VinceMcCullough

-

Posts

43 -

Joined

-

Last visited

-

Hey Vince hello, I hope you are well.

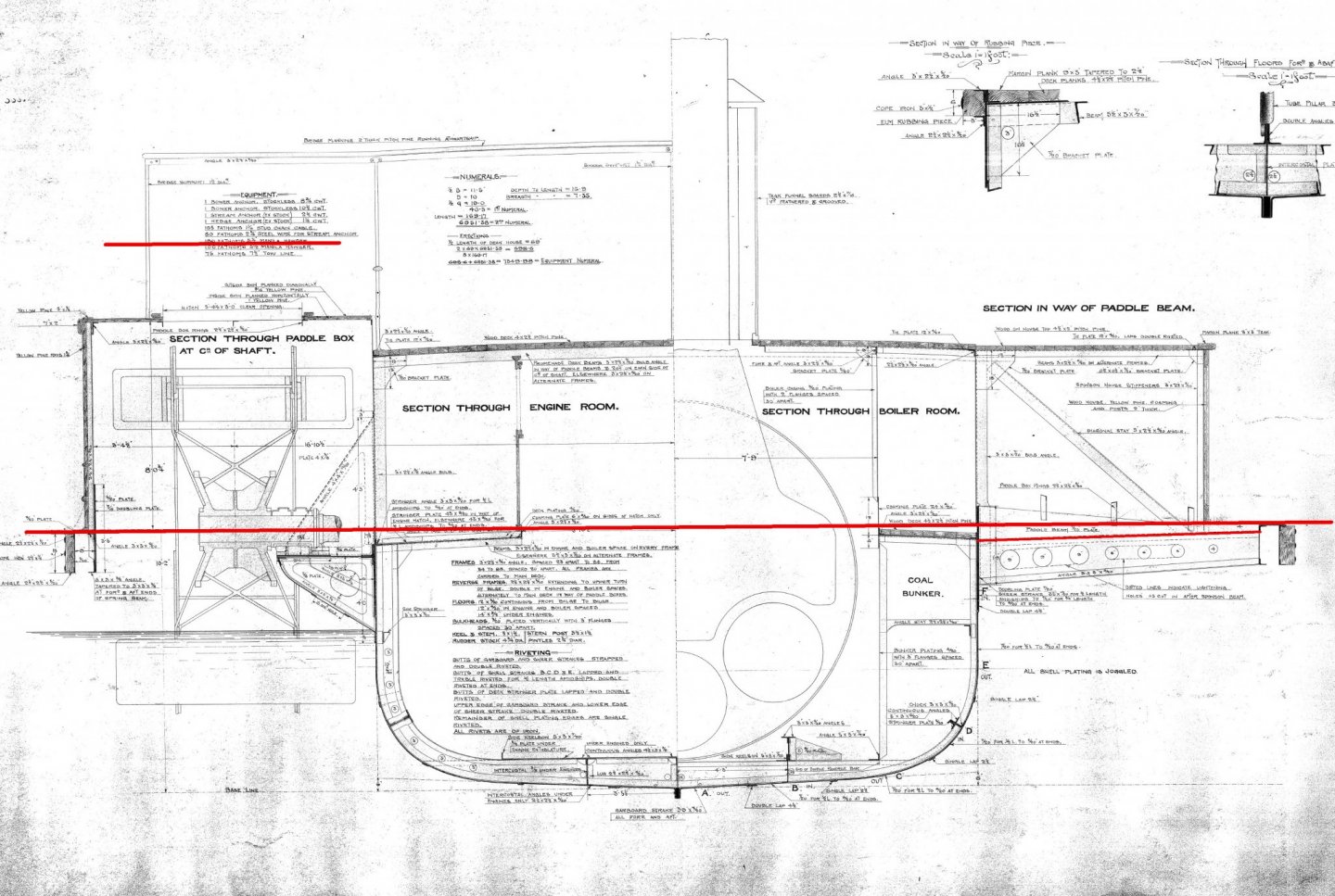

Referring to my drawings I have two more points which I'm uncertain and would ask you if you have an opinion.

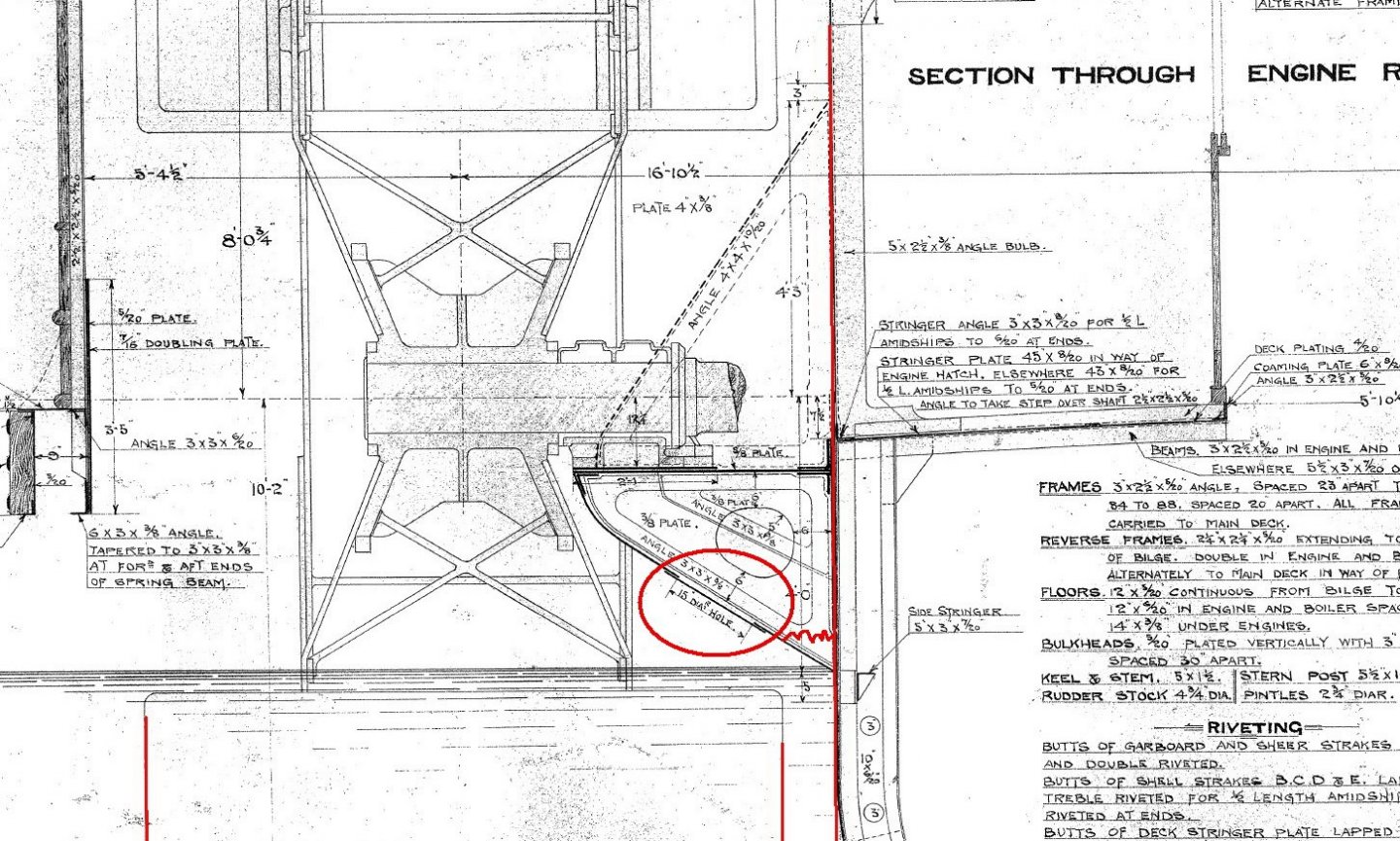

For the outside bearing support of the shaft of the paddle wheel there is only one cross section drawing. On this drawing it's said that there is a hole 15'' Dia. So I assume that this support is box like construction (like prisma) , two triangular side plates and the front is also covered with a plate with a hole in center.

But in such a case it would be always water at the bottom of the box. Is that plausible or how can this construction be? Do you have any idea ?