bartley

NRG Member-

Posts

406 -

Joined

-

Last visited

About bartley

- Birthday February 13

Profile Information

-

Gender

Not Telling

-

Location

Brisbane, Queensland, Australia

-

Interests

Reading, Classical music, Opera, Community band performance (clarinet), sailing and sometimes a bit of ship building.

Recent Profile Visitors

-

Dave B reacted to a post in a topic:

Medway Longboat 1742 by bartley - 1:24 scale

Dave B reacted to a post in a topic:

Medway Longboat 1742 by bartley - 1:24 scale

-

MajorChaos reacted to a post in a topic:

Medway Longboat 1742 by bartley - 1:24 scale

MajorChaos reacted to a post in a topic:

Medway Longboat 1742 by bartley - 1:24 scale

-

Diver reacted to a post in a topic:

Medway Longboat 1742 by bartley - 1:24 scale

Diver reacted to a post in a topic:

Medway Longboat 1742 by bartley - 1:24 scale

-

robert952 reacted to a post in a topic:

Medway Longboat 1742 by bartley - 1:24 scale

robert952 reacted to a post in a topic:

Medway Longboat 1742 by bartley - 1:24 scale

-

robert952 reacted to a post in a topic:

Medway Longboat 1742 by bartley - 1:24 scale

robert952 reacted to a post in a topic:

Medway Longboat 1742 by bartley - 1:24 scale

-

robert952 reacted to a post in a topic:

Medway Longboat 1742 by bartley - 1:24 scale

robert952 reacted to a post in a topic:

Medway Longboat 1742 by bartley - 1:24 scale

-

robert952 reacted to a post in a topic:

Medway Longboat 1742 by bartley - 1:24 scale

robert952 reacted to a post in a topic:

Medway Longboat 1742 by bartley - 1:24 scale

-

robert952 reacted to a post in a topic:

Medway Longboat 1742 by bartley - 1:24 scale

robert952 reacted to a post in a topic:

Medway Longboat 1742 by bartley - 1:24 scale

-

robert952 reacted to a post in a topic:

Medway Longboat 1742 by bartley - 1:24 scale

robert952 reacted to a post in a topic:

Medway Longboat 1742 by bartley - 1:24 scale

-

robert952 reacted to a post in a topic:

Medway Longboat 1742 by bartley - 1:24 scale

robert952 reacted to a post in a topic:

Medway Longboat 1742 by bartley - 1:24 scale

-

drilling hole through wire

bartley replied to BETAQDAVE's topic in Metal Work, Soldering and Metal Fittings

I have done this on 2 mm brass rod with a good success rate. My technique was: 1. I used a mill to ensure the hole was vertical. 2, I used a V bar and centered the drill bit on the V before clamping the rod into the V 3. I used a Kyocera bit as they a very sharp 4. You can file a very small flat on the side where the drill will enter but I did not find this necessary. John -

Stepping the mast with a plum bob...two questions.

bartley replied to HardeeHarHar's topic in Masting, rigging and sails

I agree with those who say not to glue the mast at all. However, in most cases there is quite a deep slot cut into the bulkhead under the mast which should set the rake quite at least approximately,. As you tighten up the rigging you still need to check th alignment I used to use a plumb bob but always found this a real PIA as it starts to swing on the slightest movement. I now use a laser level (quite a cheap one). I set it up about 1 m from the ship and it does NOT move and it projects a cross so that you can adjust the deck to match the horizontal line and the mast to match the vertical line. For the rake you can use a jig to tilt the ship forward by the correct amount and use the laser level again. John -

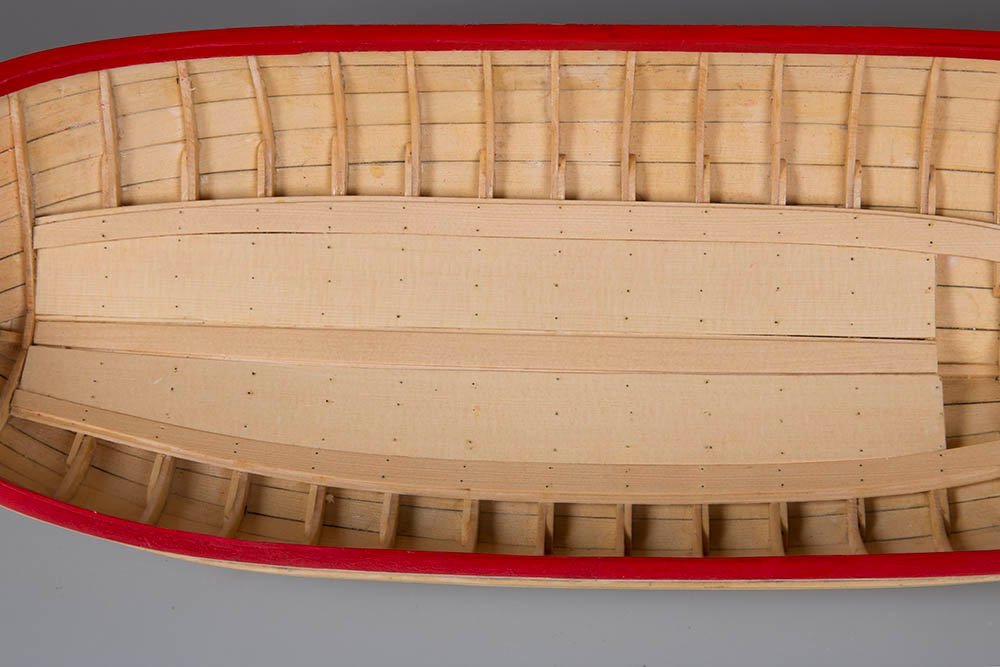

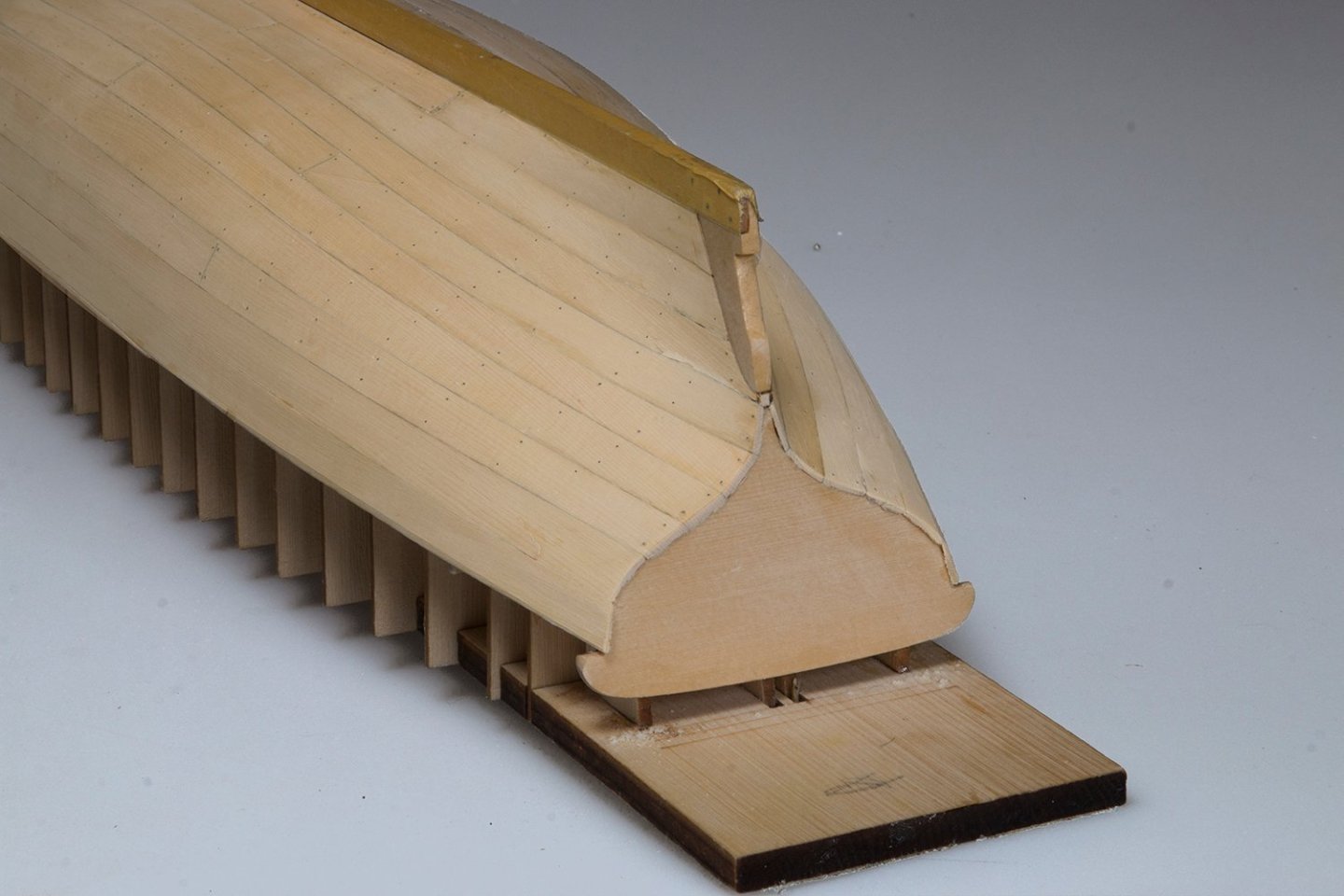

The Wales are now installed and sanded back for and aft as recommended by Chuck.: When the hull is inverted and the build board removed it looks like this: The removal of the frames was quite straightforward . However there is way too much seepage of glue into the interior of the hull . This is the first time I have used CA to fix the planks. I clearly overdid it. I was a little unsure about the faring and wanted to ensure that the planks were secure. I needn't have worried as the fit was pretty good in fact. The cap rails were then installed leaving plenty of meat on either side for sanding to shape: Next the bolsters at the bow were fabricated and fitted. A tricky little job this one. Chuck provides six blanks and I used five to get two satisfactory ones: The next task is to fair the inside and narrow down the cap rails significantly. John

-

bartley started following HMS Royal William by KeithW - Euromodel - 1/72

-

Planking completed I have all nine planks on now but the wales are still to be installed. It looks a bit "blotchy" because I gave the first five planks a coat of Wipe On Poly and when I sanded back some of it remained. It will be more uniform when I apply I final coat I am also a bit shy of the top of the frames amidships (by a little under 1/32). I could see that this was happening throughout the planking. I think maybe I did not fare quite enough in this region. Anyway I was proposing to address it by making a slightly wider second Wale John

-

Planking begins: I have three strakes in place now. I damaged the end of one garboard and had to make a new one. Mine was not quite the same as Chuck's laser cut one so the was a little asymmetry between the sides but I think I am pretty close to my tick marks now so I am reasonably happy but it is nowhere near the quality of Chuck's high standard. I am thinking that I might start the simulated nails now while I can see the frames clearly. Would I need to do light sand before attempting this? The planks are pretty thin so care would be needed. What to do people think? John

-

Completing the lining out This is quite a time consuming process but, as Chuck says, this process will be a good check on the process of planking and is good practice for future projects. It is now complete and as a check I found that it followed Chuck's templates quite well It might be a while before I start on the planking as my other hobies need to take prcedence for a couple of weeks. John

-

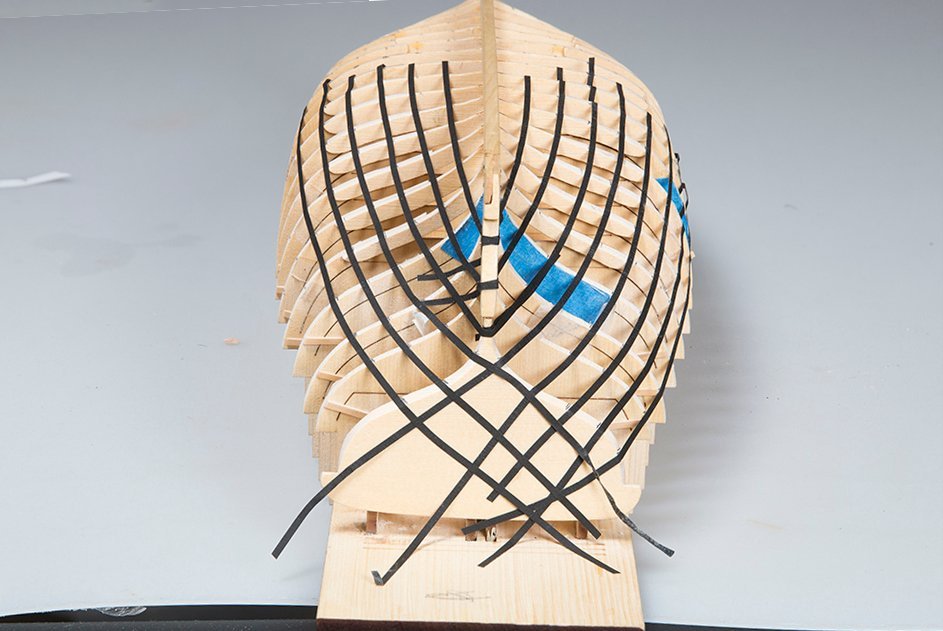

Lining Out the Hull Perhaps not strictly necessary here but it is an good to practice this important part of the planking exercise. I have started at the stern and here is what it looks like so far: The distortion in the photograph makes it look as if the planks deviate amidships. They are in fact quite parallel at this point. I also found that some of my tick-marks were a bit out so I will adjust them once I am happy with the lining out. John

-

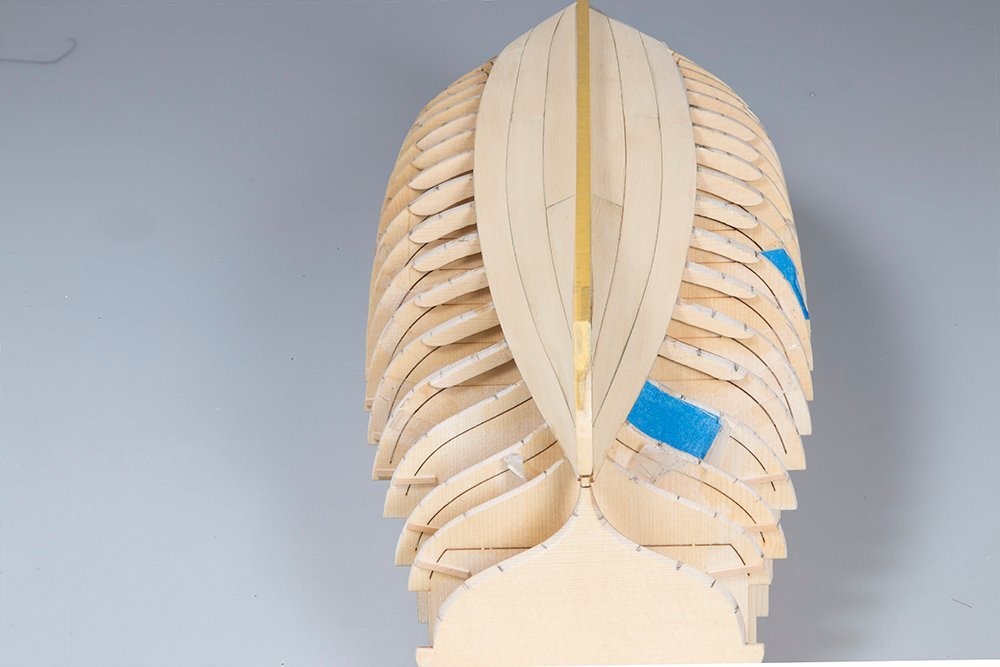

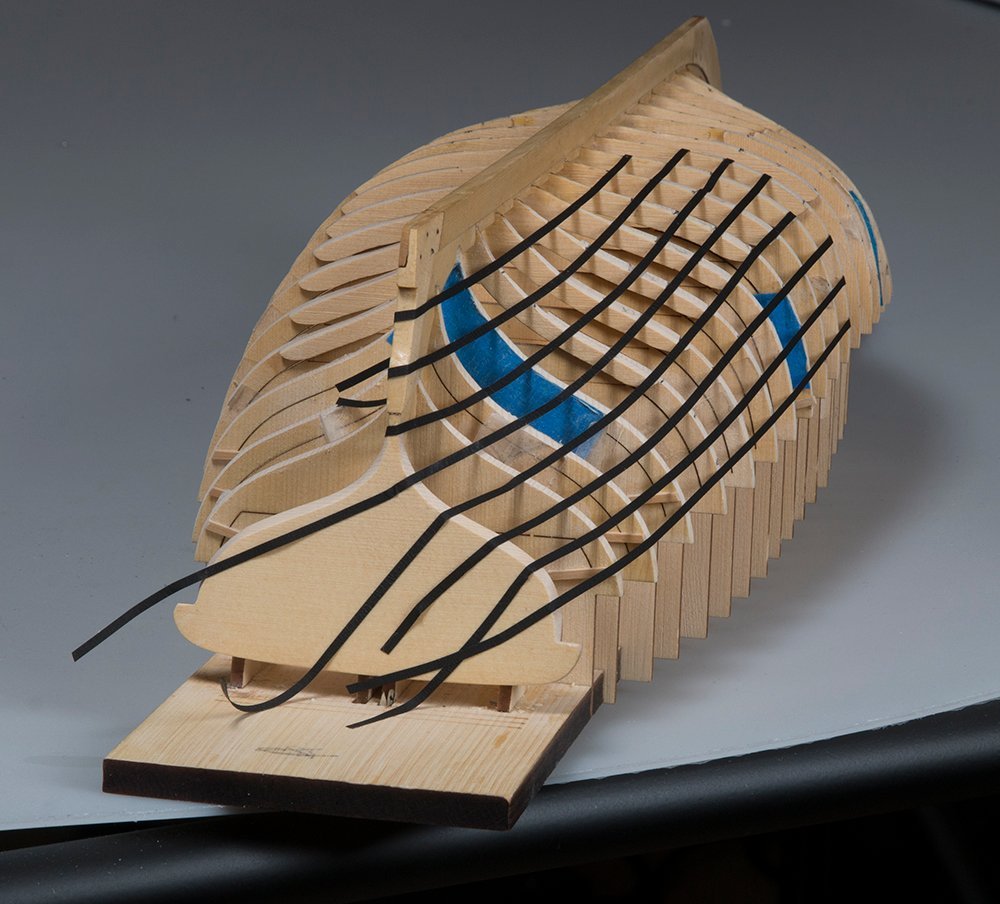

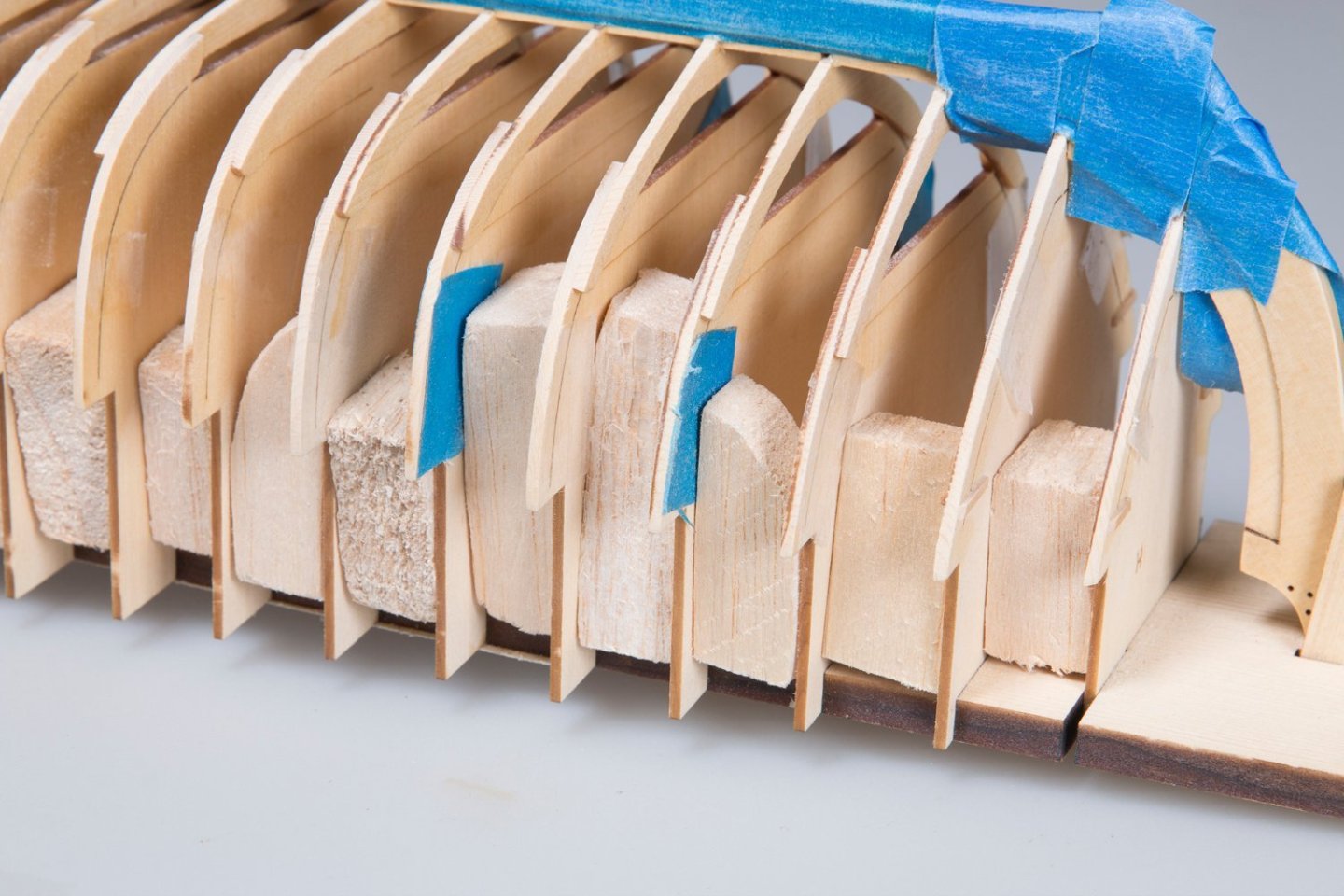

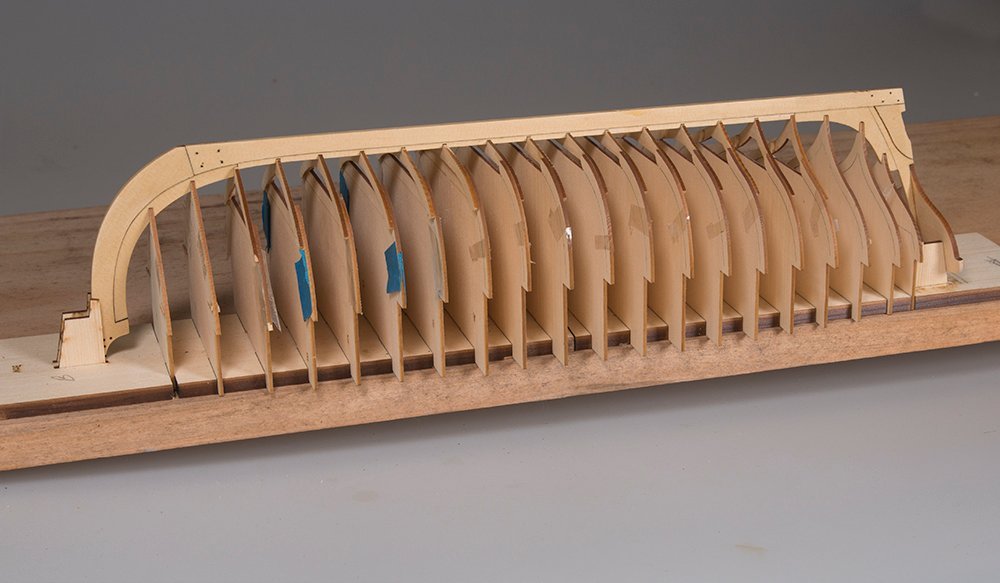

Frames Attached and Fairing Begins: The frames are now glued in place I then commenced with fairing the frames. These frames are very delicate (1/16") compared to ships that I have builtin the past so I was a bit tentative. You can see from this photo that I added some balsa blocks between the frames as a safety measure: However, when I showed this photo to Chuck he advised that I had a way to go and that I needed to keep going until the laser char was removed. So here is where I am at now: John

-

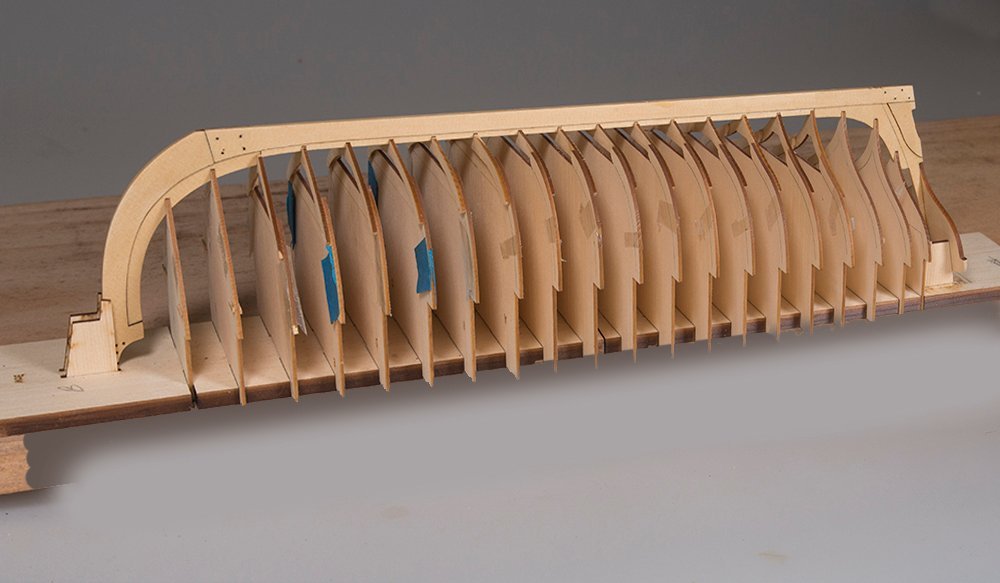

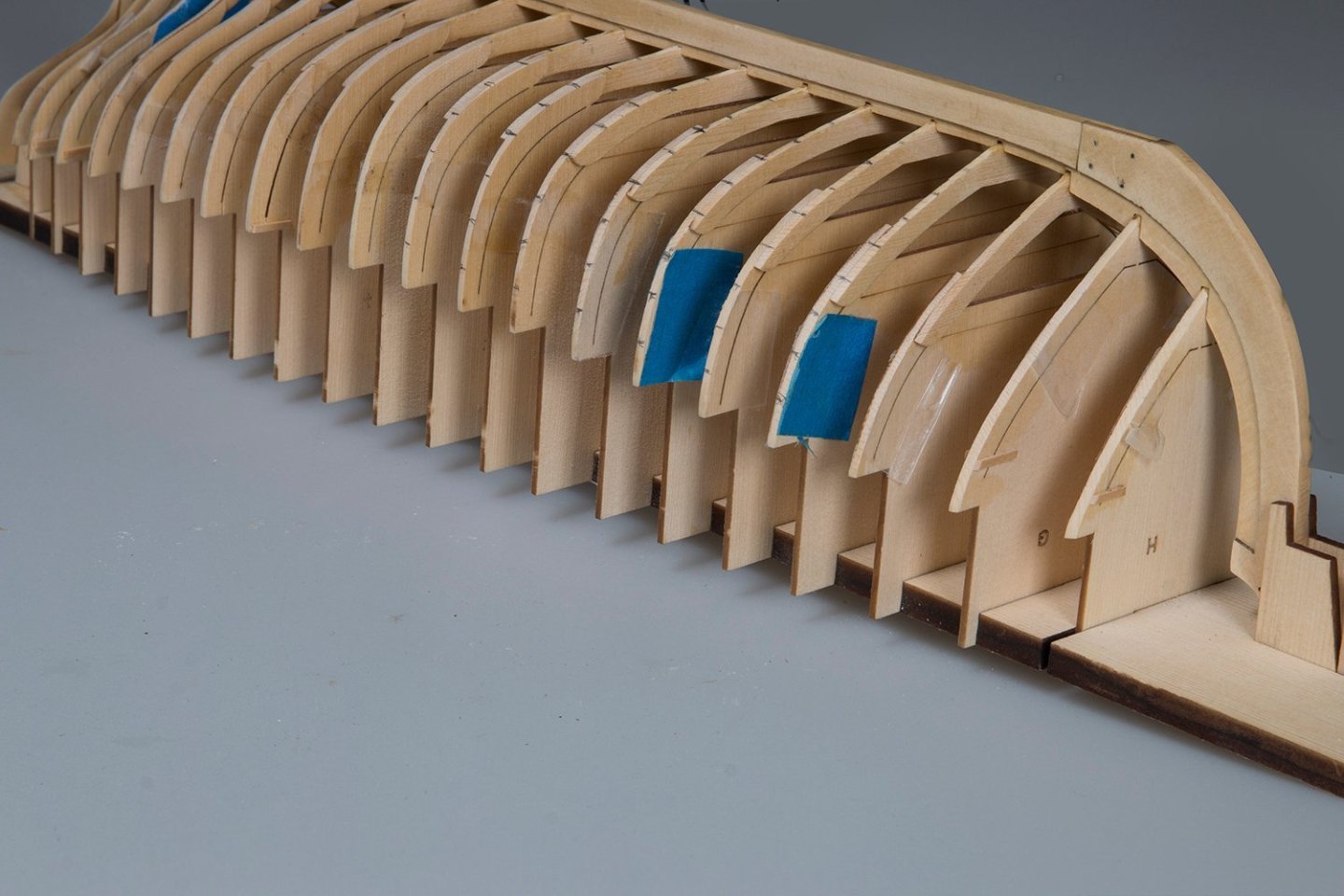

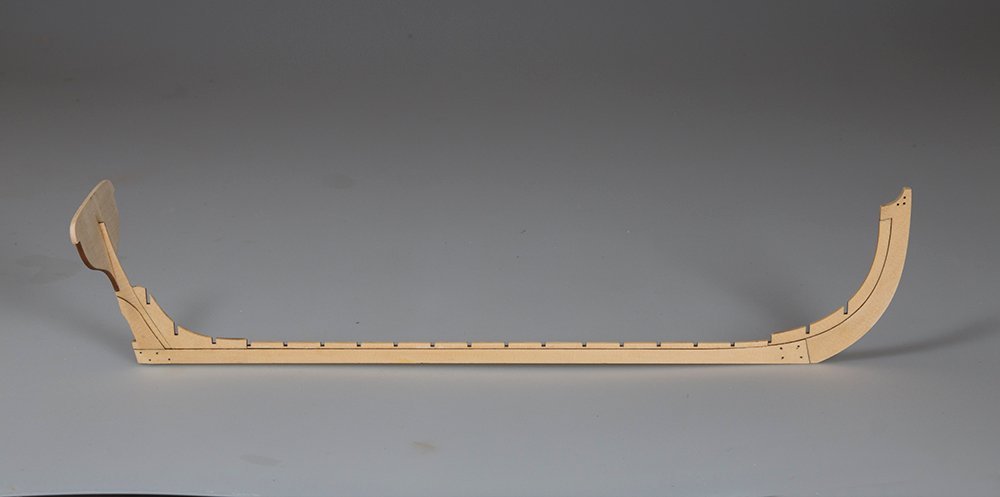

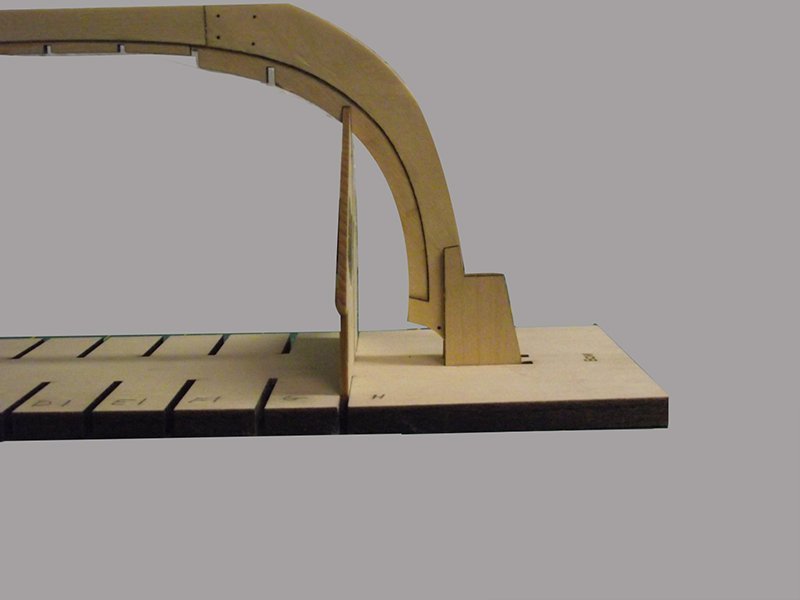

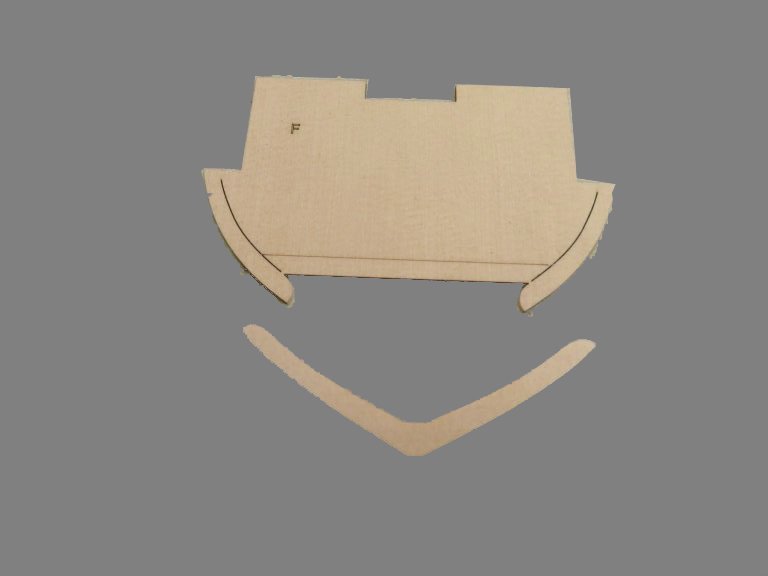

The transom and installation of the frames: The transom needs to be installed perpendicular to the keel. There is a slot cut into the frame so the "vertical" alignment is accounted for but to ensure it was perpendicular ro the keel I made this simple jigand clamped the trasome otself to this: Time to install the frames there are two types - two in the bow ( G & H)and three in the stern ( 10 , 11& 12) are flat one piece frames. These are installed onto the baseboard first and the keel dry fitted to these. The remaining frames are "double" with a floor piece glued to each frame These frames are the each dry-fitted to the keel and the alignment checked. Each was found to be perpendicular to the baseboard with no adjustment needed John

-

bartley reacted to a post in a topic:

Medway Longboat 1742 by bartley - 1:24 scale

bartley reacted to a post in a topic:

Medway Longboat 1742 by bartley - 1:24 scale

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.