-

Posts

415 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Erik W

-

Phil and Glenn, Now I don't feel so bad. Haha. I always seem to find my way back to projects I set aside for a while. I try not to have too many things half done at once though! Eric, Thanks for the nice words! I'll try to post updates regularly. The interaction with forum members helps keep me involved. One nice thing with picking Cheerful up again this late in the game is there are many other excellent builds to reference as I progress with mine. The plethora of photos are invaluable as visual aids. Erik

-

After a short, er . . . 6 ½ year break, I’ve resumed work on my Cheerful. I imagine few of you actually remember my build. It was sort of unexpected to be bitten by the wooden ship building bug again. In August I was on a vacation in the Netherlands visiting the Museum Kaap Skil maritime museum in Oudeschild on Texel Island, off the north coast. They have a huge 60 foot long diorama of the Texel Roads as it appeared around 1660. It looks to be about 1/100 scale. There are 160 ships/boats represented in the diorama! Seen here: https://kaapskil.nl/en/discover/expositions/ship-in-sight-the-roads-of-texel-and-the-world/ That led me back to Modelshipworld. And here I am. I feel a bit like Rip Van Winkle waking up from a long sleep. This website itself has changed. Yellow Cedar is a new wood of choice. Wood suppliers have changed. No more Crown Timberyard, but it looks like a good replacement with Modeler’s Sawmill. Chuck is a few projects further along after the Cheerful (the laser cut fully framed Speedwell is a fascinating project, by the way). There are still a lot of the same faces here, but the skill level on current projects has kicked up a few notches. So, my hat is off to you folks. It’s been an interesting few years for me. We had this global pandemic thing. After 14 years at the local government, I changed jobs a few times. I was a bicycle tour guide in Boulder for 7 months (a great way of keeping in shape as a 53 year old). Was the accountant for Left Hand Brewing here in Colorado. And finally settled into being an accountant for the National Center for Atmospheric Research. Though not working on Cheerful, I’ve still been active modeling from time to time. One thing I seem to gravitate towards is building things in smaller scales than the norm, and detailing them to a level of the larger scale (which is why Cheerful is unusual for me, I’d be more comfortable building something 1/96 to 1/144 scale! Haha). A few of my latest projects - A resin tugboat featured on this website: https://modelshipworld.com/topic/22995-ytl-45-taiwanese-navy-tugboat-by-erik-w-finished-1350-scale/ For my model railroad, an N scale (1/160) 3d printed boxcar that I scratch built full underframe details: https://www.therailwire.net/forum/index.php?topic=55256.msg758608#msg758608 and finished here: https://www.therailwire.net/forum/index.php?topic=55365.msg760492#msg760492 A 1/72 scale WWII F6F Hellcat on a carrier deck with super detailed engine and cockpit: https://www.militaryimages.net/threads/f6f-5-hellcat-wwii-usn-fighter-plane-1-72-scale.10858/ And probably my favorite, a 1/72 scale M1A2 Abrams tank with over 400 individual pieces of styrene and wire add by me to customize the tank. Scroll down to see the scratch built stowage items: https://www.militaryimages.net/threads/m1a2-sepv2-w-crows-ii-lp-1-72-scale-kitbash.10777/ Well, I’ve prattled on enough. Where I had left off was having finished the hull planking. The next step is supposed to be tree nailing. I’ve put a lot of thought into that and I’ve decided to skip it. It’s not because it’s time consuming and tedious as much as it’s a process that you can’t pull out and redo. Most things on the build can be pried loose if you’re unhappy with them. That, and I’d rather jump right back into cutting wood. That’ll help maintain my motivation to keep making progress. There are a few really good Cheerful builds out there where the builders have skipped tree nailing, Mike (stuntflyer), Glenn (glbarlow), and Ian (Seventynet). You all have some outstanding other builds as well by the way. Something to really aspire to for us newbies. Ian, I particularly like your Hayling Hoy. Never thought I’d desire to build a fully framed model before, but now . . . So, where I am now is I’ve done what I’d call an almost-final sanding of the lower hull. There were a few spots that needed attention. I’ll do an absolute final sanding and paint touch up later. That’s why the planking and hull still looks a bit rough. I’ve also been adding the fancy molding. It took a little trial and error to get my brass scraper made the way I wanted it. I’ve added the molding to the stern, and port side. Feels good to be building again!! If you’re new to viewing this build, it’s good to have you along. And if you’ve followed along before, welcome back! Without further ado, here are some proof of progress photos. It's hard to get the lighting right to show the contour of the fancy molding, but you get an idea from the last photo. Erik

-

Chuck, No. I haven't given up on her. Sadly, I'm afflicted with I-have-too-many-hobbies syndrome. The end result being for each project I seem to have the attention span of a squirrel sometimes. 😀 My Cheerful is lovingly protected and stored away until I resume construction (next step, a bazzilion tree nails in the hull). It's normal for me to set various projects down for a length of time, before picking them up and finishing them. Also, I'm one of the 45 million folks recently out of work now, so my immediate priority is figuring out how to land a paycheck again. Thanks, Erik

-

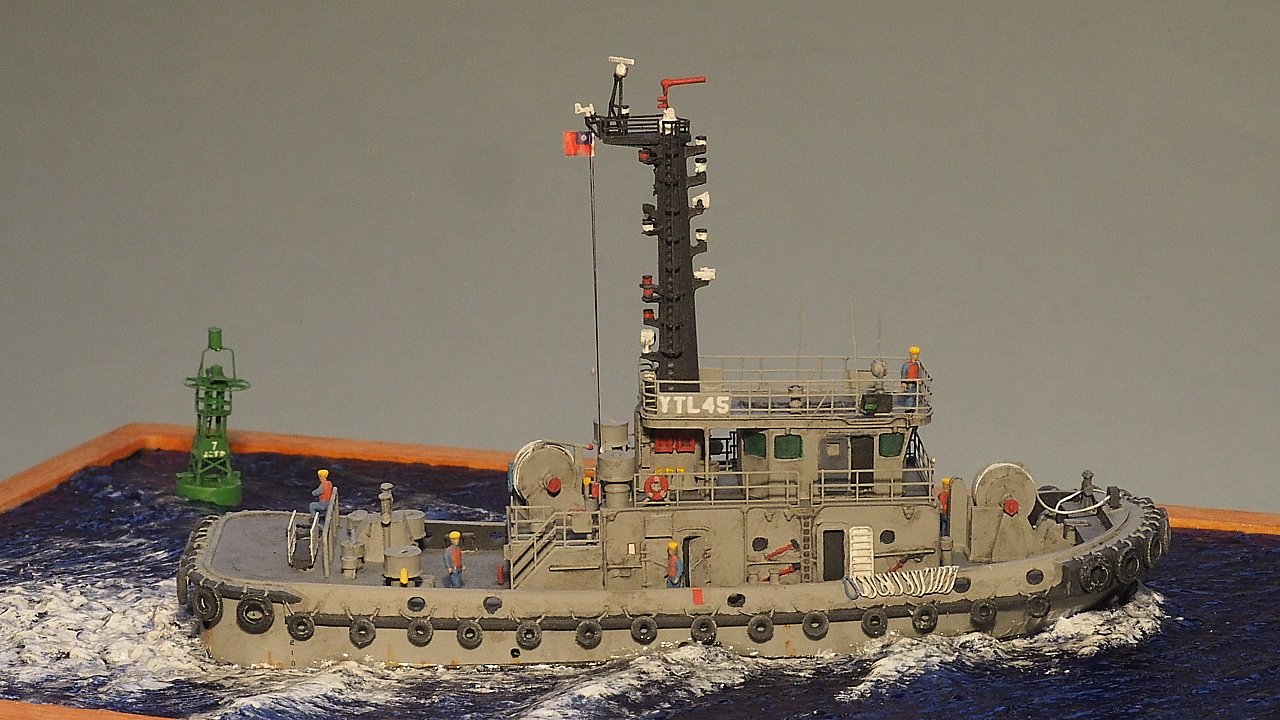

YTL-45 Taiwanese Navy tugboat by Erik W - FINISHED - 1/350 scale

Erik W replied to Erik W's topic in Plastic model kits

Chuck, Thanks. I seem to be back in modeling mode now, and had packed Cheerful away carefully expecting to pick it back up again. I'm in the middle of a small project now, so I'll see how I feel when I'm finished with that. It would be nice to move forward with the Cheerful build. Erik -

YTL-45 Taiwanese Navy tugboat by Erik W - FINISHED - 1/350 scale

Erik W replied to Erik W's topic in Plastic model kits

Thanks guys. Mike, yeah, weathering is a bit tricky in smaller scales. If you weather heavily it looks OK when viewed in person, but looks overdone in enlarged photos. Erik -

YTL-45 Taiwanese Navy tugboat by Erik W - FINISHED - 1/350 scale

Erik W replied to Erik W's topic in Plastic model kits

-

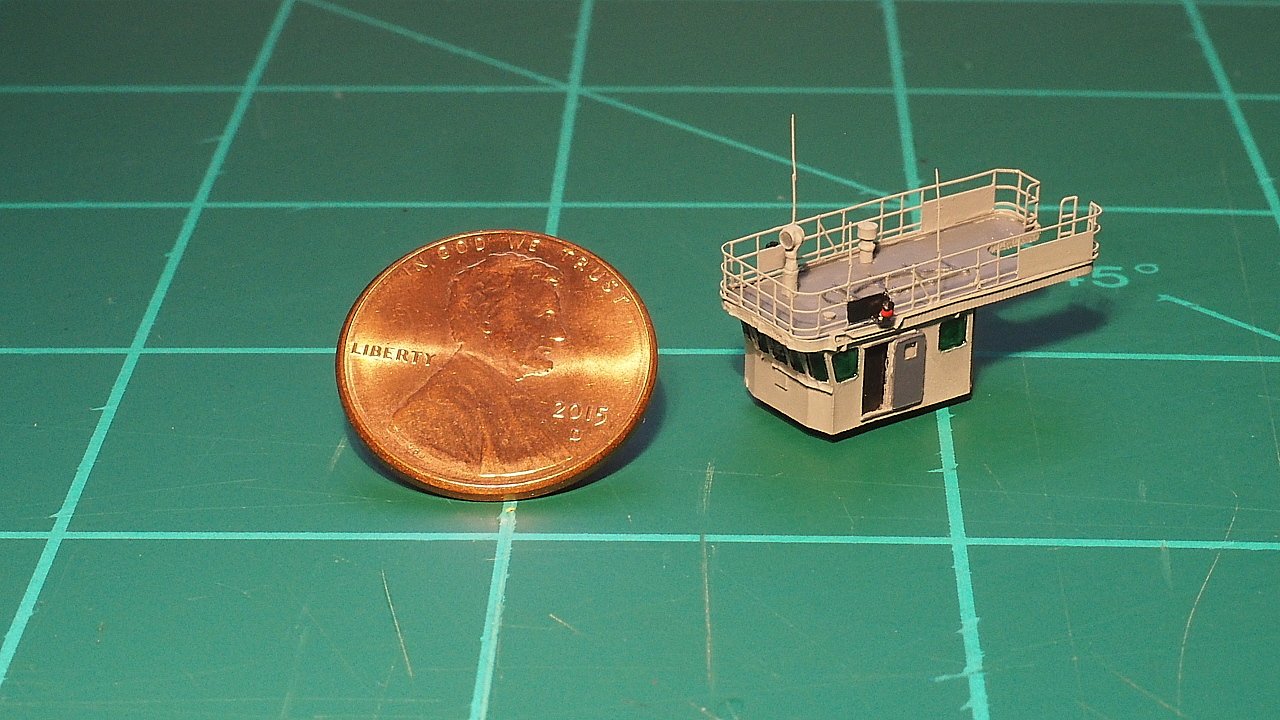

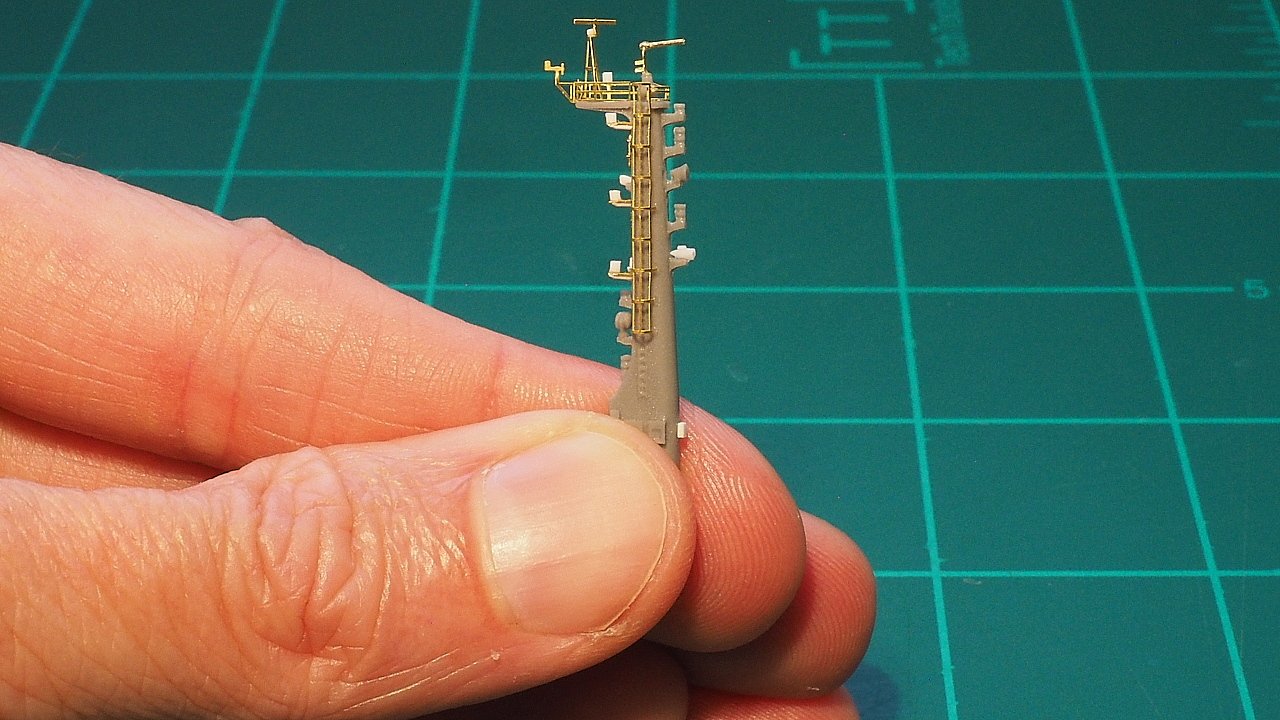

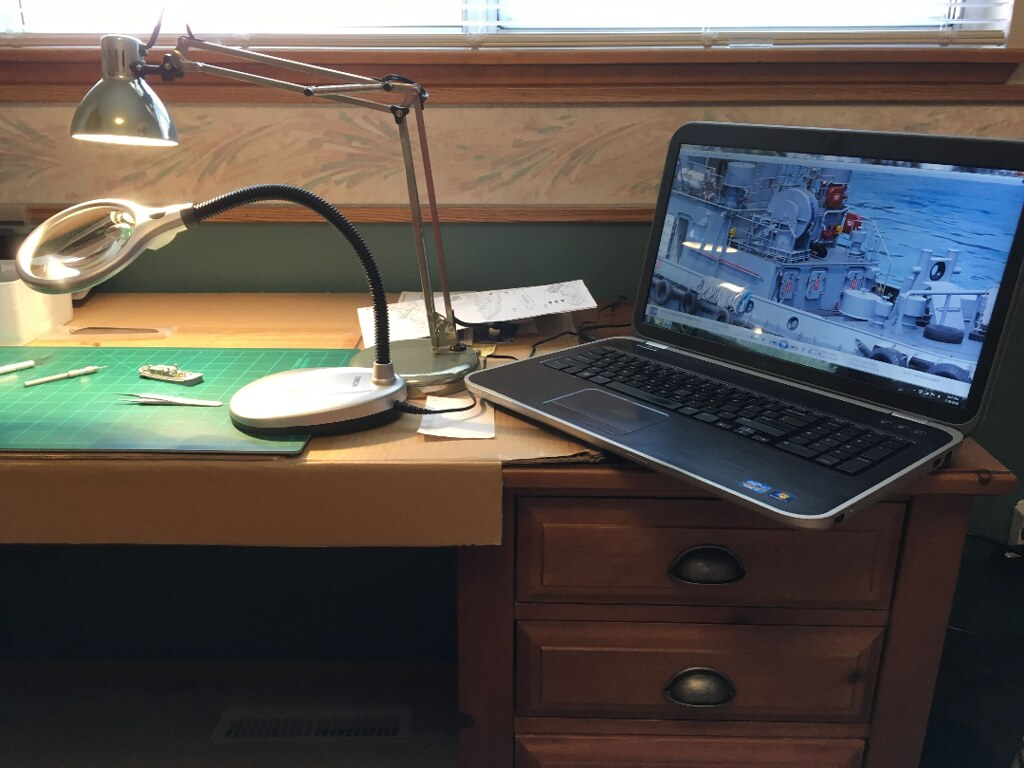

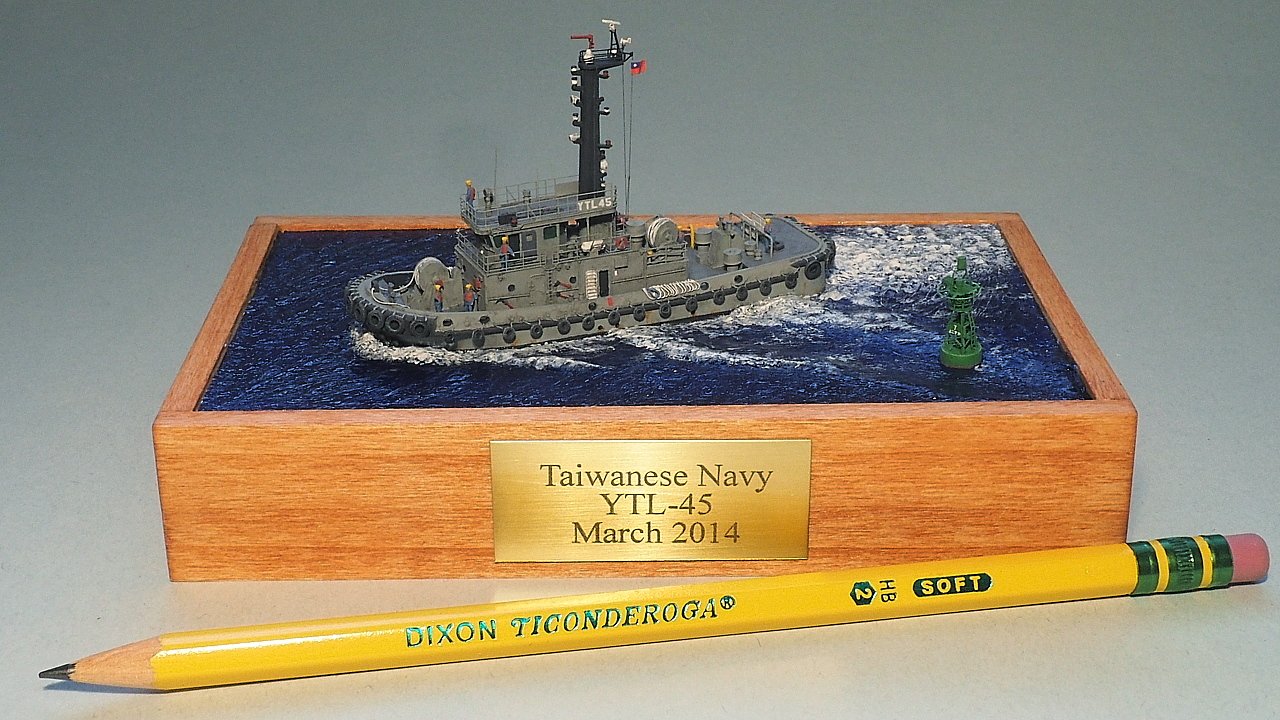

Though I haven't made any progress on my Cheerful in a couple of years, I did manage to complete a ship build. This is my Orange Hobby resin 1/350 scale YTL-45 Taiwanese Navy tugboat. The buoy is also from Orange Hobby. I work slowly, so the entire project wound up taking around 6 months. The tugboat is 240 pieces, with around 60 of those being fabricated by me. The buoy is 25 pieces! Erik

-

Chuck, That's perfect! Since I have an identical 1/48 scale longboat sitting on my shelf, that definitely helps me visual the larger boat's size. Thanks! Erik

- 421 replies

-

- medway longboat

- syren ship model

-

(and 1 more)

Tagged with:

-

Chuck, I haven't been in ship-mode for quite a while now. Real life has taken up too much of my time and mental space this year. I recently returned from a trip to Denmark, where I visited the National Maritime Museum and the Viking Ship Museum. Feeling my ship modeling interest being rekindling, I thought I'd check in here. Wow! I'm quite excited by this longboat kit you're working on. While I'm hoping to channel my renewed interest into picking up where I left off with my Cheerful build, this longboat looks like it will be a phenomenal kit. I'm impressed with how much more realistic this larger scale longboat looks, especially when compared to the 1/48 scale boat. Though I understand the size from the dimensions you've given, I'm having a hard time picturing the actual real world size of this boat. Any chance you can post a photo with something we can all relate to, like a can or bottle of soda/beer, or coin, or lighter, etc. I know that's kind of gimmicky, but 1/24 scale isn't something we're used to seeing everyday. Thanks, and glad to see after my time away that you're still doing what you do best! Erik

- 421 replies

-

- medway longboat

- syren ship model

-

(and 1 more)

Tagged with:

-

I also used individual planks. I'm a perfectionist, so planking the hull wound up taking quite a while. I'd do 1 or 2 planks a day after work, and 3 or 4 on the weekends. I started getting sloppy if I tried to do any more than that. Patience is key. As far as the plank ends go. I would mark out on the bulkhead the center point of each plank end and make sure the plank's end was perfectly vertical on the bulkhead (with the curvature of the hull this usually means the end is not square with the plank length). Sand lightly, test fit, repeat. The key for square/tight looking plank ends was that test fitting part. If there's a bit of a gap, sand lightly, test fit, repeat. Again, patience is key. This hobby in general vs. other's I have, has really taught me the value of going slow! Erik

- 574 replies

-

- cheerful

- syren ship model

-

(and 1 more)

Tagged with:

-

B.E. I've been following your Cheerful build. I've been meaning to compliment you on your progress. My build is in dry dock currently while I wait for the time and mental space before I resume work again. It's been a joy following the progress of the other Cheerful builders though. Yours is coming along nicely! Regarding the color of red you're using. I too decided to use Vallejo Flat Red #957. I knew from past experience that Vallejo paints are high quality and easy to brush paint with minimal streaks. I think you won't regret your choice. To see how the Vallejo flat red looks farther along in the build process, just check out the most recent photos of my build. Keep up the good work! . . . and keep the photos coming. Erik

- 574 replies

-

- cheerful

- syren ship model

-

(and 1 more)

Tagged with:

-

Mike, Thanks for the additional photos! You did a superb job on her . . . and set the bar high for the rest of us Cheerful builders! The detail shots will be useful as a reference when I get farther into my build. Erik

- 450 replies

-

- cheerful

- syren ship model

-

(and 1 more)

Tagged with:

-

Mike, Congratulations! This looks great!! You definitely set the bar high for the rest of us Cheerful builders. Any chance you'll do a photo shoot of the finished build and post more photos? Erik

- 450 replies

-

- cheerful

- syren ship model

-

(and 1 more)

Tagged with:

-

I finished planking the hull. Woohoo! Feels kind of weird to not be adding a plank or two after work every day. I also added the stern post, and did a more thorough sanding of the planking on both sides of the lower hull, paying close attention to getting rid of any high and low spots. I still need to do more work where the planking meets the keel and the stem. Also, the black paint on the wale has taken quite a beating. I'll fix that later. I was hesitant to include the bow shot, since the planks on either side don't line up at the stem too well. Figured it was still an interesting angle for a photo though. Erik

-

Mike, This is looking really good! You continue to set the bar high for those of us Cheerful builders following in your footsteps! Erik

- 450 replies

-

- cheerful

- syren ship model

-

(and 1 more)

Tagged with:

-

Mike, Thanks. In looking at my plans, and then looking at your yards in the photo, I understand what you did with the diameter of the yards when shortening them. One of the good things about starting my build after you guys is that you figure out some of this stuff before I get to that point in the build. Also, that shorter main yard is a good thing. I've been wondering just how wide the shelf will have to be that I display my Cheerful on! Erik

- 450 replies

-

- cheerful

- syren ship model

-

(and 1 more)

Tagged with:

-

Looks good Mike. How much did you shorten the yards? Were they mistakenly drawn too long on the plans? Thanks, Erik

- 450 replies

-

- cheerful

- syren ship model

-

(and 1 more)

Tagged with:

-

Bob, Thanks for posting more photos! She looks beautiful!! It's definitely a challenge to photograph the entire ship. Erik

-

I realized when I was planking the second belt of strakes on the first side of the hull that I wouldn't be able to use the clamps in the same way on the other side of the hull. Since the fully planked finished side is now rounded, the clamps have nothing to grip. I made a surface to place the clamps on out of a few dollars worth of basswood. I made it to a size and depth that would allow clamping of my strakes in the second belt as I work my way towards the first belt of strakes. It's working well so far. As with the other clamping I've done, I test fit the clamp position before I apply glue, so I can figure out the placement before I do it for real. Erik

-

Thanks for the kind words! I make such a mess when I do the planking, with the glue smearing the pencil all over the place, glue finger prints, etc., that I can't tell how the joints between strakes will look until I sand all the mess off. As I sanded, I was pleasantly surprised that the last strake turned out so well. To get it to the right width I cut it down to get it to the basic shape, but slightly oversized, and then started at the bow with removing material and worked my way along the length of the plank. Meaning, once I got the first 1/2" so it would fit in between the adjacent strakes, I moved onto the next short segment, carefully sanding the plank edge and test fitting until it fit correctly with a little pressure. I erred on the side of not removing enough material as I did my sanding, before test fitting. As we all have learned the hard way, you can't put material back! Erik

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.jpg.57ecfdac67818266ed17c282cbba155b.jpg)