-

Posts

2,937 -

Joined

-

Last visited

About Hubac's Historian

- Birthday 08/11/1973

Profile Information

-

Gender

Male

-

Location

New York City

-

Interests

17th Century Naval Architecture, furniture design and construction with an emphasis on the Art Nouveau period, 20th Century architecture, wood carving, muscle cars, the Knicks, and early American longrifles.

Contact Methods

-

Yahoo

Benchmarc_woodworking@yahoo.com

-

Hubac's Historian reacted to a post in a topic:

Endeavour by Bill97 - OcCre - 1/54

Hubac's Historian reacted to a post in a topic:

Endeavour by Bill97 - OcCre - 1/54

-

cotrecerf reacted to a post in a topic:

HMS EURYALUS by Matiz - FINISHED - scale 1:56

cotrecerf reacted to a post in a topic:

HMS EURYALUS by Matiz - FINISHED - scale 1:56

-

mtaylor reacted to a post in a topic:

HMS EURYALUS by Matiz - FINISHED - scale 1:56

mtaylor reacted to a post in a topic:

HMS EURYALUS by Matiz - FINISHED - scale 1:56

-

mtaylor reacted to a post in a topic:

Sloop Speedwell by Chuck - Ketch Rigged Sloop, 1752 - POF

mtaylor reacted to a post in a topic:

Sloop Speedwell by Chuck - Ketch Rigged Sloop, 1752 - POF

-

mtaylor reacted to a post in a topic:

17th-Century Speeljacht by 0Seahorse - scale 1/50 - CARD

mtaylor reacted to a post in a topic:

17th-Century Speeljacht by 0Seahorse - scale 1/50 - CARD

-

Hubac's Historian reacted to a post in a topic:

Mary Rose by Baker - scale 1/50 - "Your Noblest Shippe"

Hubac's Historian reacted to a post in a topic:

Mary Rose by Baker - scale 1/50 - "Your Noblest Shippe"

-

Keith Black reacted to a post in a topic:

HMS EURYALUS by Matiz - FINISHED - scale 1:56

Keith Black reacted to a post in a topic:

HMS EURYALUS by Matiz - FINISHED - scale 1:56

-

Hubac's Historian reacted to a post in a topic:

HMS EURYALUS by Matiz - FINISHED - scale 1:56

Hubac's Historian reacted to a post in a topic:

HMS EURYALUS by Matiz - FINISHED - scale 1:56

-

Hubac's Historian reacted to a post in a topic:

MONTAÑES by Amalio

Hubac's Historian reacted to a post in a topic:

MONTAÑES by Amalio

-

Chuck reacted to a post in a topic:

Sloop Speedwell by Chuck - Ketch Rigged Sloop, 1752 - POF

Chuck reacted to a post in a topic:

Sloop Speedwell by Chuck - Ketch Rigged Sloop, 1752 - POF

-

Jack12477 reacted to a post in a topic:

Sloop Speedwell by Chuck - Ketch Rigged Sloop, 1752 - POF

Jack12477 reacted to a post in a topic:

Sloop Speedwell by Chuck - Ketch Rigged Sloop, 1752 - POF

-

Hubac's Historian reacted to a post in a topic:

Sloop Speedwell by Chuck - Ketch Rigged Sloop, 1752 - POF

Hubac's Historian reacted to a post in a topic:

Sloop Speedwell by Chuck - Ketch Rigged Sloop, 1752 - POF

-

Hubac's Historian reacted to a post in a topic:

Sloop Speedwell by Chuck - Ketch Rigged Sloop, 1752 - POF

Hubac's Historian reacted to a post in a topic:

Sloop Speedwell by Chuck - Ketch Rigged Sloop, 1752 - POF

-

Hubac's Historian reacted to a post in a topic:

Sloop Speedwell by Chuck - Ketch Rigged Sloop, 1752 - POF

Hubac's Historian reacted to a post in a topic:

Sloop Speedwell by Chuck - Ketch Rigged Sloop, 1752 - POF

-

Hubac's Historian reacted to a post in a topic:

Sovereign of the Seas by 72Nova - Airfix - PLASTIC

Hubac's Historian reacted to a post in a topic:

Sovereign of the Seas by 72Nova - Airfix - PLASTIC

-

Hubac's Historian reacted to a post in a topic:

Sovereign of the Seas by 72Nova - Airfix - PLASTIC

Hubac's Historian reacted to a post in a topic:

Sovereign of the Seas by 72Nova - Airfix - PLASTIC

-

Hubac's Historian reacted to a post in a topic:

Sovereign of the Seas by 72Nova - Airfix - PLASTIC

Hubac's Historian reacted to a post in a topic:

Sovereign of the Seas by 72Nova - Airfix - PLASTIC

-

Hubac's Historian started following 17th-Century Speeljacht by 0Seahorse - scale 1/50 - CARD

-

This all looks great Eric. I like your aft increase in wale sheer. I’m debating whether it makes sense to have a corresponding increase in the middle band of wales, as the sheer would have run parallel. The upper main wales - at the juncture of the upper bulwarks are pretty fixed, although one could add to to top edge of the upper most wale and feather it back. It mY not really be worth all of that extra effort, though.

- 90 replies

-

- Ship of the line

- Heller

-

(and 2 more)

Tagged with:

-

Bruma reacted to a post in a topic:

Cutty Sark by Bruma - Revell - 1:96 - PLASTIC

Bruma reacted to a post in a topic:

Cutty Sark by Bruma - Revell - 1:96 - PLASTIC

-

davec reacted to a post in a topic:

HMS Tiger 1747 by Siggi52 - 1:48 - 60 gun ship from NMM plans

davec reacted to a post in a topic:

HMS Tiger 1747 by Siggi52 - 1:48 - 60 gun ship from NMM plans

-

mtaylor reacted to a post in a topic:

Carving from Belgorod

mtaylor reacted to a post in a topic:

Carving from Belgorod

-

Ian, you continue to amaze with this build! I was just talking it up to my club, last night, so you may soon have a few new on-lookers. The bulwark sweep, previously, did not jump out at me as problematic, but after modification I can see what an improvement in practicality and aesthetics you have made. Well done!

- 502 replies

-

- Quadrireme

- radio

-

(and 1 more)

Tagged with:

-

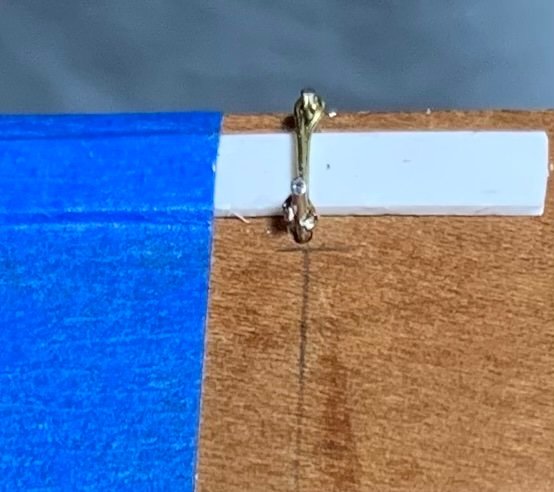

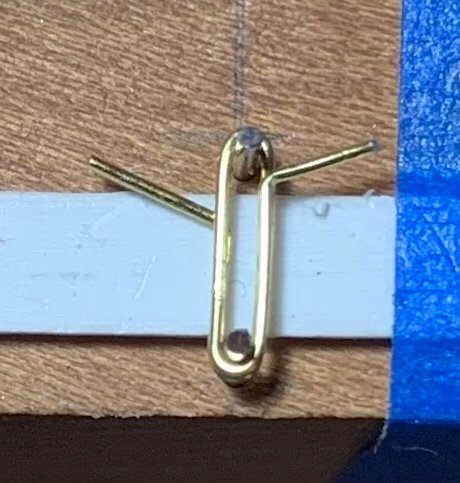

Well, the 6th grade CYO basketball season has drawn to a close and our team succeeded beyond my wildest dreams: we went 13-1, and captured the Manhattan division title. Our second and final loss came in a division matchup with the Bronx winners. We played a gritty first half, and kept it close, but made mistakes in the second half. We were simply overmatched. Nonetheless, it was a wonderful and extremely rewarding season. The Knicks, on the other hand, continue to surprise, so my attentions remain somewhat divided. That being said, I am lately looking to focus more on model building. I’ve completed all of the fore, main and mizzen channel deadeye strops. Although Andre Kudin’s particular method is definitely more efficient with less clean-up - he solders the lower strop loop at a neatly cut joint - I stuck with the R.C. Anderson overlap method I had been using because the strops were coming out uniformly, nicely shaped, and strong. I will change my approach for the deadeye strops in the tops. Next in order to be made are the chain preventer plates. One of the key differences between what I had first tried, when making the chain preventer plates, and what Andre does is that Andre bends each plate from an individual length of wire, rather than try to economize on material by wrapping a longer length of wire, many turns, around an appropriately sized former. When you do the latter, for one thing - you may succeed in crimping the continuous loop neatly around the former, but it is nigh impossible, after parting the links to get the links off the former without pulling them all out of shape. The other issue with parting the links in this way is that you end up with one neat flush end and a pinched end, which leads to a weaker solder joint. What I am after are uniformly straight chain links, free of odd kinks, and sloppy joints. To that end I set up a simple bending jig like the one I see in Andre’s videos. Following is a series of screen captures from his YouTube videos. This particular video is either #13 or #16, in the series, if I remember correctly: And following along, I first pre-bend short lengths of wire around a drill mandrel: I’ve placed a shallow spacer beneath the link area, so that the ends will be slightly raised and easier to crimp with my parallel pliers: I crimp snug around the upper pin, then use my pliers to pull each end snugly around the lower pin. I then crimp around the lower pin: I can then remove the link, and flush-cut each side of the link. A little tweezer/finger manipulation creates a nicely closed link: Silver solder paste has proven to be really great as I can control its application with the tip of an Exacto. A touch to the iron, and I have nicely soldered joints that only require a little cleanup: Now, Andre puts the soldered loops back over the two-pin jig and uses his round-nose pliers to crimp eyes at each end. I found, though, that the joints with this 28 gauge wire simply failed when I tried this: Alternatively, I found that I could place each link end over the lower pin, hold the outer end with a tweezer, and use my round nose plier to crimp around the single pin. This worked beautifully: Now, It’s a simple matter of doing that over and again about 60X. It is, of course tedious, but satisfying to achieve the result I am after. More to follow! Best, Marc

- 2,432 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

Just awesome, Bill. A beautiful display!

- 1,503 replies

-

- Le Soleil Royal

- Heller

-

(and 1 more)

Tagged with:

-

I echo the sentiments of all above - simply extraordinary!

- 397 replies

-

- cutty sark

- revell

-

(and 2 more)

Tagged with:

-

Peter, you must be in the midst of the middle phase of your working life, when it is most demanding on your time. Well, fear not - we will wait for you, when you are ready. This build is too good to simply forget about. Best, Marc

- 30 replies

-

- Corel

- wappen von hamburg

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpeg.fc5d633a7b34428fcf19419a73d56d55.jpeg)