-

Posts

1,012 -

Joined

-

Last visited

About grsjax

- Birthday 03/01/1951

Profile Information

-

Gender

Male

-

Location

Big Island, Hawaii

-

Interests

Small boats, Steam Navy

Recent Profile Visitors

-

Scottish Guy reacted to a post in a topic:

For Beginners -- A Cautionary Tale

Scottish Guy reacted to a post in a topic:

For Beginners -- A Cautionary Tale

-

grsjax reacted to a post in a topic:

Making an 1.00mm block

grsjax reacted to a post in a topic:

Making an 1.00mm block

-

grsjax reacted to a post in a topic:

Unknown Table Saw

grsjax reacted to a post in a topic:

Unknown Table Saw

-

Canute reacted to a post in a topic:

Unknown Table Saw

Canute reacted to a post in a topic:

Unknown Table Saw

-

Canute reacted to a post in a topic:

Unknown Table Saw

Canute reacted to a post in a topic:

Unknown Table Saw

-

Ryland Craze reacted to a post in a topic:

Unknown Table Saw

Ryland Craze reacted to a post in a topic:

Unknown Table Saw

-

CPDDET reacted to a post in a topic:

Unknown Table Saw

CPDDET reacted to a post in a topic:

Unknown Table Saw

-

mtaylor reacted to a post in a topic:

Unknown Table Saw

mtaylor reacted to a post in a topic:

Unknown Table Saw

-

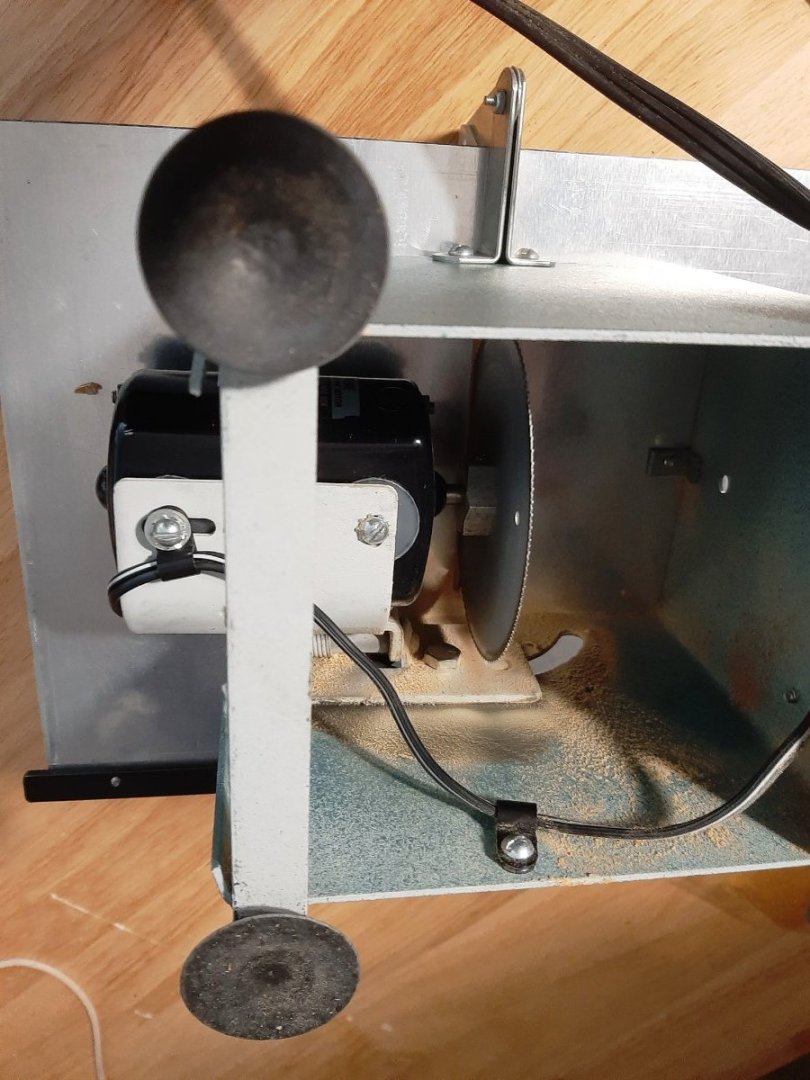

Did a bit of web crawling and found that the Jarmac is available from a number of vendors. Don't know if it is still being manufactured but seems to be plenty available. This one seems to be the "deluxe" version. Tiny motor but apparently fairly reliable. Motor can be upgraded with a new motor with the same form factor but twice the power. Going to mess around with it a bit and then pass it along.

-

davec reacted to a post in a topic:

Unknown Table Saw

davec reacted to a post in a topic:

Unknown Table Saw

-

grsjax reacted to a post in a topic:

Decent small clamps

grsjax reacted to a post in a topic:

Decent small clamps

-

Anyone know anything about this table saw? I picked it up recently and there is no brand name or indication of where or who made it. Looks well made and solid. Sorry about the upside down pictures. I am not real good at graphic editing.

-

grsjax reacted to a post in a topic:

Fridericiana Alexandrina Navis, 1st century Roman Danube River boat

grsjax reacted to a post in a topic:

Fridericiana Alexandrina Navis, 1st century Roman Danube River boat

-

mtaylor reacted to a post in a topic:

Fridericiana Alexandrina Navis, 1st century Roman Danube River boat

mtaylor reacted to a post in a topic:

Fridericiana Alexandrina Navis, 1st century Roman Danube River boat

-

Fridericiana Alexandrina Navis, 1st century Roman Danube River boat

grsjax replied to dcicero's topic in Wood ship model kits

It is available from various used book sellers but isn't cheap. About $170. -

grsjax reacted to a post in a topic:

Fridericiana Alexandrina Navis, 1st century Roman Danube River boat

grsjax reacted to a post in a topic:

Fridericiana Alexandrina Navis, 1st century Roman Danube River boat

-

grsjax reacted to a post in a topic:

CSS Alabama by Glen McGuire - FINISHED - Mamoli - 1:120

grsjax reacted to a post in a topic:

CSS Alabama by Glen McGuire - FINISHED - Mamoli - 1:120

-

grsjax reacted to a post in a topic:

Fridericiana Alexandrina Navis, 1st century Roman Danube River boat

grsjax reacted to a post in a topic:

Fridericiana Alexandrina Navis, 1st century Roman Danube River boat

-

grsjax reacted to a post in a topic:

Syren Ship Model Company News, Updates and Info.....(part 2)

grsjax reacted to a post in a topic:

Syren Ship Model Company News, Updates and Info.....(part 2)

-

grsjax reacted to a post in a topic:

Okahumkee by Harvey Golden - 1/96 scale - 1870s Inboard Stern Wheeler - post 1892 layout

grsjax reacted to a post in a topic:

Okahumkee by Harvey Golden - 1/96 scale - 1870s Inboard Stern Wheeler - post 1892 layout

-

mtaylor reacted to a post in a topic:

Mini Bench Drill Press

mtaylor reacted to a post in a topic:

Mini Bench Drill Press

-

Specs said the shaft turned in a brass sleeve. I assume that means the spindle but I could be wrong. Be interesting to take one apart and see how it is made.

-

The specs on some of these micro drill presses states that the shaft turns in a brass sleeve rather than bearings. Should be ok for light work but I don't see anyway to lube the sleeve so for anything serious I would be a little worried.

-

The Gulf Coast Scow Schooner from Chapelle's "American Small Sailing Craft" would be my first choice. Any of the sail powered fishing boats that used to be common sights in American harbors. An unusual one that few are aware of is the Hawaiian Sampan fishing boats developed by Japanese immigrants to the islands in the early 20th century. https://sanctuaries.noaa.gov/news/may20/sampans-of-hawaii.html

-

Take a look at Model Shipways Willie L. Bennett, a Chesapeake Skipjack. Not to difficult to build.

-

Keep the Atlas. You can turn wood on it no problem. Just clean the wood chips out of the lathe when you are done. There is a Facebook group for Atlas lathes that you might find useful for info and finding parts. Lots of Youtube videos about Atlas lathe operation and repair. Check out this website for wood turning on a metal lathe. https://www.lathematters.com/turning-wood-on-a-metal-lathe/

-

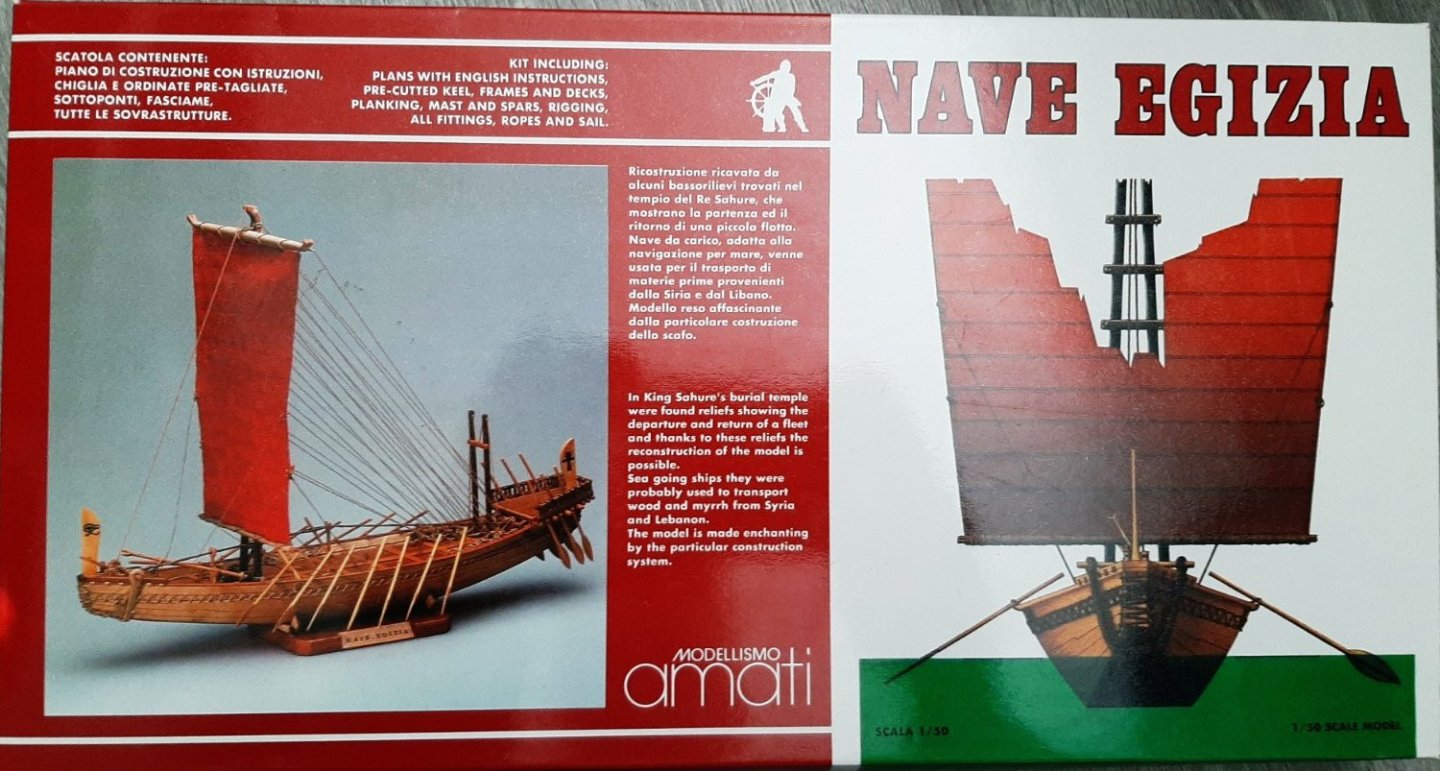

The new year is here and I have made a resolution to pare my stash down. My wife has been after me to reduce the stash for some time now, pointing out that I have far more kits than I have life left to build them. So here goes with the first batch. If you are interested but think price is to high make an offer. Nothing lost if I don't accept and you might get a great deal. Buyer pays for shipping. My preferred method is USPS ground advantage but I will ship by whatever carrier the buyer wants. I can send additional pictures to anyone interested. I will be listing some additional kits from time to time. 1. Model Airways Wright Flyer 1:16 scale. New open box. $75 2. Panart Lancia HMS Victory 1:16 scale. Old stock, complete and unstarted. $125 now $100 3. Panart Lancia Armata 1803 1:16 scale. Complete but a previous owner punched out some parts and glued them together then took them apart. In excellent condition. $150 now $125 4. Disar Marieville Sternwheel Steamer 1:72 scale. New open box. $150 now $125

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.