-

Posts

54 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by geoffs

-

Have a look at Inkscape. It has functions to convert from bitmaps/images to vectors. It's open source software and well supported

-

Returning overseas travellers can bring in goods to the value of $A900, tax and duty free. The limit is increased to $A2700 for a family travelling together. This normally deals with alcohol, tobacco, cameras, laptops and the like but there's nothing to exclude the odd machine tool 🙂

-

Fiskars Fingertip Detail Knives

geoffs replied to Richmond's topic in Modeling tools and Workshop Equipment

Spotlight do carry these knives but not the swivel ones. https://www.spotlightstores.com/embellishments/embossing/fiskars-fingertip-precision-knife/BP80096455 -

micro drill adapter for mill

geoffs replied to michael mott's topic in Modeling tools and Workshop Equipment

Wish I still had my mill for stuff like this 😞 The minimum speed of these types of tools is usually around 5000RPM. Do you find that too fast for some work? -

You've done a beautiful job on that build, well done. I like the tammie norrie design (or Grebe as it used to be). I'm a member of the Living Boat Trust here in Tasmania and we have 6 grebes, all built by local school students under supervision of a boat builder from the LBT. These boats get a lot of use and we always have one or two out of the water for a clean/repaint.

-

Tools, tools and more tools....

geoffs replied to CPDDET's topic in Modeling tools and Workshop Equipment

Still looking at the Marathon micromotor as my next rotary tool and have a couple of questions: What method is used to hold the bits? collet or chuck? What diameter shaft is used for bits? -

My top 4 most useful tools

geoffs replied to Tim Moore's topic in Modeling tools and Workshop Equipment

At the moment, I'd have to include BandAids in my top 4! Every time I pick up a knife, I manage to cut myself 😞 -

Tools, tools and more tools....

geoffs replied to CPDDET's topic in Modeling tools and Workshop Equipment

Thanks for the link! I'm probably in the market for a new Dremel and even with shipping to Oz, the Marathon micromotor is cheaper than I can get a Dremel 4000 here. Wonder if they fit the Vanda-Lay mill ... -

Hobby/micro drill press suggestions

geoffs replied to bigcreekdad's topic in Modeling tools and Workshop Equipment

Just placed an order for: ACRA mill with fine Z adjust and drill press option, lathe and a vice (hope I included that last item) I might fo go for the router table for my birthday next year... I was looking at Taig/Sherline mills but more that I really need (or can afford!) right now. Merry Christmas to me! -

Hobby/micro drill press suggestions

geoffs replied to bigcreekdad's topic in Modeling tools and Workshop Equipment

Well Larry from Vanda Lay just got back to me with a shipping quote that was less than expected. Looks like I'll be placing an order soon for an early Christmas present 🙂 -

Hobby/micro drill press suggestions

geoffs replied to bigcreekdad's topic in Modeling tools and Workshop Equipment

I have a good range of the Dremel add-ons but like the look of the Vanda Lay products. Budget will just cover an Acra Mill providing the requested freight quote isn't too high, one of the problems with living in Australia 🙂 -

Agree completely with Jim. Looking at the construction, it would not be rigid enough to do CNC milling/routing. Until I downsized, I had an X-Carve which would be a much better CNC option. A 3D printer would be rigid enough for laser engraving but not without an enclosure - lasers are dangerous! Regards Geoff

-

I can provide a scan of the instructions today but the plans will take a week or so. I have to go into town to get some previously scanned plans (Charles W Morgan) printed and I can get the two page plan scanned at the same time. Regards Geoff EDIT: Instruction PDF sent.

-

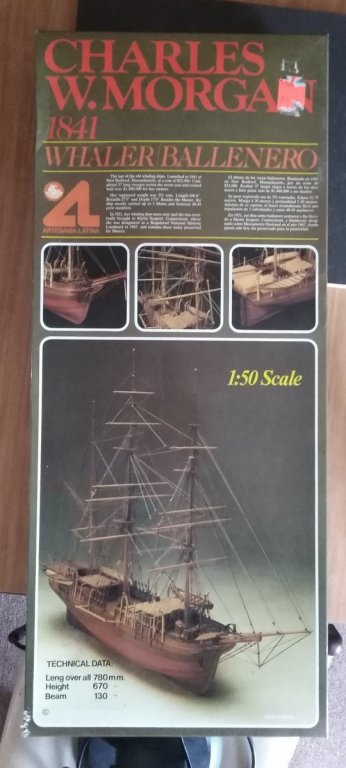

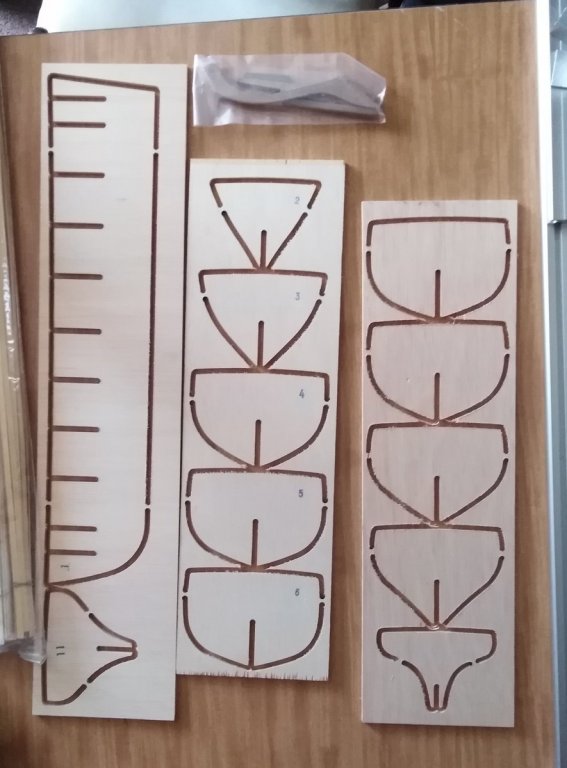

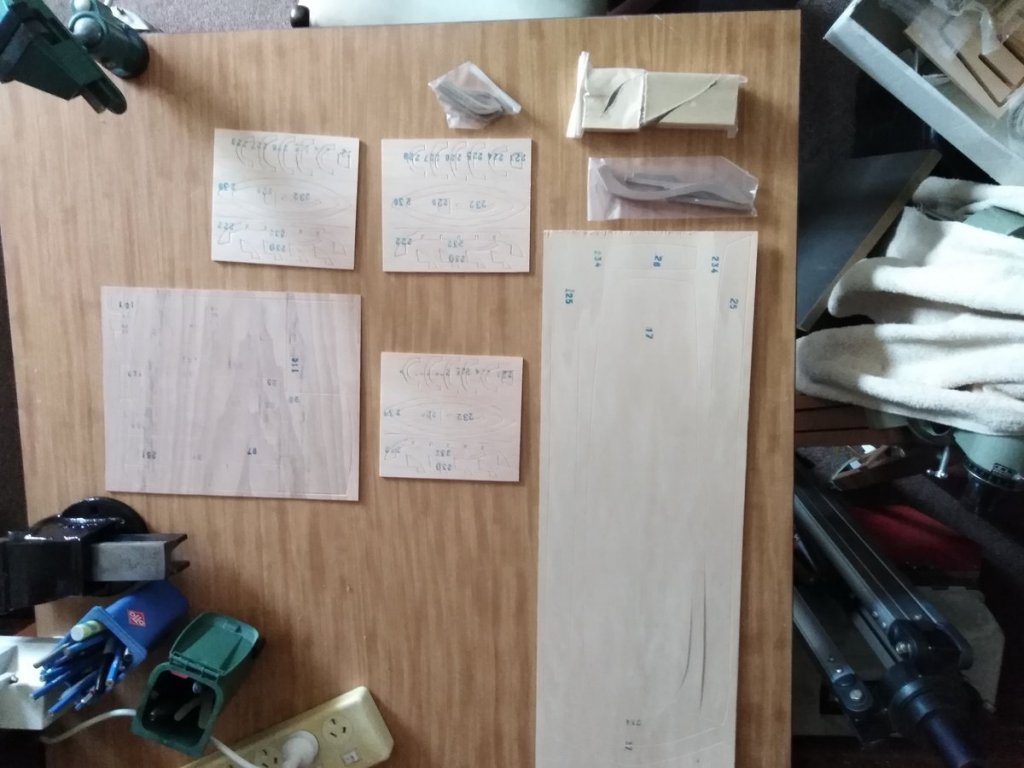

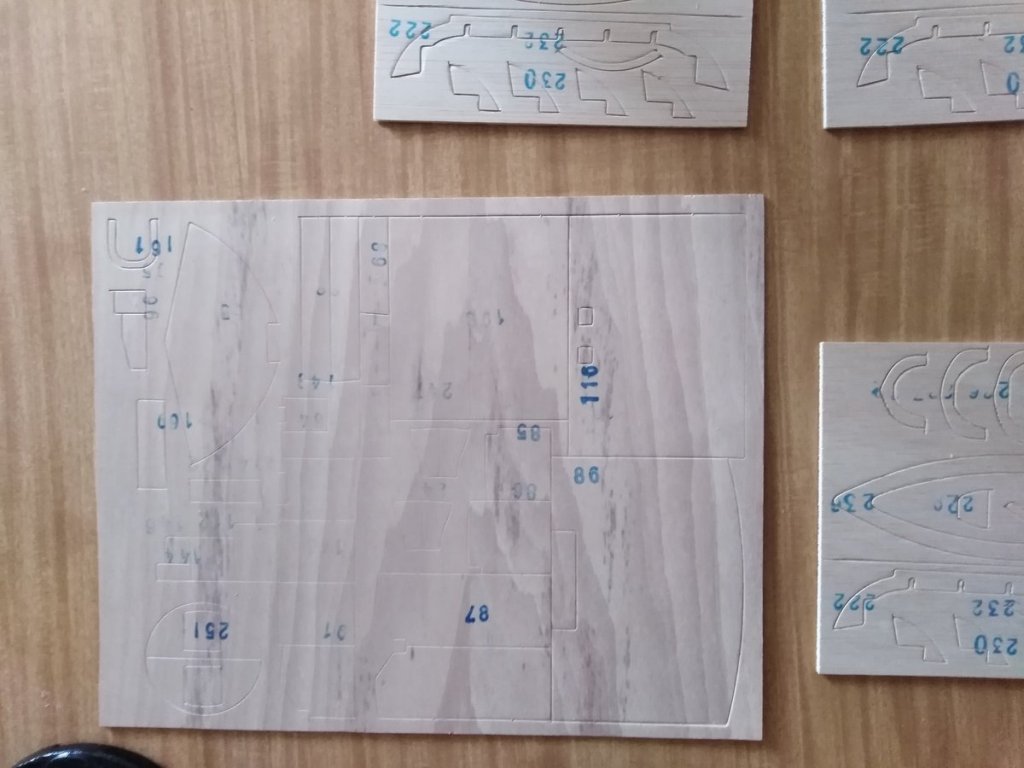

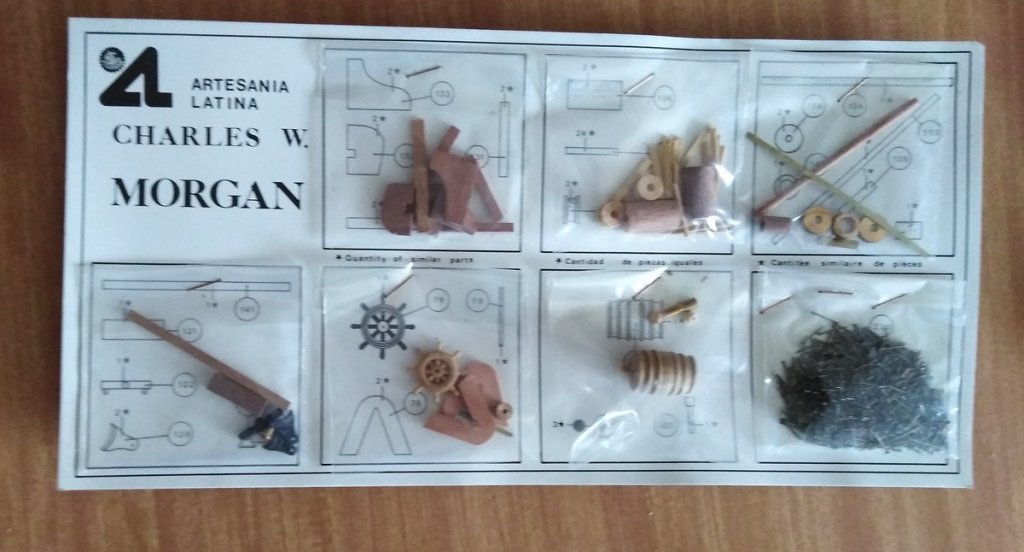

Well I'm settled enough in my new place to get started on a build. I'll call this my first build as any experience I have had, was a long. long time ago. Model is about 35 years old (guesstimate) of the Charles W Morgan my Artesania Latina. This model was donated a couple of years ago to the Living Boat Trust, I group of which I'm a member. The LBT maintain and occasionally build, wooden boats in Franklin, Tasmania. Bulkheads are router cut. Not sure if this would have been CNC given the age of the model. DIe cut parts, no lasers here! Lots of little plastic bags. I've got some partitioned containers to put these in. I think I have the necessary tools assemled. I just need to make up a board on which to build it and maybe a keel clamp - I have some aluminium extrusion and 3D printed clamps for that. Don't pull up a chair just yet, this could take a while! Regards Geoff

- 6 replies

-

- charles w morgan

- artesania latina

-

(and 1 more)

Tagged with:

-

Tools, supplies and workstation......

geoffs replied to CPDDET's topic in Modeling tools and Workshop Equipment

As someone also new to the hobby, this is all great advice. Even though I recently downsized and got rid of all the big tools, I've found the basic hand tools I did keep, are a good start for building. I've also managed to pick up some useful tools quite cheaply from a veterinary supply house that listed on eBay. Such things as hemostats, tweezers pliers and scissors. Still waiting a chance to get the plans copied before I get started on the first build. The fallout from the downsizing is still happening. Regards Geoff -

Minwax stains in Australia

geoffs replied to vossy's topic in Painting, finishing and weathering products and techniques

Have you tried amazon.com.au? They list some Minwax products as being available, at least they let me add them to my cart without complaining about my Tassie address. Geoff -

Following with interest.Hope to get lots of pointers for when I start my own build of the Charles W Morgan (Artesania )

- 145 replies

-

- model shipways

- charles w. morgan

-

(and 1 more)

Tagged with:

-

internal framing

geoffs replied to rth385's topic in Building, Framing, Planking and plating a ships hull and deck

I've been following Leo on his quest since he started, great channel. Another one I follow is about boat building from scratch i.e felling and milling the timber, is Acorn to Arabella. A pair of complete but very capable behinners. -

Privet is one thing I would not have thought of! As you say, it is a weed here and can get quite big. I also have access to cheesewood (Pittosporum) which migh be an option. I live in the main apple growing region of Australia so apple, pear and any other suitable fruit tree is readily available, tress are always being removed - and burned. What I need to do is to read up on how to mill thin timber. I volunteer at a local wooden boat group so have access to most tools I'll need if not the expertise - 2mm think planks are not a lot of use on a full size boat! Regards Geoff

- 28 replies

-

- construction

- models

-

(and 3 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.