-

Posts

1,716 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Modeler12

-

Although Jeff is no longer in the business of supplying wood for us, I hope he is still here and watching us. Thanks Jeff (again) for those great boards and pieces. You did well by teaching a younger fellow (not Chuck, of course) and the'kid' is doing a nice job as well as you did. Your instructions are well taken and saved. I use them without fail (well except about the dust problem, but that is my concern) If anyone knows who the 'kid' is . . . .

-

Have a look at this thread. The flags are 'real' and can be folded or crinkled to simulate the wind effects.

-

Mr Mackie, on his web site, shows numerous pictures of the model as well as a few facts about the sailing days. Too bad he does not give the artist who built this beauty any credit. If I have to, I'll go to the museum to find out who it was. I am sure this person must have built lots of other models.

-

When stepping the masts you don't want to permanently glue them in place. Have the blocks on the keel in place to hold the bottom of the mast(s), then cut the openings in the deck and fit the mast(s) to be sure they are at the right angle(s) and then remove the mast(s) for a later installation. There will be lots of other things to do (such as adding deck furniture, rails, deck planking, etc.) and you don't want the mast(s) to interfere with those. The same applies to the bowsprit. To align the mast(s) you can use a number of methods described in this forum. Search.

-

Miniature Russian carving tools

Modeler12 replied to druxey's topic in Modeling tools and Workshop Equipment

Looks like great carving tools. I also would like the email address and was wondering how payments and shipping are handled. In particular, I like to see more details of the shape of each tool and if I could order some individually rather than a whole set. For 23 of those at $360 total I assume a price of $18 each would not be unreasonable. -

Your first comments about 'Jim's saw' cutting up to 3/8 inch thickness is a bit limited. The blades that come with the saw include a four inch diameter 'course', carbide tipped blade that cuts boards to 3/4 inch thickness very nicely. I have used that to cut slabs of hardwood, such as maple, blood-wood and poplar, and then used the 3 inch 'fine' blade to cut planking. Both cuts were very close to what I wanted and with some adjustments of the fence 'dead-on'. I have a larger saw but for this kind of work I don't use it. The Byrnes saw does it all. PS. It was an administrative error, I am sure, but I just got another bill from Thurston for blades I bought last year and paid for by card (the normal way with them). Keep your records (receipts)

-

Proportional Dividers

Modeler12 replied to Worldway's topic in Modeling tools and Workshop Equipment

It is interesting to see the two sides of this 'coin'. If you have used the proportional dividers for a long time, I can appreciate that you like them for various reasons. In my case, I have a pair and seldom use them, but so be it. When Jud mentioned his liking for the decimal system (rather than fractions, I suppose) I agree. But when he talks about using a slide-rule - - - - I have to grin because those are dinosaurs in my college collection. Slide-rules are as accurate as proportional dividers and even more difficult to use and understand (I know Jud, you add or subtract logarithmic values, etc.). The upshot is: if you like the tool you have, use it. If you want accuracy, calculate. -

Proportional Dividers

Modeler12 replied to Worldway's topic in Modeling tools and Workshop Equipment

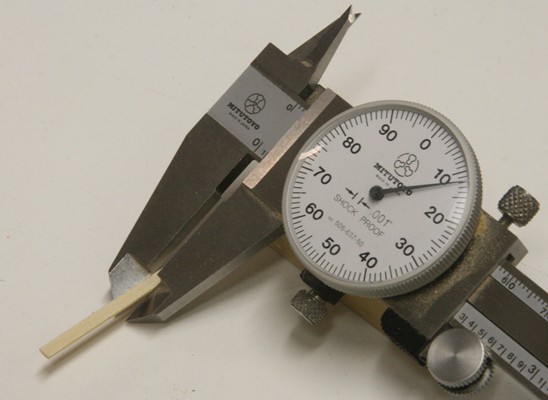

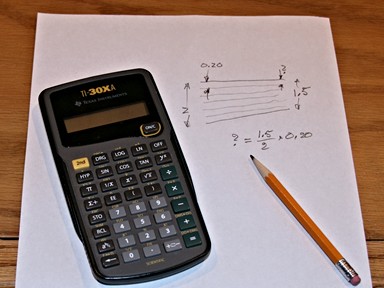

I might add a couple comments about the way I measured the planking problem I showed above. The length of the two openings (4.85 and 4.00 inches) was measured by using a piece of stiff paper. You can see that in the photograph. These dimensions were used in the calculation. The width of the planks was measure with a dial set of calipers (with a dial indicator) that is accurate to within 0.001 inch. There is no way that you can be that accurate with the proportional dividers. To pace off sets of repetitive dimensions on a chart it is cheaper and easier to use a simple pair of dividers: -

Proportional Dividers

Modeler12 replied to Worldway's topic in Modeling tools and Workshop Equipment

Ok, let me explain. Let me do this with an example, the hull planking of my cross section. If the planks need to be tapered because the space or opening as shown in the picture below changes along the hull lines, it is necessary to use the 'proportional method'. In this case, you measure the two dimensions of the opening and they are 4.85 and 4.00 inch respectively. Let's say the planks you have are 0.121 inch wide. What should the plank width measure at the other end? Obviously smaller if you put the wide end to the left in the picture. The proportional ratio is 4.00 divided by 4.82. Now multiply that ratio by the 0.121 and you get 0.100 inches, the width of the narrow end. Now you could have done this with the mechanical divider, but the accuracy becomes questionable because of the big difference in the size of the opening and plank width. -

Proportional Dividers

Modeler12 replied to Worldway's topic in Modeling tools and Workshop Equipment

I have two types of proportional dividers. The one shown below is a lot more accurate than my mechanical type and faster too. -

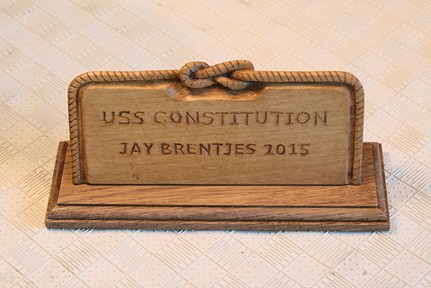

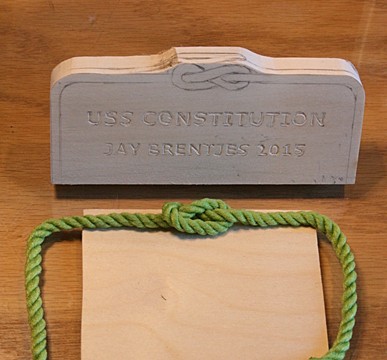

A word of caution about copying carving plans: 'don't always assume the drawing is correct'. Earlier I mentioned the book(s) by Lora Irish and how I found the examples very helpful. However, in her book of plans she makes mistakes. For example, the leaves of a rose are 'opposite' on the stem, not 'alternate'. Likewise those leaves are not lobed but serrated or toothed and much broader than hers. I realized this much later after I had carved her design. Another example is her plan for some rope, part of which is shown below. I wanted to use this for the border of a sign but noticed that the rope she shows reversed the lay on the other side of the knot. That's impossible. Likewise the knot is strange and not at all the way I tie a simple knot. So, I made a model and will change the design shown below to correspond to the green rope. The reason I decided to do this is that I wanted to do some 3-D carving. Sorry, I just realized that her knot is a figure eight knot. That is probably better looking after all, but the rope is still wrong.

-

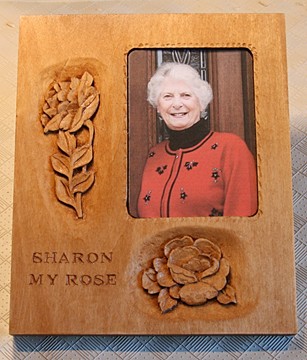

Thank you guys. The three projects thus far were fun and I learned a lot about carving and the tools involved. For future designs that involve model ship decorations I now have a better feel for what it takes. To be sure, what I have done so far is on a larger scale and I need to consider smaller tools in the future. But is that not what modeling is all about? We shrink the big things and try to duplicate them the best we can. Think big, work small. I do have one more project but I won't get into the details here. It involves making a display sign using wood and carved letters for my USS Constitution model. I was hoping to do that using a piece of the real ship but (alas) I don't have one of those pieces that was promised to me in the past. PS. Jim, the 'Rose of Sharon' is actually not a rose but a flower that is part of the hibiscus family. It just did not fit my design.

-

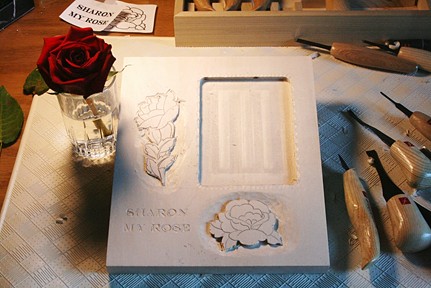

Ok Mark, if you don't mind let me add a few more comments along the way. The outline of a small design and how to cut it has been an issue here. Chuck provided the laser cut parts which was great to start with. But I had been wondering how to cut the perimeter otherwise. I am still curious how others have approach this other than 'brute-force'. For large parts it is a bit easier but just as important. I am not trying to give instructions here (after all I am very clumsy and new to the game), but let me continue to show how I am going about relief carving the roses. Carving the background comes first. In this case I wanted a simple depth cut. Because the design is rather busy I did not want to go any more than about 1/8 inch deep. The tricky part was the inside cuts, the open areas between the stem and leaves. All of this was time consuming but involved several tools. I used the gouges and chisels for most but I did end up using a couple curved files to get underneath the edges. No sandpaper at this point. It is amazing what can be done with sharp gouges alone. The fun part starts with the leaves, stem and flower. Depth perception come into play. For example, the leaf closest to the flower goes underneath. Hence it is cut deep at the tip. I might also mention that the design has a lot of notches on the leaves. The leaves of roses don't have that (see earlier picture), so I will 'smooth' them a bit and make them a bit larger. I'll show a few more steps later.

-

Ok Mark, if you don't mind let me add a few more comments along the way. The outline of the design has been an issue here with Chuck providing the laser cut parts while I had been wondering how to cut the perimeter otherwise. I am still curious how others have approach this other than 'brute-force'. For large parts it is a bit easier but just as important. I am not trying to give instructions here (after all I am very clumsy and new to the game), but let me continue to show how I am going about relief carving the roses. Carving the background comes first. In this case I wanted a simple depth cut. Because the design is rather busy I did not want to go any more than about 1/8 inch deep. The tricky part was the inside cuts, the open areas between the stem and leaves. All of this was time consuming but involved several tools. I used the gouges and chisels for most but I did end up using a couple curved files to get underneath the edges. No sandpaper at this point. The fun part starts with the leaves, stem and flower. Depth perception come into play. For example, the leaf closest to the flower goes underneath. Hence it is cut deep at the tip. I might also mention that the design has a lot of notches on the leaves. The leaves of roses don't have that (see earlier picture), so I will 'smooth' them a bit and make them a bit larger. I'll show a few more steps later.

-

Thank you Aviaamator, and since you asked, let me show the last part of this experiment. Carving letters. This basswood plague will be a Christmas present for my wife. Hopefully I can complete it in the next week or so. Her picture will be inside the recessed opening. Carving letters was a whole new experience for me. I selected an engravers font, printed it and transferred it to the wood. Then I used a V-gouge and knife to cut out the letters. They don't show too clearly, but on another piece I did the same thing and stained it quickly. That brought out the letters much clearer. I have a long way to go with the carving, but this probably will be the last post of this series. After all, this is a model ship forum. PS Aviaamator, being northeast of St. Petersburg you must have some cold weather and lots of snow. Nice for Christmas

-

The tulip is done as far as carving is concerned. It was my first attempt other than the scroll that was done with an Exacto blade (#11). I learned a lot about how to use carving tools, things I had taken for granted in the past. Keeping the edge sharp is obvious, but it did not take me long to learn that 'slicing' the wood is so much better than forcing the gouge or knife straight into the wood. I try to show that in my next project. The small gouge was used to remove some of the background material. I guided the blade with my right hand and pushed the gouge to the right with my left hand. This produced a 'slice' rather than a 'chip'. After the slice was removed, I used a knife to trim up the edges. At this point I will repeat the steps to cut the background deeper. Slicing versus dicing is something I know about in the kitchen. I now have a tendency to move the knife back and forth as I 'slice' green onions or anything else. I am curious if that could be applied to razor blades. How about slanting the cartridge at a small angle Mr. Gillett?

-

Sorry, I need to explain one more thing about grain direction After I applied a coat of Tung oil to the tulip it really showed the problem I have had with this thing. The center of the 'trunk' is clearly shown on the back of this piece, and it translates to the front. Carving was difficult......and I simply could not get rid of the pimple. That reminds me of my younger days So, for relief carving stay away from this kind of wood.

-

Ok, final picture and some comments about grain direction. I thought it would be 'cute' to carve this using a slice of a basswood branch. Never again!!! (well not in the near future if I can help it). Although my knives and gouges were very sharp and cut through wood like butter when the grain was 'right', in this case the oval shape of the growth rings made it very difficult to go 'with the grain'. For relief carving of ship decorations I will keep this in mind. For carving solid figures, if I ever graduate there, it was a lesson learned. BTW I will do a bit of sanding around the perimeter, give it a coat of sealer and call it 'Tulip #1'. It's yours Carl.

-

One more thing about carving tools. Earlier I showed the set of knives and gouges that I bought from Flexcut. They work extremely well, hold an edge quite long and only need an occasional stropping. The only one I seldom use in the set is the curved knife. However, for detailed work I needed some small chisels. I ordered a set of four Flexcuts ranging from 1/16 to 1/4 inch wide. Again they did a nice job of cutting away the background material for the tulip that I am playing around with. I am referring to the narrow channels between the leaves and flower. They still need some 'cleanup work'. I am not trying to sell the brand, I know Flexcut tools are expensive. But now I have what I need when it comes to relief carving. The 'practice board' has moved to a larger design as you can see. The actual tulip will be fun to bring out next. btw. The grain direction has given me some hick-ups. But after a while I got used to the idea of grain in this piece. Notice that the center of the branch is in the bottom left corner of the tulip. It is a dark patch.

-

Thank you Jack. For the flat pieces of wood I am working with right now the bath mat works fine for me. When (and if) I get into shapes that do not lend them to 'flat' carving, I will definitely consider other ways to hold the work piece. Your 'bench hooks' are what I was referring to when I talked about a piece of plywood with fences. As you noted, the problem with that is still one of having this platform slide around. When the part involves 3D shapes the bench hook, or slanted tray, sitting on the bath mat should work fine. I might also mention that the bath mat is large enough so the carving tools are not lying on the glass desk top. The two strops in the upper left corner were made from an old leather belt. One piece was wrapped and glued around a piece of 1/8 inch plywood and is used for the small gouges.

-

In just a week or two I have learned a lot about carving, including how to hold my work piece to the table. At first I used a piece of plywood with two 'fences'. That was awkward and it kept on slipping on the table, while clamps were in the way. A search through our linen closet yielded a rubber mat, the kind used in showers or bathtubs to prevent you from slipping. It has suction cups on the back side and the front is non-slip -- ideal for the glass top of my desk. The slight pressure from carving is enough to prevent the work piece from sliding. But yet, it allows me to rotate the work with no effort. The piece you see is basswood but because it is a section of a branch, the grain runs all over the place making this a bit more of a challenge. The design is a tulip (in honor of Carl, of course). Here is the practice board I showed earlier. That was a good lesson.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.