joined

-

Scottish Guy reacted to a post in a topic:

Professional Building Slip - Hobbyzone

Scottish Guy reacted to a post in a topic:

Professional Building Slip - Hobbyzone

-

VTHokiEE reacted to a post in a topic:

HMS Triton by Justin P. - FINISHED - Scale 1:48 - Cross Section

VTHokiEE reacted to a post in a topic:

HMS Triton by Justin P. - FINISHED - Scale 1:48 - Cross Section

-

Obormotov reacted to a post in a topic:

Harold Hahn method

Obormotov reacted to a post in a topic:

Harold Hahn method

-

Obormotov reacted to a post in a topic:

Harold Hahn method

Obormotov reacted to a post in a topic:

Harold Hahn method

-

Obormotov reacted to a post in a topic:

Harold Hahn method

Obormotov reacted to a post in a topic:

Harold Hahn method

-

Obormotov reacted to a post in a topic:

Harold Hahn method

Obormotov reacted to a post in a topic:

Harold Hahn method

-

harvey1847 reacted to a post in a topic:

HMS Triton by Justin P. - FINISHED - Scale 1:48 - Cross Section

harvey1847 reacted to a post in a topic:

HMS Triton by Justin P. - FINISHED - Scale 1:48 - Cross Section

-

harvey1847 reacted to a post in a topic:

HMS Triton by Justin P. - FINISHED - Scale 1:48 - Cross Section

harvey1847 reacted to a post in a topic:

HMS Triton by Justin P. - FINISHED - Scale 1:48 - Cross Section

-

harvey1847 reacted to a post in a topic:

HMS Triton by Justin P. - FINISHED - Scale 1:48 - Cross Section

harvey1847 reacted to a post in a topic:

HMS Triton by Justin P. - FINISHED - Scale 1:48 - Cross Section

-

Justin P. reacted to a post in a topic:

Next NRG Conference

Justin P. reacted to a post in a topic:

Next NRG Conference

-

Justin P. started following Jim Byrnes Thickness Sander Operation Tips , Next NRG Conference , Syren Ship Model Company News, Updates and Info.....(part 2) and 1 other

-

Next NRG Conference

Justin P. replied to YankeeClipper's topic in NAUTICAL RESEARCH GUILD - News & Information

I second the suggestion that a hard look at the PNW be made. Aside from Bremerton, which has historic ship museums, an undersea museum as well as a healthy maritime tradition it also has the Center for Wooden Boats, the School of Wooden Boat Building and the annual Wooden Boat Festival. Im positive a location could be had at reasonable prices with choice accommodation collocated. I also live here... which is a bonus for me :). -

Justin P. reacted to a post in a topic:

Next NRG Conference

Justin P. reacted to a post in a topic:

Next NRG Conference

-

Chuck, Ive been away from the Hobby and MSW for the last 9-months or so as I adjust to the new realities of teaching high school. Ive been poking my head in a little now and then as I start preparing for two luxurious months off back in my shipyard and must say its comforting to see you still at it - amazing everyone with your innovations and selflessly working yourself to the bone to our benefit. Congrats on the ten years - and get well soon!

-

3D Printing Cannons in Resin

Justin P. replied to thibaultron's topic in 3D-Printing and Laser-Cutting.

Great thread thus far. Ive been thinking of experimenting a little as it relates to ship modeling. Incidentally, in the last year Ive take over a High School program teaching metals design. We run a fleet of Anycubic Mono 6K's. I teach lost wax casting and lost resin casting using Sirya Tech printable casting resin. Our parts go through a burnout process and the printed parts are then cast in bronze, brass etc. Fun stuff! Following with interest! -

Jim Byrnes Thickness Sander Operation Tips

Justin P. replied to ChrisLBren's topic in Modeling tools and Workshop Equipment

I haven't tried bits that are that long, but have found that success comes when not being really aggressive. I take more passes that take less material. Also mounting the paper and holding your work carefully helps a lot. I usually need two hands to run a piece successfully. One feeding or holding a push stick and the other guiding / holding the piece flat against the bed as it comes out the other end. Most of my errors happen near the end of the feed so the opposing hand becomes critical to keep the work from being manipulated by the drum. You might also try sequencing your mill work differently. For instance, I usually rough cut my work before the thickness sander - which is likely why Ive never had to feed 24" stock. -

Helping Hands recomendations in the uk

Justin P. replied to DaveBaxt's topic in Modeling tools and Workshop Equipment

I cant imagine there would be. Maybe the plate is larger? I only have the 4 arm model and found that to be plenty. -

Justin P. started following Helping Hands recomendations in the uk

-

Helping Hands recomendations in the uk

Justin P. replied to DaveBaxt's topic in Modeling tools and Workshop Equipment

Hi Dave, I use the QuadHands as outlined here: It looks like the QuadHands unit is available via Amazon UK, but is much more expensive. To answer your question though, it is a VERY robust unit that does not move at all. The magnets are very strong and the units anti-slip feet are quite good. Its also pretty heavy so it can take some leverage without tipping or moving. https://www.amazon.co.uk/QuadHands-Deluxe-Workbench-Helping-System/dp/B01MZG2D99 -

Strange! Was the option not available in the lower corner "CC?" I just checked and it works for me, the captions are actually really good. I have enjoyed my Sherline so far, though the rigamarole assembly and squaring everything up had me a little confused. The nice thing about the Proxxon is that it is more or less plug and play.

-

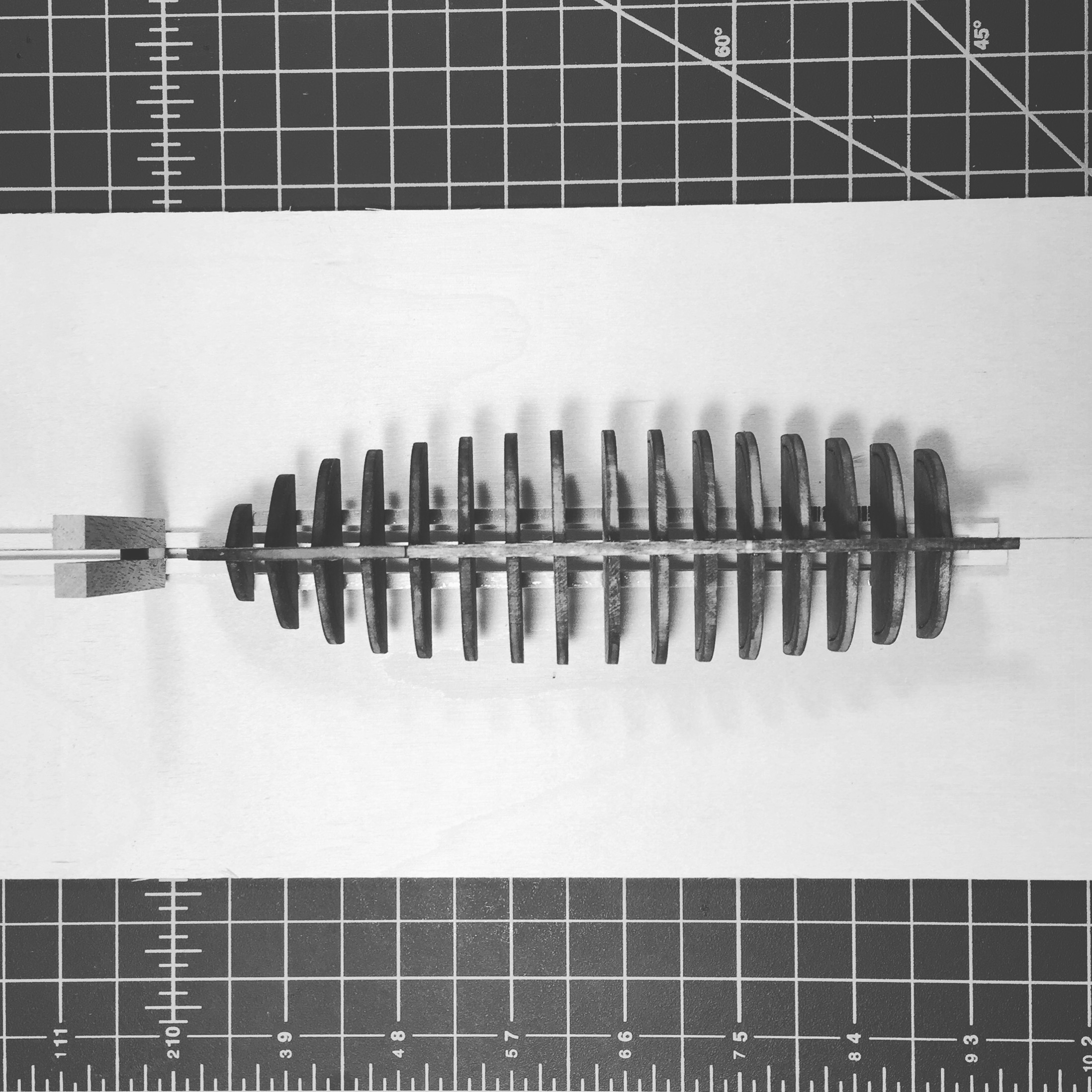

Completed. Sadly, all of the photos I took of the last stages of this build were lost. Im still not sure how this happened, but as went to update this build log I noticed they are all gone. Im supremely disappointed but happy to report that Ive completed my Triton. What a project. Im excited to have completed it, and looking forward to moving forward with a new project. Thanks to everyone for your kind words, support and assistance through this project. A relative has kindly volunteered to make a case for it, a challenge I think they welcome and are looking forward to, so I won't be taking that piece on. I did however make a temporary mount seen in the below photo and accompanying gallery. GALLERY Onward!

-

No you didn't. I perhaps incorrectly confused my launch and longboat (the terms have been interchangeable to some degree). As the longboat in this case was a painted transom I did not plank it. With the launch however, I did as not doing so didnt seem quite right. I recall as well, that particular kit manufactuer chose to laser etch a part number onto the transom that was difficult to remove or cover up. As I could not find a readily accessible reference for it, I simply did some google searching. I have also seen many open boats with transoms constructed from planks so just went with it.

-

At least you are using the Calligraphy solution and not the drawing. The calligraphy is considered "lightfast" so you can at least be sure of a consistent color over time. However it is not waterproof and will reactivate so best be sure you dont somehow get your model wet or it will be a mess! Any glue use can possibly reactivate it as well, particularly PVA - so be careful!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.