-

Posts

149 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by John Cheevers

-

Welcome back. I really enjoy following this build.

- 884 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

NAIAD 1797 by Bitao - 1:60

John Cheevers replied to Bitao's topic in - Build logs for subjects built 1751 - 1800

The key to this, as it is in any manufacturing process, is to do the hard part first. Then you can bring the res t of the object into shape but correctly indexed to the critical piece. Nice process. -

Work Table Recommendations ?

John Cheevers replied to DanB's topic in Modeling tools and Workshop Equipment

Two 2-drawer metal file cabinets and a 30" wide lauan door. -

The Thing-a-Ma-Jig: The tool that you are pointing to that no one else can see.

-

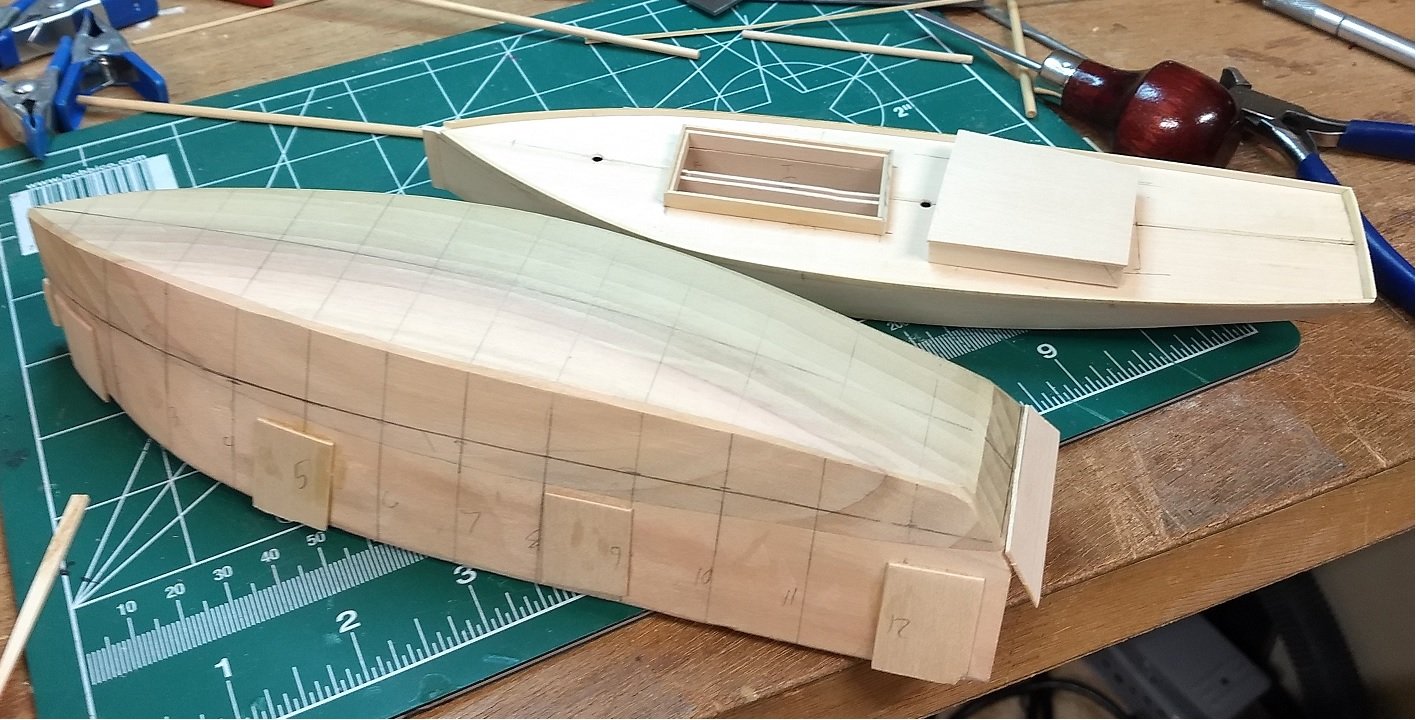

Dave, You're making great progress, and you're learning a lot about working from other folk's plans. I don't think you should be an absolute slave to the plan before you. Use it as a guide or roadmap, but don't fret the occasional road block or detour--the real builders didn't. I brought my model to a meeting to show off the jig and discuss how I glued up the pieces. The only thing missing that I wanted to add were slots for the transverse bulkheads--maybe on the next one. I was going to present the boat to show progress at our last meeting, but then I changed my mind. I'll PM you a recent shot as I kinda want to keep the model underwraps for now. John

-

Dave, Sorry, I had no idea that the photo with the jig was so blurry. Here is a better photo. All I did to keep from gluing the hull panels to the jig was to bevel the edges of the jig, as you can see in this clearer image.

-

Dave, I took a quick look at the monograph and it seems to me that the hull can be built on jig 1. The builder in the monograph does not seem to use jig 1 to help control the frame angle of the side planks. But it can be done using jig 1. Here is a look at the jig I used for my very "similar to a sharpie hull". Your thinking is correct. You can call me to discuss technique if you want. John

-

Jim, This is a really nice build, and an excellent photographic record. Can't wait until you reach the rigging... John

- 44 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.