bigcreekdad

NRG Member-

Posts

344 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by bigcreekdad

-

I received this as a gift, but with not too many starts left in me, I decided to do something a bit simpler. My first ship was a cutter by Jotika, which I enjoyed building. I really like the look of Vanguard's Cutter Alert and thought maybe that's what I should try next. In any case, I m going try selling the Grecian kit. It's been opened but that's it. Asking $325 US, plus shipping from 43528 (USA only). Message me if any interest.

-

Proxxon mini lathe verdict

bigcreekdad replied to Srenner's topic in Modeling tools and Workshop Equipment

I use mine for masts and spars as well. Does a fine job. Used to use a power drill mounted upside down in a vice. It sufficed at the time, but the Proton is better just for the ability of accommodating larger lengths. A good deal for the money IMO. I do agree the collets are pretty cheap. -

Decent small clamps

bigcreekdad replied to bigcreekdad's topic in Modeling tools and Workshop Equipment

THanks Gregory...and yes, those are the clamps I was referring to. John -

Decent small clamps

bigcreekdad replied to bigcreekdad's topic in Modeling tools and Workshop Equipment

Gregory....any specifics on brand/type? so many options on Amazon. Also, would I need a heat gun or will a hair dryer do? Thanks again/John -

I've lost it....need a refresher to get my confidence back

bigcreekdad replied to bigcreekdad's topic in Wood ship model kits

Thanks Folks! -

Decent small clamps

bigcreekdad replied to bigcreekdad's topic in Modeling tools and Workshop Equipment

great idea! -

I have many of those black or red rubber tipped clamps, but the tips come off, or wear thru, and the metal dents the wood. I'd spend more money if the darn things would last. Anything to recommend?

-

I took a near 2 year hiatus from serious building. I had started a collectable postage stamp store online and was pretty consumed with that. I had 5 very nice (IMO) builds behind me ( Convulsion, Sherbourne, Bluenose, Dos Amigos, and Flirt). None perfect re: planking but certainly more than passable (IMO). I've now quit two builds (Brig Supply and Cheerful) as my planking "skills" have disappeared. Maybe it's age (76), but it has discouraged me from continuing this hobby. Before just moving on, I thought maybe I should regroup and try a simpler build. Something with nice wood and better than average instructions. Vanguard seems to meet both those requirements. Any suggestion....Vanguard or otherwise? It does not need o be a warship (ie old fishing vessels maybe). Thanks in advance.

-

Chopper Lesson Learned

bigcreekdad replied to Todd Hart's topic in Modeling tools and Workshop Equipment

Thanks Richard....looks pretty sturdy. -

Chopper Lesson Learned

bigcreekdad replied to Todd Hart's topic in Modeling tools and Workshop Equipment

I threw my chopper away years ago. Couldn't get a straight vertical cut out of it. Wish there was something else to get perfectly straight vertical cuts. -

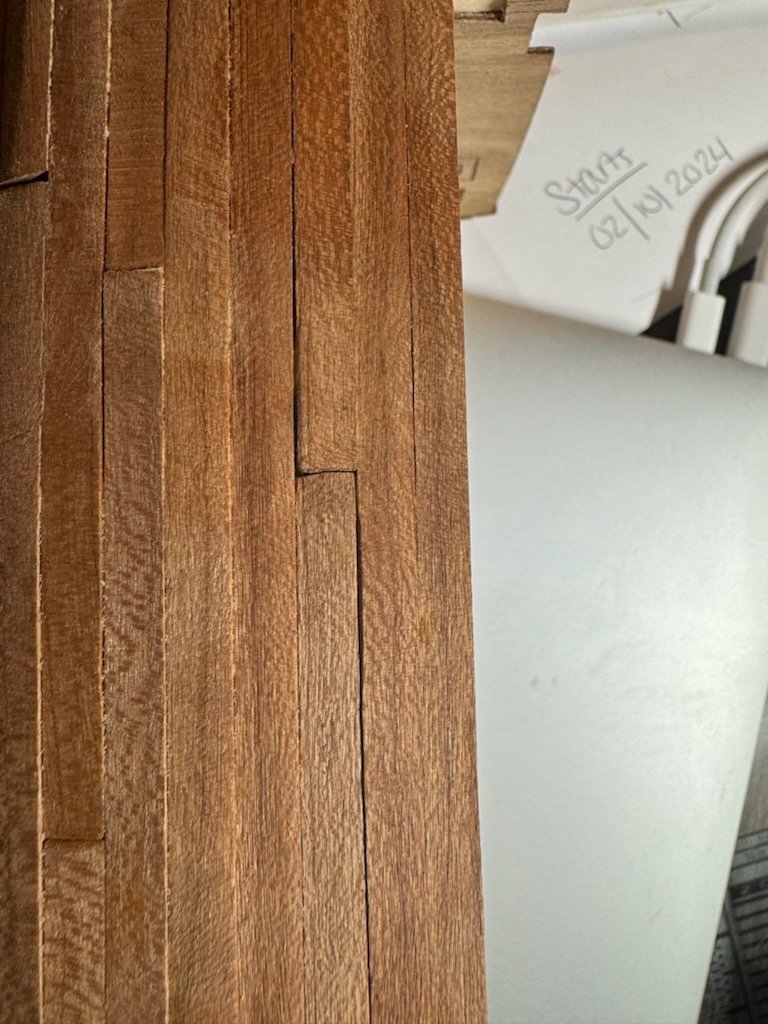

Update. I have moved on. I am seriously back to building the cutter Cheerful. I am now working on the dreaded drop plans making "practice" ones before any attempt at mounting. Also, cut a nice supply of Alaskan Cedar planks on my Byrnes saw. While I somewhat regret quitting the Brig Supply, it was just too damn frustrating. I did apply the suggestion by EMS Rich by using files, and it clearly improved the sordid job I had done. I tried to continue the planking but I still wasn't happy with it....so, to the scrapyard it went. Not sure why I fell off the plank wagon on this, but I needed to move on. Thanks for the comments.

-

Rich...I appreciate your thoughts. How big are those files....they look huge, but maybe just the close up effect. Actually, I was pretty much going to send this to the dry dock of the dead. I was going to revisit my scratch Cutter Cheerful build. I had set it aside when I got to needing a drop plank. For some reason it baffled me. Up to that point my planking of the ship was quite good (IMO). The thought of screwing it up was a huge block. I hope to finish the Cheerful while I'm still on the grassy upside, but might try your suggestions and see if I can get (reasonably) back on track. I do like the ship itself.

-

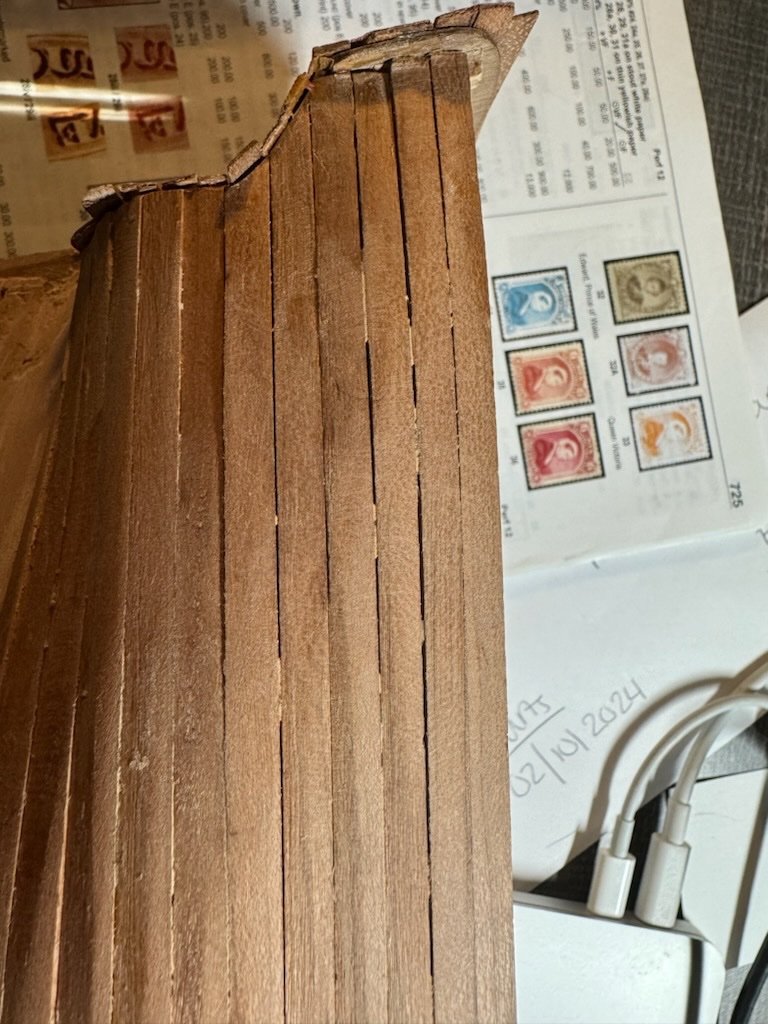

Actually...this was a rhetorical question. Sorry for confusion, but I am half way through second planking and already see that , when finished, I still had a bit (maybe a lot) of work to go on the hull. I've attached some pics which will speak for themselves. Honestly, I am not at all happy with my effort. See the pics I've attached. I've built two very nice (IMO) ships with very nice planking results. And the Supply is my second ship milling my own planks with a Byrnes saw and thickness sander that have turned out quite well (again..IMO). I'm not sure how I have lost my edge, other than if I was to start over, I would mill the strips (cherry) a bit thinner. In any case, I am at a crossroads......continue on or shitcan it and try to do a better job on another. I'm in my mid 70's so I don't have may ships in the wings, and I hate slugging along on this one not at all liking my results. I was not planning on painting....I know that's an option I would have to hide my mediocre planking. I'm rambling

-

Fantastic build!! Can't wait to see your next one. Have you given any thought to what it might be? Hopefully, this will not be a solo venture. You have too much talent. I, too, hate walnut, and have been using cherry on my last few builds. That would you use in your next build if you could choose? Have fun!

-

Into second planking on the HMS Brig Supply. Never been a big fan of walnut, so I've cutting my own planks from a light cherry piece. Before I go further, I need to decide whether I will continue with cherry, or go below the wales with something darker for some contrast. Likely will not be painting the lower hull. Any thoughts?

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.