-

Posts

32 -

Joined

-

Last visited

About Primey

- Birthday 03/30/1964

Profile Information

-

Gender

Male

-

Location

Australia

-

Interests

Cricket, Football (Aussie Rules), fishing, Vintage Bicycle Restoration.

Recent Profile Visitors

-

tasmanian reacted to a post in a topic:

Cutty Sark by Primey - Arkit - Scale 1:78

tasmanian reacted to a post in a topic:

Cutty Sark by Primey - Arkit - Scale 1:78

-

tasmanian reacted to a post in a topic:

Cutty Sark by Primey - Arkit - Scale 1:78

tasmanian reacted to a post in a topic:

Cutty Sark by Primey - Arkit - Scale 1:78

-

Primey reacted to a post in a topic:

Cutty Sark by Nenad

Primey reacted to a post in a topic:

Cutty Sark by Nenad

-

cristikc reacted to a post in a topic:

Cutty Sark by Primey - Arkit - Scale 1:78

cristikc reacted to a post in a topic:

Cutty Sark by Primey - Arkit - Scale 1:78

-

Elijah reacted to a post in a topic:

Cutty Sark by Primey - Arkit - Scale 1:78

Elijah reacted to a post in a topic:

Cutty Sark by Primey - Arkit - Scale 1:78

-

Elijah reacted to a post in a topic:

Cutty Sark by Primey - Arkit - Scale 1:78

Elijah reacted to a post in a topic:

Cutty Sark by Primey - Arkit - Scale 1:78

-

Elijah reacted to a post in a topic:

Cutty Sark by Primey - Arkit - Scale 1:78

Elijah reacted to a post in a topic:

Cutty Sark by Primey - Arkit - Scale 1:78

-

Elijah reacted to a post in a topic:

Cutty Sark by Primey - Arkit - Scale 1:78

Elijah reacted to a post in a topic:

Cutty Sark by Primey - Arkit - Scale 1:78

-

Elijah reacted to a post in a topic:

Cutty Sark by Primey - Arkit - Scale 1:78

Elijah reacted to a post in a topic:

Cutty Sark by Primey - Arkit - Scale 1:78

-

Elijah reacted to a post in a topic:

Cutty Sark by Primey - Arkit - Scale 1:78

Elijah reacted to a post in a topic:

Cutty Sark by Primey - Arkit - Scale 1:78

-

popeye the sailor reacted to a post in a topic:

Cutty Sark by Primey - Arkit - Scale 1:78

popeye the sailor reacted to a post in a topic:

Cutty Sark by Primey - Arkit - Scale 1:78

-

Primey reacted to a post in a topic:

Cutty Sark by Nenad

Primey reacted to a post in a topic:

Cutty Sark by Nenad

-

Drilled mast holes, cut out and polished up prow and stern decorations. Started on belaying pin racks but do not have a small enough drill bit. The pin rack wood is only is 3mm wide 13cm long, need 25 holes so probably only 0.5mm or 1mm drill bit. So purchased both on ebay. And to those looking forward to the copper, not for me I'm afraid. I tried but the copper has beaten me so time to move on.

-

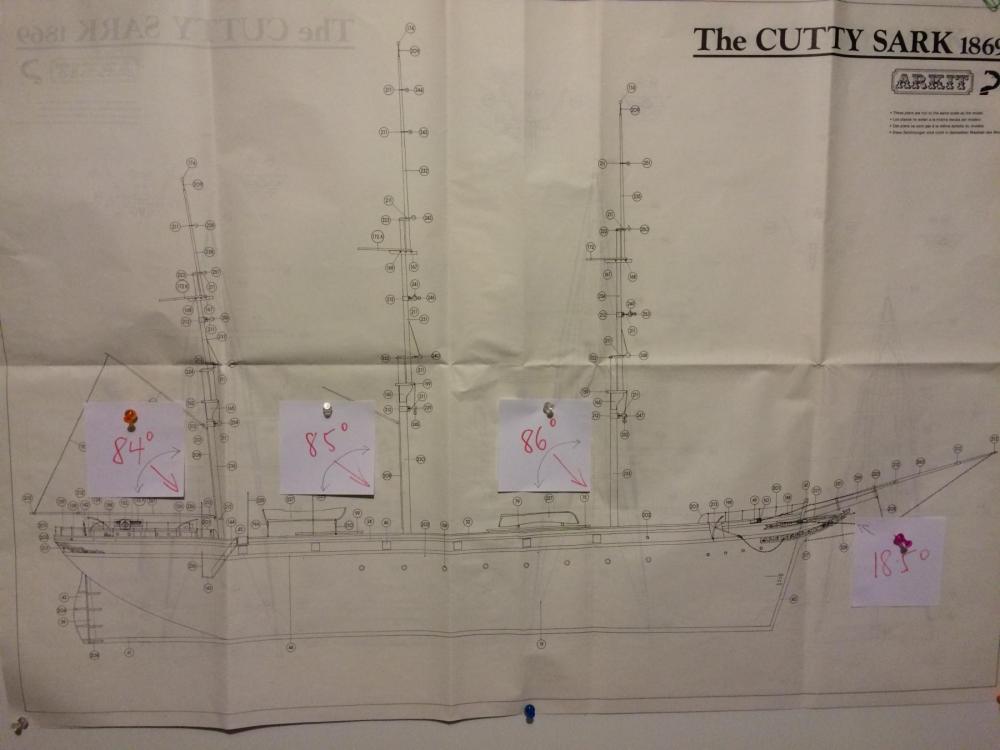

Hi All Just a question on the masts, I have seen pictures where the masts recline slightly, maybe at an angle 5 degrees (or less) to the deck, others appear to be exactly 90 degree to the deck. because my instructions are silent on this (and really just show perpendicular) , are there any rules here? I'm sure it has been asked and answered before and I have tried to find/search for the answer, so sorry for a repeated question. Thanks Primey

-

Thanks for your comments Bob and David. I have been struggling with the coppering, not just making plates but trying to visualise the 3 hull colours. The veneer does look good, and the copper plates I've made are "not so good". I am using tape but just can't seem to produce plates that look realistic, maybe using the wrong tools. looking at the finished model on the box I would say this model is meant to be artistic rather than historical. Anyway I'm ploughing on and maybe come back to the coppering later - procrastinate a little longer. Procrastination is something best put off until tomorrow.

-

Top hand rail done. Holes for freeing ports done, not sure of the position, plans don not specify so used the picture off the box as a guide. Painting the frames black. Should look good. The copper plates I have made so far are a bit NAFF, so have lost a bit of enthusiasm at the moment. Might go back to it later.

-

Primey reacted to a post in a topic:

CUTTY SARK by keelhauled - Mantua - kit bashed - First wooden ship build

Primey reacted to a post in a topic:

CUTTY SARK by keelhauled - Mantua - kit bashed - First wooden ship build

-

Primey reacted to a post in a topic:

Cutty Sark by Nenad

Primey reacted to a post in a topic:

Cutty Sark by Nenad

-

Hi Popeye, Thanks for the comments, I'm happy with the way it's going so far. Not as precise as some builders but enjoying the challenge all the same. Probably had enough to plank to waterline but decided to buy some new walnut veneer to cover the hull - the kit walnut veneer wasn't in the best shape. (very frail edges) I'm going to look at copper foil tape for the plates. Slow going affixing the veneer at the moment. - you know life gets in the way

-

Thanks Martin, Wording suggests that the kit is old. 1980's was a good era. Hope I can do it justice. Cheers Hi Tim, I did think the dark handled tool looked a bit sharp and would need dulling down. I have purchased both tools and some copper foil tape, my thought at this stage is to make individual plates and affix by overlapping each one- but will do some testing first.

-

Primey reacted to a post in a topic:

Cutty Sark by Nenad

Primey reacted to a post in a topic:

Cutty Sark by Nenad

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.