Warnerade

Members-

Posts

175 -

Joined

-

Last visited

About Warnerade

- Birthday April 27

Profile Information

-

Gender

Male

-

Location

Royal Oak, MI

Recent Profile Visitors

-

yvesvidal reacted to a post in a topic:

King of the Mississippi by Warnerade - Artesania Latina - 1:80

yvesvidal reacted to a post in a topic:

King of the Mississippi by Warnerade - Artesania Latina - 1:80

-

yvesvidal reacted to a post in a topic:

King of the Mississippi by Warnerade - Artesania Latina - 1:80

yvesvidal reacted to a post in a topic:

King of the Mississippi by Warnerade - Artesania Latina - 1:80

-

yvesvidal reacted to a post in a topic:

King of the Mississippi by Warnerade - Artesania Latina - 1:80

yvesvidal reacted to a post in a topic:

King of the Mississippi by Warnerade - Artesania Latina - 1:80

-

Knocklouder reacted to a post in a topic:

King of the Mississippi by Warnerade - Artesania Latina - 1:80

Knocklouder reacted to a post in a topic:

King of the Mississippi by Warnerade - Artesania Latina - 1:80

-

Bob Fraser reacted to a post in a topic:

King of the Mississippi by Warnerade - Artesania Latina - 1:80

Bob Fraser reacted to a post in a topic:

King of the Mississippi by Warnerade - Artesania Latina - 1:80

-

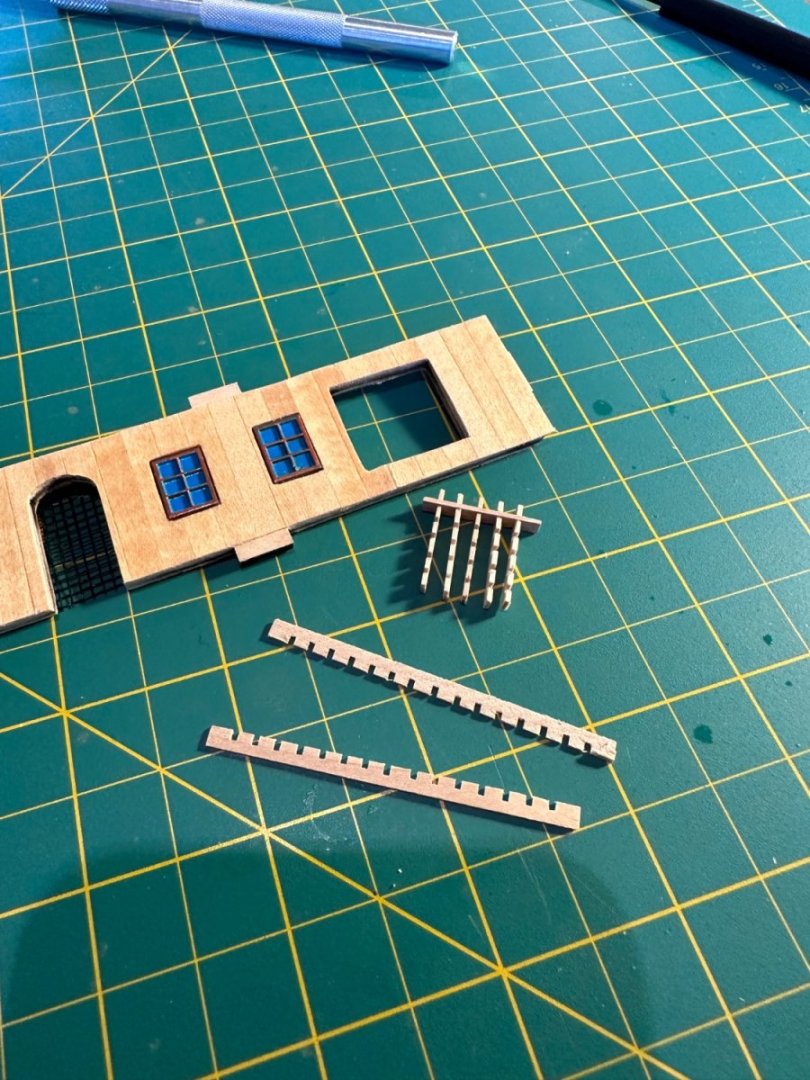

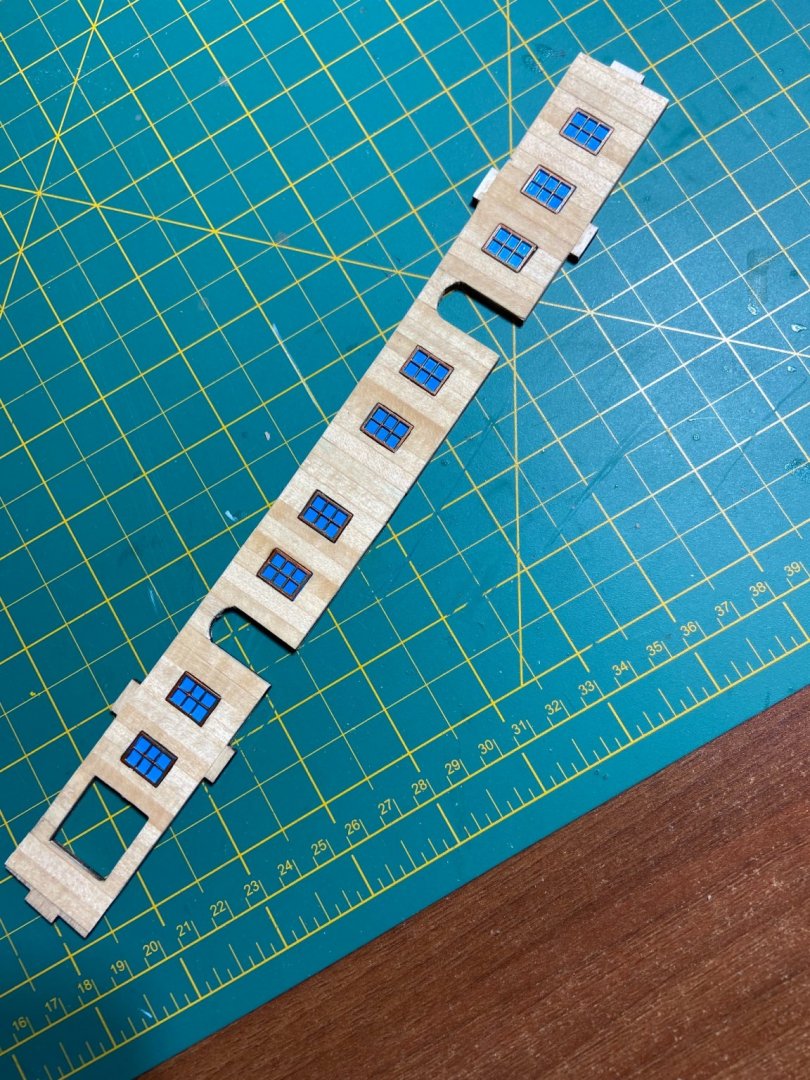

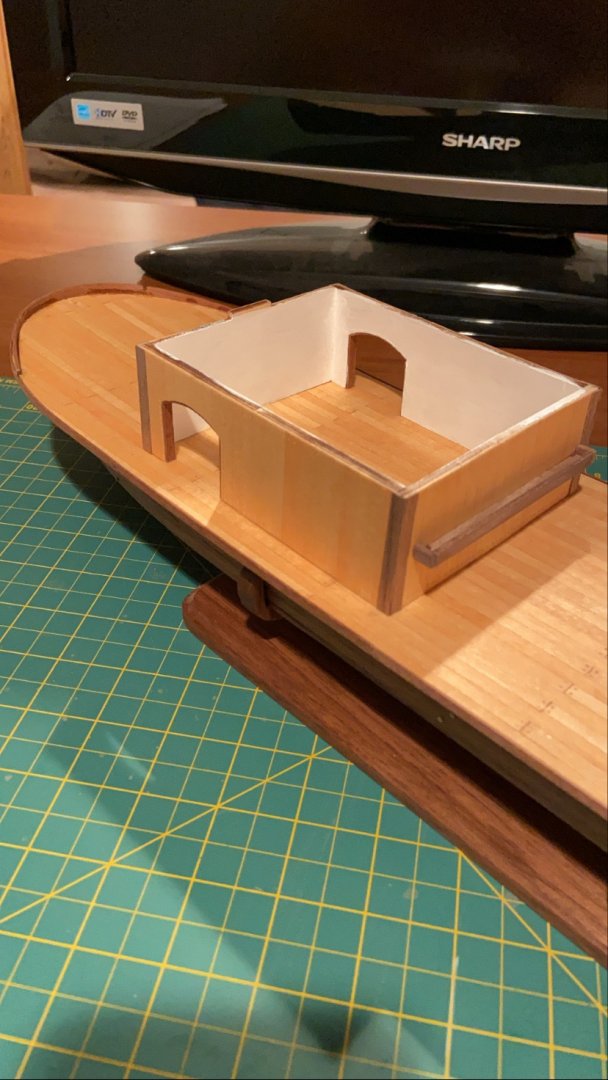

Putting the finishing touches on the walls for the second level. The cutouts for the doors were actually a little too large for the door provided (maybe 1/32” or so) so I ended up cutting some screen from a window to place behind the doors for a little more structural support with the glue and also to fill in the small gap on both sides of the door.

-

bobandlucy reacted to a post in a topic:

King of the Mississippi by Warnerade - Artesania Latina - 1:80

bobandlucy reacted to a post in a topic:

King of the Mississippi by Warnerade - Artesania Latina - 1:80

-

Cathead reacted to a post in a topic:

King of the Mississippi by Warnerade - Artesania Latina - 1:80

Cathead reacted to a post in a topic:

King of the Mississippi by Warnerade - Artesania Latina - 1:80

-

Bob Fraser reacted to a post in a topic:

King of the Mississippi by Warnerade - Artesania Latina - 1:80

Bob Fraser reacted to a post in a topic:

King of the Mississippi by Warnerade - Artesania Latina - 1:80

-

Prowler901 reacted to a post in a topic:

King of the Mississippi by Warnerade - Artesania Latina - 1:80

Prowler901 reacted to a post in a topic:

King of the Mississippi by Warnerade - Artesania Latina - 1:80

-

BobG reacted to a post in a topic:

King of the Mississippi by Warnerade - Artesania Latina - 1:80

BobG reacted to a post in a topic:

King of the Mississippi by Warnerade - Artesania Latina - 1:80

-

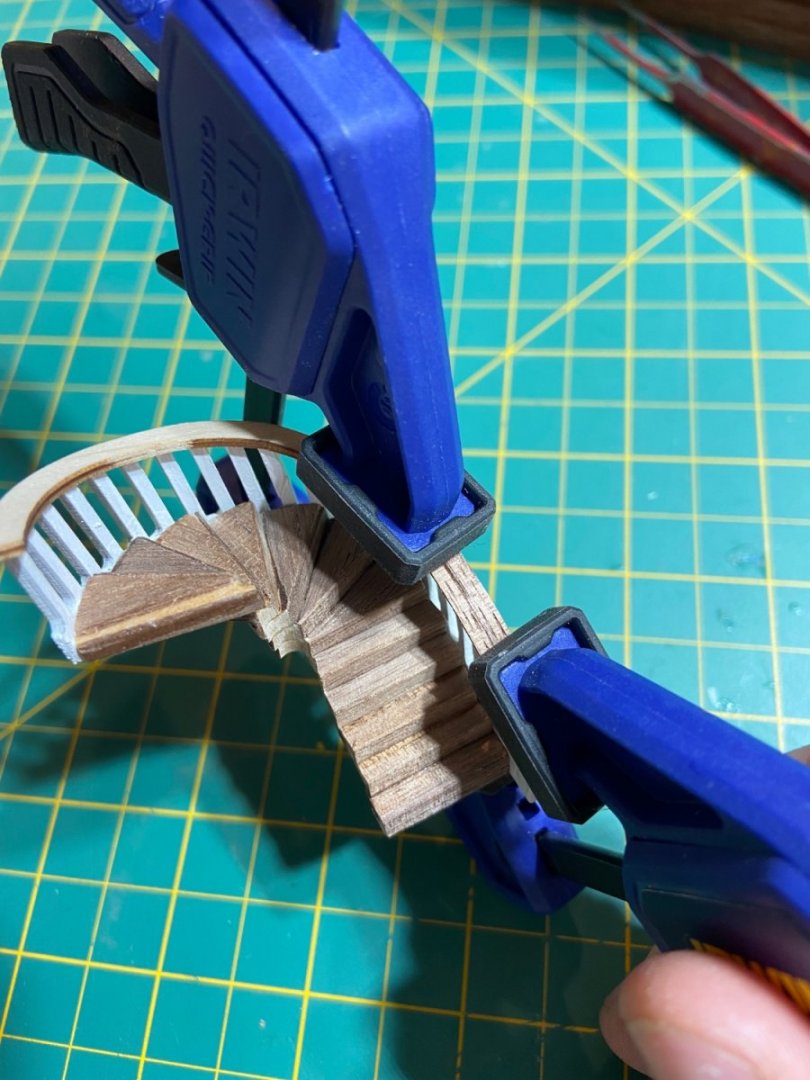

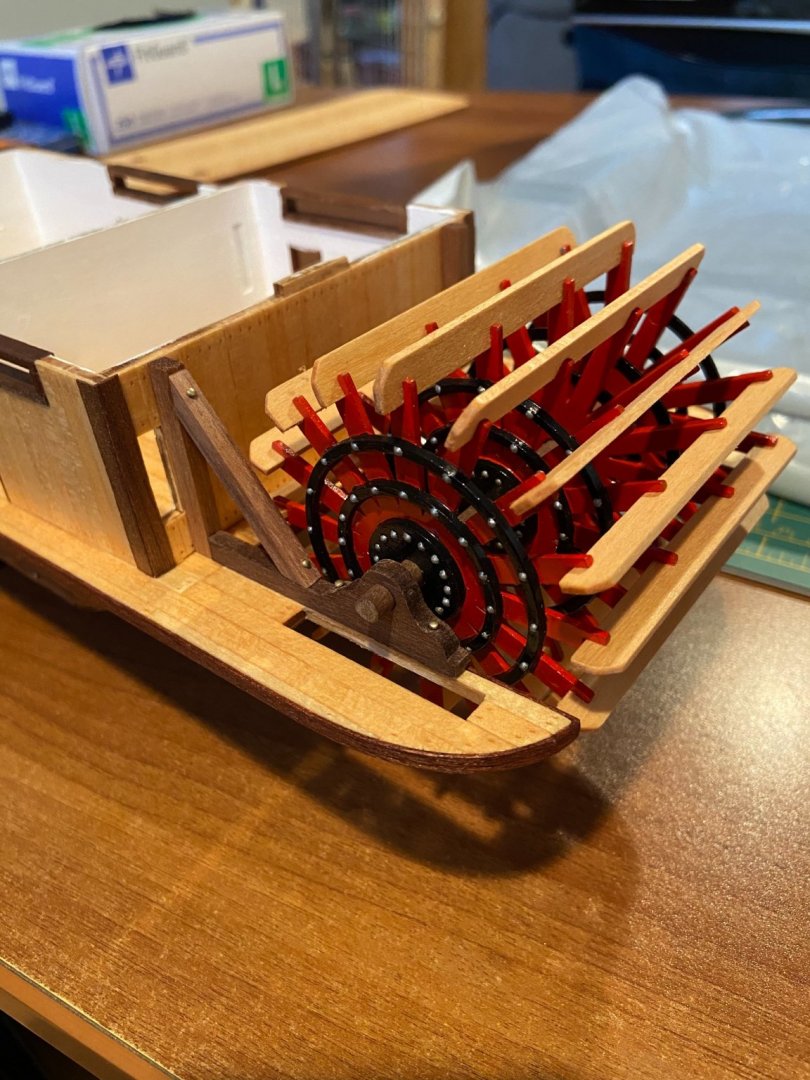

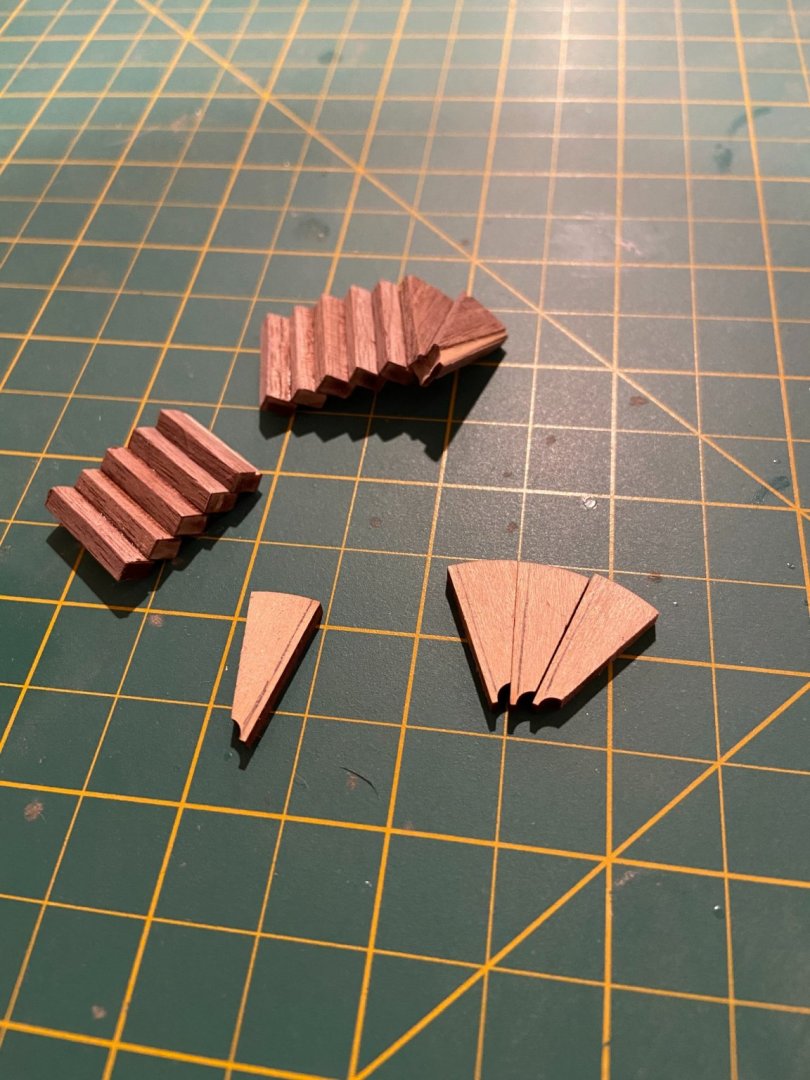

Finally got the stairs coated in Tung oil and glued in. They did not fit perfect (as expected) as to have the first step flat on the deck the last step didn’t like up exactly with the 2nd level deck. There’s an air gap, worst on the starboard side. To fix it I am going to use some extra walnut planks and glue to the top step / underside of the deck. I’m pretty happy with the outcome of them, thankfully was able to make it pretty symmetrical from the front view.

-

After having it for a few years, I still love it. My box is the Oh, conversion made with veneers, it was not solid oak. It is held up well. Although it’s used only indoors and doesn’t get too dirty, or Dusty, I use wood polish on it occasionally, and it still looks brand new. Some people have this box in the garage, and my level of OCD just could never allowed to get that dirty. 10/10 recommend

-

Thank you, yes those stairs were QUITE a PITA, they’re still not done. I have basically taken a long break unfortunately. I recently finished residency, and moved back to Ohio and had a second child while we already have a 16 month old, my hands have been pretty tied these last two years. I’m just now getting settled after being in my house for about seven months and plan on starting to work on it slowly again. Hopefully. my next step is to put tongue oil on all of the walnut Veneers on the stairs, and then finally glue the darn things into place and move on. I have also started The port side support beams, they are all dry fitted, and once I get them covered tongue oil, I will do them in place and get the railings on as well.

-

I hope I never have to make another set of spurs stairs again. I wrapped the railing in some extra walnut so it matches the stairs. It doesn’t fit perfectly in place, but overall I’m happy with how they turned out. Now I just have to finish the other side and hope they fit at least just as good. Blah.

-

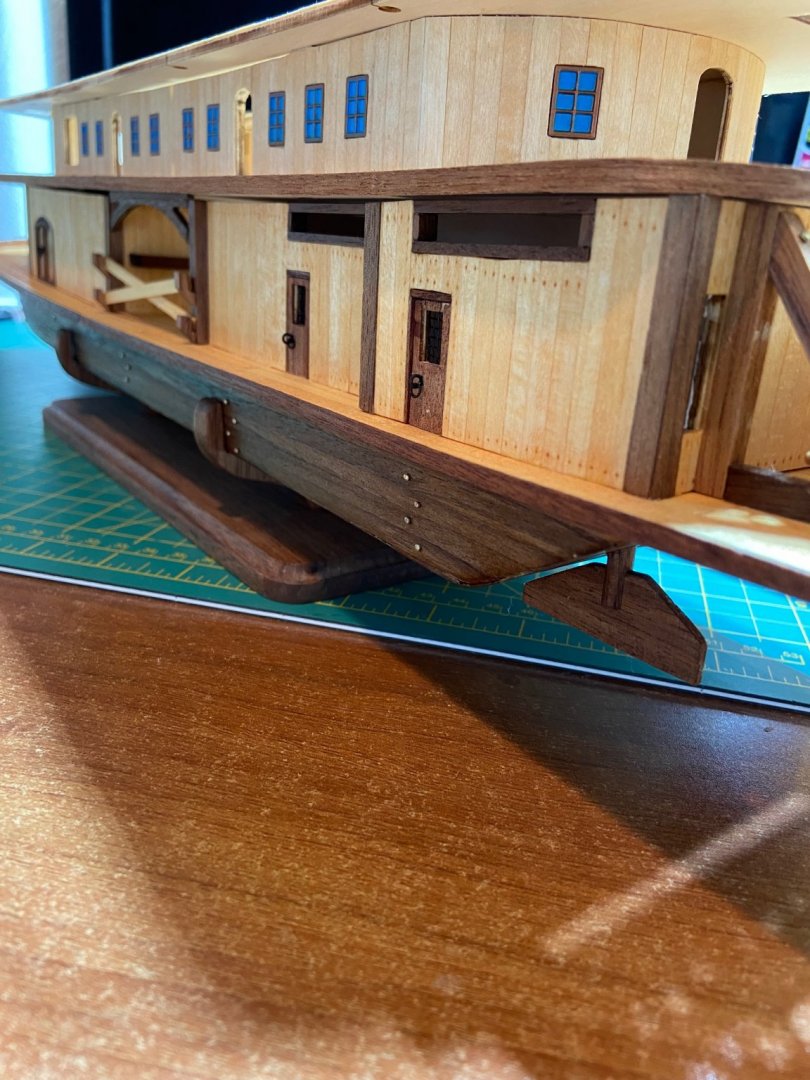

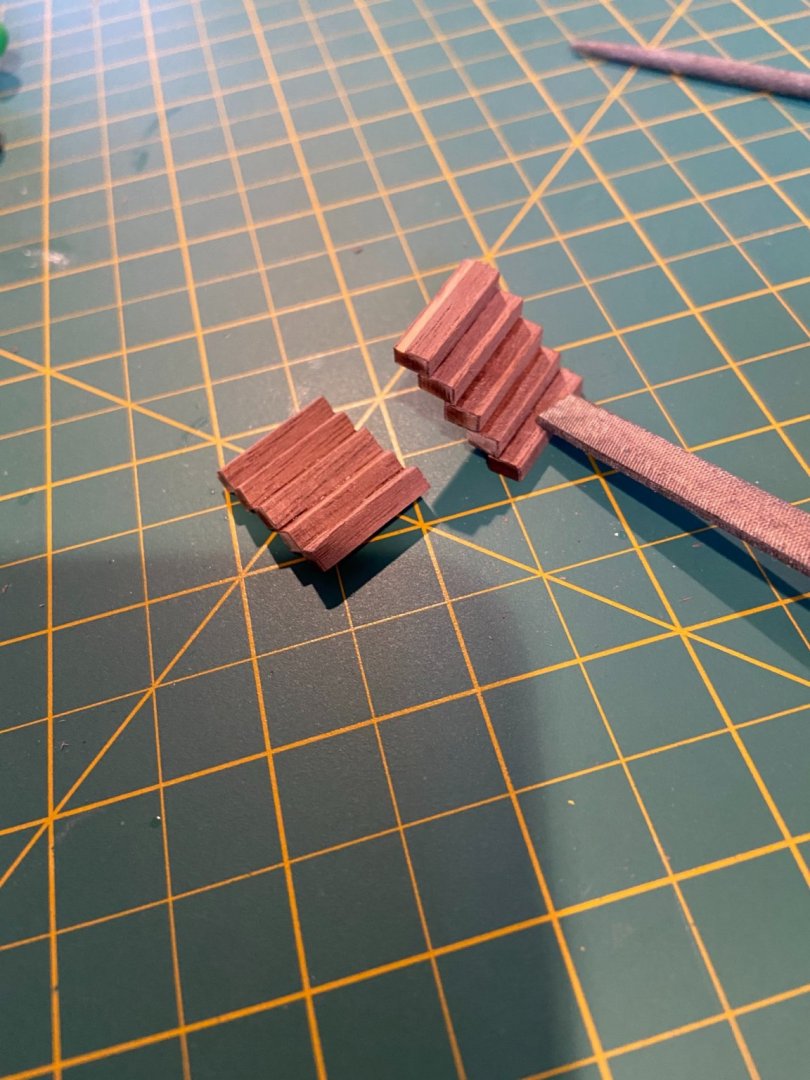

Finally glued the second level deck on and started working on the support beams. The instructions say 42mm height but mine varies from 42 to ~44mm. The directions were not clear on how to start for placement, so I looked at the blueprints supplied. They are all spaced 35mm apart and this is also the width of the double doors located on the first level. The prints show there are no posts blocking these doors, so that’s where I started. Making 2 35mm space blocks to use as I place each one. they are currently just sitting with a tiny dab of glue. Once I dry fit them all I will remove them, cost with tung oil, and glue permanently.

-

Warnerade reacted to a post in a topic:

King of the Mississippi by Warnerade - Artesania Latina - 1:80

Warnerade reacted to a post in a topic:

King of the Mississippi by Warnerade - Artesania Latina - 1:80

-

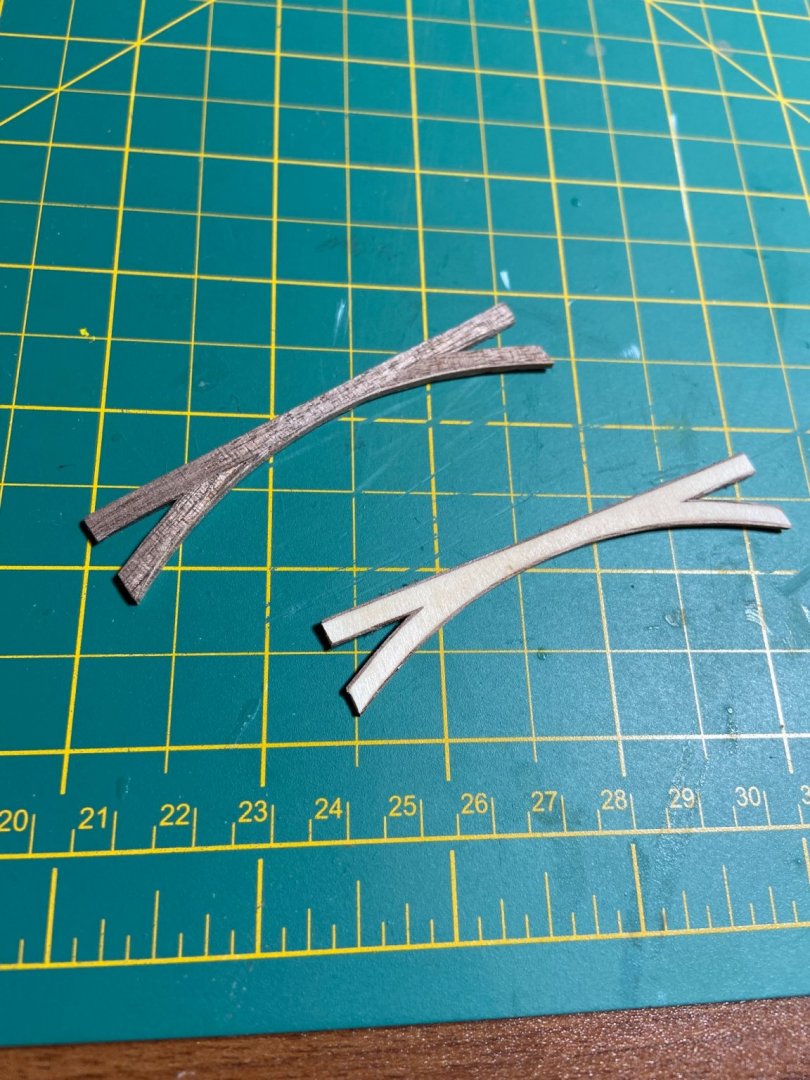

Slow and steady i am sticking with the curved stairs, I have to finish the doors and a few miscellaneous things for the forst deck before I glue the second deck on but I’ve come too far to give up haha witg the supporting arches between the first deck rooms, I decided to cover them with walnut planking as well. I’m not a fan of the look of wood without grain

-

You're not alone, I too have been working on other things, taking a break from the wooden ships temporarily. I love that aged buzz model haha

- 699 replies

-

- victory

- constructo

-

(and 1 more)

Tagged with:

-

Warnerade reacted to a post in a topic:

HMS Victory by Paul0367 - Constructo - Scale 1:94 - First wooden ship build

Warnerade reacted to a post in a topic:

HMS Victory by Paul0367 - Constructo - Scale 1:94 - First wooden ship build

-

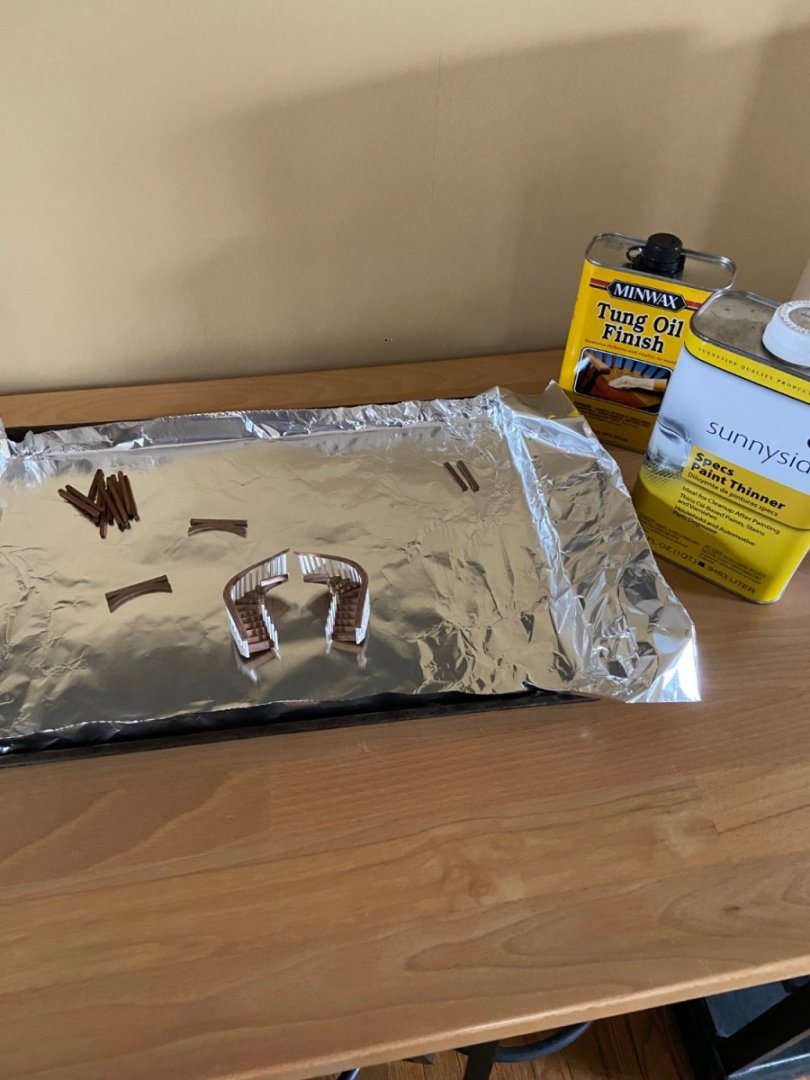

Well, I’m really glad to see this thread wasnt deleted for inactivity haha. Life has been nuts, great, but nuts. Not much time at all has been spent on the ship. I recently got married and my wife is pregnant, so my wife and I have been focusing a lot of our time on preparing for the baby. I do have some updates from the last post. However, I have to put a layer of Tung oil on everything before I glue things together. For now. I’ll just post a picture of the stairs (which I loathed) and a few recent projects I made for the house.

-

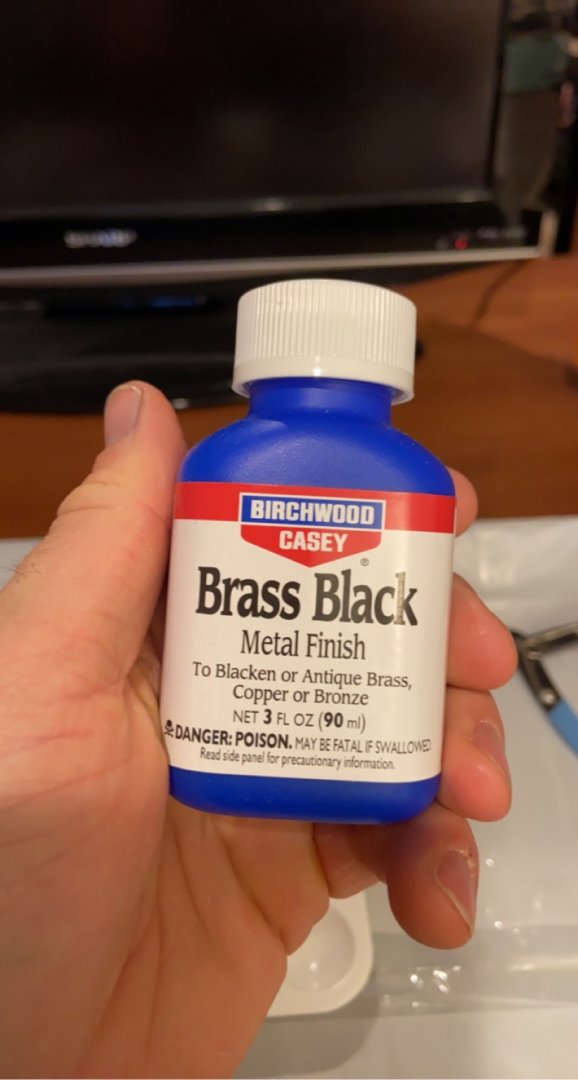

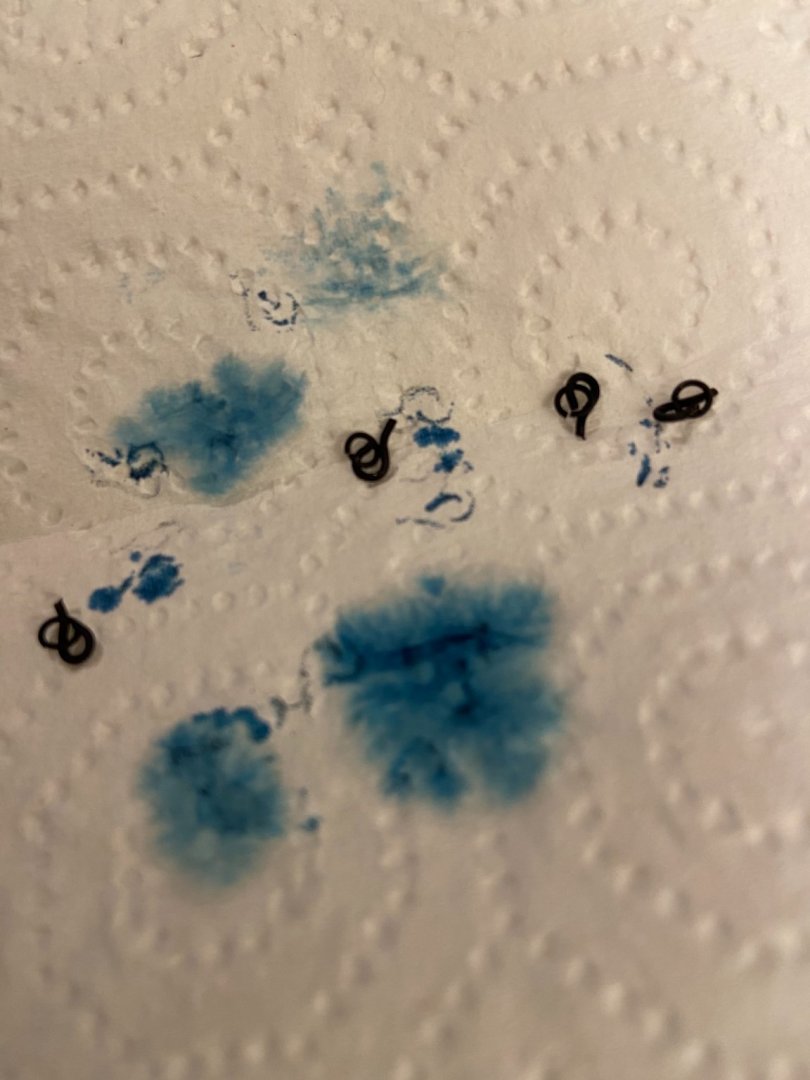

Glued the remaining rooms on and got the entire deck / walls coated in tung oil. For the small doors in the back rooms, i used window screen and superglued it on the back to allow to see inside, the inside walls are all painted white and I am debating one what else to put inside the rooms. for the doors themselves, I got the brass rings ready for the door handles and rather than keep them brass finished I let them sit in an oxidizing agent called brass black to give it a more rustic blackened look. I used the same method on a previous ship, huge fan.

-

Got the steps finished up, when I put the last piece on it ended up being a little more then 180 degree turn (see picture) so I took my cut off wheel and free handed a small section off so it lines up. Nice and straight meow. Then the outer edge of the steps had sections of overhang so I put a flap wheel attachment on the dremel and rounded them out nicely. the first deck and one of the rooms is now glued on, next I will be adding the remaining engine room, putting in whatever decorations I can think of to add to the rooms and then going through the painful process of adding lights to the model.

-

I finally decided to finish the Hull and the stand. once the sanding was complete with a 220 and then 320 sanding block, I used a little compressed air to blow the dust off and then coated the stand and the hull with Tung oil. First application was 3/4 tung and 1/4 paint thinner to really allow the tung a chance to soak in and absorb, letting it sit for 15 minutes and constantly reapply to any area the starts to dry up. After 15 min I wiped it clean and the second coat was tung with just a hint of thinner and I used the same technique. The third coat was pure tung oil and it turned out fabulous. (I used this same technique for more things that I coat in tung, there are YouTube tutorials on it, I think it works wonders) I forget what length i measured as far as where I was putting the nails, but once I got my measurements I drew a parallel line 2.5mm on each side, alternating back and forth.

-

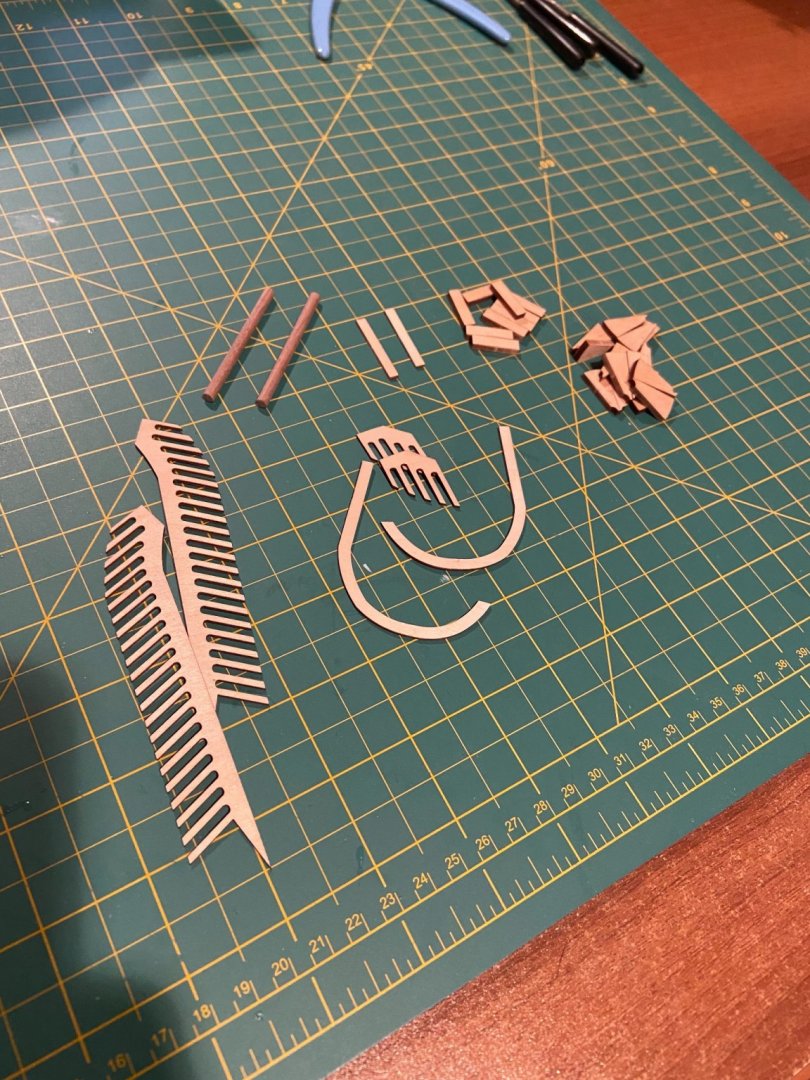

Working on the spiral staircases at the stern end of the ship. My kit was actually short a few walnut planks for the hull (or I just royally messed up) so I emailed AL, they were more than willing to send another batch of planks. so for these spiral steps, I actually covered all of the visible portions in black walnut plank, leaving a 2mm gap on top where the next step would be glued to. It made gluing fairly simple and I think looks quite nice. for the spots section, it was hard to line up the center around the wooden shaft so I ended gluing the planks at an angle and it made it much easier to line up and allowed for kore surface contact for gluing.

-

Sorry for how much I am bouncing around with this. I am just now finishing up the main deck. Lining the outside of the deck with the finished trim was pretty easy, just soaked, bent, clamped / taped, and then glued it on after it dried. But on the front with the wave catcher was a little harder. Even after it was bent, the wood naturally wanted to spring to a larger size. the directions have it sitting directly on top of the outside trim but I have no idea how I was going to pull that off. Thankfully I left a small lip on the trim as it was maybe 1/2 a mm above the deck. This allowed me to put the wave catcher on the inside of the trim and clamp it it up against the outside trim. once I got it in place and finished (using wood glue and super glue), I realized I forgot to taper the edges. I know a lot of people try to avoid power tools with their ships, but the dremel and the sanding wheel made this an easy correction.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.