-

Posts

73 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by albergman

-

I haven't been here for a while as I have no more maritime projects and I've turned to other subjects. However, I like to return occasionally just to check on Altair. This is such a tour de force and I know we've all run out of superlatives ... I have anyway. We should all just sit and watch quietly till it's done then all gush at once!! Truly admire your ability to find an elegant solution for every problem that might be a show stopper for the rest of us. You've raised the bar so high Keith that we can all wear our top hats as we walk under it. You, of course, won't be wearing your topper as your head has probably swelled too much from all the well deserved admiration! LOL. Now, get back to work! Frank

-

Hi Gil I've been enjoying riding along and watching your Dragon come to life. I built a Billings Dragon probably 40 years ago when my wife gave it to me for Xmas. It was only in the last 5 or 6 years that I decided to tart it up a bit and showed it here. It's wonderful to see someone else disregard the plans and apply their own imagination to the project. You're taking yours much further than I ever did and I love it!! Keep up the good work. Frank

- 60 replies

-

- dragon class

- billing boats

-

(and 2 more)

Tagged with:

-

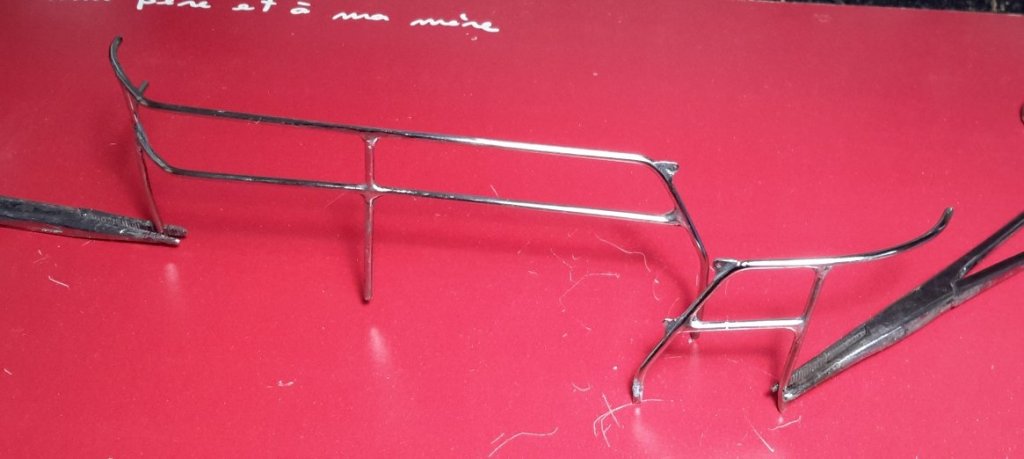

Time for a bit of an update. Been busy with mostly car projects for the past couple of years but now returning to do some much needed updates on the half hull model of our own Alberg 37 sloop (since sold). I mentioned at the beginning of this thread that I wasn't happy with the metal work on this model as it was done back in the days when I was using plain steel rod and ordinary solder. This has now tarnished and blackened so it's time to replace all that with stainless steel and S/S solder. Have taken the model out to my shed and have it mounted on a work board which itself is screwed to a cabinet near my workbench. This lets me easily reach the model while reducing its handling. It was pretty dirty after several years on the wall so after a wash down with Q-tips and soft, wetted rags I gave it a polish with the automotive stuff (Meguires polishing compound) I use on my car models. Gave it a shine it never had. I've glued a couple chunks of Renshape together to give me a surface on which to build the new bow and stern pulpits. Drilled a few holes where needed and start bending stainless rod to the shapes. This rod is actually sold as stainless steel welding rods and is lovely to work with. Solder in the extra rails then remove from the Ren. File down the excess solder. wet sand it and finally polish with a metal polish. Here's my 2 new rails ... There are tiny tabs that need to be added to the rails where the lifelines will attach. These I cut from a tin can lid and soldered in place. I use a large piece for ease of holding then grind it to size with a Dremel grinding disk. Tabs seen here on the bow pulpit. That's about as far as I've got. Need to make a few stanchions and the 2 special ones for the "gate". Back later. Frank

-

Hi Judi This is getting interesting! You probably know that your plank-on-frame approach to the cabin isn't exactly my style of building so, if your heart is set on the framework route. I'd invite Keith or any of the better scratch builders to chime in with ideas. While it would be elegant and definitely more in keeping with proper yacht construction I'm thinking it might end up very fragmented if you know what I mean? Considering the smallness of the final shape I'm more inclined to take the "Bernini solution" and reduce a solid block of mahogany (or whatever you intend to use) to the shape you want. This piece can still be hollowed out inside if you wish to show some access to below deck and window openings are easily scooped out with Dremel bits. What you are aiming for, as I see it, is just a slightly larger version of the cabin roof I shaped for my Dragon. I know this isn't what you asked for but I know I couldn't assemble a (relatively) small cabin structure from frames and planks and have it look elegant at the end. Hope you have a great holiday. Frank

-

I was only asking because I thought you might want to have it down before you make your cabin. No doubt the planking could just as easily be cut to butt against it after the fact.

-

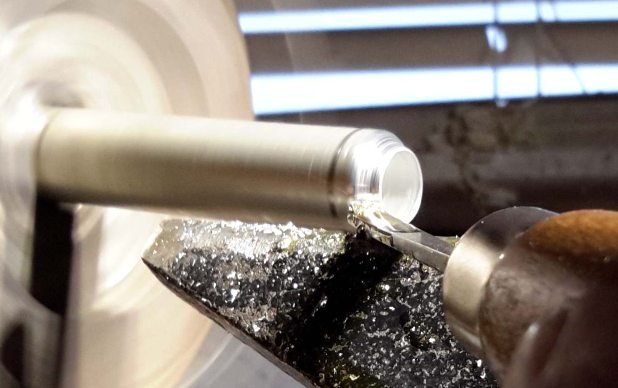

That's a wonderful shop you had Julie ... truly envious. My entire shop is 5 x 8' and my "workbench" is 3 x 2'. Sure makes me stay tidy. Can you fit a chuck on that lathe? You might find the rod a bit too hard but maybe not ... depends on the alloy. I'm using an 8' 1/2" rod that I bought to make wire wheel parts and it IS hard. I used to have great success making winches out of aluminum Exacto handles. Will you be using your wood lathe tools for this? The smaller the chisel the more agile you can be. Here's a few pics of my setup and tools. My old chisel collection ... actually carving tools. I've said earlier that I salvaged a chuck out of a hand drill and it's great for getting small pieces away from the dangerous 3-jaws of the big one. Here's a winch (ex-Exacto handle) in progress ... See ... it CAN be done. OK, feel free to ask any questions. Good luck. Frank

-

Oh my ... I found that 44 too and what a beauty! I see why it appeals. Is the house listed yet? Ah well, fun to dream. OK, carry on with the J boat. Frank

-

I was guessing it was going to be a sailing model because you mentioned adding shot ballast. Maybe I missed something there as my "dust collectors" don't require ballast and they work VERY well in that regard. Frank

-

- 424 replies

-

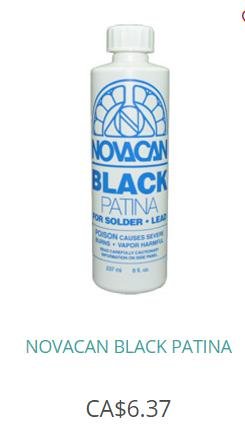

Dilbert I found it in a shop that sells stained glass supplies. Those people use it to darken the lead on a stained glass piece. Frank

- 424 replies

-

Windows ... That's what I was hoping you'd say. More like this maybe? Is this going to be a sailing model? F

-

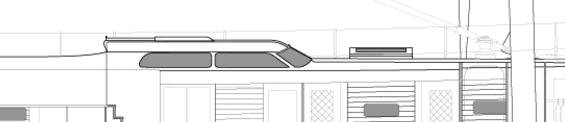

Hi Julie Nice hi-tech way to approach the project. Not sure I know exactly what I'm looking at but I suspect this is your CAD drawing of the S130 cockpit ... no changes. Anyway, will be a nice clean layout. Are you thinking about using their same style of windows? F

-

That's the site I saw many years ago and couldn't find now ... out of business huh? Beautiful stuff they had. I don't know if carbon fibre can be turned (probably) but there's lots of black plastics that could substitute. Y'know, if you were to go with a plastic or something that soft you could use a drill press or even a drill (held in a vise?) as a "lathe" and cobble up some sort of tool rest and go at it. If you're thinking of black winches then consider maybe using this new-fangled composite "wood" sold for decks and docks and paint them. That's what I built the powerboat model with and it's interesting stuff ... uniform throughout, waterproof and dense (so it would take fine detailing). Almost all of them have free samples. An alternative might be acrylic rods ... here on eBay Frank

-

Glad the picture meant something to you ... not everyone's cup 'o tea. That was Pipe Creek in the Exumas and we stayed there almost a month. What kind of boat did Dad have and ... have you done a model of it? OK ... high speed tools, yes, I only use HSS blanks to make my tools for the machine lathe. You don't need carbide to work aluminum or brass (but carbide cuts them nicely too). As I said above I used to buy Chinese wood carving tools when I'd find them on sale then re-shape the heads using these disks you buy for Dremels if I needed a particular shape. e.g. to make the self-tailing slot on a winch I'd taper a carving tool to that shape. You'll find that HSS is actually what the better carving tools are made from. Pry one out of its handle and you'll find the familiar square shape of an HSS blank. Just curious but what colour of finish will your modern winches have .. black, silver or brass. If black then maybe you could make them in wood or a composite and paint them. Frank

-

Hi Julie Funny you should use that expression about "chipping away everything that ....". I had used it on a car model that started as a block of mahogany and a viewer asked me how I did it and I said "just chip away .... not Ferrari". I don't really know how it comes out (usually) correctly as I rarely have plans ... an eye for the correct line I suppose. As I said I'm a retired computer geek with nothing in my background to build on. Ah, sailing. Retired at 55, sold everything, quit 2 good jobs, kicked out the last kid (23) and moved aboard the Alberg (top of this piece) then left for the Caribbean. Stayed aboard 4 years then sailed back to Toronto and sold it. Waking up here is what I called living ... Sigh .... OK, sounds like you've seen what I said about using a wood lathe and, if you don't want to get into a "real" lathe this isn't a bad option. There's a freedom of movement with a hand held chisel that you don't get with a metal lathe and that is often important with the kind of things you might want to shape. Frank

-

Oh lovely! This looks nicely proportioned too. Winches ... I saw Harken miniature winches available years ago so maybe someone on here knows where to get them ... I turn my own and they're not hard to do. Be glad to chat about that if you want to try it. Frank

-

Woohoo!! Great! Look forward to seeing what you do with this. I first came across Spirit when one was used in the Bond film Casino Royale ... when they took a pale blue one into the Grand Canal in Venice. So-o-o glad you didn't pick Wally. Ahem, I'll say no more. Frank

-

I'm with you there Julie ... that really old, boxy look just doesn't do it for me either. Can I be so bold as to suggest you look at this 130' modern yacht but with classic lines built by Spirit Yachts . I like the modern look of the deck "house" and you might get inspiration from it. I think it's a wonderful blend of the modern and classic. Frank

-

Thanks Julie ... you give me too much credit. Patrick ... you got me there for a few seconds. I'm thinking ... maybe there's been something wrong with the video all along. Anyway, I think your eyes are just suffering from all that exquisite modelling you do in the micro-world. Frank

- 18 replies

-

- honey bear

- fishing

-

(and 1 more)

Tagged with:

-

Congratulations Julie I've been watching quietly from the background and willing you on to finish this beautiful hull. Pity about the minor setback but I knew you'd figure it out. That lacquer finish just makes it all worth while for me ... seeing all those individual planks suddenly transforming into a uniform, beautiful, organic shape!! Love it. Frank

-

Thanks Patrick ... but please don't bring the law after me!! I just remembered that over a year ago I started a YouTube channel to show films I'd make about my models ... well, that was the plan and I only ever made one movie (this Honey Bear model) and posted it. After that, no matter how I searched for it using all the key words I'd given it I couldn't find the d*mn thing and, as a result, to date only 20 people have ever found it ... all of them being myself and the friend I made it for. Needless to say I gave up on that idea till I learned more about YouTube. Anyone who wants to see it can find it here and I'd be curious to hear what they think of the idea. Frank

- 18 replies

-

- honey bear

- fishing

-

(and 1 more)

Tagged with:

-

Greg ... When you put it that way even I find it hard to believe!!! But yes, it's made just the way you said. The cardboard was used but just as a pattern for the sides. It was replaced by Arborite samples (you know those little 3x2 samples hanging on a board in the hardware store?) ... where a flat strong surface was needed. I found thin sheets of smoked plastic (sold as replacement for the visor of a welder's mask) and they made perfect tinted windows. My neighbour is still puzzled by the missing boards in his deck!! The steering wheel rim was made from a little aluminium flashlight I got when I bought a new razor ... it had a solid ring of the right diameter on the end ... just needed to be liberated. Made a perfect wheel with stainless rod bent to shape and pulled into 4 shallow holes The real thing All I'm trying to show is that with a little imagination (and a healthy stockpile of scrap metals) you can find items that contain the shape you need. Frank

- 18 replies

-

- honey bear

- fishing

-

(and 1 more)

Tagged with:

-

Hello from the Colonies ... Ontario, Canada

albergman replied to albergman's topic in New member Introductions

Thanks for the kind words gents ... and all others who have clicked the "Like" button. I have to say I've looked at so many amazing builds on this site and believe me there are scratch builders here who are far more talented and that's not false modesty. Anyway, I just build for myself and usually give everything away ... I presently have 5 models out of 25 I've made. If you're interested you can see a couple of different things here and here. Cheers Frank

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.