-

Posts

431 -

Joined

-

Last visited

About rshousha

- Birthday 05/21/1959

Contact Methods

-

Website URL

http://www.modellers-workshop.com

-

Skype

rick.shousha

Profile Information

-

Gender

Male

-

Location

Montreal, Canada

-

Interests

3D CAD drawings, helping people choose the right model and tools.

-

Scottish Guy reacted to a post in a topic:

For Beginners -- A Cautionary Tale

Scottish Guy reacted to a post in a topic:

For Beginners -- A Cautionary Tale

-

Rik Thistle reacted to a post in a topic:

Value-for-Money Airbrush

Rik Thistle reacted to a post in a topic:

Value-for-Money Airbrush

-

Keith Black reacted to a post in a topic:

Cutty Sark by Richard Dunn - 1/40 scale - scratch built semi-kit prototype

Keith Black reacted to a post in a topic:

Cutty Sark by Richard Dunn - 1/40 scale - scratch built semi-kit prototype

-

72Nova reacted to a post in a topic:

Sovereign of the Seas by 72Nova - Airfix - PLASTIC

72Nova reacted to a post in a topic:

Sovereign of the Seas by 72Nova - Airfix - PLASTIC

-

rshousha reacted to a post in a topic:

HMS Indefatigable 1794 by Kevin - Vanguard Models - 1:64 - Feb 2023

rshousha reacted to a post in a topic:

HMS Indefatigable 1794 by Kevin - Vanguard Models - 1:64 - Feb 2023

-

rshousha reacted to a post in a topic:

Cutty Sark by Richard Dunn - 1/40 scale - scratch built semi-kit prototype

rshousha reacted to a post in a topic:

Cutty Sark by Richard Dunn - 1/40 scale - scratch built semi-kit prototype

-

druxey reacted to a post in a topic:

Cutty Sark by Richard Dunn - 1/40 scale - scratch built semi-kit prototype

druxey reacted to a post in a topic:

Cutty Sark by Richard Dunn - 1/40 scale - scratch built semi-kit prototype

-

rshousha reacted to a post in a topic:

Cutty Sark by Richard Dunn - 1/40 scale - scratch built semi-kit prototype

rshousha reacted to a post in a topic:

Cutty Sark by Richard Dunn - 1/40 scale - scratch built semi-kit prototype

-

mtaylor reacted to a post in a topic:

Cutty Sark by Richard Dunn - 1/40 scale - scratch built semi-kit prototype

mtaylor reacted to a post in a topic:

Cutty Sark by Richard Dunn - 1/40 scale - scratch built semi-kit prototype

-

mtaylor reacted to a post in a topic:

Cutty Sark by Richard Dunn - 1/40 scale - scratch built semi-kit prototype

mtaylor reacted to a post in a topic:

Cutty Sark by Richard Dunn - 1/40 scale - scratch built semi-kit prototype

-

mtaylor reacted to a post in a topic:

Cutty Sark by Richard Dunn - 1/40 scale - scratch built semi-kit prototype

mtaylor reacted to a post in a topic:

Cutty Sark by Richard Dunn - 1/40 scale - scratch built semi-kit prototype

-

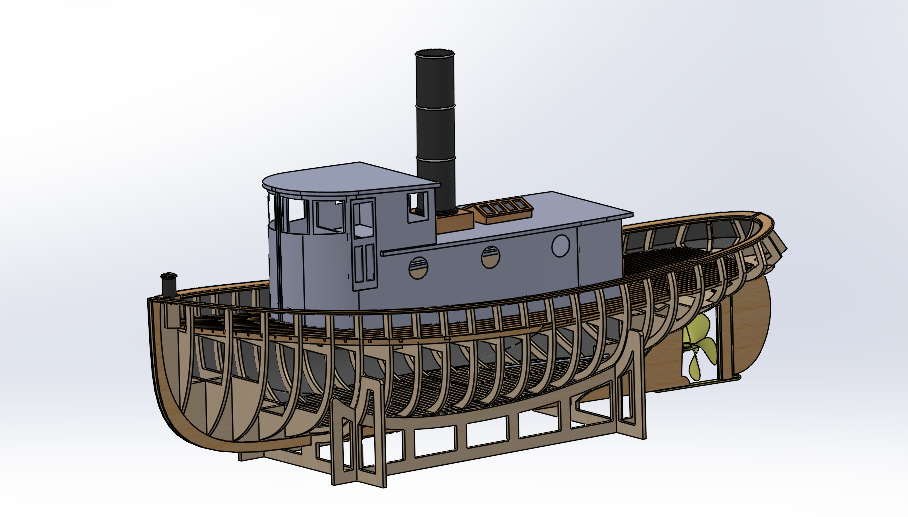

Wow, that's amazing. I just bought a Rhino license, but I have asked a fellow in Ontario to make the organic shapes for me. He's very good and I am sure he can use the features you are mentioning. I will have to talk to him about it. I use Solidworks and I am a bit tired of the $2000 USD annual maintenance fee. The software is really good but I don't use it enough to warrant the cost. I may buy the license for 2025, but that will be my last one. For now, I use a combination of Rhino, to create the organic shapes, and SW, to create all the internal parts, and make the 2D drawings. I suspect, from looking at your work, that Rhino can deal with the work just as well as Solidworks, for a quarter of the cost.

-

I am looking forward to seeing the fit of the deck. I use pretty good software and can't make my deck conform to curves front-to-back as well as side-to-side. I use sheet metal fabrication to make the curved surfaces and those can only be "flattened" the way they would be with real steel. I do not have "stamping" software that is found in the high-end CAD solutions like Catia. It looks like you have some real experience with CAD.

-

rshousha reacted to a post in a topic:

Cutty Sark by Richard Dunn - 1/40 scale - scratch built semi-kit prototype

rshousha reacted to a post in a topic:

Cutty Sark by Richard Dunn - 1/40 scale - scratch built semi-kit prototype

-

Nice-looking parts! Going back to the laser-vs-CNC question, these parts look so much more "finished" than anything that could come off a laser. It just takes a tiny bit of cleaning and the parts are pristine. The inside corners of the windows might not be square, like what you come out of a laser, but that is easily rectified with a quick pass of a file. And any work that you do with a file is directly related to cleaning or adjusting the part. It is not related to simply getting the char off in order to get glue to work well.

-

rshousha reacted to a post in a topic:

Le Gros Ventre by marsalv - FINISHED - 1:48 - POF

rshousha reacted to a post in a topic:

Le Gros Ventre by marsalv - FINISHED - 1:48 - POF

-

rshousha reacted to a post in a topic:

Cutty Sark by Richard Dunn - 1/40 scale - scratch built semi-kit prototype

rshousha reacted to a post in a topic:

Cutty Sark by Richard Dunn - 1/40 scale - scratch built semi-kit prototype

-

My company builds frame sets for large-scale R/C boats. We have been making frame sets since 2015 and have always used a laser. When I visited my supplier, Jotika, a couple of years ago, I spent a few hours with John Wright, the owner, and he really opened my eyes about the difference between a laser and a CNC cutter. There is no doubt, for many reasons, that the CNC does a much better job. First, the precision is much higher with the CNC machine. As long as you measure your drill bit and your material, you can get more precision that with the laser. Even you account for the kerf on the laser, and you measure your material, you still have a char on the laser-cut parts. That char needs to be removed or the glue doesn't penetrate the material. Second, you can make pockets with a CNC. For example, you can make parts fit without passing all the way through. Also, with pockets, you can do things like "engrave" windows in the stern panels of models. In your case, you might find that quite interesting for your model. That cannot be done with a laser-cutter. I spent about a year using a full-size CNC machine at a furniture-maker, designing furniture, and then actually using the machine and making the prototypes myself. It was great fun and taught me a lot about woodworking. So, as soon as I can find someone around here that has a decent CNC machine, I will start designing for that. I suspect the price of my frame sets will go up slightly but, when people are paying many thousands of dollars to build a big R/C model, I think they will appreciate the improvement in quality. (By the way, I am planning on building the Cutty Sark myself, in 1/48 but, hey, your model might be even more fun to do!) In brackets because I do not want to market a kit in 1/40 scale. It just isn't part of the large scales that I use. Best Regards, Rick

-

rshousha reacted to a post in a topic:

HMS Victory by Marinus - Caldercraft - 1/72

rshousha reacted to a post in a topic:

HMS Victory by Marinus - Caldercraft - 1/72

-

rshousha reacted to a post in a topic:

HMS Royal William by KeithW - Euromodel - 1/72

rshousha reacted to a post in a topic:

HMS Royal William by KeithW - Euromodel - 1/72

-

rshousha reacted to a post in a topic:

Corsaro II by mtdoramike - FINISHED - Corel

rshousha reacted to a post in a topic:

Corsaro II by mtdoramike - FINISHED - Corel

-

I painted the hull, as well, and ended up using that thin mahogany for a zillion other models. For example, it worked beautifully as the outside surface of a large model of a stagecoach.

- 42 replies

-

- Corsaro II

- Corel

-

(and 1 more)

Tagged with:

-

rshousha reacted to a post in a topic:

Corsaro II by mtdoramike - FINISHED - Corel

rshousha reacted to a post in a topic:

Corsaro II by mtdoramike - FINISHED - Corel

-

Where were all these extra spars stored? That's another forest they had to carry.

-

Nicely done! I like the little seat cushions. They look quite comfy. Regards, Rick

- 84 replies

-

- Corsaro II

- Corel

-

(and 1 more)

Tagged with:

-

Hi Snug Harbor Johnny, You make an interesting point about the lack of carvings, etc. I see what you mean. Still, I doubt the company expected to sell many of those kits so the price may have been a little higher than you mention because of that but I am sure your price estimate is pretty close. I had no idea you were so interested in this period. This model will surely be a prized display among your friends! I am looking forward to seeing the construction develop. Cheers, Rick

-

Hello All! So Johnny Snug Harbour has decided to buy the Henri Grace-a-Dieu kit I had in stock. Actually, it's a good thing he bought it because it really is the most amazing kit I have ever seen, with almost 200 cannons and zillions and zillions of small parts. I had decided to keep for myself. I just love those period ships and there are very few kits out there. So, Bounty is still for sale.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.