Matt763

Members-

Posts

24 -

Joined

-

Last visited

Recent Profile Visitors

-

PohjolanMatti started following Matt763

-

GrandpaPhil reacted to a post in a topic:

Virginia 1819 by Matt763 - FINISHED - Artesania Latina - Scale 1:41 - First Build

GrandpaPhil reacted to a post in a topic:

Virginia 1819 by Matt763 - FINISHED - Artesania Latina - Scale 1:41 - First Build

-

Altduck reacted to a post in a topic:

Virginia 1819 by Matt763 - FINISHED - Artesania Latina - Scale 1:41 - First Build

Altduck reacted to a post in a topic:

Virginia 1819 by Matt763 - FINISHED - Artesania Latina - Scale 1:41 - First Build

-

I took a look at their website and they seem to have quite a selection of products on there! Do you have any recommendations on which manufacturer to go with? This one I just finished was a Latina model and I'm hoping for something with a bit more detail and quality. Good news on the duty though but I've bought plenty of bicylcle parts from the UK and have always had to pay duty on them, maybe model ships fall under another category that is exempt.

- 50 replies

-

- artesania latina

- Virginia

-

(and 2 more)

Tagged with:

-

Matt763 reacted to a post in a topic:

Virginia 1819 by Matt763 - FINISHED - Artesania Latina - Scale 1:41 - First Build

Matt763 reacted to a post in a topic:

Virginia 1819 by Matt763 - FINISHED - Artesania Latina - Scale 1:41 - First Build

-

Matt763 reacted to a post in a topic:

Virginia 1819 by Matt763 - FINISHED - Artesania Latina - Scale 1:41 - First Build

Matt763 reacted to a post in a topic:

Virginia 1819 by Matt763 - FINISHED - Artesania Latina - Scale 1:41 - First Build

-

Matt763 reacted to a post in a topic:

Virginia 1819 by Matt763 - FINISHED - Artesania Latina - Scale 1:41 - First Build

Matt763 reacted to a post in a topic:

Virginia 1819 by Matt763 - FINISHED - Artesania Latina - Scale 1:41 - First Build

-

Ryland Craze reacted to a post in a topic:

Virginia 1819 by Matt763 - FINISHED - Artesania Latina - Scale 1:41 - First Build

Ryland Craze reacted to a post in a topic:

Virginia 1819 by Matt763 - FINISHED - Artesania Latina - Scale 1:41 - First Build

-

mikiek reacted to a post in a topic:

Virginia 1819 by Matt763 - FINISHED - Artesania Latina - Scale 1:41 - First Build

mikiek reacted to a post in a topic:

Virginia 1819 by Matt763 - FINISHED - Artesania Latina - Scale 1:41 - First Build

-

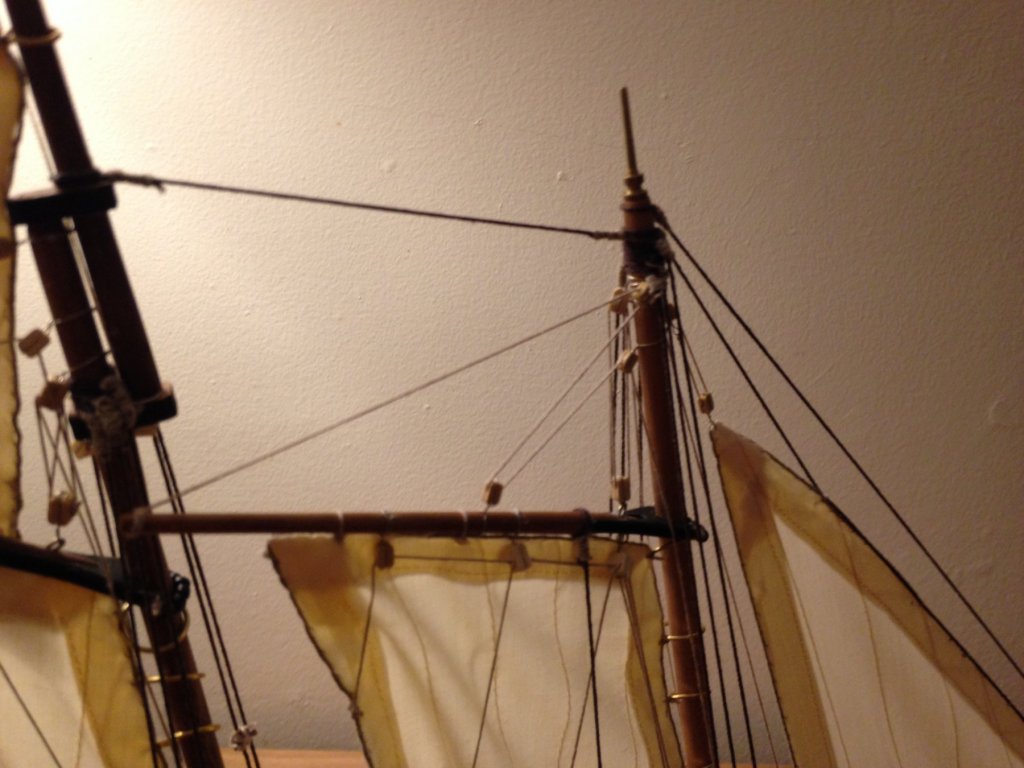

Well, it has definately been a fun 10 months. Some times of frustration, head scratching, looking at references and a little bit of swearing too. But it is finally done! This has by far been my longest modeling project and quite the undertaking. My past experience has been in plastic model making and this was a whole different ball game, but so worth the time put in and what a reward to see this beautiful boat finished! I am overall really happy with the result and it is going to be a model that i can proudly display. Like every artist or model maker, we always see the slight imperfections in our work, but i will just take that as motivation and lessons learned for the next one! I have to say that i really under estimated the rigging portion of the build. I thought planking would by far be the hardest most tedious part of the build but boy was i wrong. Rigging took waay longer than i thought and was way tougher than i thought. I decided that i didnt want to glue down my masts and instead used shims to hold it in place until the standing rigging was attached, a realistic way to rig the ship. While the masts stayed in place quite nicely with the standing rigging, i found that doing the running rigging afterwards was made 1000X more difficult trying to work around it. I also did not pre stretch the lines so as i kept leaning my hand against it while tying knots, it slowly started to go slack and was not as tight as it was. Fortunately the slack is not noticeable thanks to the waxing, but i am thinking next time it might be better to do running rigging first to avoid this problem. Any thoughts on this?? But anyways, enjoy the pictures and note that a real base for the model is in the pipeline! Dont want to leave it sitting on a foam noodle forever, what a shame that would be! While my log is not as detailed as many others i have read on here, i do hope that it can help people out who are building this ship too and answer some of the many questions im sure we all had with this kit. Enjoy!! P.S. I am looking into buying the Modelshipways Bluenose II as my next kit but am not sure where i should get it from. I know it is on the model expo website since they are the manufacturers but I live in Canada so the shipping and duty is not going to be cheap. I was just wondering if anyone knew of any Canadian suppliers where i can get the kit to hopefully avoid that problem. Matt

- 50 replies

-

- artesania latina

- Virginia

-

(and 2 more)

Tagged with:

-

Once you take a break for so long its hard to get back into it, so consider yourself lucky Mike! Wish i had more time than i do to work on my models

- 50 replies

-

- artesania latina

- Virginia

-

(and 2 more)

Tagged with:

-

Matt763 reacted to a post in a topic:

Virginia 1819 by Matt763 - FINISHED - Artesania Latina - Scale 1:41 - First Build

Matt763 reacted to a post in a topic:

Virginia 1819 by Matt763 - FINISHED - Artesania Latina - Scale 1:41 - First Build

-

Heinrich der Seefahrer reacted to a post in a topic:

Virginia 1819 by Matt763 - FINISHED - Artesania Latina - Scale 1:41 - First Build

Heinrich der Seefahrer reacted to a post in a topic:

Virginia 1819 by Matt763 - FINISHED - Artesania Latina - Scale 1:41 - First Build

-

Robin Lous reacted to a post in a topic:

Virginia 1819 by Matt763 - FINISHED - Artesania Latina - Scale 1:41 - First Build

Robin Lous reacted to a post in a topic:

Virginia 1819 by Matt763 - FINISHED - Artesania Latina - Scale 1:41 - First Build

-

mikiek reacted to a post in a topic:

Virginia 1819 by Matt763 - FINISHED - Artesania Latina - Scale 1:41 - First Build

mikiek reacted to a post in a topic:

Virginia 1819 by Matt763 - FINISHED - Artesania Latina - Scale 1:41 - First Build

-

No, I have not given up!! Let me just say that it has been a crazy few months that have passed. Changed jobs, had some family issues but most of all, it was summer time! I also thought it a fun idea to enter a triathlon for september so that ate away alot of my time too. I did well though, totally worth it!! But sadly, progress on the Virginia slowed down and i was only able to do it every now and then. But now that triathlon over and that its getting colder out, back to work!! I will be moving in december so my goal is for it to be done by then which i think is more than doable. I was also a bit bad about taking pictures as i went, you are going to see quite the jump from my last post up to this one! Looking back at the log, last time i was here i had just put up the railing stringers and was about to fit on the railing. Well now all of the deck furniture has been attached and i have rigged up all the masts and spars, so just about ready to get to the standing rigging and make the ship come alive!! I think that so far it looks pretty nice. I have a feeling that my rigging will not be at the same level as lots of others on here as i am finding it quite hard to do with the instructions given. I am using more glue than i am knots and am sure that things will not be excatly in the right place, but for my first ship its not that big of a deal. One example of this is how i rigged up the anchor. Went through the whole process until when i was finally done i realised i had done it wrong :p. Instead of tying the rope to the anchor, passing it over the side of the ship and then through the small hole in the hull to be fixed, i attached it to the anchor and put it through the hole before draping it over the side. Clearly the laws of physics will not allow my anchor to get off the ship, but stranger things have happend :p. I tried to show it in the pictures, hopefully you can see it clealy! Other than that the build has been quite easy going. I looked online for lots of references of ships and came across one build log in particular. If anyone else is building this ship and wants a reference log with lots of photos (that is something mine lacks a bit) then you should really check out this one. A beautiful build and great reference pictures, i relied on it heavily! Other than that, enjoy!! The next post will probably be the finished ship all rigged up but if anyone has advice on rigging to give, i am certainly all ears! Oh and i have also been thinking for my next model of doing the Bluenose II by model ship ways. I thought i might try out a Modelship ways kit as they look to be of pretty good quality, i thought Artesania Latina cheaped out on some things here and there and didnt necessarily give you enough materials. Again, id love to know peoples opinion on ModelShip ways and the Bluenose II kit in general. I am a canadian and i went to visit the ship this summer, very impressive! Now i must have one of my own :)) Anyhow, enjoy!

- 50 replies

-

- artesania latina

- Virginia

-

(and 2 more)

Tagged with:

-

Matt763 reacted to a post in a topic:

Virginia 1819 by Matt763 - FINISHED - Artesania Latina - Scale 1:41 - First Build

Matt763 reacted to a post in a topic:

Virginia 1819 by Matt763 - FINISHED - Artesania Latina - Scale 1:41 - First Build

-

mikiek reacted to a post in a topic:

Virginia 1819 by Matt763 - FINISHED - Artesania Latina - Scale 1:41 - First Build

mikiek reacted to a post in a topic:

Virginia 1819 by Matt763 - FINISHED - Artesania Latina - Scale 1:41 - First Build

-

mikiek reacted to a post in a topic:

Virginia 1819 by Matt763 - FINISHED - Artesania Latina - Scale 1:41 - First Build

mikiek reacted to a post in a topic:

Virginia 1819 by Matt763 - FINISHED - Artesania Latina - Scale 1:41 - First Build

-

semorebutts reacted to a post in a topic:

Virginia 1819 by Matt763 - FINISHED - Artesania Latina - Scale 1:41 - First Build

semorebutts reacted to a post in a topic:

Virginia 1819 by Matt763 - FINISHED - Artesania Latina - Scale 1:41 - First Build

-

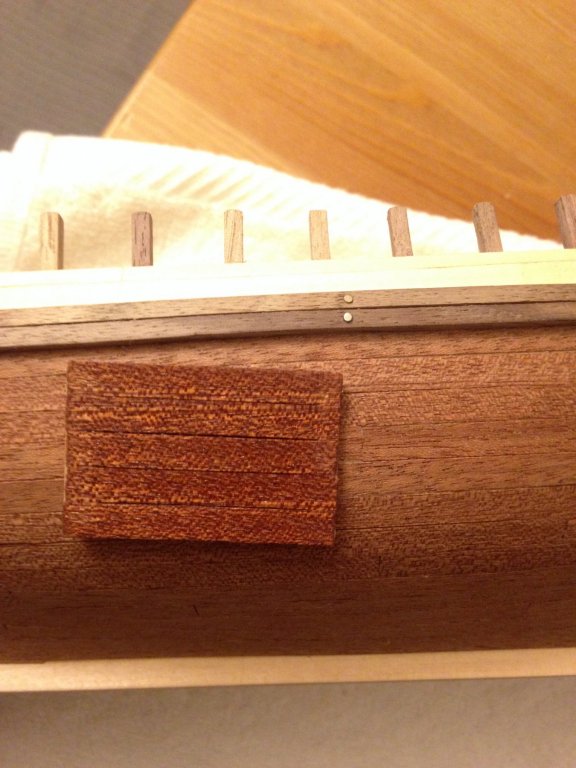

I am sorry for the lack of posts lately, but i have had some time to work on the ship here and there so ill give a quick update! Since the last time, i have taken the leap and finished the hull. After trying a few methods out, i went with the Tung oil and i have to say that aside from the smell (seriously, that stuff stinks!), it turned out really really nice. I like the fact that it really shows off the grain of the wood and having planked the hull with Mahogony, showing off the grain is the way to go. Even the decking wood (which is Sapeley i think?) is showing a grain that i didnt even know it had when planking with it! Since it took about 2 days or so for each coat to dry, i had time in between to work on some of the deck furniture. I finished off the companion that i was working on in my last post and got that sanded smooth and ready for it to get a coat of Tung oil, i sanded and finished the hatch thingy that holds the cannon balls (name for that thing please?!) and i also put together the bow mast head. The parts that they provided for that were made out of cast metal and i really didnt like the look of it. So i took some scrap applewood i had left over and remade the parts out of that, and what a dfifference! So happy i did it. There is another part in the kit (which the name eludes me) also made out of cast metal and i am going to remake those out of the apple wood as well. A little bit of extra work like that goes a long way! I am now getting to the stage of the build where i will be tackling all the little details. It is quite a change of pace since up to now it has all been work on the overall structure of the ship, so i am looking forward to testing out and learning new techniques! I will need to set the top rail and adjust all the struts, attach the pintles and gudgeons for the rudder and fix that into place, work on the cannon and start attaching all the eyelets for the rigging. The rigging is starting to make me a bit nervous though. The instructions really arent very clear and even with the help i have gotten on here i dont feel confident in where i am going with it. So please, if anyone has any detailed references or advice for the rigging, i would be ever grateful! One technique i have seen and am planning on using is that of coating all the rigging line in beeswax. This way it gives it a more taunt look when attached and so that it doesnt sag all over the place. Other than that, tricks and pro tips will be very helpful.

- 50 replies

-

- artesania latina

- Virginia

-

(and 2 more)

Tagged with:

-

Mike, you are definitely right about the need to taper the long edge, the fit i got wasnt as good as i wanted so that would be something to fix the next time i have to do the same thing. As for the timber heads you called it right again! One or two got bumped, and needed to be reglued. Not the end of the world but i still think it was good having them on for the oiling of the hull. I did just check the fit though between the struts and the railing itself and there are several struts which are too short, so that is something to adjust aswell.

- 50 replies

-

- artesania latina

- Virginia

-

(and 2 more)

Tagged with:

-

Ah okay that does make sense i can see the advantage in that. When i went to the hardware store and asked the people there though they recommended the oil finish when i told them what kind of look i was going for plus i am not too worried with durability since i am planning on making a case for this to sit in when its done. I hope i dont beat it up too much before its done! We will see what happens i guess but i will try and be extra careful Its been a little while since i last gave an update, so here it is! Since I have finished the planking, i moved onto adding the bells and whistles on the hull. I added on the rubbing strakes to both sides of the ship which is done in Applewood and for that i decided to leave the brass nails showing, i really like the look that the give. I also began working on the railing. There is a thicker beam which runs along the inside of the bulwarks of the ship and then there are struts which rise up from it to hold the eventual railing. This was all done in Applewood aswell and i have to say that working with it wasnt too easy, takes alot of force to bend that stuff even after soaking! I decided to stop there with the hull until i finish it. Adding on the railing is just going to complicate things i think so i am going to finish it off and then continue with some assembly. I made some test swatches to check out what the Tung oil finish on the Mahogany wood looks like and after 2 coats, it looks pretty good! im going to try a third one out to see where i should go to with it. Each coat takes 24 hours to dry though so it is going to take a little while to see what result it gives and to decide if i want to go that route or not. So in the mean time, i began work on some of the deck furniture starting with the companion. And i have to say that this little bugger gave me tons of problems. Namely because you have to bend the plywood roof to a curve to properly fit over. My first attempt was to use steam and clamps to bend it to shape but i found out pretty quick that plywood and steam dont mix, it delaminated pretty soon after starting So i went out and bought another sheet and remade the roof from scratch. The piece i got was alot thicker than the kit supplied one which i liked, but it was tough to bend. I tried making jigs out of scrap wood and i soaked the wood and then clamped it to them to see if it would hold the shape. That didnt work either though and they would spring back keeping only a slight curve. I then tried clamping the piece directly to the sqaure plywood frame that makes up the body of the companion but with no supports, i snapped that too. In the end, i added square reinforcement blocks in the corners making the body rigid, i then soaked the roof and clamped it down to the right shape, painted some thinned out wood glue all over the roof and on the seams to help the wood keep its shape and when all that dried, added a little CA glue inside for insurance. Worked like a charm! The roof isnt perfectly centered but i can live with it and think that it looks good overall. Next steps are to finish off the deck furniture and hopefully start finishing the hull. More to come soon!

- 50 replies

-

- artesania latina

- Virginia

-

(and 2 more)

Tagged with:

-

thanks for the advice! i have been doing a bit of research and from what i have read natural oils seem like a good option as well. Read about Tung oil, linseed oil, danish oils, etc.. and they seem to be rather easy to apply and when they fade away over time as most finishes will, you can simply apply another coat and buff it easily. Any reason to go with a varnish over a natural oil?

- 50 replies

-

- artesania latina

- Virginia

-

(and 2 more)

Tagged with:

-

The wood is actually Mahogany and i agree it looks beautiful as well! I definately didnt want to stain it another color just wanted to know the best way to bring out the natural look and seal in the finish. Natural stain will leave the original color? If so that sounds great to me! And no i didnt want a glossy finish but i was thinking of something more in the middle like a satin maybe.

- 50 replies

-

- artesania latina

- Virginia

-

(and 2 more)

Tagged with:

-

Another update! I have since finished planking the hull and the inside and outside of the bulwarks of the ship. Huge milestone for me and for this build and i have to say that while it is not perfect, i am quite pleased with how it turned out and hopefully the rest of the build will be just as nice! The next step is to attach the rubbing strakes onto either side of the ship which mask the transition line between the bulwarks and the hull (although my transition line is pretty smooth if i do say so myself hehe ;)) and to also begin working on the famous stern post and rudder so that i can prepare the ship for varnishing. I havent quite decided yet what finish i want to give the ship and what will look nice. I have prepared some small samples to do tests on but suggestions would be much appreciated too! Let me know what you guys think and hopefully you are enjoying the log so far! P.S. the masking tape on the deck is there to mark the position of the bulkheads for when i go to nail in the rubbing strakes and what ever else is needed on the hull. Id rather nail into something solid then into the hollow hull. -Matt

- 50 replies

-

- artesania latina

- Virginia

-

(and 2 more)

Tagged with:

-

Thats true Mike, there must be some way out there to avoid it though! Ill keep searching and let you know Trufo, Thank you so much for those plans i definitely think that they are going to help me out quite a bit! Latina tried to show this over an actual picture of the ship with arrows and stuff and to me that just makes it less clear and more confusing. Your pictures are way better so it will go along way!

- 50 replies

-

- artesania latina

- Virginia

-

(and 2 more)

Tagged with:

-

Matt763 reacted to a post in a topic:

Virginia 1819 by Matt763 - FINISHED - Artesania Latina - Scale 1:41 - First Build

Matt763 reacted to a post in a topic:

Virginia 1819 by Matt763 - FINISHED - Artesania Latina - Scale 1:41 - First Build

-

Thanks for the the kind words Steve! I really did try to do the whole thinking 5 steps ahead and I actually noticed the issue before I did the second layer of planking. I decided to leave it as is and fix the problem by remaking the rudder instead of the stern post (or both). I kind of like the way the stern post looks right now and I think it will look better with a wider rudder anyways. As for rhe glue, I had did a few tests with some CA glue (which I think is the same thing?) and I quickly discovered that I am not the cleanest of workers and I got finger prints all over it. I didn't know about the lacquer thinner though so I will definately look into that for next time because using tape to clamp the planks down takes a really long time to do. I would love love to see some pictures of your build because I think the rigging is going to be challenging based on the unclear instructions. I appreciate all all the help though! Currently finishing off the planking so hopefully will have an update with pictures soon! Matt

- 50 replies

-

- artesania latina

- Virginia

-

(and 2 more)

Tagged with:

-

Well I wasn't planning on getting glue on the hull more putting glue on the wooden splinters and then wiping off the excess just to fill the gaps. I don't want to get spots though so if that's what is going to happen I'll probably just leave it as is. Would rather have a few small gaps then a spotty hull! Thanks chuck! Your stuff looks pretty great too

- 50 replies

-

- artesania latina

- Virginia

-

(and 2 more)

Tagged with:

-

Hey Mike, Yeah that is kind of what i figured. When the wood is thicker it has more material to twist on and it goes alot easier but i think i overall did a pretty good job with it so im not too upset with the result. I had been trying to take little splinters of wood and use that to fill the gaps and it did work, might continue doing that and then give it a light sanding afterwards.

- 50 replies

-

- artesania latina

- Virginia

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpg.62d1d69fed1f32364417cb1f9cdeb009.jpg)