-

Posts

178 -

Joined

-

Last visited

About Johnnyreg

- Birthday 06/10/1952

Profile Information

-

Gender

Male

-

Location

Harrogate, North Yorkshire, UK

-

Interests

Walking, Fishing, Photography, Model making, growing stuff from seed

Recent Profile Visitors

-

EricWilliamMarshall reacted to a post in a topic:

Black wire for eye bolts/rings

EricWilliamMarshall reacted to a post in a topic:

Black wire for eye bolts/rings

-

EricWilliamMarshall reacted to a post in a topic:

Black wire for eye bolts/rings

EricWilliamMarshall reacted to a post in a topic:

Black wire for eye bolts/rings

-

michael mott reacted to a post in a topic:

Black wire for eye bolts/rings

michael mott reacted to a post in a topic:

Black wire for eye bolts/rings

-

michael mott reacted to a post in a topic:

Black wire for eye bolts/rings

michael mott reacted to a post in a topic:

Black wire for eye bolts/rings

-

michael mott reacted to a post in a topic:

Black wire for eye bolts/rings

michael mott reacted to a post in a topic:

Black wire for eye bolts/rings

-

Johnnyreg reacted to a post in a topic:

HMS Fly by Dfell - FINISHED - Amati / Victory Models - Scale 1:64

Johnnyreg reacted to a post in a topic:

HMS Fly by Dfell - FINISHED - Amati / Victory Models - Scale 1:64

-

Thanks for the kind words Martin & BE. I’ve studied in detail both your amazing Fly/Pegasus builds which have been an inspiration for my Fly build so thank you. I have to to apologise for the slump in my progress but I assure you it’s only temporary. This is the summer home for my Fly 😭 We’ve had a cracking summer here in the UK and the Admiral and I can’t bear to be stuck inside. Normal service will be resumed when it get colder and wetter, which it will.

- 110 replies

-

Johnnyreg reacted to a post in a topic:

HMS Fly by Johnnyreg - Amati/Victory Models - Scale 1:64

Johnnyreg reacted to a post in a topic:

HMS Fly by Johnnyreg - Amati/Victory Models - Scale 1:64

-

Johnnyreg reacted to a post in a topic:

HMS Fly by Johnnyreg - Amati/Victory Models - Scale 1:64

Johnnyreg reacted to a post in a topic:

HMS Fly by Johnnyreg - Amati/Victory Models - Scale 1:64

-

Johnnyreg reacted to a post in a topic:

HMS Fly by Dfell - FINISHED - Amati / Victory Models - Scale 1:64

Johnnyreg reacted to a post in a topic:

HMS Fly by Dfell - FINISHED - Amati / Victory Models - Scale 1:64

-

Johnnyreg reacted to a post in a topic:

HMS Fly by Dfell - FINISHED - Amati / Victory Models - Scale 1:64

Johnnyreg reacted to a post in a topic:

HMS Fly by Dfell - FINISHED - Amati / Victory Models - Scale 1:64

-

Johnnyreg reacted to a post in a topic:

HM Brig Supply by Jobbie - Caldercraft - Scale 1:64

Johnnyreg reacted to a post in a topic:

HM Brig Supply by Jobbie - Caldercraft - Scale 1:64

-

Johnnyreg reacted to a post in a topic:

HM Brig Supply by Jobbie - Caldercraft - Scale 1:64

Johnnyreg reacted to a post in a topic:

HM Brig Supply by Jobbie - Caldercraft - Scale 1:64

-

Johnnyreg reacted to a post in a topic:

HM Brig Supply by Jobbie - Caldercraft - Scale 1:64

Johnnyreg reacted to a post in a topic:

HM Brig Supply by Jobbie - Caldercraft - Scale 1:64

-

Johnnyreg reacted to a post in a topic:

HM Brig Supply by Jobbie - Caldercraft - Scale 1:64

Johnnyreg reacted to a post in a topic:

HM Brig Supply by Jobbie - Caldercraft - Scale 1:64

-

Amazing progress Denis and looking good. Love the portholes and how you made them.

- 171 replies

-

- krabbenkutter

- authentic models

-

(and 1 more)

Tagged with:

-

That was funny Denis . We have a program over here called “You’ve been Framed” where you would have got £250 for the video of that. In future just keep the camera rolling just in case . Good work by the way.

- 171 replies

-

- krabbenkutter

- authentic models

-

(and 1 more)

Tagged with:

-

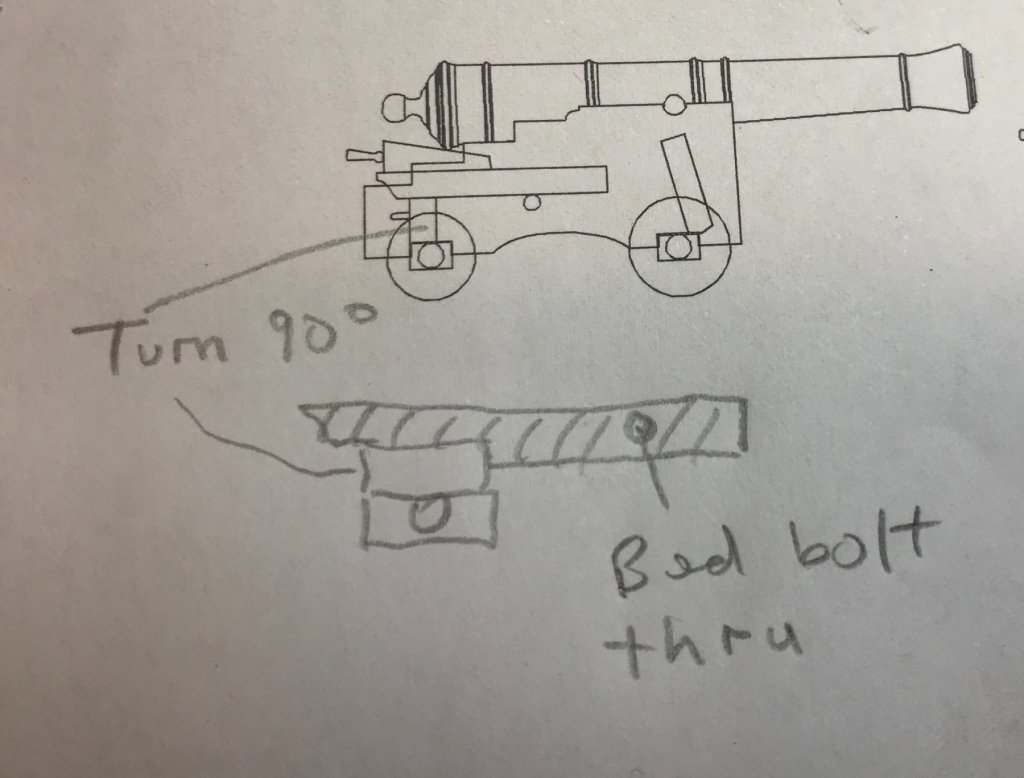

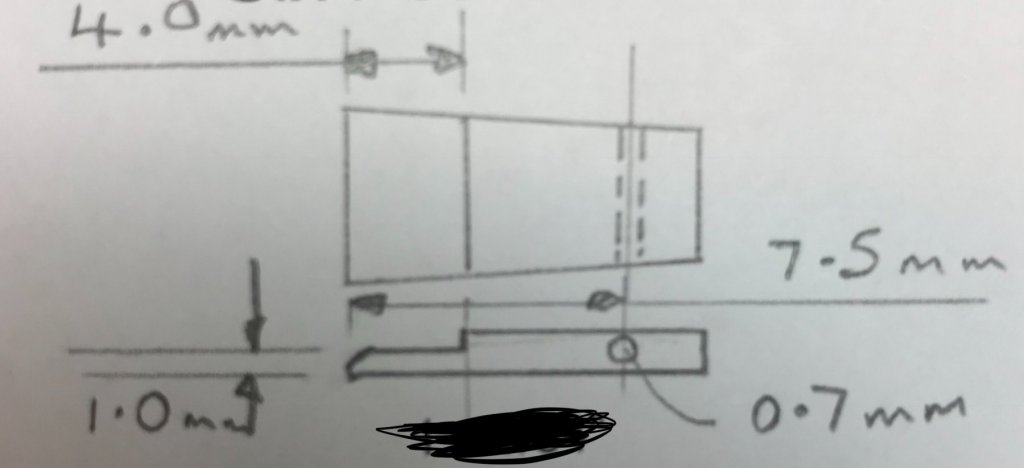

Thanks Jason & Denis for your good words. Jason - my approach to reduce the gun angle isn’t much different to what you did. This is what I ended up doing. * Turn the bolster through 90deg. Bolster was 2.2 high x 1.7mm wide so after turning 90 deg becomes 1.7 high x 2.2 wide. This drops things down by 0.5mm * At the end of the stool bed that sits on the bolster, reduce the thickness from 1.7mm to 1.0mm. This drops things down by a further 0.7mm * Because the top surface of the stool bed is now 1.2mm lower it can no longer sit on top of the bed bolt so I drilled a 0.7mm hole through the centre of the stool bed. Hopefully these pictures will explain Stool bed mods Denis - looking at real life cannons definitely helped me with getting the detail something like so my recent trip was very much worthwhile. I noticed you haven’t come up for air after your terrific Norden build and you’re straight into another one. I will be following with interest but please catch your breath first

- 110 replies

-

Thanks OC & SpyGlass for your kind words. Yes the thing that surprised me most about the Victory was how low the beams are. I’m not tall at 5’ 9” but managed to bang my head quite a few times (I’m now 5’ 11” with all the bumps on my head ). Lord Nelson was 5’ 4” so he would have been ok I think. I’m still doing a bit, mainly de-charring the laser cut gun carriage parts, scribing and drilling the brackets for the ironmongery. Very time consuming but I’m really enjoying this part of the build. Picture update soon when I have some visible progress to show.

- 110 replies

-

Black wire for eye bolts/rings

Johnnyreg replied to Johnnyreg's topic in Metal Work, Soldering and Metal Fittings

I was trying to be humorous but still handy to know for the future, thank you. -

Black wire for eye bolts/rings

Johnnyreg replied to Johnnyreg's topic in Metal Work, Soldering and Metal Fittings

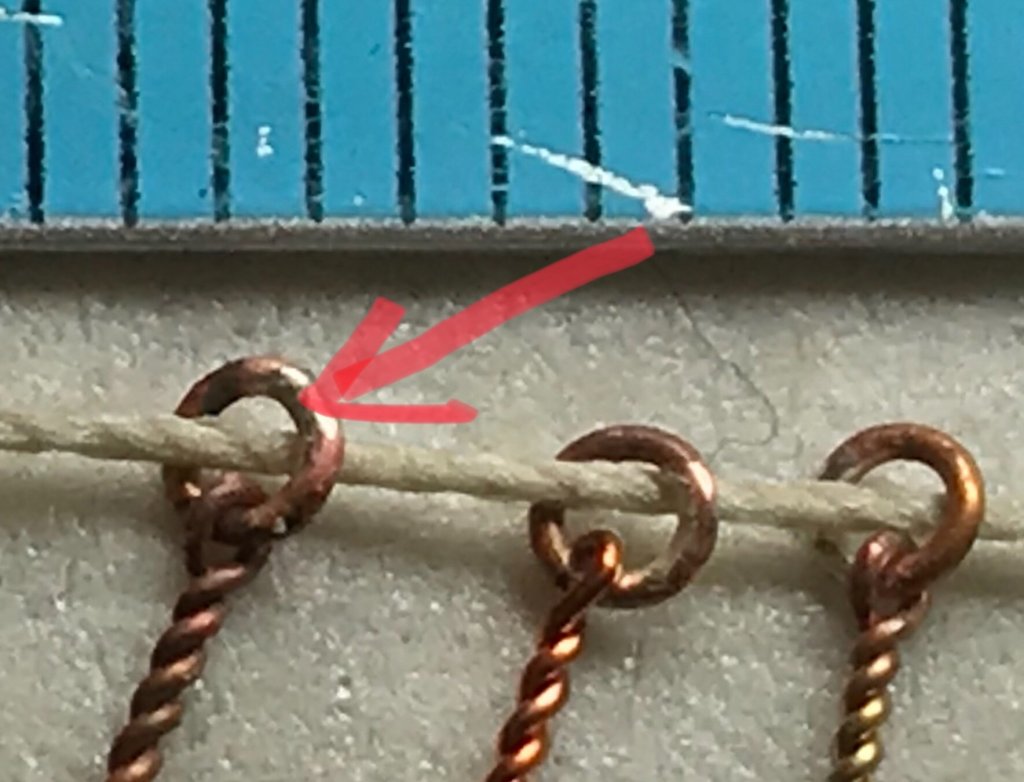

Thanks aviaamator. Neat looking eyes and rings. I’m using same method for creating rings but I’m committing to using bare copper now then blacked after. Thanks Greg. All good advice. I think your right about the silver soldering of the rings being a bit overkill but it’s a new skill I need to master so will do a few more that way until I get confident or bored, whichever happens sooner. Hmmm... where can I get some 2mm cannon balls Anyway thanks to all of you for your great comments. I’ve put it all into practice now and here is what I came up with. My Blackening routine was: 1 Clean in hot soapy water with an old toothbrush and rinse in water 2 Soak in White Vinegar for 10 minutes and rinse in water 3 Soak in neat Birchwood Casey Brass Black (BCBB) for about 30 secs and rinse in water 4 Clean any CA residue patches (not blacked) with Acetone 5 Polish with paper towel 6 repeat previous steps from 3 until satisfied (3 or 4 times I found for me) I didn’t get a true black finish but I’m reasonable happy with the dark grey that I got. Also I only handled the items with tweezers during the blacking process. Thanks all again. -

It’s been a while but as you know, if you’ve been following, we spent a week in Portsmouth which was very exciting, for me anyway. I learnt so much. If you get chance it’s well worth a visit and there is so much to see at the Historic Dockyard there, where we spent 3 days looking at all the attractions. We went on the HMS Victory twice and really got a feel of what it must have been like to sail and work on her back in the day. Elsewhere at the Dockyard, I particularly liked Boathouse 4 where you can have a guided tour and see experienced and student boat builders at work building new boats and restoring old ones. They nearly roped me in as a volunteer, which I was very tempted by as full training would have been given, but I live just 270 miles too far away. For anyone that’s interested in visiting take a look here http://www.historicdockyard.co.uk/index.php Anyway back to my build… I’ve been concentrating my labours on building one gun and carriage set to determine height and also the method of building the others. I have been playing around with different ways of doing the gun tackle eyes and rings. I’ve tried with pre-blacked enamel coated copper wire and bare copper wire which was blacked afterwards and to cut a long story short (full story here), here are my findings. The breaching tackle eyes/loops & rings done to scale at 1:64 & (full size) would be * eye loops - 0.2 wire & 0.6mm hole (1/2” & 1-1/2”) * breeching ring - 0.35 wire & 1.2mm hole (7/8” & 3”) * breaching rope - 0.5mm (1-1/4”) Here are my attempts at the Breeching rings in both black Jewellery wire and Bare Copper. The divisions are mm by the way. Everything is almost to scale but I have made changes as shown below. I rounded the 0.35mm up to 0.4mm because that’s all I have and the 0.2mm up to 0.3mm because I found the 0.2 wire too thin and a pig to work with. * eye loops - 0.2 0.3 wire & 0.6mm hole (1/2” & 1-1/2”) * breeching ring - 0.35 0.4 wire & 1.2mm hole (7/8” & 3”) * breaching rope - 0.5mm (1-1/4”) Here is the almost finished gun and carriage set Note the scribed line to simulate the two halves of the side piece (bracket) Note the GR/Crown monogram super glued onto the gun Just in case you think it’s a full size canon I’ve photographed (it could be a really MASSIVE pencil though ) Just to recap what we have here: * Carriage is from Chuck/Syren * Gun is 32mm from RB Models * Eyes/loops are twisted bare copper (blacked) - 0.3 wire & 0.6mm hole * Breeching rings are silver soldered bare copper (blacked) - 0.4 wire & 1.2mm hole * Carriage bolts (6 vertical bracket bolts, Bed bolt and Transom bolt) blacked brass - 0.7mm * GR/Crown monograms are etched brass parts supplied in the Fly Upgrade set (curved to match curve of gun) My Blackening routine was: 1 Clean in hot soapy water with an old toothbrush and rinse in water 2 Soak in White Vinegar for 10 minutes and rinse in water 3 Soak in neat Birchwood Casey Brass Black (BCBB) for about 30 secs and rinse in water 4 Clean any CA residue patches (not blacked) with Acetone 5 Polish with paper towel 6 repeat previous steps from 3 until satisfied (3 or 4 times I found for me) I didn’t get a true black finish but I’m reasonable happy with the dark grey that I got. The gun tackle eyes/loops were inset into the Brackets by creating a horizontal groove across the hole with the help of this screwdriver I modified Work still to do on this one are the Truck keys and the cap squares and bolts and then it’s only another 15 to do

- 110 replies

-

Your too kind. Not sure I want the competition though . Seriously though I would be honoured and thank you for giving me loads of ideas to shamelessly nick on my next fishing boat build.

- 378 replies

-

- t78 norden

- billing boats

-

(and 1 more)

Tagged with:

-

Excellent job Denis. Lots of innovation and detail. A model to be proud of.

- 378 replies

-

- t78 norden

- billing boats

-

(and 1 more)

Tagged with:

-

Black wire for eye bolts/rings

Johnnyreg replied to Johnnyreg's topic in Metal Work, Soldering and Metal Fittings

Thanks again. All much needed good advice. -

Black wire for eye bolts/rings

Johnnyreg replied to Johnnyreg's topic in Metal Work, Soldering and Metal Fittings

Thanks Steve. Interesting, I’ll see how easy it is to blacken when the darn solution arrives. Seller say I should have had it by now so is re-sending. If it’s a pain to do I may reach the same conclusion and decide silver soldering the rings are a bit overkill too. We are going away on Sunday for 5 days to Portsmouth to see HMS Victory so I won’t get chance to do any blackening. Hopefully the solution will be waiting for me when I get back -

Black wire for eye bolts/rings

Johnnyreg replied to Johnnyreg's topic in Metal Work, Soldering and Metal Fittings

Thanks Steve. Just to clarify I’m not silver soldering the eyes but I am silver soldering the Breeching ring ends to close the ring after threading through the eye. I wrongly or rightly assumed every one did this. What do others do? -

Black wire for eye bolts/rings

Johnnyreg replied to Johnnyreg's topic in Metal Work, Soldering and Metal Fittings

Hi Dave. Thanks for your tips. I’ve committed to Birchwood Casey Brass Black now (as recommended by Hornet) so will have to experiment with that. Not sure if you can brush this on locally. Still waiting for delivery but it’s 2 days late now so will have to chase the seller. Yes Betty’s tearoom is still there. We don’t go in often as there is usually a queue full of tourists from Switzerland . They do nice biscuits too which come in nice handy tins.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.