-

Posts

2,227 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by EJ_L

-

Finally getting back into the shipyard. Should be much more regular with updates again and I am ready to build! While I have been busy over the past few months, I have managed to get in small bits of build time and have been particularly active this week resulting in all three lower masts and tops built. Neither masts nor tops are glued yet, just rough fitted. I will build all the masts, caps, crosstrees, etc. then switch to rigging. After all this time it will be nice to start going vertical.

-

Some work on the bowsprit mast. As with all masts and yards, I’m trying to attach as many blocks and other components as possible before securing to the ship. This is made trickier as I intend to have sails but of course the rigging plans do not include that information. To figure out what is needed, a lot of consulting other books and examples is taking place for each sail to try to find all the components needed. Even more fun is that I am used to building ships with spritsail topmasts, and this one has a jib boom and sail. My accumulated knowledge of the former is not helping right now…

-

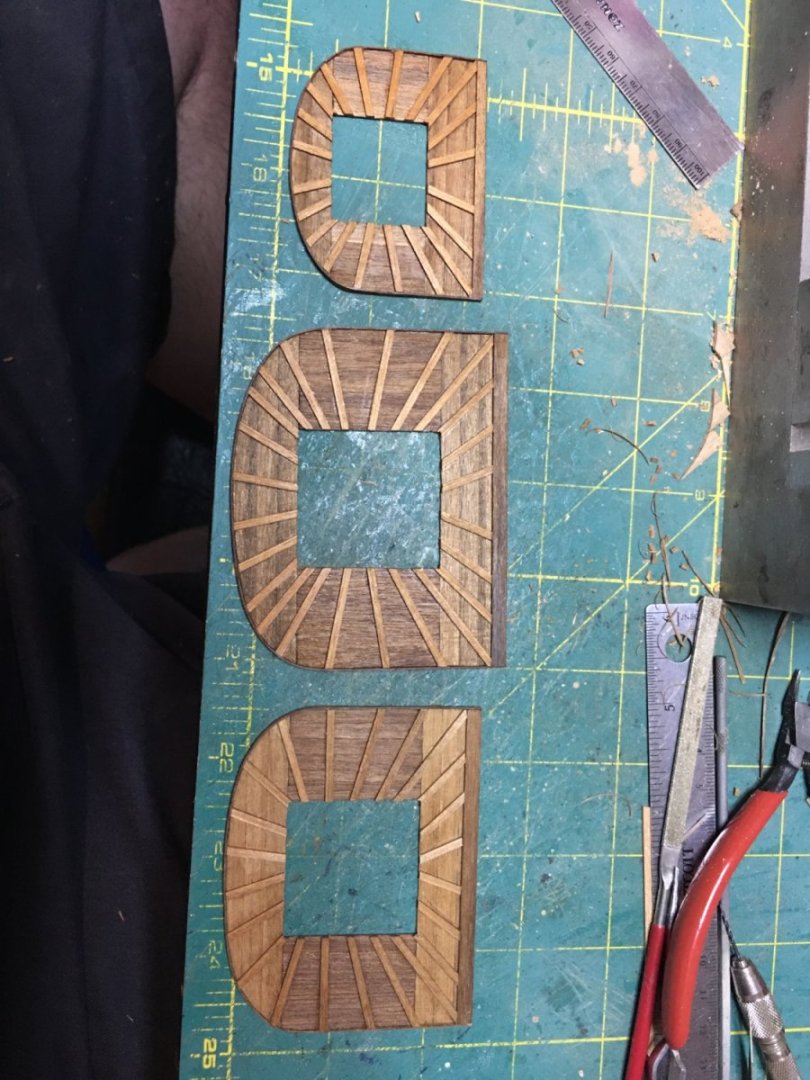

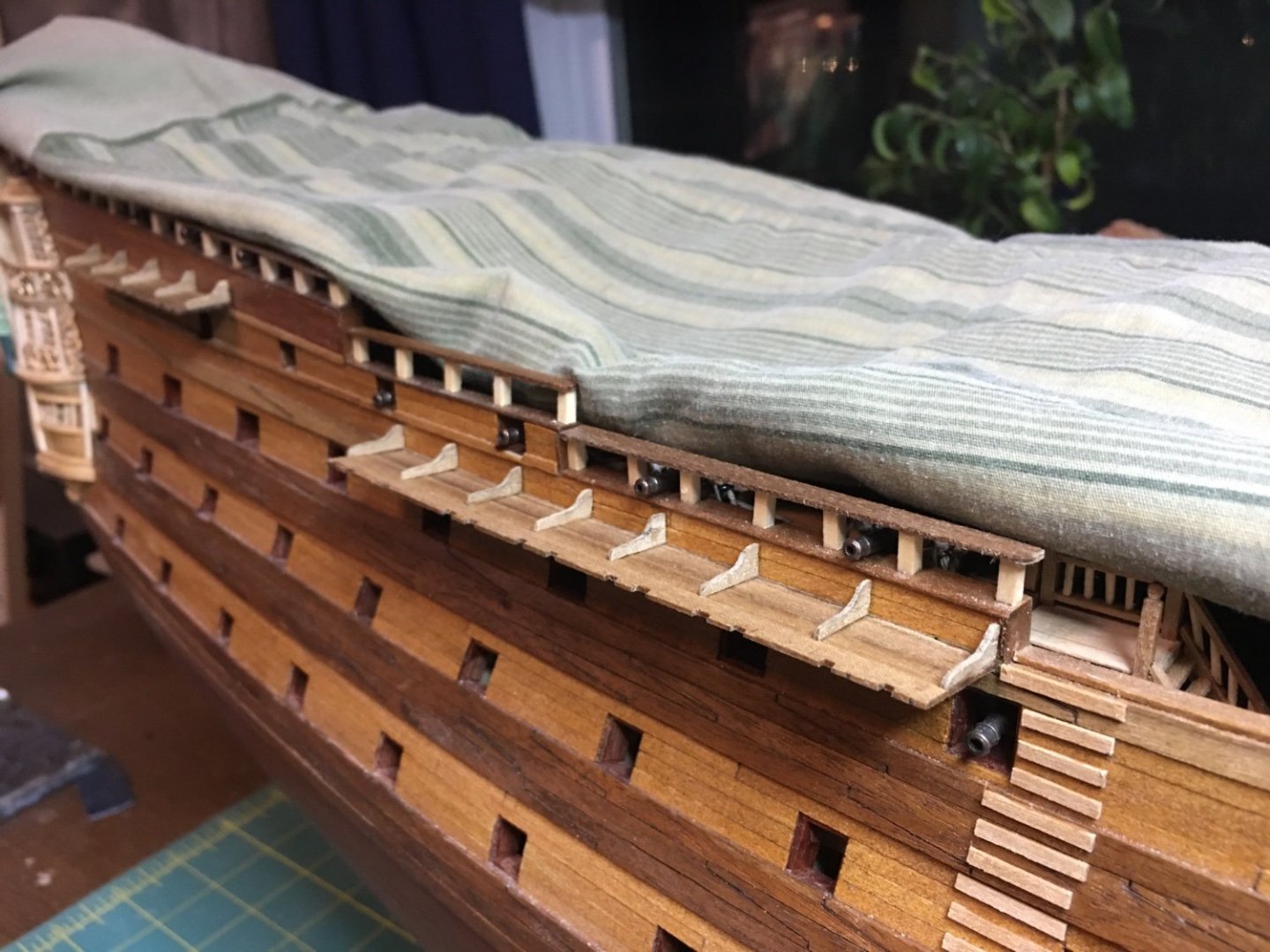

Wow! It has been a while since I’ve updated this log. Been busy with many different things including starting a new HO scale railroad and my bonsai club has been a bit more active lately with new members which has been exciting. Also I have decided to return to college to complete my degree, so that has been taking up a lot of my remaining free time and will till the end of next year. Still, I have been working when I can. Channels have been installed and now I am constructing the gun port hatches and getting ready to install them and the gun barrels.

-

I will echo Kevin in his statement of your ability to see all of these compound angles and layers and translate them from 2D to 3D. I work in construction reading 2D plans to visualize 3D buildings, but even with all of that practice, I struggle to see what some of these artists try to convey in their pictures. Your model, aside from being simply astounding, has done a lot to help me understand the make up of these vessels complex curves and angles and how they interact to form the complete picture. You pick out details that are easily overlooked and workout incredible ways of making these difficult pieces look, maybe not simple, but doable. Bravo!!

- 2,432 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

I feel your pain! You know I love to chop up the framing on kits to allow for interior build-outs and other modifications, and what seems a simple change at first, later reveals itself to be a major issue. I now have a hefty pile of kit decks that would no longer fit the structure as intended, especially balconies. Almost all of mine end up being scratch built to either align properly with the interior decking or to fit the curves of the hull. I think your plan to extend out the framing to add more hull will work fine... just a lot of frustrating work. I have watched you recover from "whoops" before beautifully. I believe you will do so again. You do have an added bonus of the hull being black in this area which will help hide mistakes or imperfections easier than natural wood. Otherwise, she is looking great!

-

Royal Caroline by EJ_L - Panart - 1:48

EJ_L replied to EJ_L's topic in - Kit build logs for subjects built from 1501 - 1750

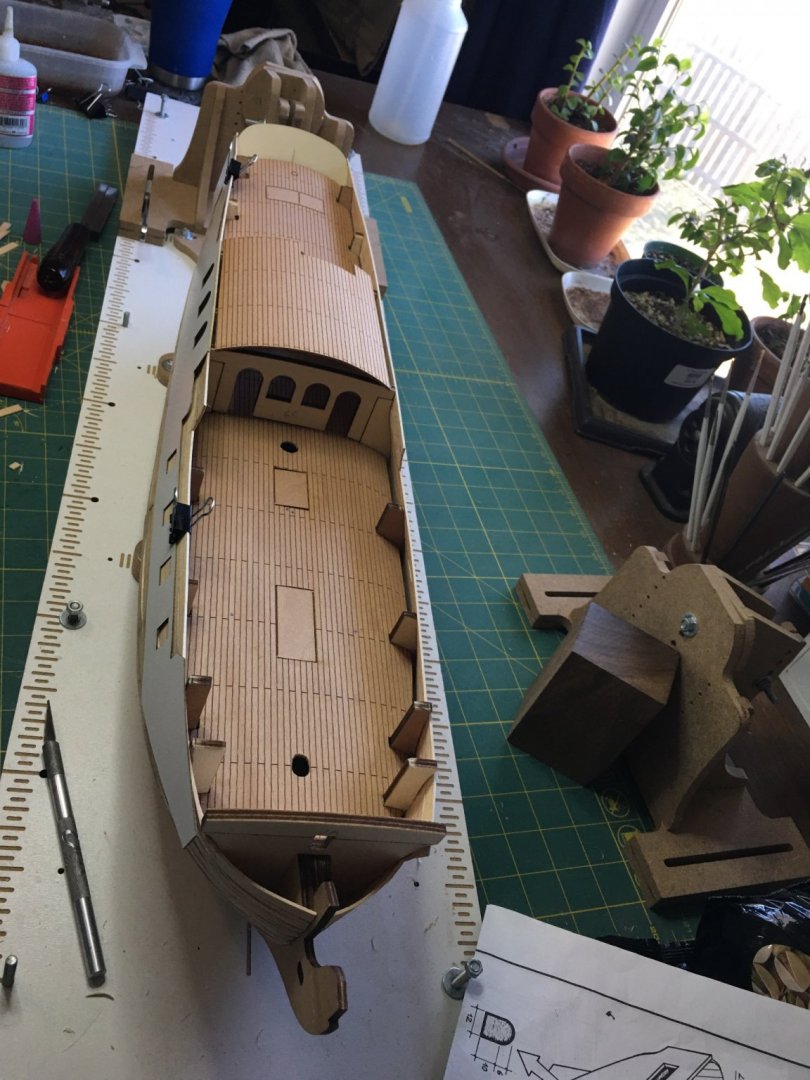

Upper-work planking installed. Caroline is now ready to take a trip to the wood shop for sanding and finishing. Once the finish is complete, I can start fitting trim and painting the areas that will be painted. Deck planking and interior planking will follow. While the finish work is taking place, I will be switching back to Royal Louis for a while. Thank you all for the continuing interest. -

Royal Caroline by EJ_L - Panart - 1:48

EJ_L replied to EJ_L's topic in - Kit build logs for subjects built from 1501 - 1750

Thank you Marc! It is from people like yourself and the work and effort that you put into a project that inspire and push me to continue to try to improve. Well, the last few weeks have been busy ones as I have been working on installing the second planking layer. As of today, I have finished from the wales to the keel. The wales are in walnut as are the keel, stem and stern post. The lower hull has been planked in cherry. None of this has been sanded or finished yet so it is a bit uneven and faded in color. Next up I will flip her over to continue moving up the hull with planks. Still working through some of the upper color scheme and deciding if I want to represent the colors with natural wood or paint. This will really come down to what colors are chosen. -

Sometimes it is for the best. You are not alone in shelving a model project for any number of reasons. I've got a few unfinished ones myself. Maybe one day you will return to it, maybe not. In either case, life is too short to be unhappy in a hobby. I will keep an eye out for your Surprise build log. Good luck on that build!

- 35 replies

-

- Mantua

- Sovereign of the Seas

-

(and 1 more)

Tagged with:

-

I've built this model and the easiest thing about it was opening the box. If all you use is glue and a hobby knife, you will end up with a pile of wood sticks and metal decorations stuck together in a vague shape of a ship after it was tossed ashore by a hurricane. As someone who has never been traditional in building easier ships and gradually working up to the big ones, I will not say a beginner cannot do this ship, but you will need more than a knife and glue and chances are high that one will become extremely frustrated with the instructions and time involved and never complete it. I forget the exact count, it is on my build log, but I know I worked on this model for over 2,000 hours.

-

I've done gilt and colored. My S.R. was done in gilt in the more common method of all ornaments painted gold. Many years ago though I painted the decorations on the stern of Constitution in a variety of colors and my current build of Royal Louis has also been done in colors. I intend to do the same with my Royal Caroline, though she will likely have more gilding as she was the King's yacht.

-

I will echo that painting the sculptures in a variety of color adds a great deal to the model over just the gold. Likely more realistic as well. I have done them both ways now and I love how they pop and become more interesting with colors. On the reigns, you may look at jewelry wire from crafting stores. It comes in a variety of thicknesses and colors where you may be able to find something that does not look oversized. You could also stiffen sewing thread of the color you want with glue if you need to go extremely thin. I have always struggled with the practicality of many railings. Real, practical, functional or simply artistic. I believe that there is truth to much of it. From safety, while there was concern, we can easily overthink it with modern safety practice. With artistic, the artist wanted to convey the appearance rather than function. Dimensions should not be taken as exact, rather suggestive. I think if you find a happy medium that you like you will be okay.

-

Royal Caroline by EJ_L - Panart - 1:48

EJ_L replied to EJ_L's topic in - Kit build logs for subjects built from 1501 - 1750

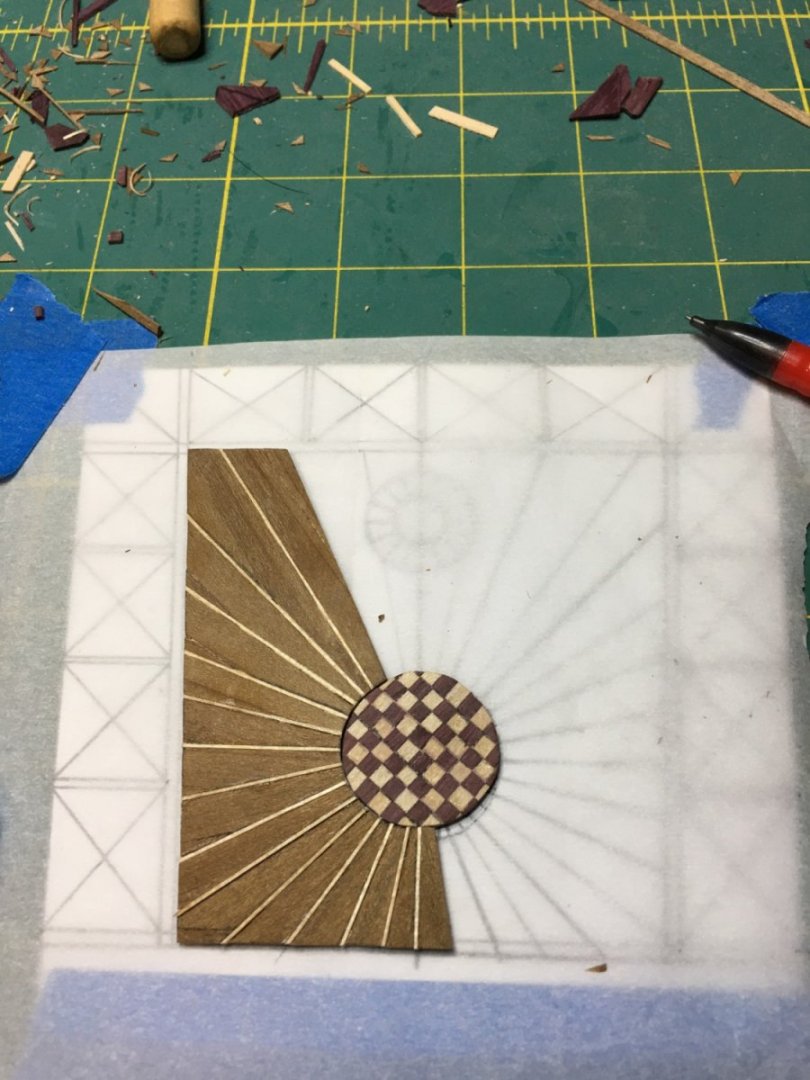

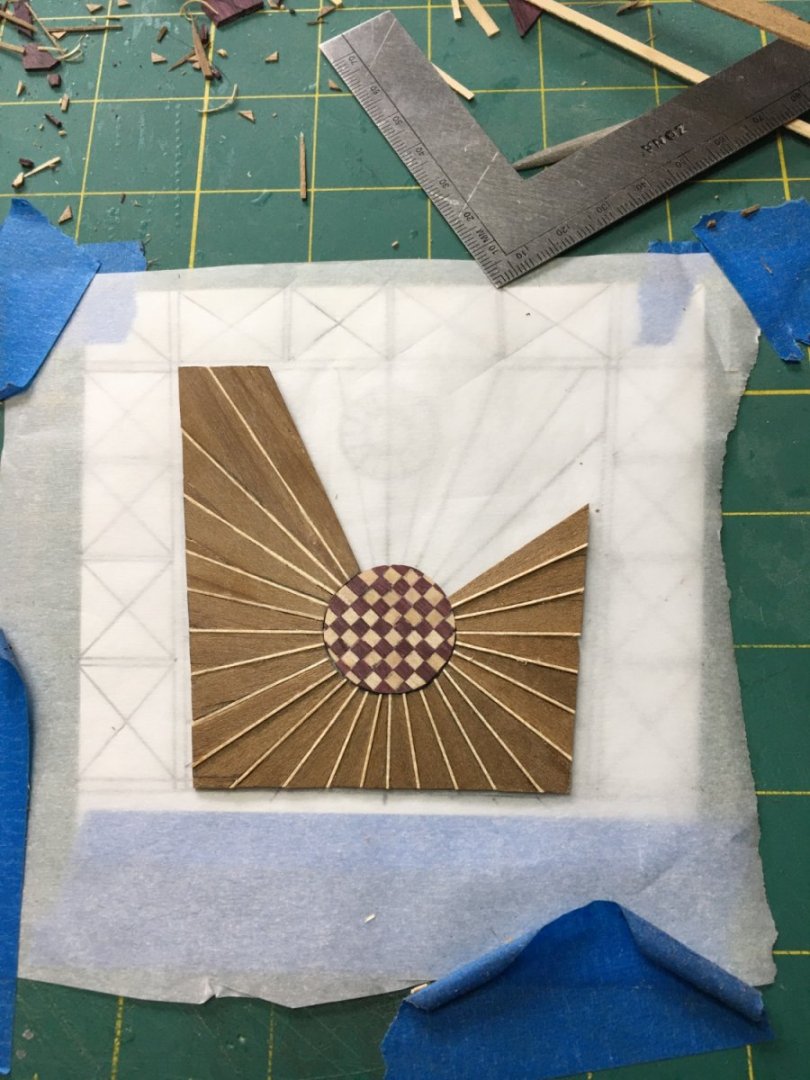

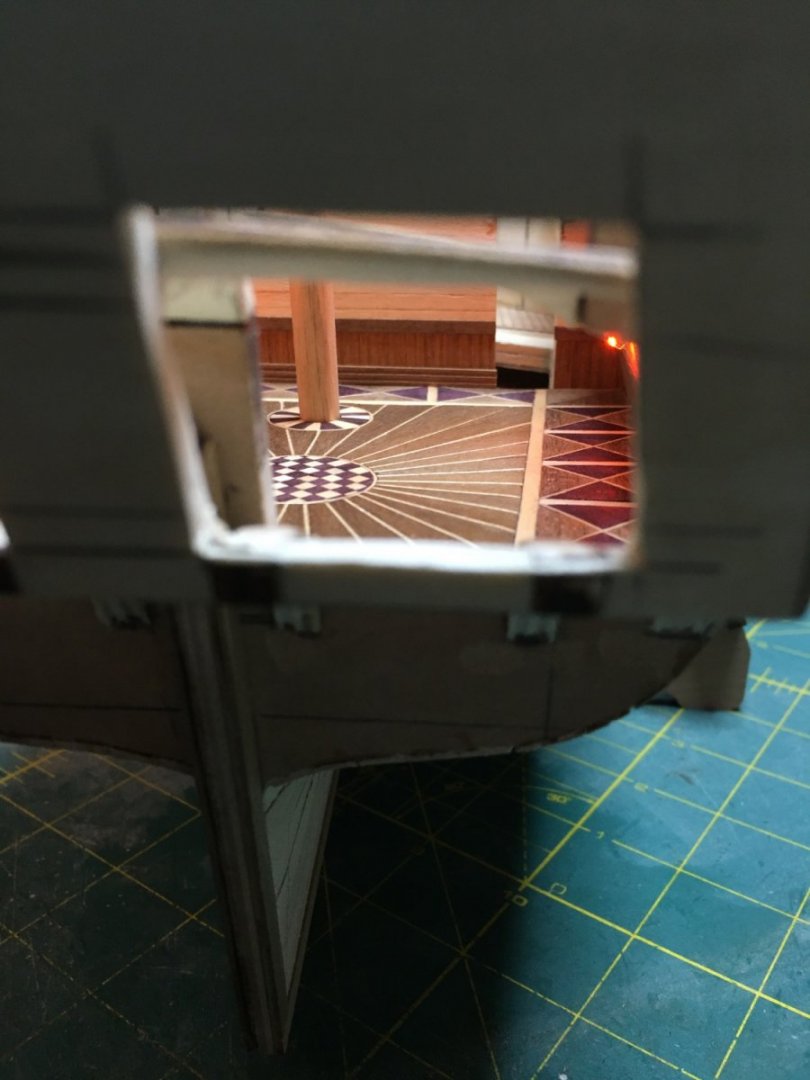

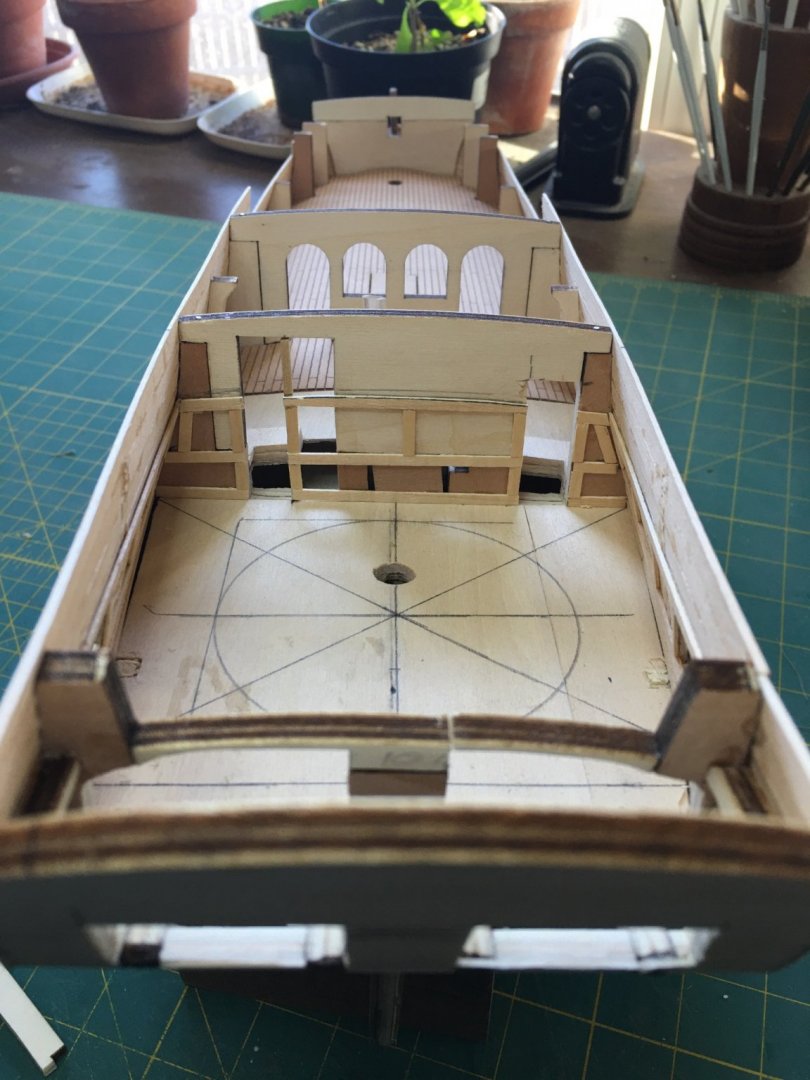

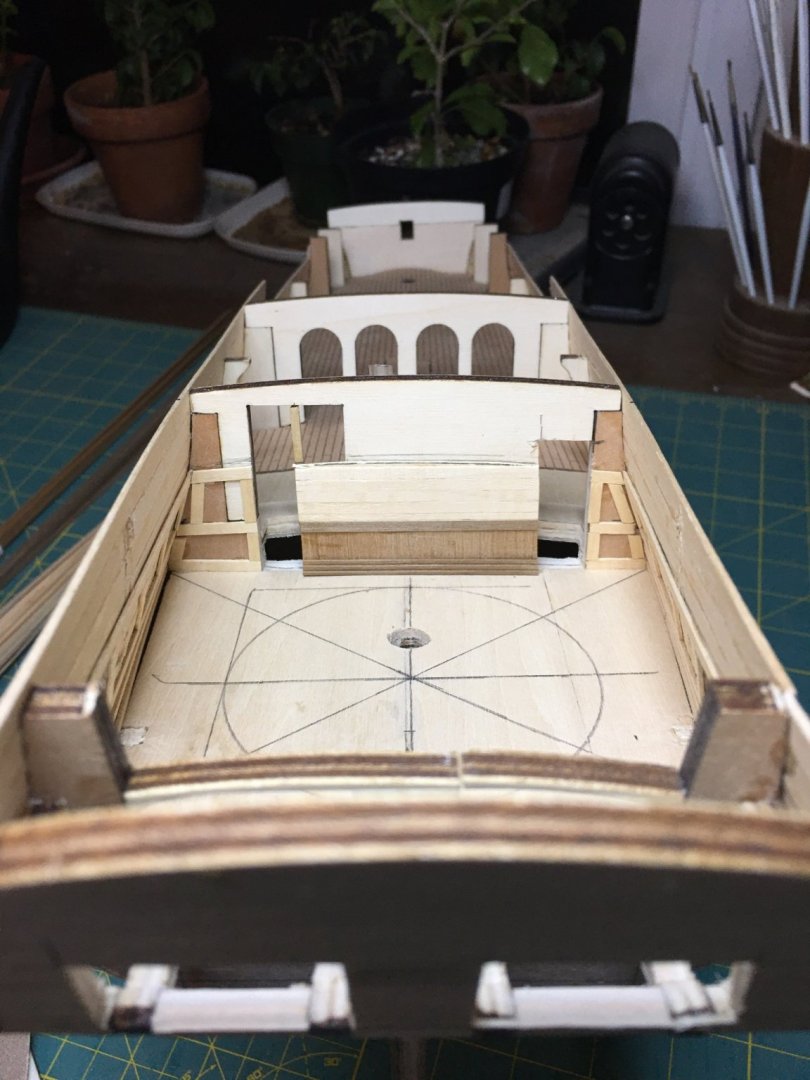

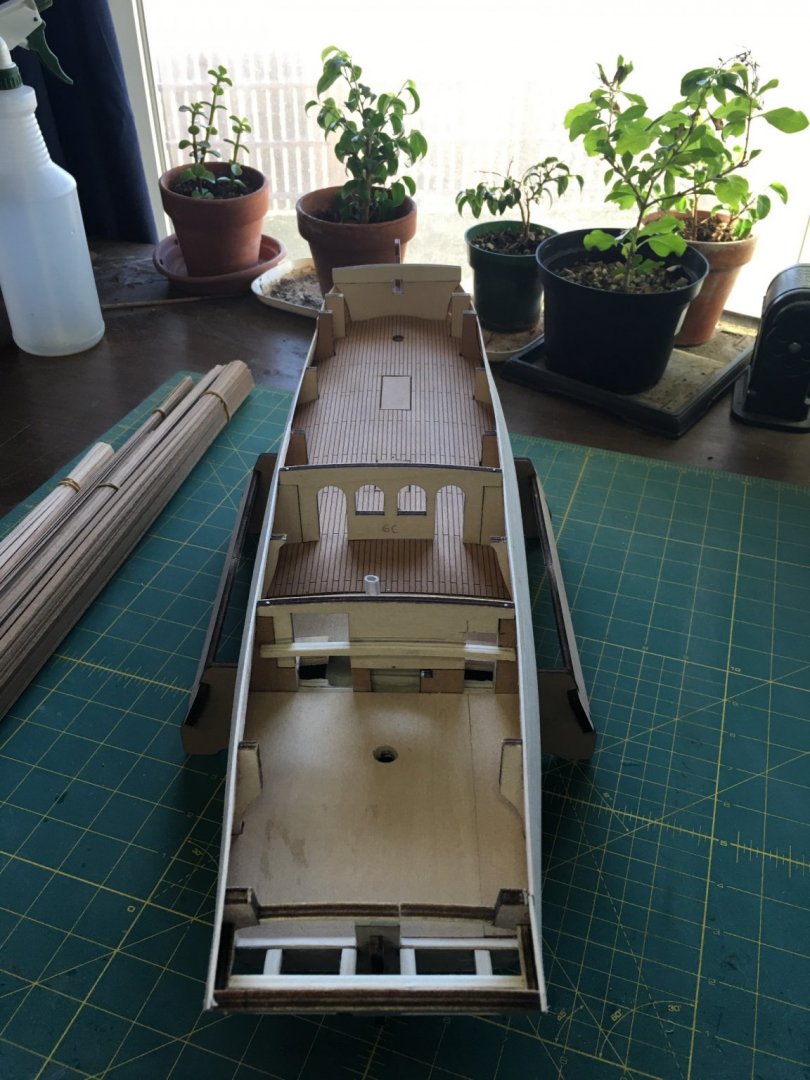

Main cabin floor is complete! Now I can start to trim the room and install the aft seating in front of the stern windows. First though I will apply the second planking layer. Best to get that finished before I add too many interior details. Here are some pics of the floor in progress as installed. -

Royal Caroline by EJ_L - Panart - 1:48

EJ_L replied to EJ_L's topic in - Kit build logs for subjects built from 1501 - 1750

More cabin progress has been made. Wall paneling is well underway and the LED's for two of the lamps have been installed. I finished designing the floor pattern and have begun building it. Very time consuming, but fun! A different sort of challenge than those normally faced with model ships. I also took some time and milled down a pile of lumber for the outer planking. When I finish the cabin flooring I will switch back to planking to put the finish planks on. To help with all of this, I got a new band saw for Christmas. Been needing one for a long time so when my tool store announced a sale, I quickly hopped in the truck and drove down to get one. -

Royal Caroline by EJ_L - Panart - 1:48

EJ_L replied to EJ_L's topic in - Kit build logs for subjects built from 1501 - 1750

Thank you all very much! Indeed, learning from each other, be it a new technique, historical data, or creative inspiration is a blessing of MSW. Christos, I have been following your log as well and your model is coming along beautifully. It is one that I have bookmarked and reference often. OC, Kurt, thank you both for the kind words. I feel rather intimidated by this build as there are several very beautiful models of her on here. Small update of work in progress. Picked out some different wood that I will be milling down over the Christmas holiday for the outer planking. In the meanwhile, I have been working on the interior bulkhead paneling in the aft cabin as well as figuring out the floor pattern. I will also be locating lamp placements for the lighting and paths for thee wires. -

Royal Caroline by EJ_L - Panart - 1:48

EJ_L replied to EJ_L's topic in - Kit build logs for subjects built from 1501 - 1750

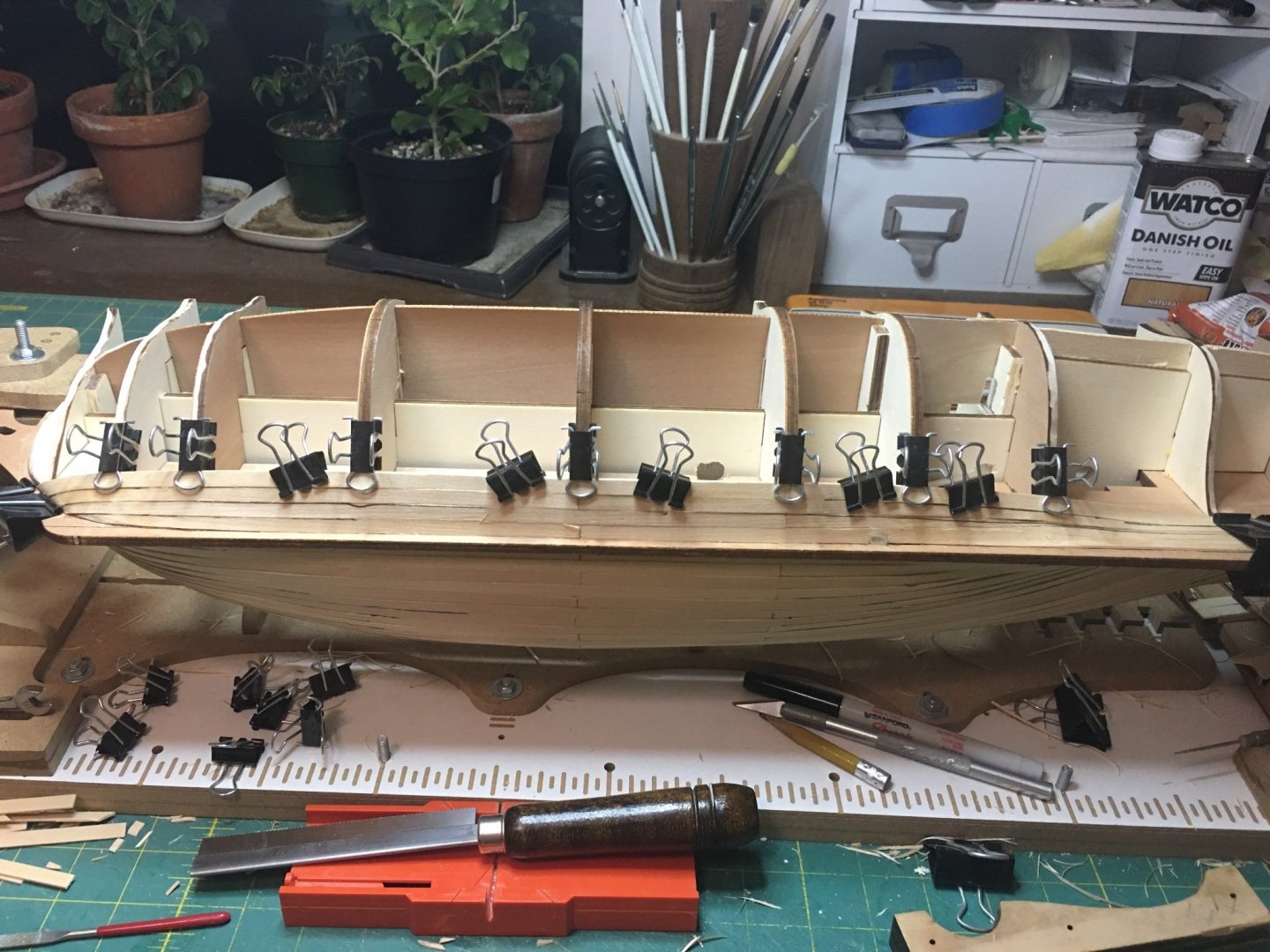

First layer of planking has been largely completed. I now have a shaped hull to begin cleaning up for the second planking layer of a yet to be determined wood species. The kit came with walnut for the hull, and while I will use it for accent colors, I want the field to be a lighter coloring. I’m leaning towards a cherry wood at the moment… we shall see. The upper works still need to be cut and shaped as right now they are left long and high to be cut to correct shape later. I’m also having some issues with the forecastle elevation. To me, it seems awfully tall so I am looking back through drawings and the Anatomy of a Ship book for Royal Caroline to see what makes sense. On the interior, I have begun to locate and plan for the cabin builds. Not much beyond some measurements and markings thus far, but it all starts somewhere. -

Royal Caroline by EJ_L - Panart - 1:48

EJ_L replied to EJ_L's topic in - Kit build logs for subjects built from 1501 - 1750

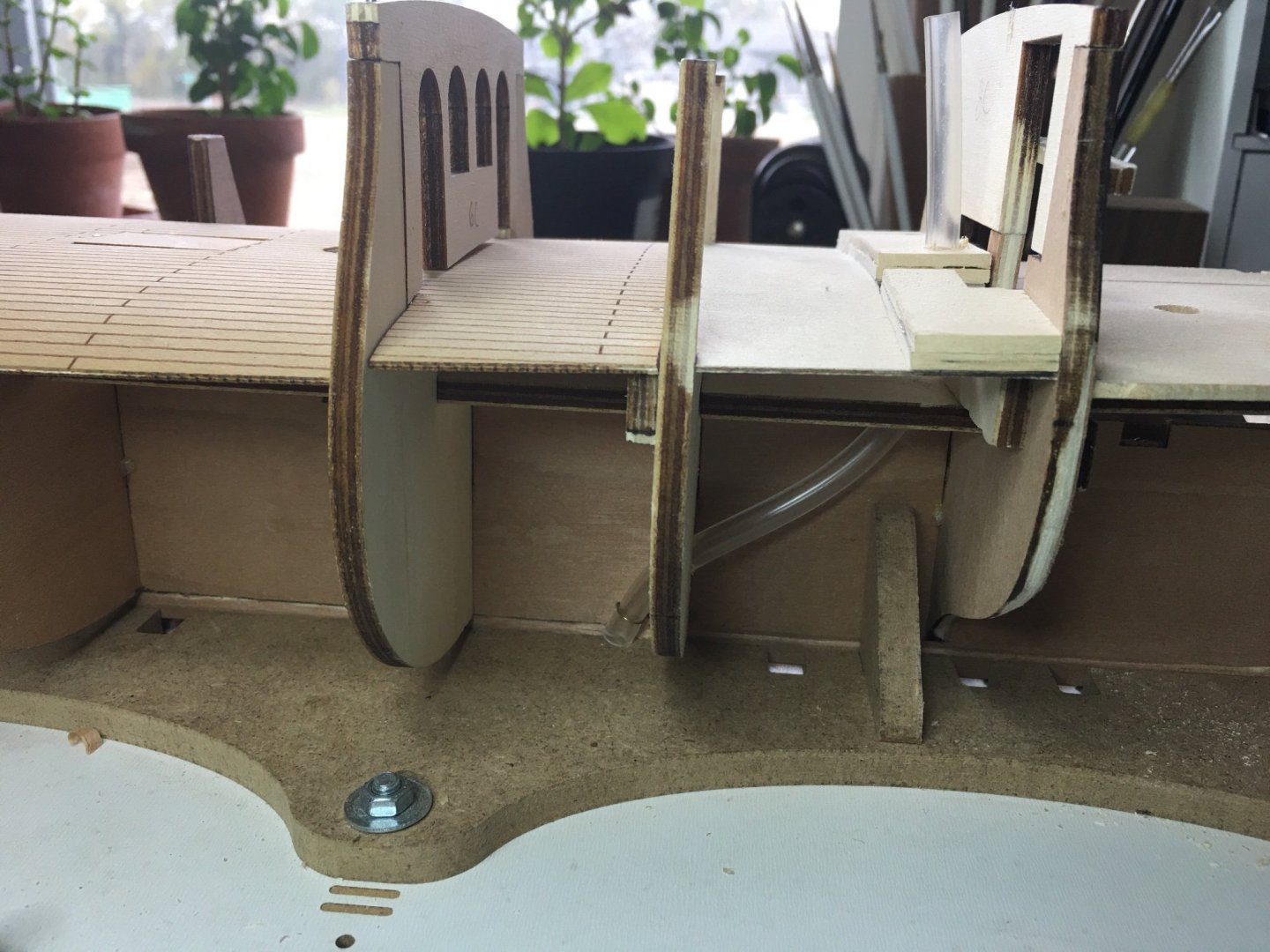

I know it’s been a while, but at long last an update. I have been working on the first layer of hull planking. Climbing steadily and I hope to be ready for a round of sanding by next weekend. I’m still trying to decide how I want to plank the finish layer and of what wood species. Here are some progress pictures showing the planking process. The first one also shows the flex tube that I installed as a conduit for the LED wiring.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.