-

Posts

1,308 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Kevin Kenny

-

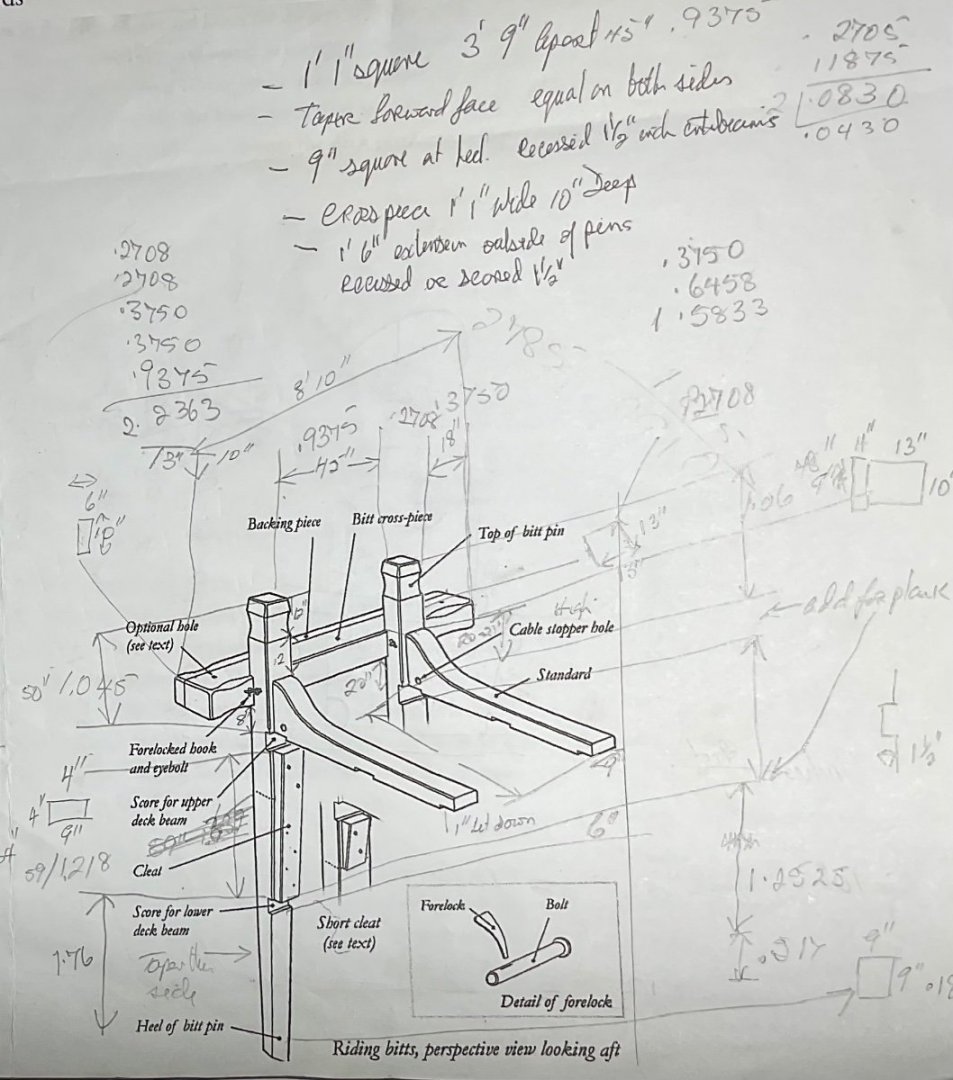

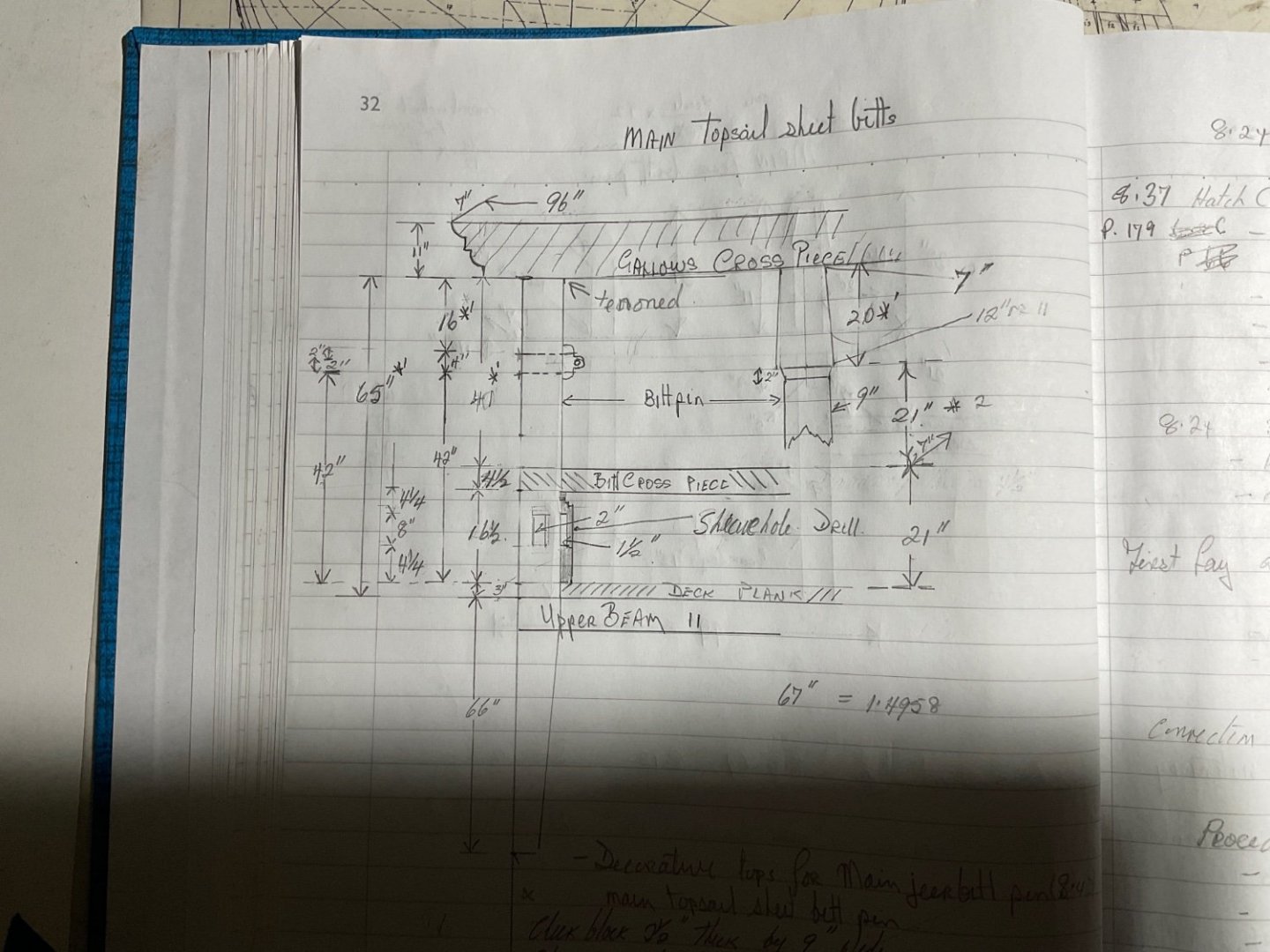

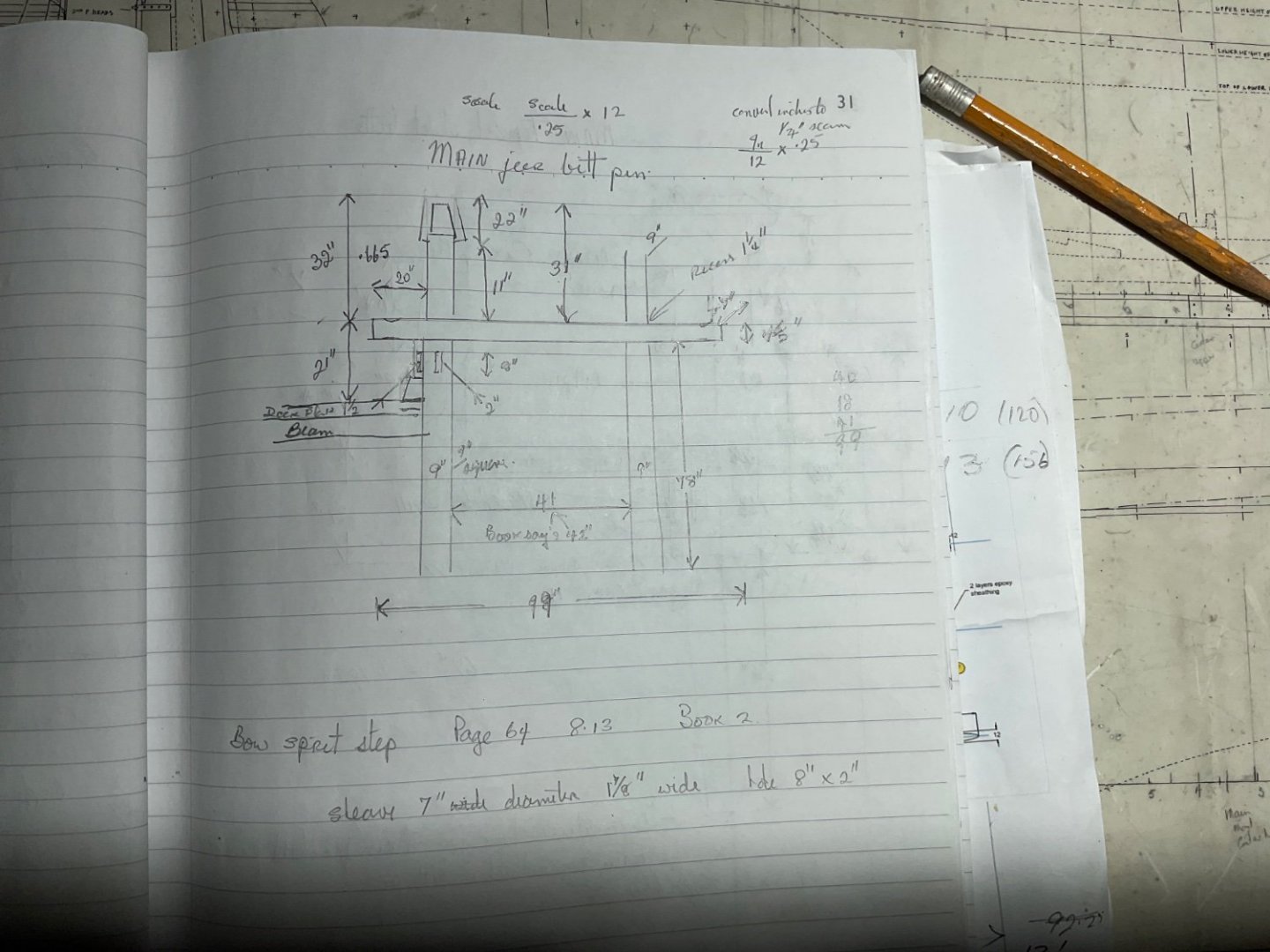

I cant remember as that was so long ago. I still say the key is the location of the beams. The photos i shared give you a good idea of the correlation. Looking back at the notes that i sent you it is clear that i was estimating the measurements above the main deck. They should have given us the measurements. I have it as 27” above the main deck. This is why today i have a written log so i can tell you why and what i did.

- 976 replies

-

- 976 replies

-

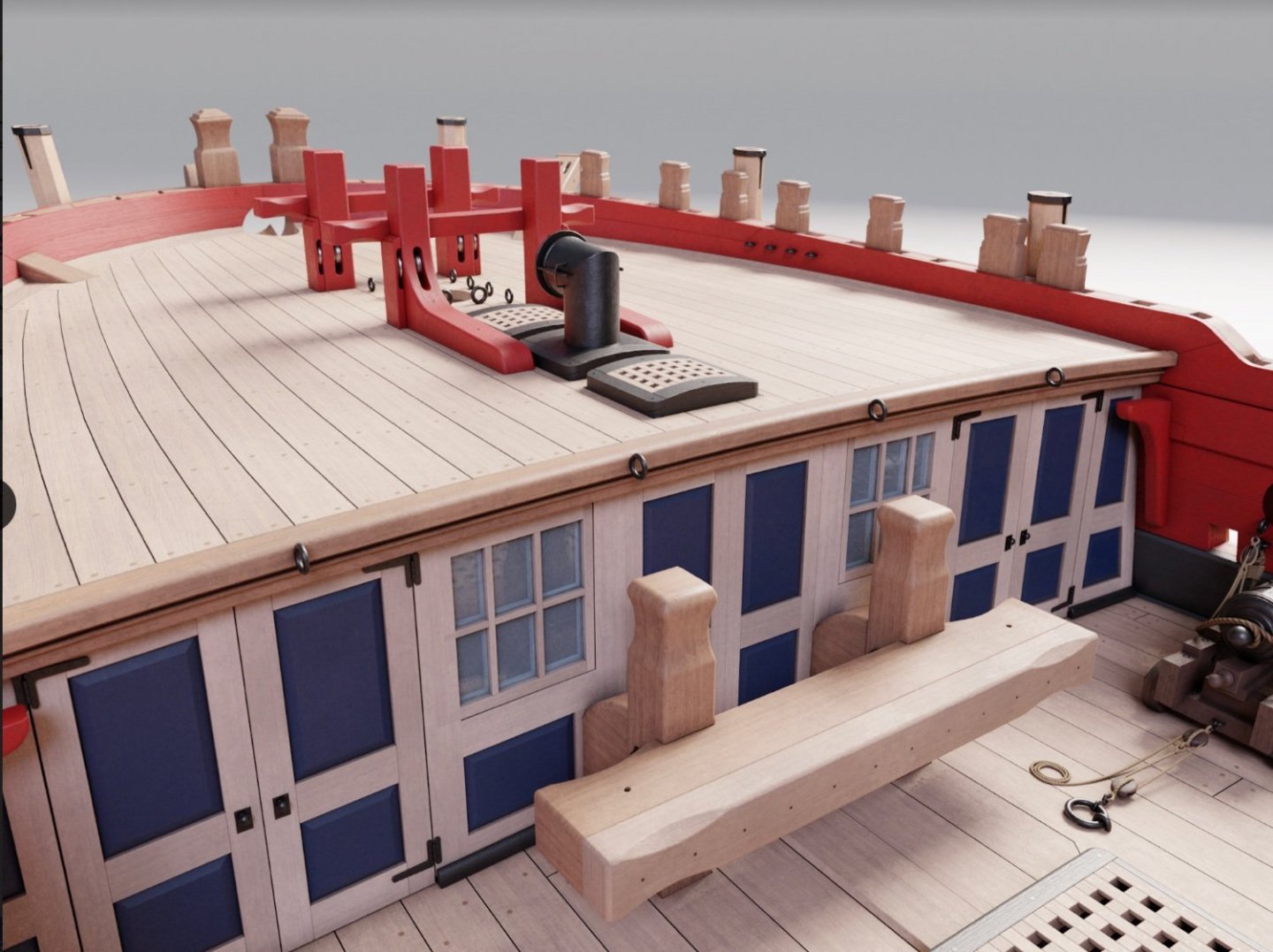

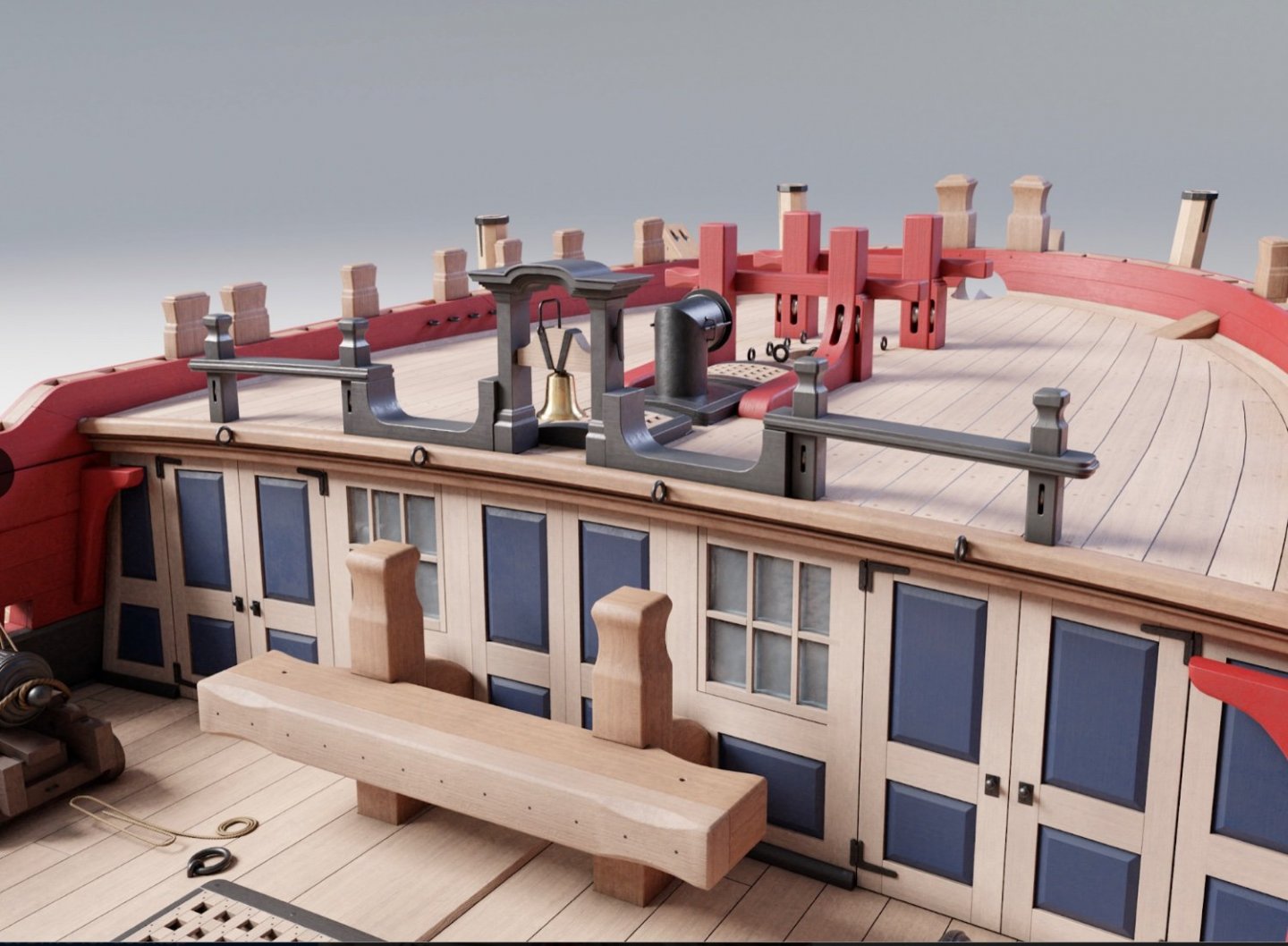

On my model the Top of the pin is .101 the top of the cross piece is .42 one of the best investment i made was to buy the 3D images frim Admarility models. It allow you to visualize everything in much more detail.

- 976 replies

-

Video 47 at 9.04 is the first reference to the location of the pins.

- 976 replies

-

Video 64 again discusses issues with the bitts and their location to the beam. I have a feeling I remade it at this point in time.

- 976 replies

-

just went back in the build to page 8 of the build log Video 50, time 7.33 discusses the same issue you are having. it seems what I did was make up the bottom slots for the beam and as I added the beams made the adjustments in the pins. ill look again and see if there is any other reference

- 976 replies

-

Harry this was quite a while ago and the pieces are now stuck in the model. I made a number of mistakes until I got the beams installed.once the beams are installed you can make the measurements off your model. If you look in my draw you’ll see the results my many mistakes. I think because everyone’s model is slightly different they did not give detail dimensions. I remember having lots of discussions with Greg on this . It was after this I started keeping a written log.

- 976 replies

-

- 976 replies

-

- 976 replies

-

Henry the key was to install the deck beams and then follow the plan.ill check the videos as i know its covered

- 976 replies

-

- 976 replies

-

Every time i tried to do something like you have done i find the only way i can make them is to simulate them. Mine are not functional like yours . You are a master sir. I have long thought of going to work in a jewelry shop. I did have a friend build a spot soldering machine for me but it did not work that well. I should have forked out the $600 and purchased it directly. Keep up your fantastic internal work. kevin

-

The details are fantastic. Perhaps slightly out of scale but at these sizes its almost impossible to get this absolutely right. In many cases if the scale was correct i don't think the pieces could be built. One of the models i submitted recently for judging, one of the points i was heavily criticized for was as the hole size for the seine in the boat was too small. It was the best i could find, and yes it was smaller than the real size for the seine , but the only other option was to leave the seine out all together. It was a fishing boat that used a seine so i am not sure what sense that would have made. i am rambling. Makes me wish i had done this with the Thorn.

-

Hi Will

just want to cheek your surname Niwot? I am mengioning you in my next video

-

Metal bashing

Kevin Kenny replied to michael mott's topic in Metal Work, Soldering and Metal Fittings

I would love to see the link if you come across it again -

Metal bashing

Kevin Kenny replied to michael mott's topic in Metal Work, Soldering and Metal Fittings

Its wonderful to see your handy work Michael. I have kept away from metal work so far but would love if someone would share their knowledge in this area. I always wondered how those brass wind scoops or air ventilators were made. My guess its some extension to what you have done here. -

I did the port side in the video. This was the starboard side, so it now complete

- 976 replies

-

- 976 replies

-

- 976 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.