mrmdpc

Members-

Posts

15 -

Joined

-

Last visited

Recent Profile Visitors

-

Ty for the picture. I always have an easier time making something look like something I have already seen.

-

mtaylor reacted to a post in a topic:

Jib stops?

mtaylor reacted to a post in a topic:

Jib stops?

-

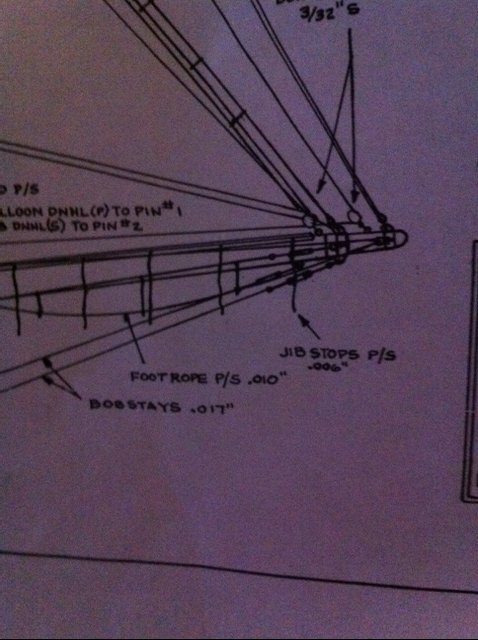

That actually makes sense. Thanks for the information and the photo. I can make that work. Marty

-

I have not been able to find out what a "jib stop" is, what it does and how it is used. The only place I see it is on the set of drawings (not in the instructions) and only in this one place. This is a MS Bluenose kit build. Anyone have any insights?

-

Jack12477 reacted to a post in a topic:

Sizing the Dory oars - MS Bluenose

Jack12477 reacted to a post in a topic:

Sizing the Dory oars - MS Bluenose

-

mtaylor reacted to a post in a topic:

Sizing the Dory oars - MS Bluenose

mtaylor reacted to a post in a topic:

Sizing the Dory oars - MS Bluenose

-

mrmdpc reacted to a post in a topic:

Precision router base for Dremel 4000 etc.

mrmdpc reacted to a post in a topic:

Precision router base for Dremel 4000 etc.

-

I am making the deck furniture for my MS Bluenose 1:64 scale. At this size a fair amount of detail shows. The plans call for a reasonably contoured molding around most of the structures. Apart from grinding down a razor blade does anyone have alternative methods for consistent production of a contour on these relatively small pieces? Do I need to abandon the basswood from the kit and use a harder wood?

-

Canute reacted to a post in a topic:

Problems brass blackening using Jax Pewter Black

Canute reacted to a post in a topic:

Problems brass blackening using Jax Pewter Black

-

I am trying my hand at blackening brass. I applied Jax Pewter Black with a very quick dark black coating on the brass. The only problem was that rinsing the part with water washed off most of the color as well. What am I doing wrong? Does it need to be allowed to dry before rinsing? That doesn't make any sense since leaving in the solution too long is supposed to result in a coating that flakes off. Open to any suggestions. Just saw the post from July on this same topic. I will renew my efforts painting it on.

-

gregkthompson reacted to a post in a topic:

Phantom 1868 by gregkthompson - Model Shipways - 1:96 Scale - New York Pilot Boat

gregkthompson reacted to a post in a topic:

Phantom 1868 by gregkthompson - Model Shipways - 1:96 Scale - New York Pilot Boat

-

Hi Greg I am no expert, actually kind of a newbie myself. I did complete the Phantom a few months ago, It took a lot of slow gradual carving to bring the contour of the hull to match the templates. The most had to be removed from around the sternpost. Just take your time. I used a combination of a Dremel, wood chisels and sandpaper. Just follow the grain as best you can. As to the glue, if you are putting all this time into the build, it is worth the $3-4 for a fresh bottle of wood/carpenters glue. It gets tacky to hold within a few minutes and works well. Marty

-

mtaylor reacted to a post in a topic:

First time planking a POB hull

mtaylor reacted to a post in a topic:

First time planking a POB hull

-

I am just starting to lay out the planking on my MS Bluenose 1/64 scale. Looking at the strake just below the waist, the planks take a twist, heading back towards the stern. There is no "curve" needed for the plank and a batten does lie flat, but it looks like it will take a 45 degree twist in the plank to get it to lie flat by the time it reaches the stern bulkheads and transom. I have read through the instructions and the planking tutorials and didn't see that issue mentioned. Am I missing something?

-

I am looking for my second project. Just completed the MS Phantom and now looking for a planked hull kit that is rigged with sails for a second go at it. Does anyone have any experience with the MS Bluenose kit? Any other suggestions?

-

Thanks Sal, I appreciate the drawing, as long as the scaling is on or close the PDF will be fine. I have been lucky enough to able to leave AutoCad to others. Marty

- 139 replies

-

- phantom

- model shipways

-

(and 1 more)

Tagged with:

-

Sal I am about to start planking the deck on my Phantom. Your deck plans look perfect. ( I think that only an engineer could produce it or appreciate what it takes to draft it.) Would you be willing to share the PDF of that drawing? I read the forum download article on deck planking and liked the look of the crossmarkings of the individual planks on every 5 rows. So...I am trying to plank it with individual planks. I have cut the scribed sheet into 15 foot scale lengths and then used the scribed marks to cut the sheet into individual planks sanding the edges smooth. I did a trial layout on a piece of cardboard and it looked good with tight joints. Getting the seams to stand out may be difficult though. I am not sure how to get to a PM to get you my email address if you are agreeable to sending the file. Thanks Marty

- 139 replies

-

- phantom

- model shipways

-

(and 1 more)

Tagged with:

-

Sal I also recently started this kit and have been following your build. Thank you for taking the time to post all of this. As a newbie, even with the the practicum and the instructions there are always still alot of details that seem to be left out. Your descriptions and questions are helping to fill alot of those gaps. I am still coppering the hull. As I have been working on it I found that some of the corners of the plates will lift. Have you been seeing much of that as you have been working through the rest of the build? I am just wondering if it would be better to seal the copper just to keep the corners from wanting to lift and bend. Keep up the good work and the posts! Marty

- 139 replies

-

- phantom

- model shipways

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.