Ben752

Members-

Posts

64 -

Joined

-

Last visited

-

Ben752 reacted to a post in a topic:

US Brig Niagara by xken - FINISHED - Model Shipways - Scale 1/64

Ben752 reacted to a post in a topic:

US Brig Niagara by xken - FINISHED - Model Shipways - Scale 1/64

-

Ben752 reacted to a post in a topic:

Adjusting (aligning) scanned ship plans

Ben752 reacted to a post in a topic:

Adjusting (aligning) scanned ship plans

-

mtaylor reacted to a post in a topic:

Adjusting (aligning) scanned ship plans

mtaylor reacted to a post in a topic:

Adjusting (aligning) scanned ship plans

-

Kris, I shared a few things just to show some similar research but totally agree with your analysis. I was curious if you happen to have Mac version or even better a GitHub repo with the source? I’ve encountered the same challenge and love your approach. As an aside, I wrote a small a Python script that used scipy’s genetic algorithm to fit splines that output control points compatible with how Fusion 360 constructed knots. Great work!

-

Canute reacted to a post in a topic:

Veritas Miniature Worktop from Lee Valley Tools

Canute reacted to a post in a topic:

Veritas Miniature Worktop from Lee Valley Tools

-

Altduck reacted to a post in a topic:

Veritas Miniature Worktop from Lee Valley Tools

Altduck reacted to a post in a topic:

Veritas Miniature Worktop from Lee Valley Tools

-

mtaylor reacted to a post in a topic:

Adjusting (aligning) scanned ship plans

mtaylor reacted to a post in a topic:

Adjusting (aligning) scanned ship plans

-

mtaylor reacted to a post in a topic:

Veritas Miniature Worktop from Lee Valley Tools

mtaylor reacted to a post in a topic:

Veritas Miniature Worktop from Lee Valley Tools

-

Ryland Craze reacted to a post in a topic:

Veritas Miniature Worktop from Lee Valley Tools

Ryland Craze reacted to a post in a topic:

Veritas Miniature Worktop from Lee Valley Tools

-

Jack12477 reacted to a post in a topic:

Veritas Miniature Worktop from Lee Valley Tools

Jack12477 reacted to a post in a topic:

Veritas Miniature Worktop from Lee Valley Tools

-

Veritas Miniature Worktop from Lee Valley Tools

Ben752 replied to Jack12477's topic in Modeling tools and Workshop Equipment

I have quite a few of the miniatures, I use the shoulder plane and block plane constantly. My favorite vice is one of these https://www.cousinsuk.com/sku/details/vices-bench-vice-jaws/v9692 -

Just want to point out this is: Awesome Computer Vision research The known references certainly assist dramatically. I recall reading a paper about removing lense distortions by using a reference photo of a checkerboard, fitting the edges to make grid points and then fitting a transform function. Seems like an adaptable solution. https://mzucker.github.io/2016/08/15/page-dewarping.html https://arxiv.org/pdf/2007.09824.pdf https://github.com/gwxie/Dewarping-Document-Image-By-Displacement-Flow-Estimation/blob/main/90_paper.pdf

-

Ben752 reacted to a post in a topic:

English boxwood availability

Ben752 reacted to a post in a topic:

English boxwood availability

-

Thought others might like to know that there has been a small bit of green and some dry boxwood as of late, presumably due to the ongoing infestation of the box tree moth caterpillars. Regardless, I’ve ordered from several different sources listed below: https://www.workshopheaven.com/wood-blanks/boxwood.html (limited stock) https://www.ebay.co.uk/usr/hucrompto0 (in stock) https://www.englishwoods.co.uk (out of stock) The green logs, albeit many are twigs, I purchased as lot for £9 plus shipping. So deals are out there, I found eBay saved searches indispensable.

-

Ben752 reacted to a post in a topic:

Chuck Passaro's planking Videos - Where are they?

Ben752 reacted to a post in a topic:

Chuck Passaro's planking Videos - Where are they?

-

H.M.S. Atalanta - Drafting my own plans

Ben752 replied to Ben752's topic in CAD and 3D Modelling/Drafting Plans with Software

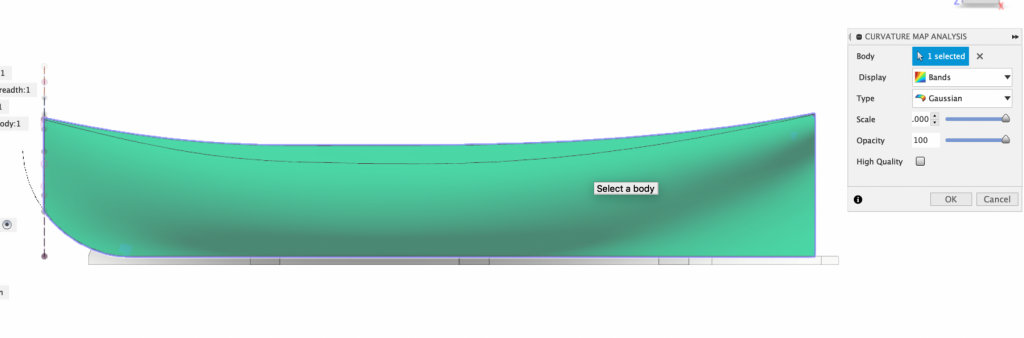

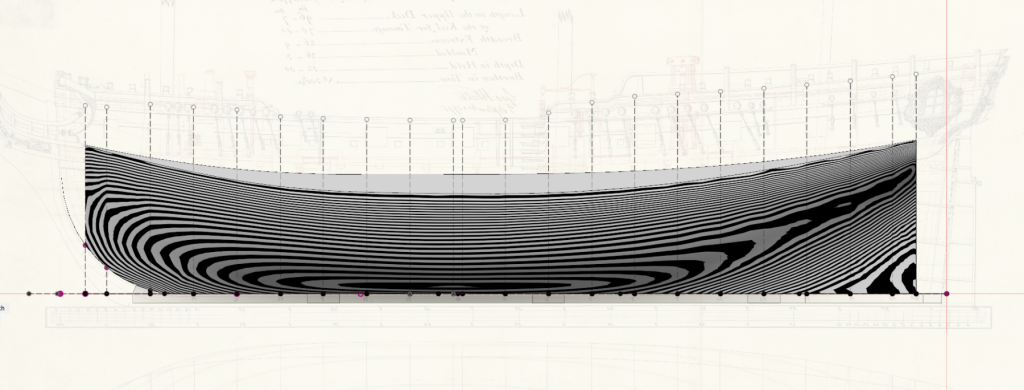

"a pile of patches" was actually pretty accurate in that it was constructed with several tangent arcs. I had a similar experience of feeling it was just not right -- and that a different technique was needed. Fusion 360 has curvature combs, draft analysis and curvature map analysis features. Here is a curvature map analysis I ran, I haven't been able to to see much except when using the min/max settings and cranking the max values way up. Hopefully this is a good thing (my prior hull showed more variance). The CVs close together are a byproduct of using a mathematical fitting technique. Fusion using fixed spacing for knot placement of curves. While I'm not NURBS expert from the match side, my understanding is that if you are using uniform knots then you would need two CVs close together for it to generate the curves. Now whether they should be split vertically like that, my guess is probably not. I did run the fitting routine several times and it tended to favor placing them like that. While i'm not totally satisfied with it, i'm trying to remind myself that I aught to start working on other areas and come back to it later. When I intersected a plane with the hull the pattern for a frame seemed to match up well against other resources I have so hopefully that's a positive side. -

Ben752 reacted to a post in a topic:

H.M.S. Atalanta - Drafting my own plans

Ben752 reacted to a post in a topic:

H.M.S. Atalanta - Drafting my own plans

-

H.M.S. Atalanta - Drafting my own plans

Ben752 replied to Ben752's topic in CAD and 3D Modelling/Drafting Plans with Software

That was my thinking! My own inability to be happy with moving the CVs (i'd never be happy enough) led to me searching for a different solution. I ended up using the Python library scipy as it has the relevant spline objects in scipy.interpolate and I used the differential evolution algorithm as the solver. -

H.M.S. Atalanta - Drafting my own plans

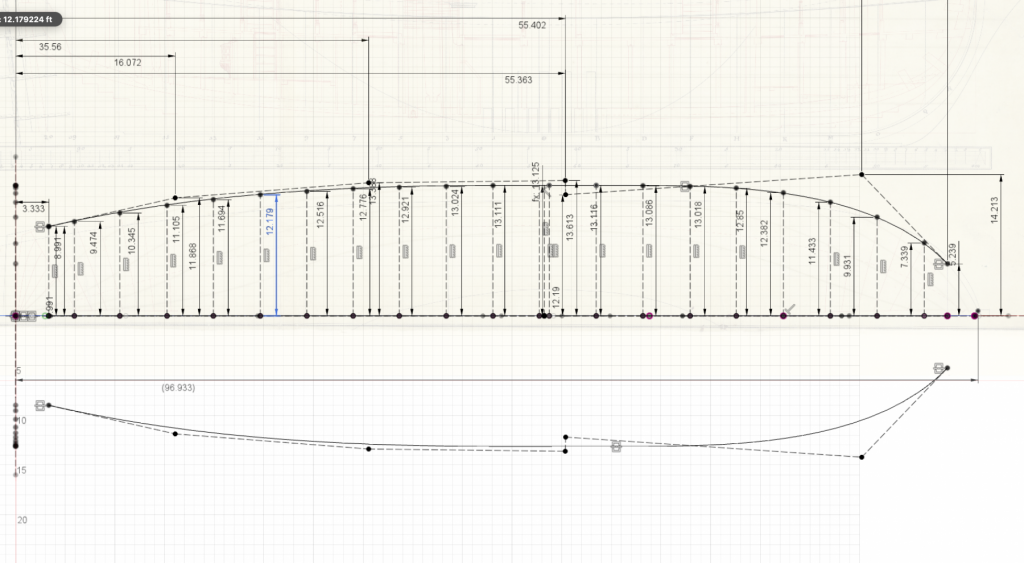

Ben752 replied to Ben752's topic in CAD and 3D Modelling/Drafting Plans with Software

That is correct. It took quite a few tries to figure out exactly how AutoDesk implemented the spline knots (they actually confirmed it in a support request in their forums). In the first screenshot above, I used measurements at each station line and it gave me the output of the 7 control vertices (with the first and last being the corresponding points I provided). -

H.M.S. Atalanta - Drafting my own plans

Ben752 replied to Ben752's topic in CAD and 3D Modelling/Drafting Plans with Software

Hi everyone, I wanted to give an update on my progress. Normal life stuff has been busy since the last post. My company was acquired, subsequent expansion of our office here in the U.K., met a nice English girl and more focus on my U.S. Brig Niagara. All sorts of great things. Anyways, enough about that. As I was progressing through later parts of drafting, I came to realize I wasn't really happy with how some of the lines were formed. Also, AutoDesk launched CV splines for Fusion 360! I ended up starting a starting over my 3d model to incorporate lessons learned about Fusion and feedback from ya'll. Also, I stopped straddling the fence on how much to use from the TFFM plans and the original drafts -- I've decided to go using the original references almost exclusively. In this second start, I've switched to the following techniques in fusion: Using CV splines for the body plan and striving to keep the same number of control vertices Defining key curves using CV splines that are fit using numerical optimization methods. This last part took some R&D (I work in technology and spend a bit of time doing data science/AI type solutions). Below is an example of what I've done relating to this. I started by taking measurements off the drafts and correlating them across plans. This yields points to fit, one challenging is that fitting CV Splines isn't a common practice. This is partly because they are parametric which to my knowledge doesn't have an analytical solution. What I did was use a genetic algorithm to solve for solutions that are very close using the points that match above. The result seems to be a more smoother fit that is much closer to real curve than I could manage moving points around. FWIW, there are a few naval architecture research papers that describe this technique. Below is an example of a breadth curve fit to the measurements. One interesting consequence of this is that it yields a fully constrained sketch in Fusion. It seems that splines also tend to work better when lofting. I think overall it's a much nicer fit than the previous technique I used. -

Ben752 reacted to a post in a topic:

H.M.S. Atalanta - Drafting my own plans

Ben752 reacted to a post in a topic:

H.M.S. Atalanta - Drafting my own plans

-

Opinions on Sherline DRO for Lathe

Ben752 replied to rtropp's topic in Modeling tools and Workshop Equipment

Does anyone happen to know the specs on the DC power supply for the DRO box? -

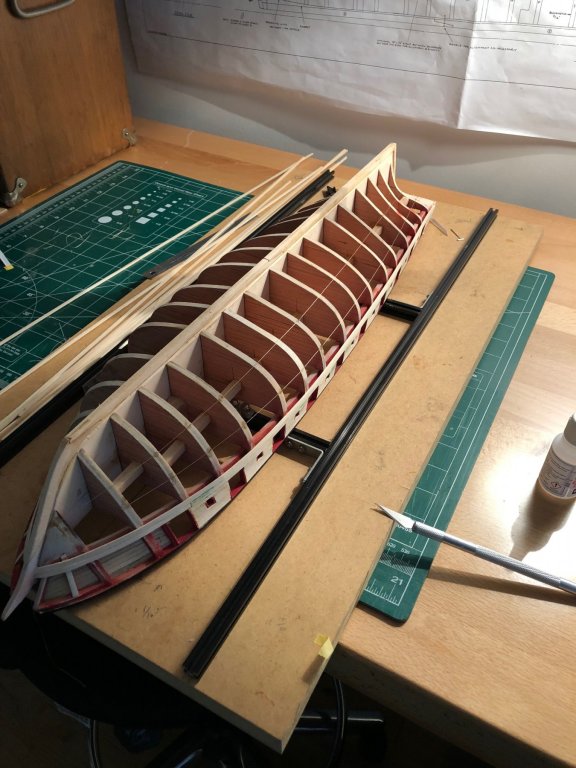

Finally the new model workshop setup after my move to Edinburgh, Scotland. There is a rather impressive hobby store called Wonderland Models just walking distance from my flat. I found this squadron green putty a good substitute for the bondo spot putty. I laid out the deck in a similar manner to xken, and used dark Titebond II along with some black grey to mimc the caulking. I then used my miniature veritas bench plane to remove the excess and borrowed a piece of glass from my furnished flat to create a flat surface to plane on. Later I ghosted the plank ends using a mechanism pencil, a compass to create a pattern to trim the deck. Last evening, I started laying out the plank belts using thread.

- 18 replies

-

- niagara

- model shipways

-

(and 1 more)

Tagged with:

-

Ben752 reacted to a post in a topic:

HMS Bellerophon 1786 by AON – scale 1:64 – 74 gun 3rd Rate Man of War, Arrogant Class

Ben752 reacted to a post in a topic:

HMS Bellerophon 1786 by AON – scale 1:64 – 74 gun 3rd Rate Man of War, Arrogant Class

-

Steel files vs. diamond files

Ben752 replied to Moab's topic in Modeling tools and Workshop Equipment

Steel files are the way to go, diamond impregnated ones seem to cut too fine for wood. After buying cheap ones and then later purchasing some Vallorbe needle files (I think Grobet USA is the same company), I can say it’s one of the best purchases I’ve made. https://contenti.com/jewelers-metal-files http://www.ottofrei.com/jewelry-tools-equipment/bench-tools/files If you want to hog lots of wood, woodcraft has some great needle rasps. -

Charlie1805 started following Ben752

-

H.M.S. Atalanta - Drafting my own plans

Ben752 replied to Ben752's topic in CAD and 3D Modelling/Drafting Plans with Software

Turns out they just launched CV splines (control vertices), https://www.autodesk.com/products/fusion-360/blog/july-26-2018-product-update-whats-new/ -

H.M.S. Atalanta - Drafting my own plans

Ben752 replied to Ben752's topic in CAD and 3D Modelling/Drafting Plans with Software

One of the limitations of fusion is that the spline support is far from great compared to others out there. They should be launching proper CV curves within the next year or so. They have recently published a post showing some of the upcoming capability, which should put them more inline with that of solidworks. -

Ben752 reacted to a post in a topic:

H.M.S. Atalanta - Drafting my own plans

Ben752 reacted to a post in a topic:

H.M.S. Atalanta - Drafting my own plans

-

H.M.S. Atalanta - Drafting my own plans

Ben752 replied to Ben752's topic in CAD and 3D Modelling/Drafting Plans with Software

This is great info. I've was going back and forth of using two different radii on this. Seeing this confirms it's possible that might be the case. -

H.M.S. Atalanta - Drafting my own plans

Ben752 replied to Ben752's topic in CAD and 3D Modelling/Drafting Plans with Software

Thank you druxey. I revisited the the sternpost and found that the roughly matching the rate of concave curvature inward on the the half breadth plan suggests the head would be approximately where you said it should be. Reconciling the different plans and sources certainly adds a wrinkle to selecting the right path when they don't appear to agree!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.