-

Posts

3,247 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by KeithAug

-

Excellent authenticity Andy, and a nicely engineered jig.

- 88 replies

-

- Vigilance

- Sailing Trawler

-

(and 1 more)

Tagged with:

-

Hakan Seems a little cold and a good reason to stay indoors - although I hear our Canadian friend think it is shorts and T shirt weather at that sort of temperature. My workshop has rarely dipped below 10 c so far this year so no recourse to heating as yet but today the temperature is heading down at a fair old rate. Hull looking very good.

-

Titanic by Tsm209 - 1/100

KeithAug replied to Tsm209's topic in - Build logs for subjects built 1901 - Present Day

The hull turned out rather well. -

Roger - Too true. I constantly think I would be much more productive if i just spent my time building the same model over and over again. On the other hand the most interesting bit is the problem solving. The hatch cover removal process seems like a nightmare. I assume they don't do it that way anymore. I'm not quite sure how the jig is working. Is the taper peg just a holding (tensioning) feature?

-

I am taking my time preparing stuff before I commit to the glue. I sorted out the small frames at the bow and stern. I spent a happy day stripping the cutting templates from the frames. I didn't find any of the usual solvents worked particularly well on pritt stick adhesive but peeling / sanding worked ok. The cut line for the deck made the frames very flexible and I wanted them to be a little stiffer for the future hull sanding process. I therefore temporarily glued small strips of wood across the deck cut line to increase the stiffness. I also sorted out the correct vertical position of the keel. The keel slots were cut deeper than needed so I cut the keel strip and then assembled it into a few of the frames before setting it to the correct heights fore and aft. With friction holding the keel in place I glued tabs to the frames to fix the keel position. The line of the keel is broken at frame 61 and the next job is to sort out the position of the aft section of the keel. Not very exciting but progress is progress.

-

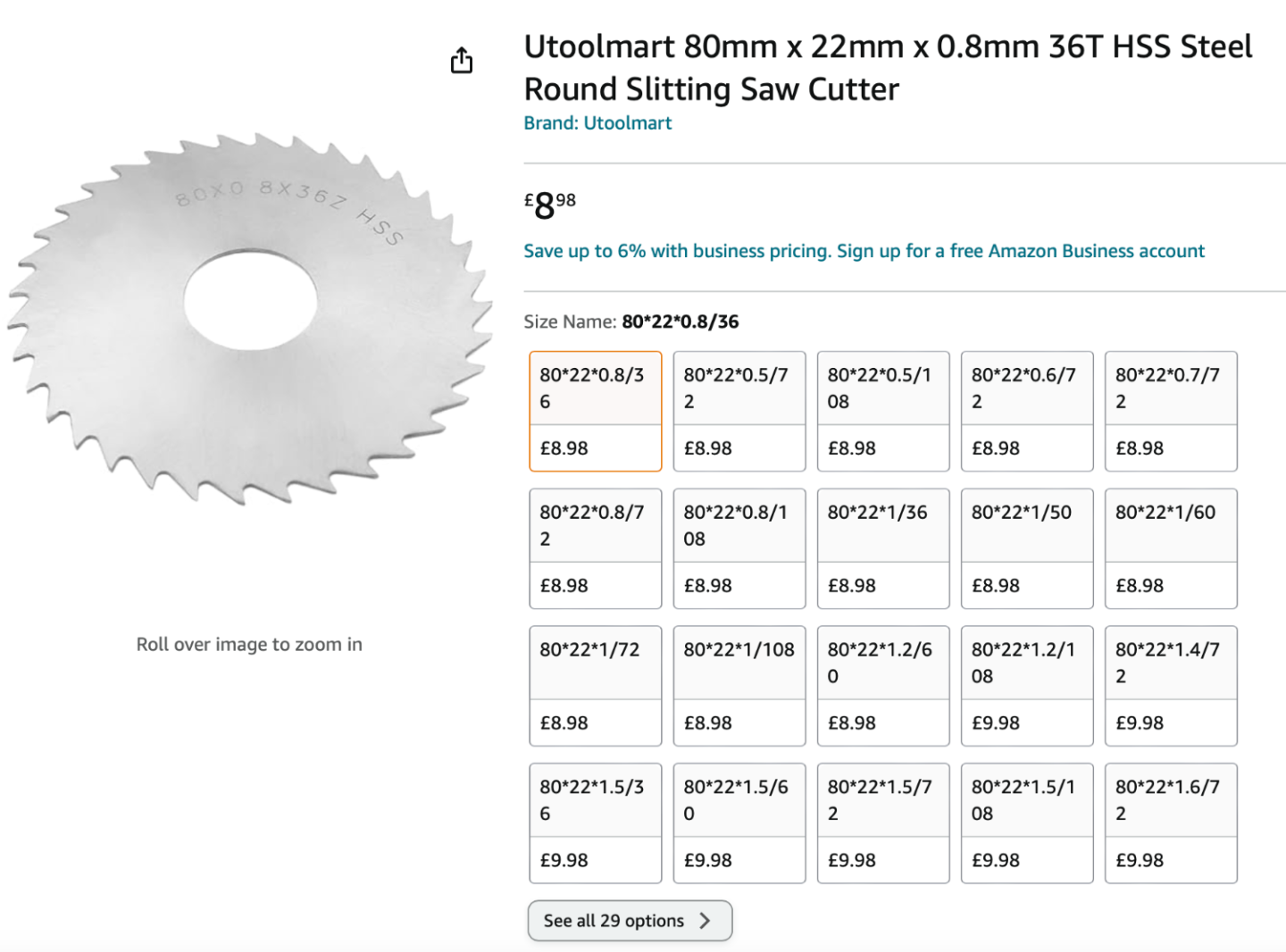

I agree. I tend to use the thinnest blade I can get away with to reduce waste. In practice I never find anything less than a 1/32" (0.8mm) slitting blade is stiff enough to prevent it flexing and wandering off line. If the wood is difficult (pronounced grain, hard, high moisture) I tend to use a .040" (1.0mm) blade. I always go for a slitting saw with large teeth.

-

Bigcreekdad - One other possible cause is the grain direction on the wood you are cutting. If you are using a narrow blade and the grain tapers away from the fence then the blade tends to follow the grain and the resulting planks can have a taper. If this is the case try flipping the wood over lengthways so the grain taper is towards the fence. This usually improves the accuracy of the cut plank.

-

Andy - It would make a nice lamp base. That is the sort of thing I say to my wife when I am in need of a tongue lashing. I like the thinness sander.

- 88 replies

-

- Vigilance

- Sailing Trawler

-

(and 1 more)

Tagged with:

-

Nice little model Phil. It seems like the rule is "the older you get the quicker you get". I'm looking forward to my imminent speed increase!

-

Eric - I find the older I get the quieter they get! Nice progress and a great way to see the old year out.

- 254 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.