-

Posts

183 -

Joined

-

Last visited

About PeteB

- Birthday 07/18/1950

Profile Information

-

Gender

Male

-

Location

South Coast NSW Australia

-

Interests

Flying GA aircraft and Gliders / Sailing and Old Ships

Flight Simulation mainly Tube Liner Study Sims

Models - Plastic Mainly Aircraft but a couple of S Boots in there

A 90% Norske Loeve Originally Billings kit but a lot of scratch masts tops etc

looking to build a POF next

Recent Profile Visitors

-

PeteB reacted to a post in a topic:

HMS PEGASUS by giampieroricci - Scale 1:36 - Swan-Class Sloop from plans by David Antscherl & Greg Herbert

PeteB reacted to a post in a topic:

HMS PEGASUS by giampieroricci - Scale 1:36 - Swan-Class Sloop from plans by David Antscherl & Greg Herbert

-

PeteB reacted to a post in a topic:

HMS PEGASUS by giampieroricci - Scale 1:36 - Swan-Class Sloop from plans by David Antscherl & Greg Herbert

PeteB reacted to a post in a topic:

HMS PEGASUS by giampieroricci - Scale 1:36 - Swan-Class Sloop from plans by David Antscherl & Greg Herbert

-

PeteB reacted to a post in a topic:

HMS PEGASUS by giampieroricci - Scale 1:36 - Swan-Class Sloop from plans by David Antscherl & Greg Herbert

PeteB reacted to a post in a topic:

HMS PEGASUS by giampieroricci - Scale 1:36 - Swan-Class Sloop from plans by David Antscherl & Greg Herbert

-

PeteB reacted to a post in a topic:

HMS PEGASUS by giampieroricci - Scale 1:36 - Swan-Class Sloop from plans by David Antscherl & Greg Herbert

PeteB reacted to a post in a topic:

HMS PEGASUS by giampieroricci - Scale 1:36 - Swan-Class Sloop from plans by David Antscherl & Greg Herbert

-

PeteB reacted to a post in a topic:

HMS PEGASUS by giampieroricci - Scale 1:36 - Swan-Class Sloop from plans by David Antscherl & Greg Herbert

PeteB reacted to a post in a topic:

HMS PEGASUS by giampieroricci - Scale 1:36 - Swan-Class Sloop from plans by David Antscherl & Greg Herbert

-

PeteB reacted to a post in a topic:

HMS PEGASUS by giampieroricci - Scale 1:36 - Swan-Class Sloop from plans by David Antscherl & Greg Herbert

PeteB reacted to a post in a topic:

HMS PEGASUS by giampieroricci - Scale 1:36 - Swan-Class Sloop from plans by David Antscherl & Greg Herbert

-

PeteB reacted to a post in a topic:

HMS PEGASUS by giampieroricci - Scale 1:36 - Swan-Class Sloop from plans by David Antscherl & Greg Herbert

PeteB reacted to a post in a topic:

HMS PEGASUS by giampieroricci - Scale 1:36 - Swan-Class Sloop from plans by David Antscherl & Greg Herbert

-

PeteB reacted to a post in a topic:

HMS PEGASUS by giampieroricci - Scale 1:36 - Swan-Class Sloop from plans by David Antscherl & Greg Herbert

PeteB reacted to a post in a topic:

HMS PEGASUS by giampieroricci - Scale 1:36 - Swan-Class Sloop from plans by David Antscherl & Greg Herbert

-

Mike Y reacted to a post in a topic:

Mf 70 Proxxon Mill Spindle Mod to take ER11 Collets from 1mm to 7mm

Mike Y reacted to a post in a topic:

Mf 70 Proxxon Mill Spindle Mod to take ER11 Collets from 1mm to 7mm

-

PeteB reacted to a post in a topic:

Remington Industries

PeteB reacted to a post in a topic:

Remington Industries

-

sakumar reacted to a post in a topic:

Le Gros Ventre by marsalv - FINISHED - 1:48 - POF

sakumar reacted to a post in a topic:

Le Gros Ventre by marsalv - FINISHED - 1:48 - POF

-

Alan Cabrera reacted to a post in a topic:

MONTAÑES by Amalio

Alan Cabrera reacted to a post in a topic:

MONTAÑES by Amalio

-

Canute reacted to a post in a topic:

My laser cut planks

Canute reacted to a post in a topic:

My laser cut planks

-

PeteB reacted to a post in a topic:

sanding sealer

PeteB reacted to a post in a topic:

sanding sealer

-

My laser cut planks

PeteB replied to modeller_masa's topic in Building, Framing, Planking and plating a ships hull and deck

Hi Gregory - which 20W /40W Blue diode laser would you recommend looking at having regard to our modelling needs? Cheers Pete -

Saburo reacted to a post in a topic:

HMS PEGASUS by giampieroricci - Scale 1:36 - Swan-Class Sloop from plans by David Antscherl & Greg Herbert

Saburo reacted to a post in a topic:

HMS PEGASUS by giampieroricci - Scale 1:36 - Swan-Class Sloop from plans by David Antscherl & Greg Herbert

-

Obormotov reacted to a post in a topic:

MONTAÑES by Amalio

Obormotov reacted to a post in a topic:

MONTAÑES by Amalio

-

Obormotov reacted to a post in a topic:

MONTAÑES by Amalio

Obormotov reacted to a post in a topic:

MONTAÑES by Amalio

-

Cirdan reacted to a post in a topic:

Cannon Armed Clipper Thermopylae

Cirdan reacted to a post in a topic:

Cannon Armed Clipper Thermopylae

-

thibaultron reacted to a post in a topic:

A little ripper from Veretas

thibaultron reacted to a post in a topic:

A little ripper from Veretas

-

A little ripper from Veretas

PeteB replied to PeteB's topic in Modeling tools and Workshop Equipment

Hi Ron can see one side is 1000 grit - could you let me in on the secret sauce recipe by whispering what grit you have on the reverse? Cheers Pete -

My Veritas Miniature low angle Block Plan arrived yesterday and it is a little ripper - I wasn't sure just how practicable it was going to be but a few trial strokes on some swiss pear straight out of the box convinced me, with shavings peeling away with little effort. I don't have small hands yet it was a natural fit into the mitt - so to speak - can see plenty of use for this and wasn't at all expensive costing me just $79au. Well worth the price of admission. Cheers Pete PS If you buy one don't throw the little cardboard square out - It is, quoting the instructions "a corrosion inhibiting chip offering continuous corrosion protection for up to two years"

-

Hi Keith - mate I bought them off evilbay just to see what they were like, at $35au they aren't .005 tolerance but for my purposes that isn't needed. As mentioned I used the Mark 2 eyeball and not a dial gauge to measure runout but to the eye and a trial step cut with the 3mm, 5mm and 7mm into Swiss Pear it looked ok to me. There were quite a few stating they were within a .005mm tolerance for not a lot more. Cheers Pete https://www.ebay.com.au/itm/385040245651?hash=item59a62fe393:g:9WYAAOSwf2li6jHN

-

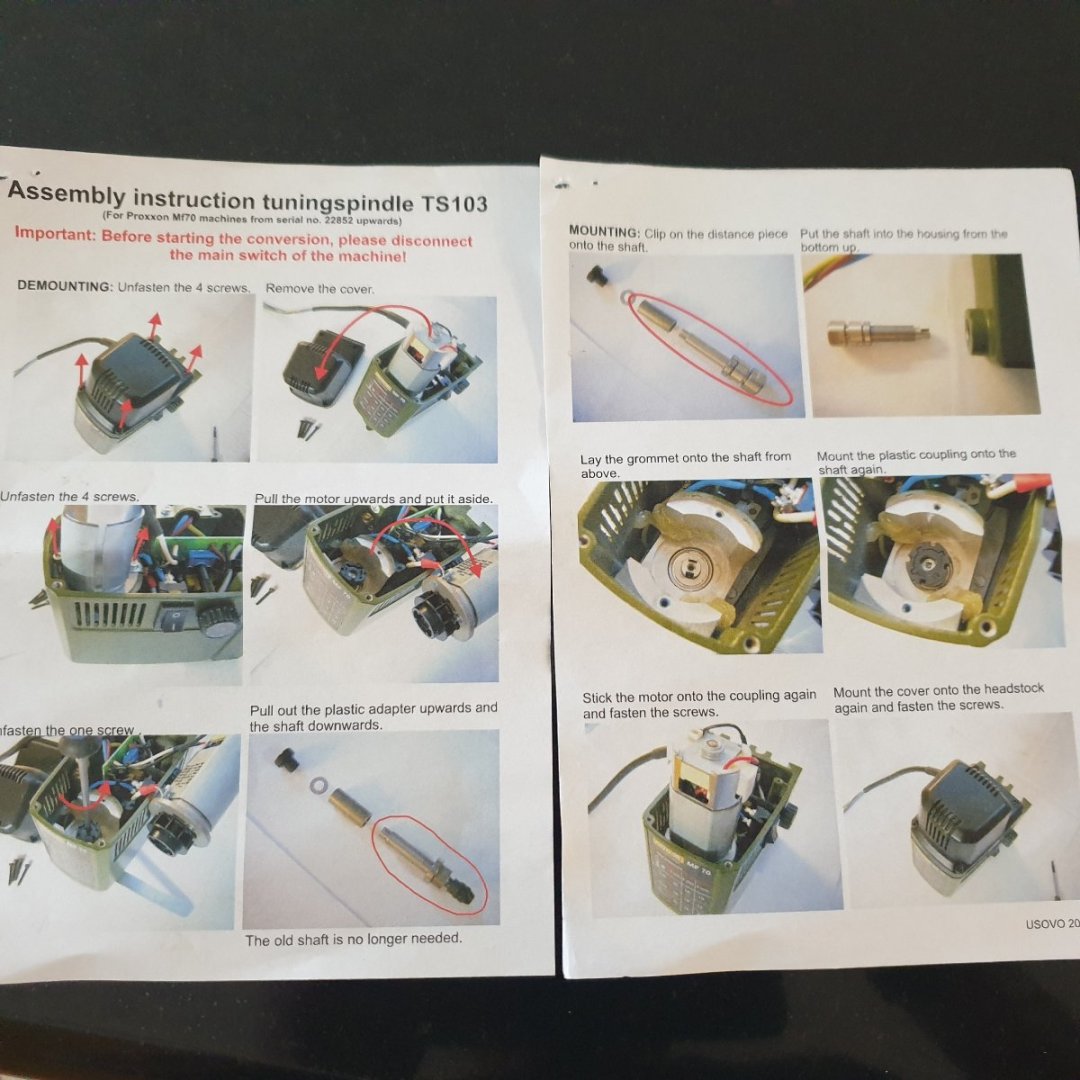

I’ve been looking for a solution to the Proxxon 3.2mm max shank size limitation for some time as there are very few standard profiles available in this size and I didn’t want to try and turn down shanks given the hardened metal alloys they are manufactured from. I recently came across a replacement Spindle kit manufactured by a German Firm Usovo which will accept ER 11 collets – 1mm to 7mm - have purchased and installed the new Spindle and very happy so far. The install is very straightforward but I had one gotcha involving the removal of the original Proxxon drive collar. The collar is retained by a 3mm Phillips Head which rounded first try and had to be drilled out. This isn’t really a problem as the intention is for the original spindle to be discarded but I used an 2mm easy out to remove the remaining part of the screw after I removed the original spindle so as to retain it as a spare. When fitting the new spindle, I used a new 3mm Hex socket head machine screw to replace the OEM Phillips Head - just a heads up as it isn’t part of the kit. The offending screw is shown in the instruction sheet photo step 5. Photo 1 - Instruction sheet – see step 5 and 10 for a better view of the retaining screw and drive grommet. Photo 2 - shows the original Proxxon Spindle, bearings and the Drive collar. I was pretty disappointed to note the pitting and rough machining of the original spindle in what is a new and not inexpensive machine, especially when compared with the kit spindle machining shown in photo 3. Photo 3 - Kit contents – note the lower ball race is already pressed in place on the new spindle. Also note the instructions don’t mention the obvious ie that the old bearings have to be removed. Photo 4 - shows the Hex Head Machine screws used to retain the motor so why didn’t they use one for the drive collar retainer instead of a Phillips head?? Photo 5 – Comparison of Collet holders and old bits removed. The black plastic drive collar is shown but there is a more flexible grommet not shown which press fits over the top of the drive collar Photo 6 - New spindle installed with collet holder and a 5mm collet. The first run was noticeably quieter with no discernible runout. Very happy so far. Photo 7 – Range of ER 11 collets 1mm – 7mm. Bought these on line for just under $40 and despite the homey labels they were nicely machined and supplied in individual oil filled plastic bags. Comparison of the 3mm Proxxon to the 3mm ER11 collet. When using the larger mill bits, one has to have regard to the limited torque available and take shallower cuts but to me this is a easy limitation to accept for the far greater Type and range of standard milling bits available to the ER11 collets than the 3.2mm Proxxon max. The link to the spindle kit is https://www.usovo.de/en/c/cnc-technology/proxxon-mf70-accessories they were great to deal with and while not cheap at 99 euro for me it offered value for money. There are two versions available for mill serial numbers above or below serial 22852. They also offer a beautiful planetary reduction gearbox for the earlier serials to give more torque for the larger mill bits – would love one for mine, a later serial, but not in the works at the moment unfortunately. I have no financial nor any interest in the firm just posted as a heads up for many of us that have the machine. Hope this is of use to others. Cheers Pete.

-

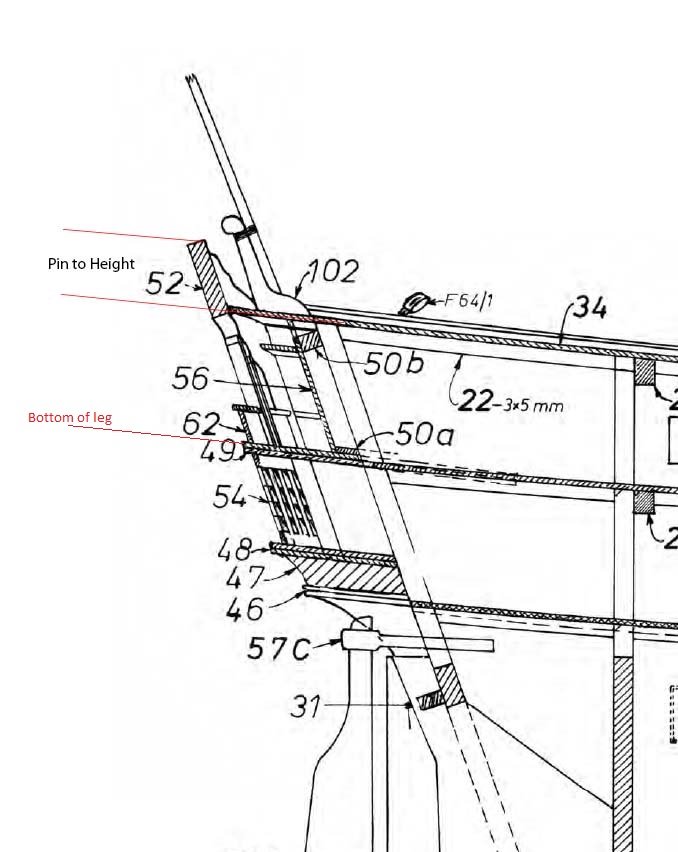

Ed at the risk of stating the obvious maybe I should have added that the ply parts 46, 48 and 49 will need to be steamed to match the deck camber before you try and pin them in place for a trial set up. Once this is done and your happy with the fit - you can sand and/or pack Part 47 as required to match the camber and space between your pined parts 46 and 48. Cheers Pete ps - like your Sherman M4A3E8 nicely done. (in another life served in Centurions RAAC 69-71 SVN)

-

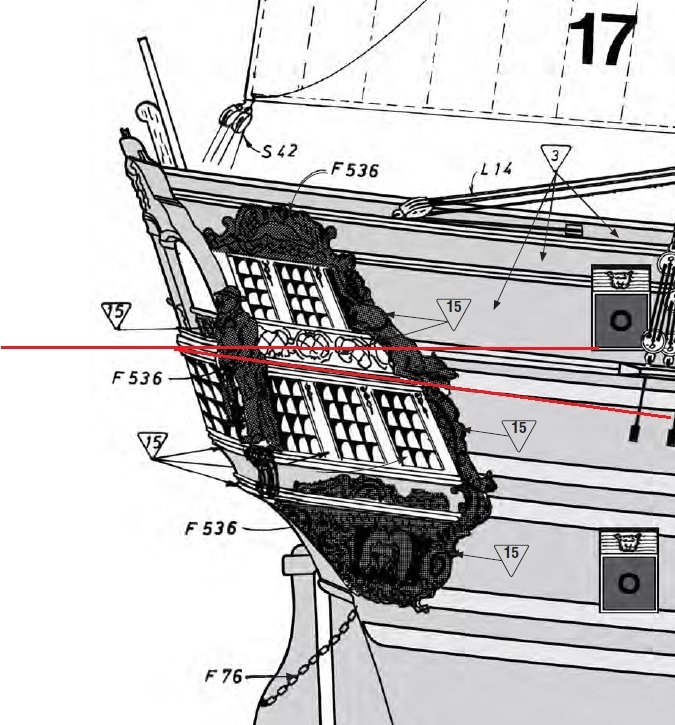

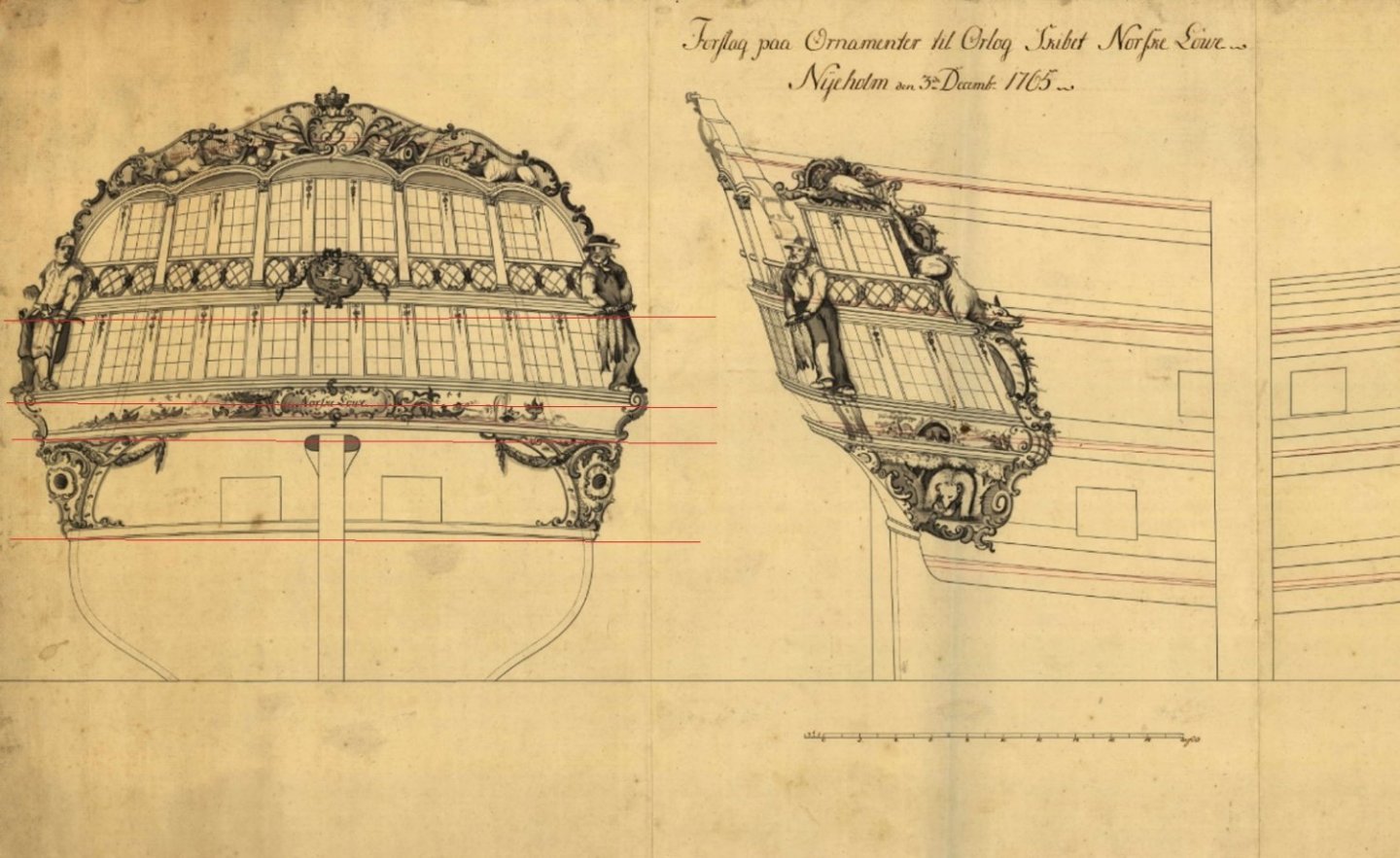

Hi Ed - don't bash yourself up you're doing pretty well getting to where you are with things looking pretty shipshape. I think the low number of completed models of the Norske on the www shows that a lot of guys have put it back into the cupboard and gone on with something simpler but you’re still in the game. Perhaps I could offer a heads up on a couple of parts that tripped me up - right around where you are now? At first glance part 47 (the lower stern gallery filler piece) appears to be flat if you just look at the sectioned sheer plan or at least it did to me, but in fact when looking from astern the gallery floors curve down from amidships to each outer corner which in turn sets the height of the gallery wings. I didn't notice first time round and had to strip it out and make another. Suggest maybe you use the large Gallery board ? - part 52 - and pin that in place first by referencing the height above the upper deck on the sheer plan. Once you’ve got that in place the legs should then give you the level of the upper gallery deck to pin in place amidships having regard to the deck camber and then the sheer plan showing both the upper deck wings and lower gallery windows sloping down to the waist in line with the Wales. Get the above sorted and you’re home and hosed. Enjoy the rest of your build. Cheers Pete

-

Hi Giampiero - Mate you are a “Machine”. First the beautiful “L'Amarante” at 1:30 then you follow it up with the superb “La Venus at 1:96 and to just to make it a bit more interesting you launch her in 12 months no less. And without taking a breath here we are already on page 3 of your HMS Pegasus build log, 7588 nails later (you haven't got any of Santas Elves working off-season in your workshop have you? ). Mate that’s what gets you the title of a “Machine” down my way 🙂 – all absolutely beautiful work that I admire each time I read a post. - No pressure but we are expecting perfection this time 😉 Stay safe Cheers Pete

-

Hi Richard Thanks from me as well - best 5 hrs I've spent acquiring CAD skills specific to our hobby . Gave me good insight into where I've been going wrong and the advantages Rhino offers in hull construction simplicity once you know the rules. Much appreciate you giving up some of your family time so close to Xmas. Best wishes to you and yours, Cheers Pete

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.jpg.d84ec4dad1d7791e855dca06210ab6f3.thumb.jpg.f45209242e851d4409eca1a09293165b.jpg)