-

Posts

369 -

Joined

-

Last visited

About maaaslo

- Birthday 06/09/1981

Contact Methods

-

ICQ

313838066

-

Skype

maaaslo_mobil

Profile Information

-

Gender

Male

-

Location

wickford, uk

-

Interests

sailing ships in generall, paper modelling

Recent Profile Visitors

-

Scottish Guy reacted to a post in a topic:

For Beginners -- A Cautionary Tale

Scottish Guy reacted to a post in a topic:

For Beginners -- A Cautionary Tale

-

maaaslo reacted to a post in a topic:

Syren Ship Model Company News, Updates and Info.....(part 2)

maaaslo reacted to a post in a topic:

Syren Ship Model Company News, Updates and Info.....(part 2)

-

Obormotov reacted to a post in a topic:

MONTAÑES by Amalio

Obormotov reacted to a post in a topic:

MONTAÑES by Amalio

-

Obormotov reacted to a post in a topic:

MONTAÑES by Amalio

Obormotov reacted to a post in a topic:

MONTAÑES by Amalio

-

Obormotov reacted to a post in a topic:

MONTAÑES by Amalio

Obormotov reacted to a post in a topic:

MONTAÑES by Amalio

-

Obormotov reacted to a post in a topic:

MONTAÑES by Amalio

Obormotov reacted to a post in a topic:

MONTAÑES by Amalio

-

maaaslo started following Vladimir_Wairoa

-

BLACK VIKING reacted to a post in a topic:

Pinta by Maaaslo - Shipyard - 1/96 - card

BLACK VIKING reacted to a post in a topic:

Pinta by Maaaslo - Shipyard - 1/96 - card

-

BLACK VIKING reacted to a post in a topic:

Pinta by Maaaslo - Shipyard - 1/96 - card

BLACK VIKING reacted to a post in a topic:

Pinta by Maaaslo - Shipyard - 1/96 - card

-

maaaslo reacted to a post in a topic:

Pinta by Knocklouder - FINISHED - Amati - 1:65

maaaslo reacted to a post in a topic:

Pinta by Knocklouder - FINISHED - Amati - 1:65

-

catopower reacted to a post in a topic:

HMS ENTERPRIZE by DominichSteven - FINISHED - Shipyard - 1/64 - CARD

catopower reacted to a post in a topic:

HMS ENTERPRIZE by DominichSteven - FINISHED - Shipyard - 1/64 - CARD

-

tkay11 reacted to a post in a topic:

Pinta by jct - Shipyard - 1/96 scale - CARD

tkay11 reacted to a post in a topic:

Pinta by jct - Shipyard - 1/96 scale - CARD

-

GrandpaPhil reacted to a post in a topic:

Pinta by Maaaslo - Shipyard - 1/96 - card

GrandpaPhil reacted to a post in a topic:

Pinta by Maaaslo - Shipyard - 1/96 - card

-

Bob, thank you for the praise. I liked building this model, nice and simple. I substituted sails for the paper bag as i a)could not find the set i purchased b)fabric is too thick for this scale. c)i like the way it looks. i will finish this model. Trouble is, i was forced to move household and do not have a dedicated modeling room anymore, heck i dont have a dinig table. No space!. current stage is: all paper parts used. Currently hanging main sail, will make the yard and a sail for fore-mast. Finish the rigging and make some small enclosure. Almost done to be honest.

-

maaaslo reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates

maaaslo reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates

-

maaaslo reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates

maaaslo reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates

-

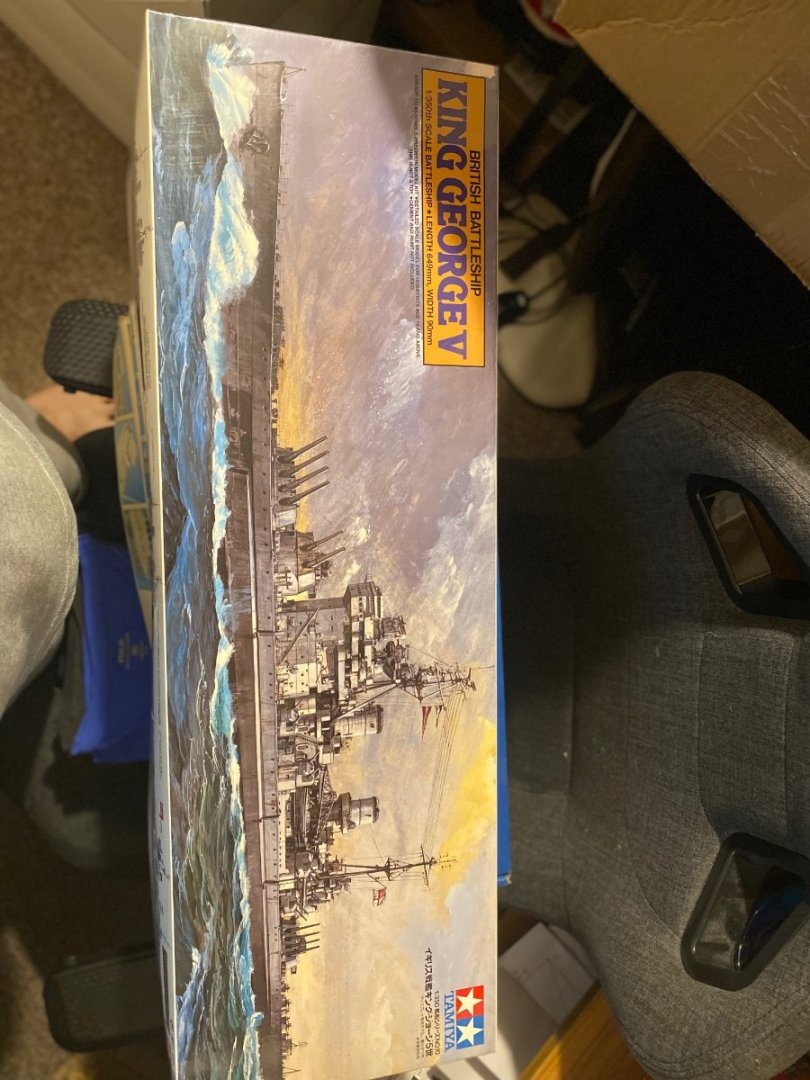

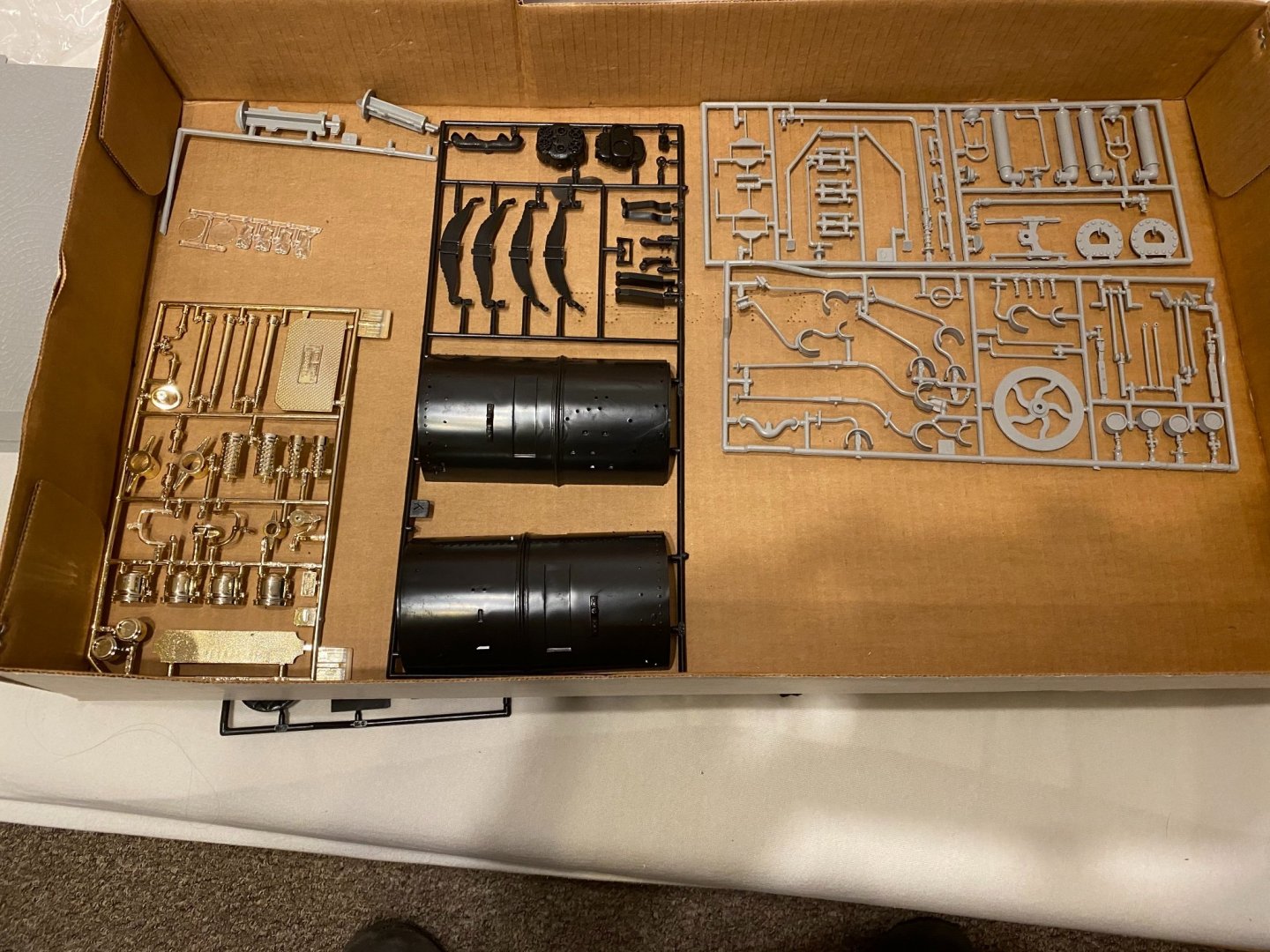

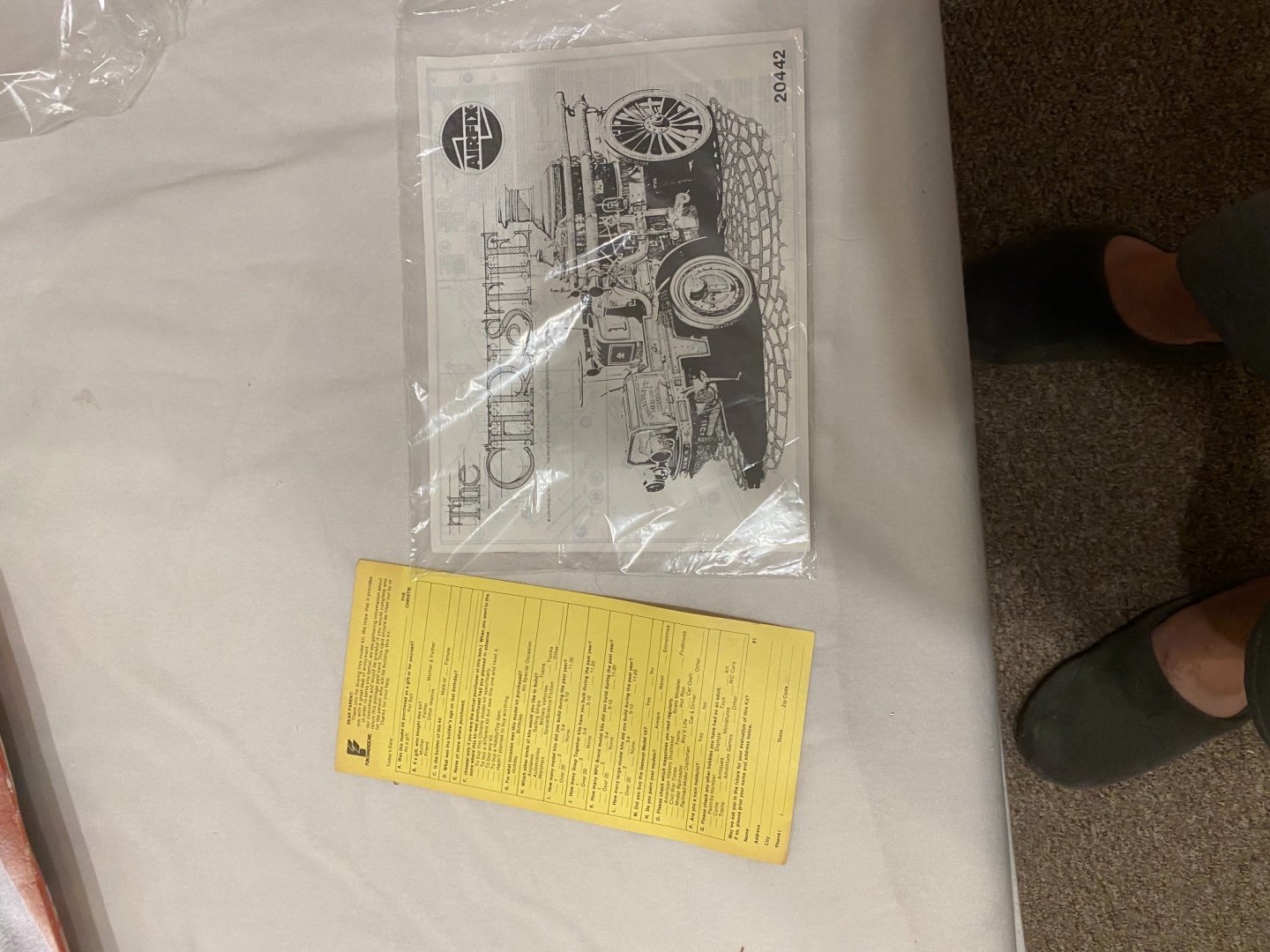

I have been given this kit a few years ago and it has been sitting in my stash ever since. I dont build plastic models anymore and since i am moving the house i need to make space. kit is unstarted, no parts bags opened all sealed. Opened to take a picture that is it. will accept offers ranging around 45-50GBP still goes for 65-70gbp on amazon and other outlets. i will post free in UK, postage to abroad paid by the buyer, same as customs or any other fees. any questions just ask. oh and there are no addditional enhancing packs coming with this, i never planned on building this beauty.

-

well, probably best he has the model under the glass cover now. that is the reason why everyone covers theirs, to protect from environment

- 28 replies

-

- Shipyard

- Enterprize

-

(and 2 more)

Tagged with:

-

erm, you wont mate. sadly Dan passed away recently so there wont be any work done on any of his models.

-

how is this kit build going on? i hope you did not get rid of it, it would be such a waste...

- 83 replies

-

- marcle models

- card

-

(and 1 more)

Tagged with:

-

maaaslo reacted to a post in a topic:

Pinta by Maaaslo - Shipyard - 1/96 - card

maaaslo reacted to a post in a topic:

Pinta by Maaaslo - Shipyard - 1/96 - card

-

Since the scale is so small i was looking for a good substitute for the sails that used to be sold as extra for this model. Obviously out of stock so had to look elsewhere… behold, the new sail stock… feels a little… vaxy but takes glue and pencil. Stiff enough to hold the shape. Easy enough to work with. As its paper, all holes had to be reinforced with superglue and drilled with 0.6mm drill to take thread.

-

Everyone, i am back the kit was dormant for some time, mothballed for the times i am in the mood again. i dusted her, cleaned som spider webs and looked up the instructions. i think i am getting the hang of all this sailmaking and hanging the spars whatnot. appologies for quality of light but its 8pm here and as its winter time its dark outside.

-

if that was corrugated cardboard, it certainly wont work in this case... the original construction pieces did not account for the extra thickness.

-

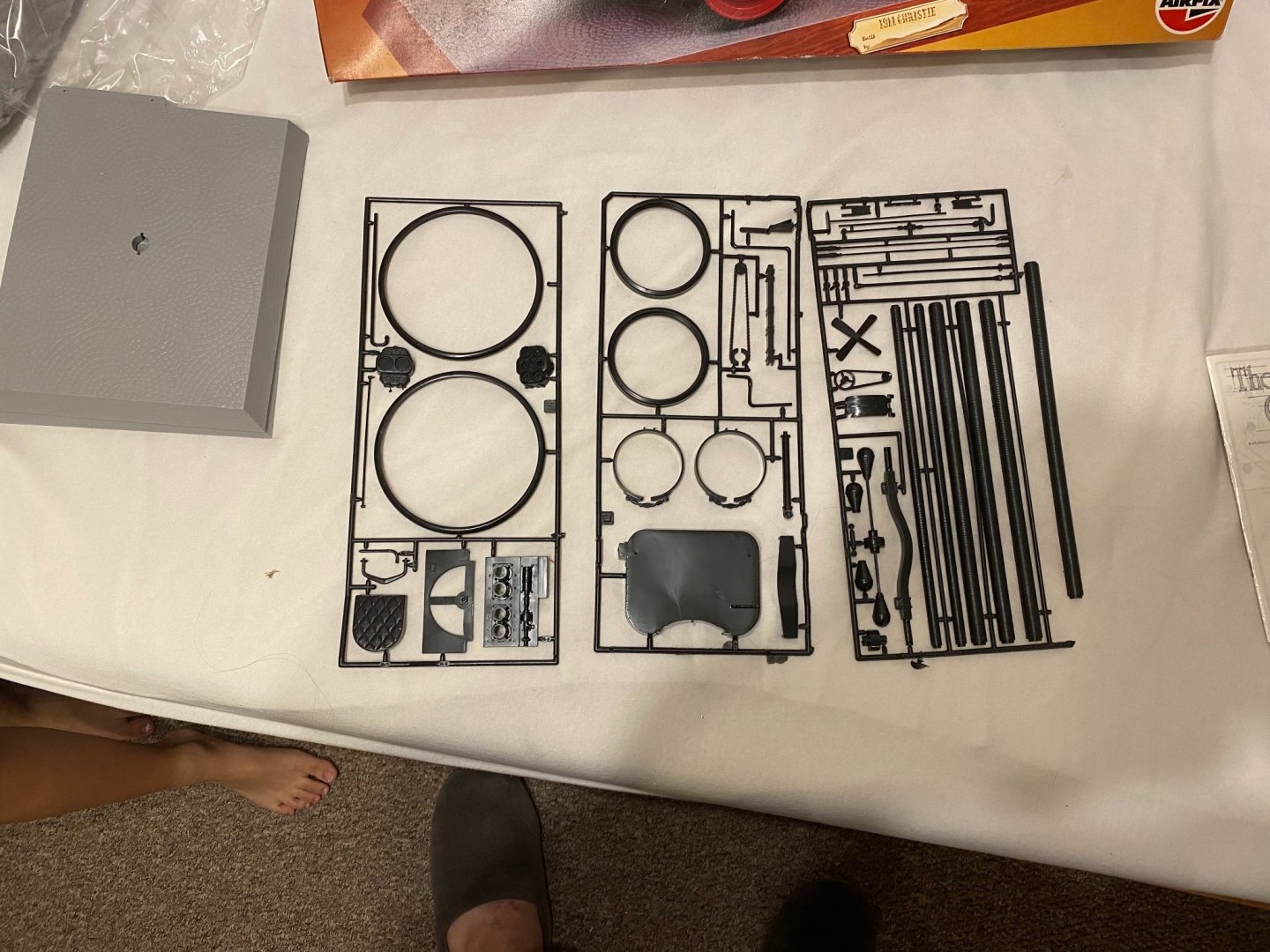

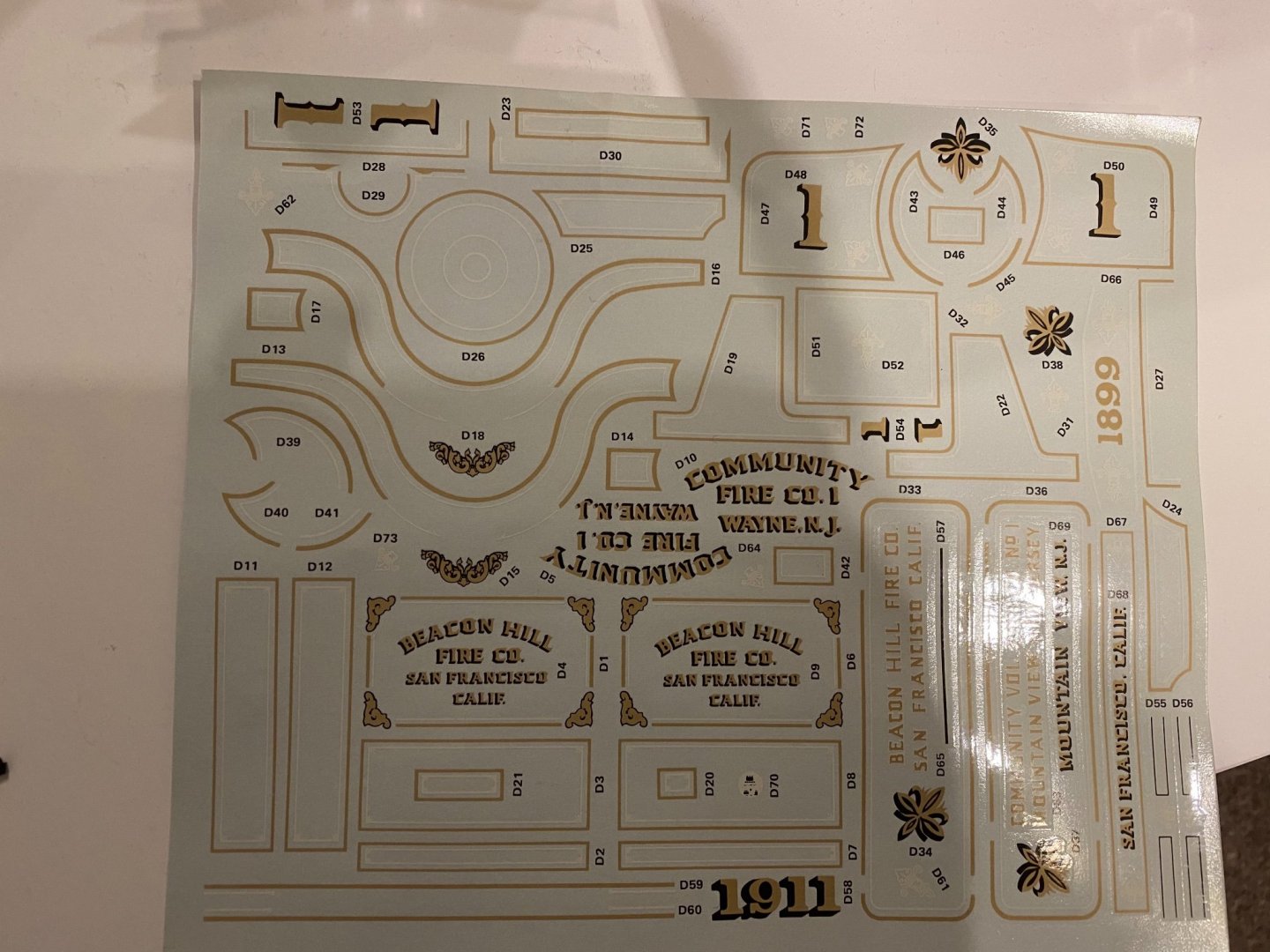

Everything in the box is in remarkable condition for its age. This kit is of a first edition as per the number on the box. there is a small handfull of parts taken out of their frames. Box has got one corner damaged and a small piece of the damage on the top of the box from the tape. The water transfer sheet is present and undamaged. Instructions and a warranty card present. i dont have a slightest clue of what this is worth i just know how much i paid a week ago. As long as i get that (or equivalent in other means) i will be happy.

-

erm, what eyes dont see, heart dont care about... just tell her you found it in scrap...

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.