-

Posts

467 -

Joined

-

Last visited

About BenD

- Birthday 01/09/1990

Contact Methods

-

Website URL

https://ropesofscale.com/

Profile Information

-

Gender

Male

-

Location

Toronto Ontario Canada

Recent Profile Visitors

-

BenD reacted to a post in a topic:

HM Gun Brig Adder 1797 by DB789 - Vanguard Models - 1:64

BenD reacted to a post in a topic:

HM Gun Brig Adder 1797 by DB789 - Vanguard Models - 1:64

-

BenD reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

BenD reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

-

BenD reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

BenD reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

-

BenD reacted to a post in a topic:

HM Cutter Alert by Thukydides - Vanguard Models - 1:64 - first build

BenD reacted to a post in a topic:

HM Cutter Alert by Thukydides - Vanguard Models - 1:64 - first build

-

BenD reacted to a post in a topic:

1:80 Endeavour – America’s Cup 1934 - Amati

BenD reacted to a post in a topic:

1:80 Endeavour – America’s Cup 1934 - Amati

-

BenD reacted to a post in a topic:

Redoing Oseberg

BenD reacted to a post in a topic:

Redoing Oseberg

-

BenD reacted to a post in a topic:

Le Superbe by colpatben - Mantua Model - 1:75

BenD reacted to a post in a topic:

Le Superbe by colpatben - Mantua Model - 1:75

-

BenD reacted to a post in a topic:

Le Superbe by colpatben - Mantua Model - 1:75

BenD reacted to a post in a topic:

Le Superbe by colpatben - Mantua Model - 1:75

-

BenD reacted to a post in a topic:

The Black Pearl by Twokidsnosleep (Scott) - Zvezda - 1/72 scale - PLASTIC

BenD reacted to a post in a topic:

The Black Pearl by Twokidsnosleep (Scott) - Zvezda - 1/72 scale - PLASTIC

-

BenD reacted to a post in a topic:

The Black Pearl by Twokidsnosleep (Scott) - Zvezda - 1/72 scale - PLASTIC

BenD reacted to a post in a topic:

The Black Pearl by Twokidsnosleep (Scott) - Zvezda - 1/72 scale - PLASTIC

-

mtaylor reacted to a post in a topic:

Citadel paint better for hand painting?

mtaylor reacted to a post in a topic:

Citadel paint better for hand painting?

-

Thukydides reacted to a post in a topic:

Citadel paint better for hand painting?

Thukydides reacted to a post in a topic:

Citadel paint better for hand painting?

-

For brush painting, it really comes down to how much thinning is needed. I've found the Vallejo paints made for air-brush are really nice out of the bottle for hand brushing. I was looking at some Citadel paints at a hobby shop a few days ago. I should have bought some to try them out. The Vallejo model color ones I have need quite a lot of thinner to make the brush strokes disappear. As for mixing paints on models, I've personally had no issues. I only use acrylics. I also bought some mixing balls a few months ago. They are really amazing at getting a bottle mixed up and ready to go. I highly recommend them to anyone.

-

ferretmary1 reacted to a post in a topic:

Rope and cable - various sizes - Ropes of Scale

ferretmary1 reacted to a post in a topic:

Rope and cable - various sizes - Ropes of Scale

-

modeller_masa reacted to a post in a topic:

Which one is the best ropewalk machine?

modeller_masa reacted to a post in a topic:

Which one is the best ropewalk machine?

-

mtaylor reacted to a post in a topic:

Which one is the best ropewalk machine?

mtaylor reacted to a post in a topic:

Which one is the best ropewalk machine?

-

Which one is the best ropewalk machine?

BenD replied to modeller_masa's topic in Modeling tools and Workshop Equipment

People get confused about cable-laid ropes quite a lot. That 3.8mm cable-laid is three 1.8mm ropes laid together. Each 1.8mm rope has 39 yarns, which means the cable has 117 yarns. -

mrjuan reacted to a post in a topic:

Rope and cable - various sizes - Ropes of Scale

mrjuan reacted to a post in a topic:

Rope and cable - various sizes - Ropes of Scale

-

flying_dutchman2 reacted to a post in a topic:

Ropes of Scale developments and updates

flying_dutchman2 reacted to a post in a topic:

Ropes of Scale developments and updates

-

flying_dutchman2 reacted to a post in a topic:

Ropes of Scale developments and updates

flying_dutchman2 reacted to a post in a topic:

Ropes of Scale developments and updates

-

flying_dutchman2 reacted to a post in a topic:

Ropes of Scale developments and updates

flying_dutchman2 reacted to a post in a topic:

Ropes of Scale developments and updates

-

Back at it! I like how the ship's wheel turned out. You'll be done with your Wolf before I even take mine off the shelf.

-

This is totally how polyester behaves. One thing I've found about rope made with Gutermann E thread is it takes CA glue really well. Some polyester threads I've tried end up weak and crusty after being glued with CA but this stuff gets super strong. Another way to shape this rope is to use "super thin" CA, it goes right into the rope and then holds whatever shape you want. You will need a good applicator to pull this off. Every type of thread I've used for making rope has problems. I'm always looking for new threads to try.

- 478 replies

-

- vanguard models

- alert

-

(and 1 more)

Tagged with:

-

Absolutely beautiful ship. Estimating 2,500 hours of work involved... sounds about right for this level of kit bashing. Looking forward to the photo shoot. What's next up in the shipyard?

- 204 replies

-

- kitbashing

- Woodcarving

-

(and 4 more)

Tagged with:

-

I have an article about pine tar that might interest you https://maritime.org/conf/conf-kaye-tar.php It states that the production went on well into the 1900s. I'm pretty certain the industrial process for coal tar didn't pick up until the 1850s (Can't seem to find my article on it). The Grecian being an American vessel I'm not sure about what tar would be used. The Royal Navy would have used Pine tar to the bitter end no doubt. On tall ships today they use pine tar and coal tar mixed together from what I've read.

-

I've been working on the HMS Snake for years on and off. I'm not saying it's a bad kit, it's just a lot is expected from the modeler to just figure out. Who knows maybe it's right up your alley. Some day I'll finish that damned thing! I'm with the rest of the group on recommending The HMS Speedy or Flirt from Vanguard. Good quality laser cut parts and excellent instructions.

-

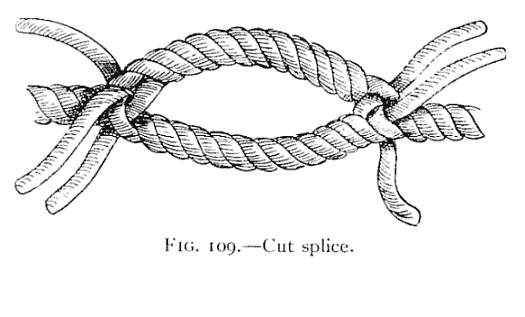

The way you are doing it on your build is just fine. I will add some pictures of the ways I know. There is the "cut splice" way. which is a bit difficult to do for a model. Wrap around the cascabel like The way you have done on your build log. The next one only works if there is a ring on the gun. There is another way with a four-strand rope but I don't have any pictures. I've also seen some breach ropes that run through the carriage itself and not even touching the gun.

-

Danny Vadas' masting and rigging spread sheet

BenD replied to allanyed's topic in Masting, rigging and sails

I was asking what word processor are you using to open the spreadsheet. If you said Microsoft is blocking it I'm assuming you are using Microsoft Word. I have not been able to get it working on that program. I've been using a free word processor called Open Office to open the spreadsheet. I'll add a download link. https://www.openoffice.org/ -

Danny Vadas' masting and rigging spread sheet

BenD replied to allanyed's topic in Masting, rigging and sails

I have no problem opening it. I'm using Open Office 4.1.7. What are you using? -

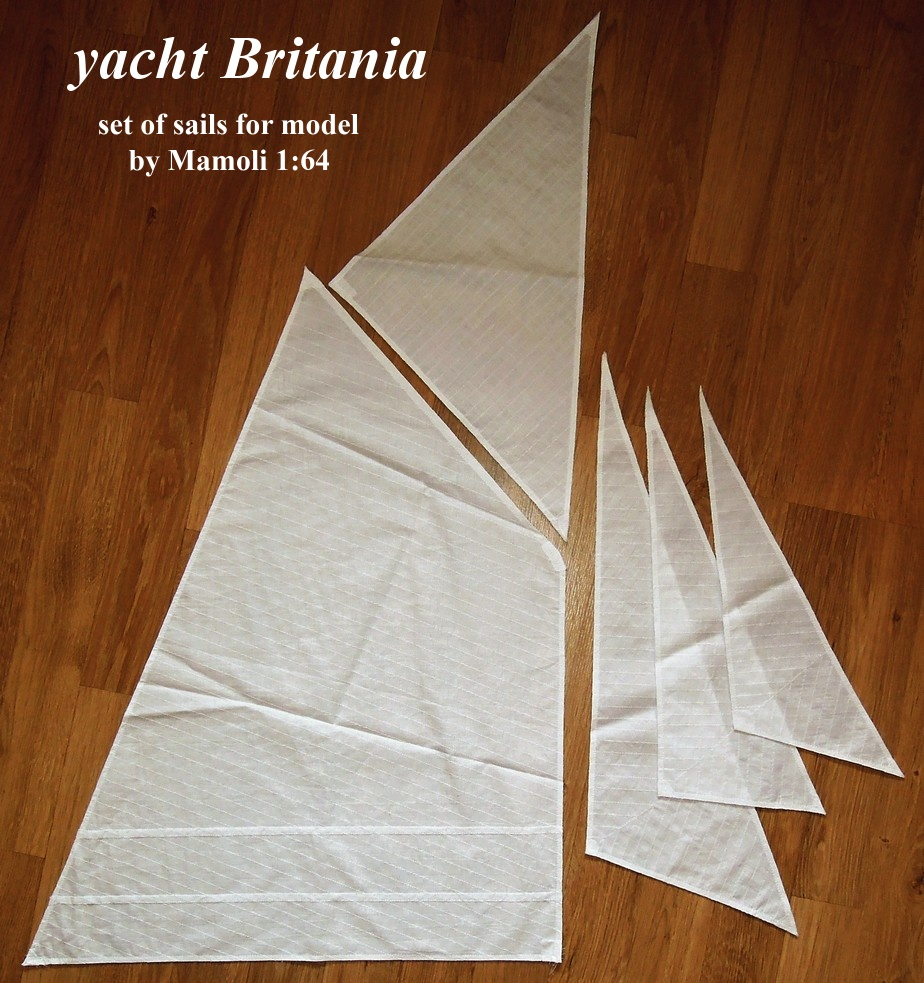

Looking for pre-made sails for Mamoli Britannia

BenD replied to MOURADATOR's topic in Wood ship model kits

I think I found what you are looking for. They are not cheap, but they are well made. They might also take 2-4 weeks to arrive as they are made to order. https://www.hismodel.com/articles-detail-414 -

The closeups look incredible! The Ramshead block you scratch-built just fits right in. 👍

- 204 replies

-

- kitbashing

- Woodcarving

-

(and 4 more)

Tagged with:

-

I've been watching that build as well. I have the HMS Wolf on the shelf and keep looking in the box at the perfectly cut laser parts, drooling a bit.. then eventually putting it back. Need to finish other projects first. The 1/72 card kits are more expensive but you get so much more. I'd say do as much as you can with this one then try out laser-cut ones. They even have the Le Coureur in 1/72. I'll be watching your progress, good luck.

- 8 replies

-

- Le Coureur

- Shipyard

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.