-

Posts

391 -

Joined

-

Last visited

Profile Information

-

Location

Temecula- Wine Country, California

Recent Profile Visitors

-

Scottish Guy reacted to a post in a topic:

chain sources

Scottish Guy reacted to a post in a topic:

chain sources

-

highlanderburial reacted to a post in a topic:

USLSS 36'Lifeboat

highlanderburial reacted to a post in a topic:

USLSS 36'Lifeboat

-

Montaigne reacted to a post in a topic:

PILAR by Pat Matthews - Radio - Hemingway's Pilar in 1:12

Montaigne reacted to a post in a topic:

PILAR by Pat Matthews - Radio - Hemingway's Pilar in 1:12

-

Montaigne reacted to a post in a topic:

PILAR by Pat Matthews - Radio - Hemingway's Pilar in 1:12

Montaigne reacted to a post in a topic:

PILAR by Pat Matthews - Radio - Hemingway's Pilar in 1:12

-

Montaigne reacted to a post in a topic:

PILAR by Pat Matthews - Radio - Hemingway's Pilar in 1:12

Montaigne reacted to a post in a topic:

PILAR by Pat Matthews - Radio - Hemingway's Pilar in 1:12

-

Scallywag reacted to a post in a topic:

Constitution's Guns?

Scallywag reacted to a post in a topic:

Constitution's Guns?

-

ibozev reacted to a post in a topic:

Photographing your models

ibozev reacted to a post in a topic:

Photographing your models

-

Montaigne reacted to a post in a topic:

PILAR by Pat Matthews - Radio - Hemingway's Pilar in 1:12

Montaigne reacted to a post in a topic:

PILAR by Pat Matthews - Radio - Hemingway's Pilar in 1:12

-

Patrick Matthews started following Fire Fighter , Atlantis by Thistle17 - FINISHED - Robbe , Tugboat Dearborn and 1 other

-

Atlantis by Thistle17 - FINISHED - Robbe

Patrick Matthews replied to Thistle17's topic in RC Kits & Scratch building

Sorry I missed your post! Email or PM will get my attention faster. Let me know if help is still needed. -

Very nice & complete work! Yes, my goal is to document vessels in a manner useful for modelers. I'm not creating 3d printable files. But my documentation includes 2d drawings as well as a 3d CAD model. The cad model can be used directly, or examined to better understand my abbreviated 2d work I do like the DS lines drawings, and that's another area that F360 erects unnecessary roadblocks... But I'm finding ways to work around those too. See my Fire Fighter model for example: https://grabcad.com/library/fire-fighter-fireboat-1

-

Nope on the 3D DXF. That results in a mesh not unlike an STL- points joined by straight connectors, resulting in a faceted surface. It is NOT a smooth curvy surface. The IGES export is smooth & curvy... I just don't know if the entire side of my hull with its compound curved surfaces comes out in one patch or not. Why do this? Because while Fusion 360 can be a pain for creating lofted hulls, it's a champ for making all the other details. And it has history, which is priceless in large complex models. So if I can make a correct hull in DS, I'd just export the shape to F360. But as I detail above, that subdivided surface from DS using a control mesh is WRONG, and it requires a lot of tweaking to correct. Now, with much gnashing of teeth, I have been able to create a reasonable lofted hull in F360... so it's just a matter of which path is less headache. My F360 generated hull:

-

Thanks! My biggest question regards the IGES output, only available in the Pro version. They told me it can output many, maybe hundreds, of surface patches, which would likely look like a mosaic when used in other CAD software. But if, for example on my tug hull, it comes out as smooth single patch for the main surface, that would be fine. They sent me a sample IGES file, but it was of a simple developable hull, so not really a test of this feature. The transom (port) was fractured, but I stitched the surface patches in Fusion360, and it all merged nicely (stbd).

-

Here's an end view showing some of these features: White: Original control points and the control mesh with its straight Tinkertoy connectors. The control points lay on the proper body sections from the lines drawing. Green: Body sections cut through the DS developed hull surface... they miss by a lot. Even at the deck edges. Pink: Nice curvy marker curves that DS draws for the second import of the original control points. These markers are the target, I need to move the green lines to match them. To move any one point: Click on it, and you can enter new numbers or use the little arrow to move the point by set increments, very handy. Move each and every one this way to drag the developed sections around.

-

So here's the second most important thing for DS users to know: Lines imported from a lines drawing DO NOT create a hull true to those lines! First most important? It can be fixed. As above: "The developed hull shape does NOT go through the control points, which are input from the original lines drawing... they just INFLUENCE the shape. Fine except it's not, because the developed form no longer matches the original. There must be a work flow that gets the generated shape closer to the desired form." Indeed the DS developed hull cuts corners, it's always well to the inside (concave side) of input curves, except at the "corners". Imagine you have a magnetic rubbery sheet pegged by its 4 corners to the floor, exactly where you want the corners. Then you hang a bunch of magnets from the ceiling, and each magnet is hanging exactly where you want the sheet to stretch and rise to, defining some sort of hill (I'm picturing Richard Dreyfuss building Devil's Tower in his living room). But while the sheet is stretchy, it's not THAT stretchy, and it hovers over the floor but doesn't quite reach the magnets. Oops. That's what we have in DS, with the developed hull not reaching the input points. How to fix it? Just keep raising the magnets until the sheet rises to the proper place. In DS, I did this, though there may be more efficient ways: 1. Import the control points once to define the control mesh and its resultant malformed hull. 2. Import the control points a second time as "marker curves". Markers are static curves, immutable, and they serve as references of where the original control points and desired hull sections are. 3. In an end view, compare the developed body sections (which are wrong) to the desired shape shown by the marker curves. Now start moving control points sideways or vertically to slowly pull the body sections towards their markers. Yes, this modifies the original control points and mesh! 4. Note that this is iterative... moving one point affects the adjacent surface faces, so you'll need to sweep back and forth over all the points to get everything close. 5. Also note that the four edges of your rubber sheet between the corner pegs were also pulled off the floor when the magnets started lifting the center. Same thing in DS- the edges at deck edge and keel also have moved out of place. So the adjusting exercise needs to address those too. I did this for my tugboat hull, and while it still needs some adjustment, it's much closer to the desired shape now (below). More: While you can get close by doing this, you can also turn on curvature displays to better smooth (fair) your new shapes. I haven't done this yet, may not need to for my present purposes. More #2: The Pro version of DS has an "automatic fairing" tool. I'm not sure how this works, but it could be of help.

-

I did receive replies from DS HQ: 1. The forum is not broken, new posts are moderated. But still, not so much recent activity, which is curious. 2. Hull surfaces exported as IGES are "smooth parametric surfaces, but please keep in mind that the exported hull can consist of many (sometimes hundreds) of such surfaces." So it's not clear yet whether that would look like a broken mosaic when imported into my CAD.

-

Thanks and yes, but a lot of material is a bit dated. I don't see much recent activity, makes me wonder if this is still a popular tool? I sent an email to DS HQ asking why their forum is broken... no answer yet. But I'm wrestling with topics like: - The developed hull shape does NOT go through the control points, which are input from the original lines drawing... they just INFLUENCE the shape. Fine except it's not, because the developed form no longer matches the original. There must be a work flow that gets the generated shape closer to the desired form; - Deck camber- the "Extrude Curved" tool is supposed to generate a nicely cambered deck, except it doesn't... it's generating garbage for me; - You can pop 160 euro for the Pro version which will output the surfaces in IGES format. But what format? A faceted mesh, or a proper smooth surface? The available exports in the free version just give the faceted mesh, which looks terrible when imported into, say, Fusion360 (as seen below). Unusable. The whole reason for me exploring Delftship is its better ability to generate hull shapes, compared to the buggy tools in F360, whadda headache (that area around the sternpost/stern counter is a BEAR to loft). Maybe I should pop for Rhino, $995 ouch.

-

Fire Fighter

Patrick Matthews replied to Patrick Matthews's topic in CAD and 3D Modelling/Drafting Plans with Software

Or instead of spending hundreds of hours drawing it, spend a few bucks to get them properly scanned and then post them somewhere for posterity. It's a shame how many drawings are out there that will never get shared... -

Fire Fighter

Patrick Matthews replied to Patrick Matthews's topic in CAD and 3D Modelling/Drafting Plans with Software

You keep saying that! 😆 -

Years ago I attempted to correct the Revell Fire Fighter kit with a load of 3d printed parts. Now I've finally completed a CAD model of FF, and posted it and a bunch of supporting info on GrabCAD for free download. No printable parts in the file, but I've created a correct shape for the hull and house, and show where all the "ornaments" are hung: https://grabcad.com/library/fire-fighter-fireboat-1 You can spin the model around using GrabCAD's 3d viewer.

-

USLSS 36'Lifeboat

Patrick Matthews replied to Patrick Matthews's topic in CAD and 3D Modelling/Drafting Plans with Software

The 3D CAD model is complete and available for free download from GrabCAD: https://grabcad.com/library/lifeboat-uslss-1908-mclellen-type-e-36-footer-1 Find the 3D STEP file there, along with reference photos and the original 2D drawings I worked from. Take the model for a spin at GrabCAD! -

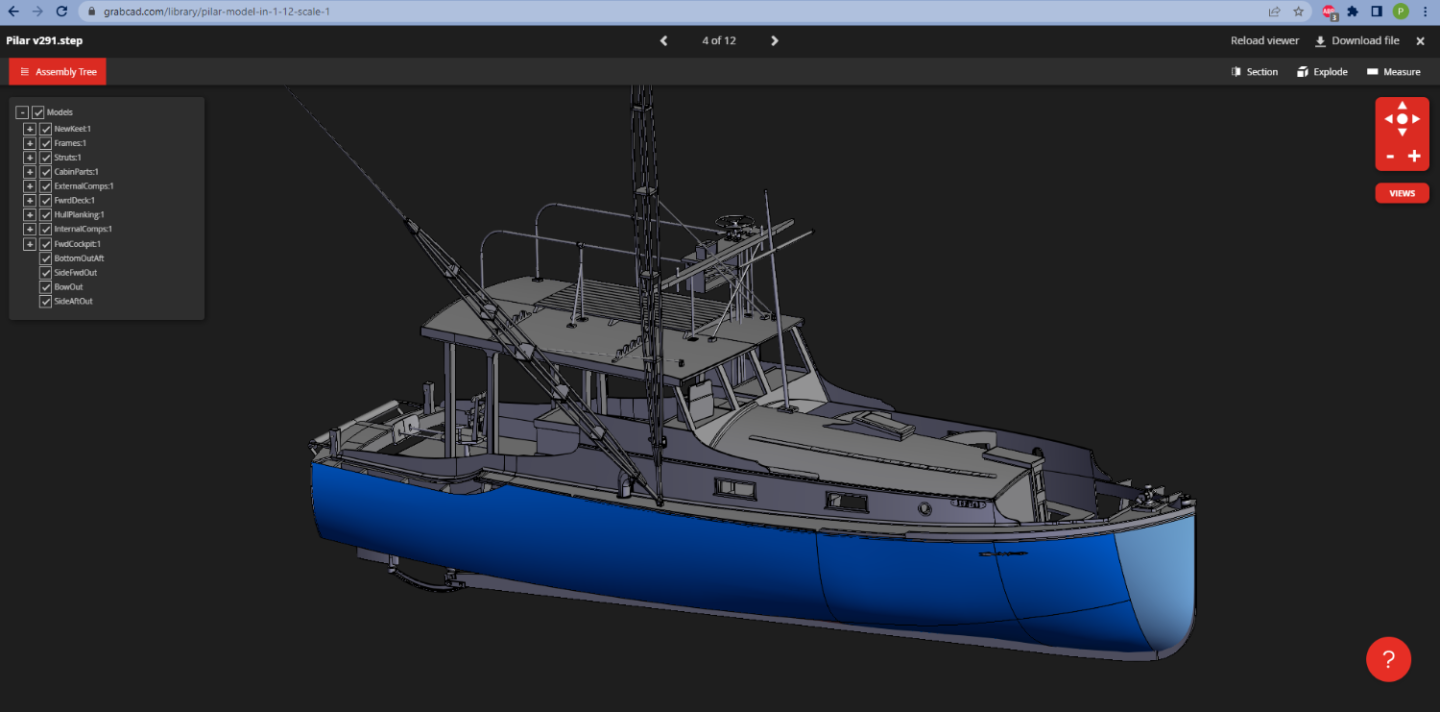

Another update- the entire PILAR 3D model is now on GrabCAD, along with 2D drawings for the cabin structure. I may be adding more 2D detail drawings, but the underlying geometry is all there now in the 3D STEP file. Take the 3D model for a spin at GrabCAD! https://grabcad.com/library/pilar-model-in-1-12-scale-1

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.