-

Posts

5,536 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by wefalck

-

These machines are just not worth the (financial) effort for something that can be done with simple hand-tools. Keep in mind that the copper-sheet should be very thin, 0.1 mm max (which is the thinnest one can normally get), and this would be very soft, so no machinery needed to shape them. Another aspect would be, that one would literally iron out any embossing to simulate the nail pattern, if one goes for that. Or vice versa, putting the embossing in after rolling the plates would straighten them again.

-

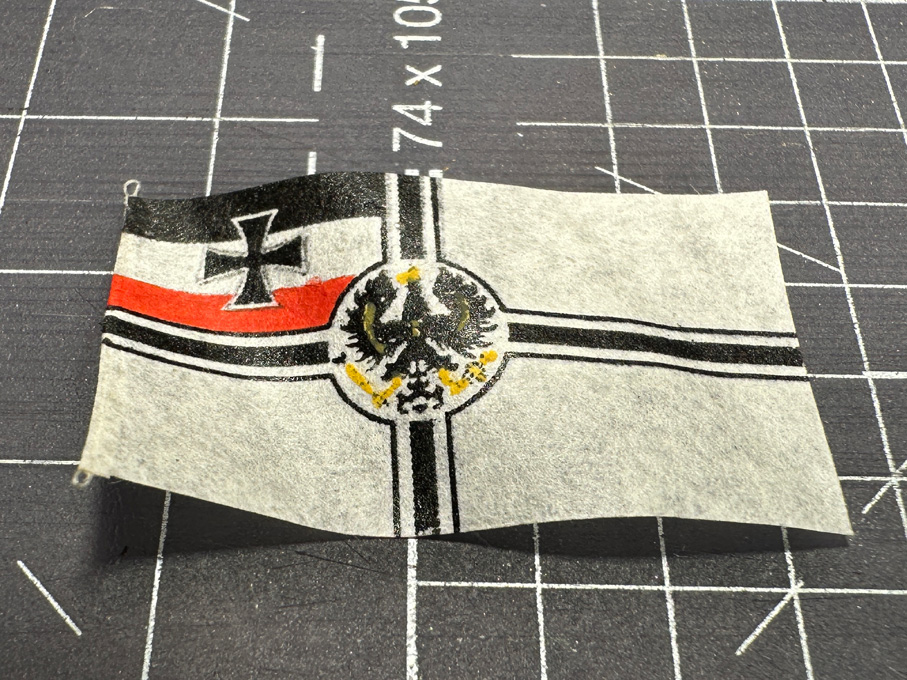

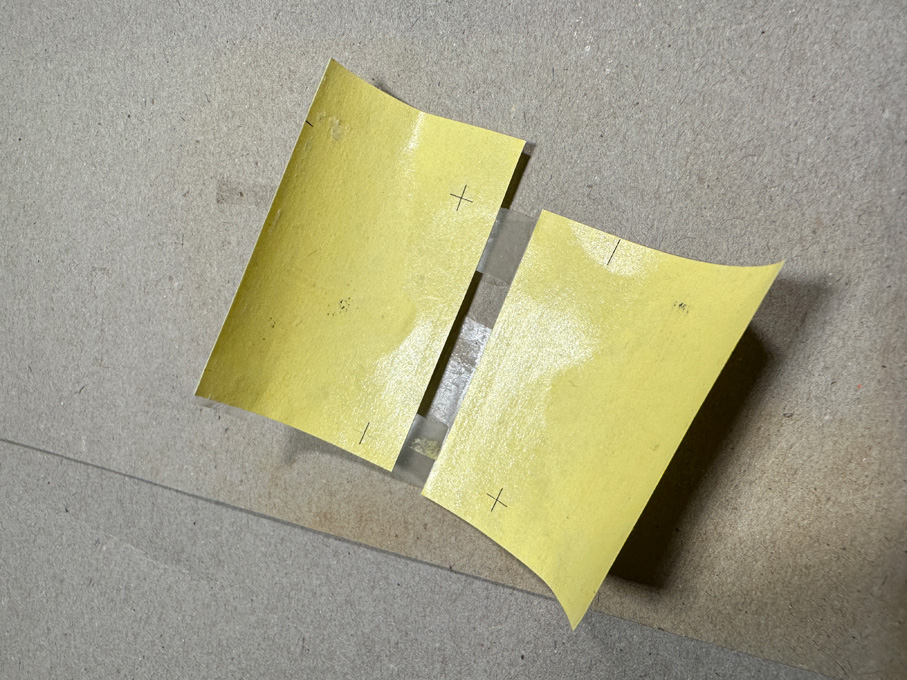

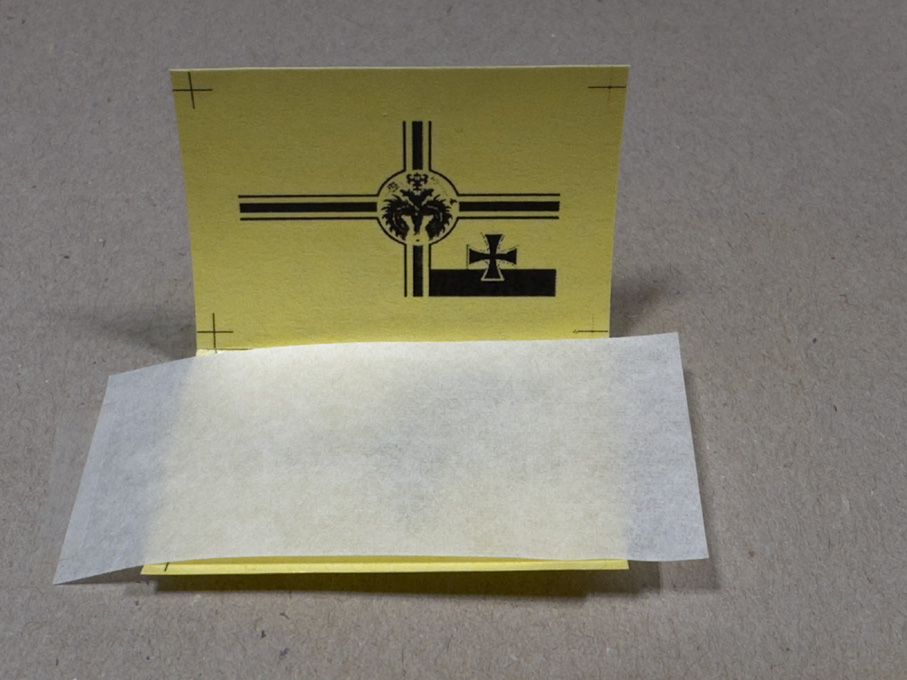

Once again, Thank You for your kind comments ! Again, real life including (business) travels got in the way of progress on this project. In addition, while I was having dinner in a restaurant together with colleagues, suddenly some ‘floaters’ appeared in one eye. I went immediately to the eye-doctor, who checked my eyes thoroughly. Luckily the floaters are harmless, but annoying signs of age. No retina-detachment or something else serious. Apparently, they can spontaneously disappear or the brain sort of ignores them after a while – keep fingers crossed. For the moment they are quite bothering, when working on really small things … so on to the ensign. ************************************ The Imperial German Navy Ensign This ensign was first conceived for the navy of the North-German Alliance (Norddeutscher Bund) in 1867, bringing together the colours of the dominant powers, namely Prussia (black-white) and the Hanseatic City States, Hamburg, Bremen und Lübeck (red-white). The design obviously was inspired by the British White Ensign and makes reference to various medieval symbols, such as the cross of the Teutonic Order, and the more recent Iron Cross from the Napoleonic War. After the proclamation of the 2nd Empire on 18 January 1871, this ensign became also the ensign of the Imperial German Navy and remained it until the end of the Empire in 1919. There have been, however, some smaller modifications over the years, thus the eagle was somewhat modified and in 1902 the arms of the cross were made heavier in order to avoid confusion at distance with the White Ensign of the Royal Navy. Overall, it is rather complex design to reproduce purely manually. First, I had to find a correct image for the ensign, as it looked in about 1878 and was lucky, as the Internet furnished a digital image of sufficient size and resolution. The idea was to print it on both sides of very thin paper (the kind that was used in the old days for carbon copies on type-writer, of which I kept a small supply). Such paper, however, does not feed well through the laser-printer and aligning for double-sided printing is practically impossible. Therefore, I resorted to so-called transfer-sheets. These are a kind of waxed paper that is used to transfer laser-printouts to T-shirts, mugs and such things. Laser-printer toner is basically carbon-black mixed with some plastics powder. It can be remelted with a heat-source, such as an ironing-iron and thus transferred to another substrate. I also experimented with overhead-sheets, but the results were not as good. Printing layout for the ensign (as it would appear on the transfer sheet) In a first step, the red stripe in the flag was eliminated from the image in Photoshop, as it would print grey otherwise. The ensign was then scaled to the right size on the basis of some trial-and-error, as the laser-printer prints a few percent undersize. I then added reference marks some distance from the image and duplicated this for mirroring. Several of these left-right-pairs were arranged on an A4-sheet and then printed onto the transfer-sheet using the highest quality print setting. Preparing the pouch for double-sided toner-transfer to the ensign-blank Using the best matching pair, I made a small pouch (as you would do for the masks, when producing photo-etched parts), aligning the images against each other for a perfect match on an illuminated board (they can be bought for a few €/£/US$ on ebay et al. and are powered through a USB-charger). An oversized strip of the thin paper was slipped in between and everything taped down onto a piece of thick cardboard. I pressed down an ironing-iron set to the lowest temperature onto the package, which made the toner firmly stick to the paper and no residues left on the transfer-paper. And voilà, a double-sided printed flag with a very detailed eagle etc. The toner is (almost) completely transferred to the ensign-blank In the next step the missing red stripe was added using red acrylic paint. I also added colour to the legs and beak of the Imperial Eagle, to the Imperial Insignia and the crown using yellow-ochre acrylic paint. If one has a colour laser-printer this step would not be necessary. The flag was cut out exactly to size, except for the rear, where it was left a tad longer to provide for a hollow ‘seam’ into which a thread with two loops at the end was laid The seam was glued down with some diluted white glue. This area also needed a bit of touch-up afterwards with black acrylic paint. The ensign before adding the colours Draping the flag is best done or least pre-arranged on the flag-staff. The paper was slightly wetted and the flag laid into diagonal folds in alternate directions. Toothpicks ensured that they became folds and not creases, which would be unnatural. Such a large ensign (2.9 m x 4.96 m) would fully unfold only in a moderate breeze and not in the light wind assumed in the scenic setting. So it flaps lazily in the wind, which I tried to reproduce. The completed ensign To the thus prepared ensign the halliard was attached as a loop. This loop was taken over the top of the flag-staff and a tiny laser-cut paper disc glued on as truck. There was no way to cross-drill the staff for the halliard. The halliard was belayed on the clamp. With this the assembly is ready for installation on the boat. But I will not hoist the ensign before the crew is on board. The recruitment process is still on-going … Ensign wetted and shaped Sorry, this was a rather lengthy essay on just and ensign, but the idea was to describe in detail, how to arrive on a reasonably realistic looking flag at such as small scale. The ensign attached to the flagstaff To be continued ....

-

I have seen historic and contemporary films on YouTube that show the use of English Wheels and there may be one or two that show the construction of shop-made ones. To be honest I don't really see a need for such a gadget in ship-model building. In the automotive sector they are used to reproduce complex and tightly curved panels with beads or similar features. If you use single copper-plates or even whole strakes in most cases no particular shaping apart from pushing it snug against the wooden hull would be needed. In the worst case you could gently rub on it with a round wooden dowel or something like this on a soft and thick cardboard. In boat-building the vertical iron panels for so-called Francis-patent boats were hammered to shape over wooden formers. The same later in the early years of the car industry, before mass-production.

-

Thanks, Kurt, these are interesting insights into the operation of such tow-boats. Of course, if these flanking rudders can move, they make perfect sense, when going backward. This would be a classical application for Schottel-props, but I gather they may be too delicate for the shallow rivers full of debris. There is also a limit to the amount of HP they can bring into the water. Turnable pods with Kort-nozzles would obviate the need for all those rudders, but again debris might be a problem and the shallow draught needed. In the early 20th century for working on shallow (central and eastern) European rivers systems, where the props worked in half-tunnels were developed. Some tow-boats also used early forms of water-jet propulsion to aid maneuvering and turning in tight bends.

-

Greg, what do you mean by 'dernier line'? Dernier normally is a measure for the fineness of a thread (1 den = 1 g per 9000 metre) and was also used to classify ladies' stockings and pantyhoses. There are other systems, such as the tex. I am not a great fan of monofilament, as it tends to be relatively springy and, thus, knots tend to unravel, unless immediately secured with some varnish. Some time ago, I became aware of this high-end Japanese fishing line. It's braided, available in 'steel-gray' and down to diameters of 0.06 mm: https://fish.shimano.com/en-GB/product/line/braided/a155f00000c5ijoqa3.html. Quite pricey. I have not tried it myself, because I didn't have a need for 'wire-rope', which it might simulate quite well.

-

BTW, talking about toolmaker's buttons: I learned about them about 25 years ago, when I purchased from Lindsay Publications (now sadly defunct) a bunch of reprints of early 20th century machinist textbooks and the likes. Among these was JONES, F.D. (1915): Modern Toolmaking Methods.- 309 p., (Industrial Press, reprint 1998 by Lindsay Publications Inc., Bradley IL). Just checked on archive.org and one can now download a copy from there: https://archive.org/details/moderntoolmakingmethodsbyfranklind.jones.

-

I have a separate hard-drive for backing up everything (as I also use the computer for work) around once a month and I only remove images from the telephone, once I have copies on two independent devices ... I was wondering about these rudders in front of the Kort-nozzles: do they move? If not, the boat would be quite sluggish to turn, I could imagine. And: oh, yes, the project is coming on nicely !

-

OUTSTANDING Mini Drill

wefalck replied to Bill Jackson's topic in Modeling tools and Workshop Equipment

That's a bit of thread drift now, but for really delicate work I use a watchmakers archimedean drill that requires both hands, as it does not have a return spring. I can precisely control the pressure needed/permissible (with tiny drills). Of course, the workpiece has to be fixed (some 'cello-type' suffices often), but this is good practice anyway. Mine can clamp drills down to 0.1 mm diameter. -

Talking about other people's projects: there is German colleague, I just remembered, who build a Viking-ship (the HAVHINGSTEN after one of the replicas after the Roskilde finds) in 1:25 scale and he had a whole boatload of 'Vikings' (or what he declared to be such). Not sure, whether you can see this without registering: https://www.segelschiffsmodellbau.com/t6718f20-Havhingsten-fra-Glendalough-21.html. He did a really good job in painting those figures.

-

Well, the sleeves around the smoke stacks are not just 'decorative': in order ensure sufficient draft, the smoke-stacks have to long, but then would cool down quickly. The sleeve isolates the actual smoke-stack, so that it stays hot. As even the sleeves become quite hot and old-time oil paints did not take the heat very well, ship company logos were painted onto an outer sleeve, some distance from the the sleeve that housed-in the smoke-stacks. Normally, the engine-exhausts are led into a condenser to improve fuel-economy. Some ships may have had the possibility to redirect the exhausts temporarily into the smoke-stack to increase draft (as is done on railway locomotives), but more commonly fans were used. The pipes placed behind or in front of the smoke-stacks are normally the exhausts for the safety-valves. Talking about pilot-houses open to the back: over here in Europe, when the pilot-house began to be enclosed, crews on some ships complained, because previously they got warmth from the radiating smoke-stacks, but now they were cold in the enclosed, but unheated pilot-houses ...

-

Can't respond on possible figurines. There may be something in 1/24 that could be converted with some effort. As to any goods, this would depend from where to where the ship was sailing and in what mission: trade or loot (I gather the border between the two might have been a bit muddled at times ...) Right up to the 19th century, perishable goods and those, where humidity either had to be kept in (say pickled fish, beer, wine, etc.) or out (metal ware, dried fish, cereals/flour, etc.) where stored in closed barrels, the containers of the time. A typical good of a ship sailing to Island or Greenland would have been wood, pitch and all sorts of provisions. Ships sailing from the Eastern Baltic would have carried inter alia pine-tar, pitch, wood, hemp etc. There were some major trade-hubs, such as Haithabu and Birka, where everything from agricultural produce, metal ware, luxury goods to slaves were traded.

-

Actually, in the physical archive there are two resources, the books that list the ships by name and then the folders with the drawings in the vaults. These books are a great resource, because they list all the archive numbers that belong to one particular ship, which allows you to collect all the drawings pertaining to this ship. I have physically worked though some of those books in the Rigsarkivet in Copenhagen some 25+ years ago. Then you wrote down the number for the staff and they would bring you the folder an hour later or so. These books now have also been digitised. In consequence, there are two ways of working with the material, you can either look up the drawings for a particular ship you are interested in, or you can go to the group of drawings that show particular details, e.g. anchors or ship's stoves etc.

-

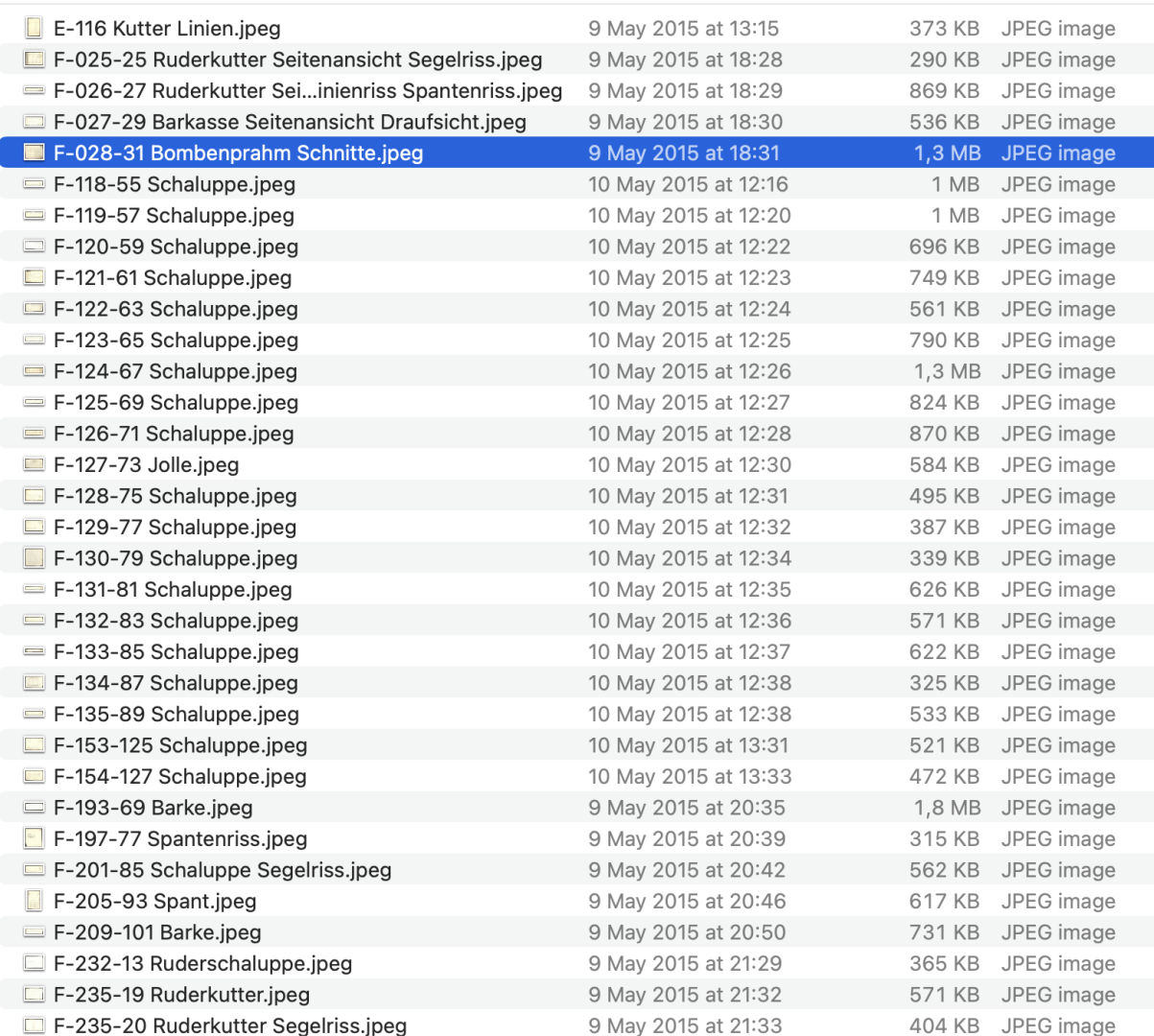

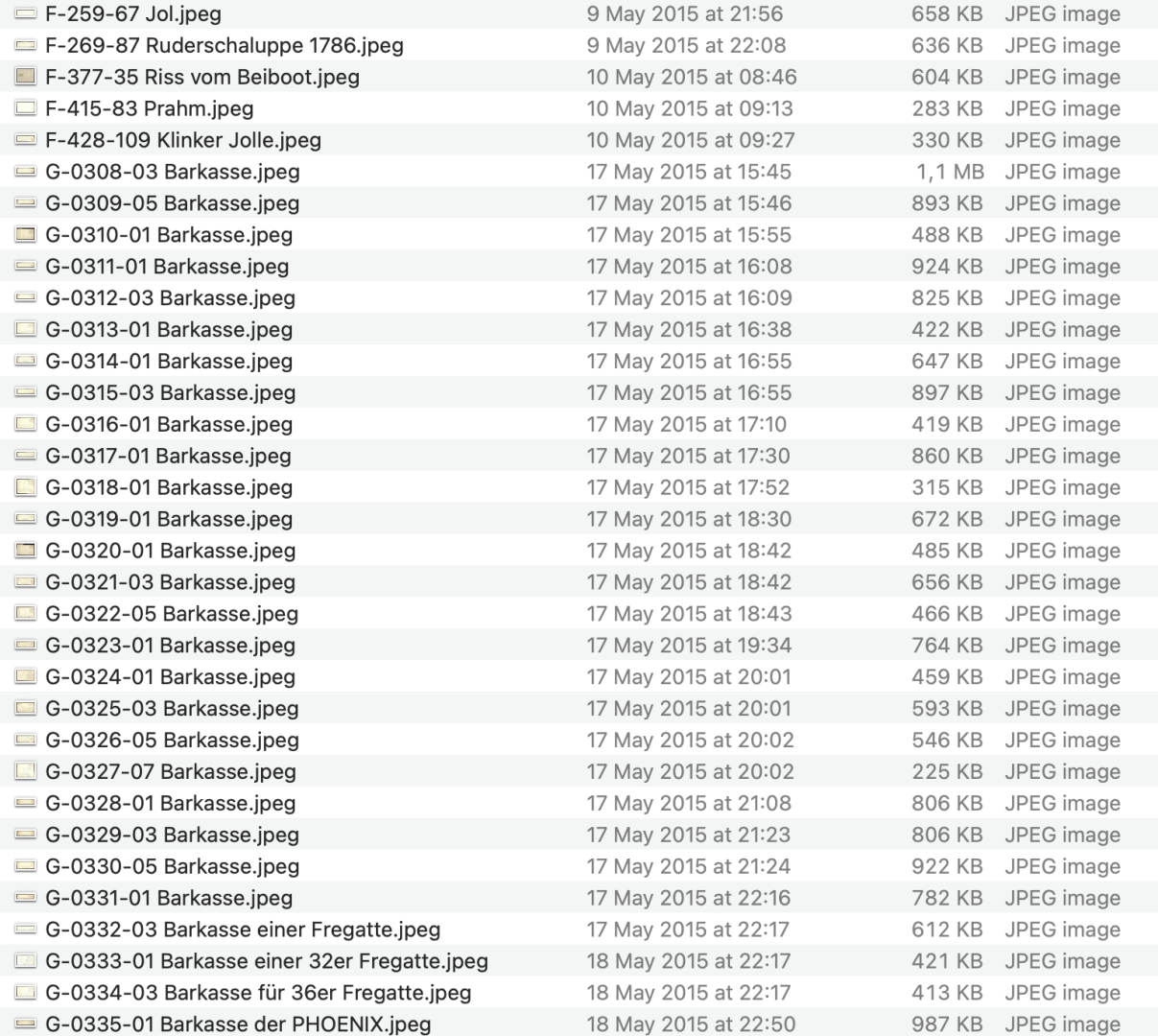

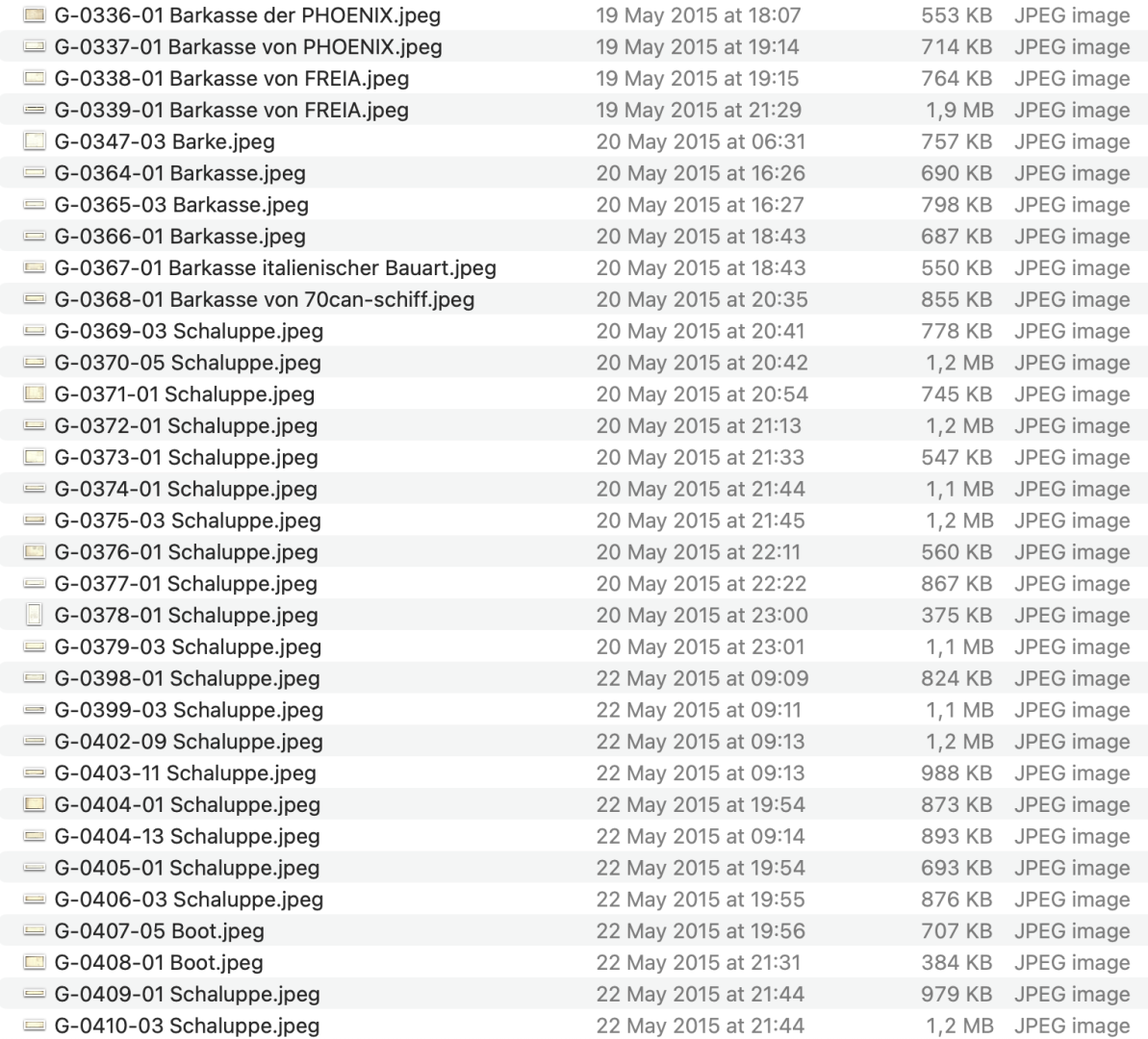

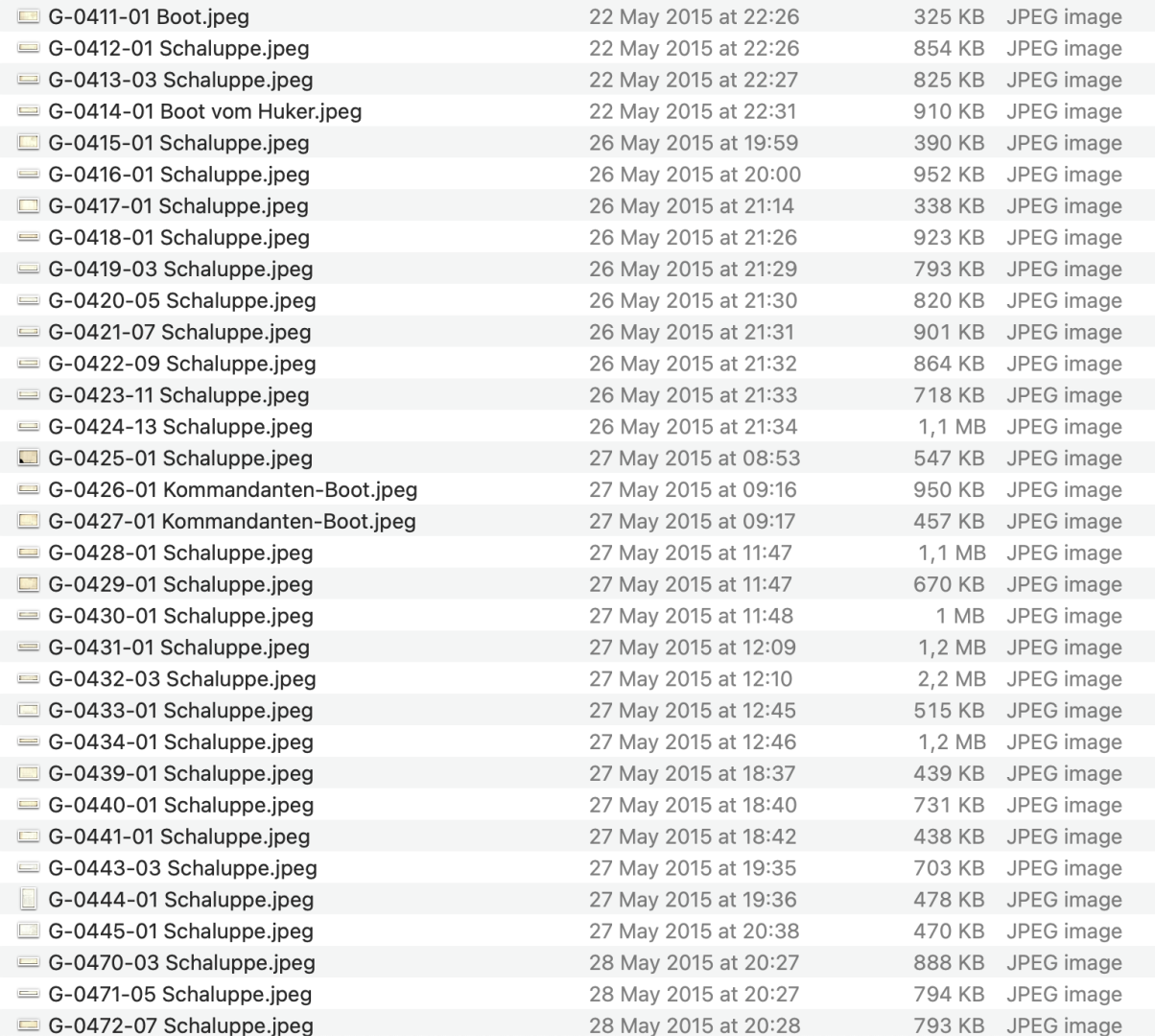

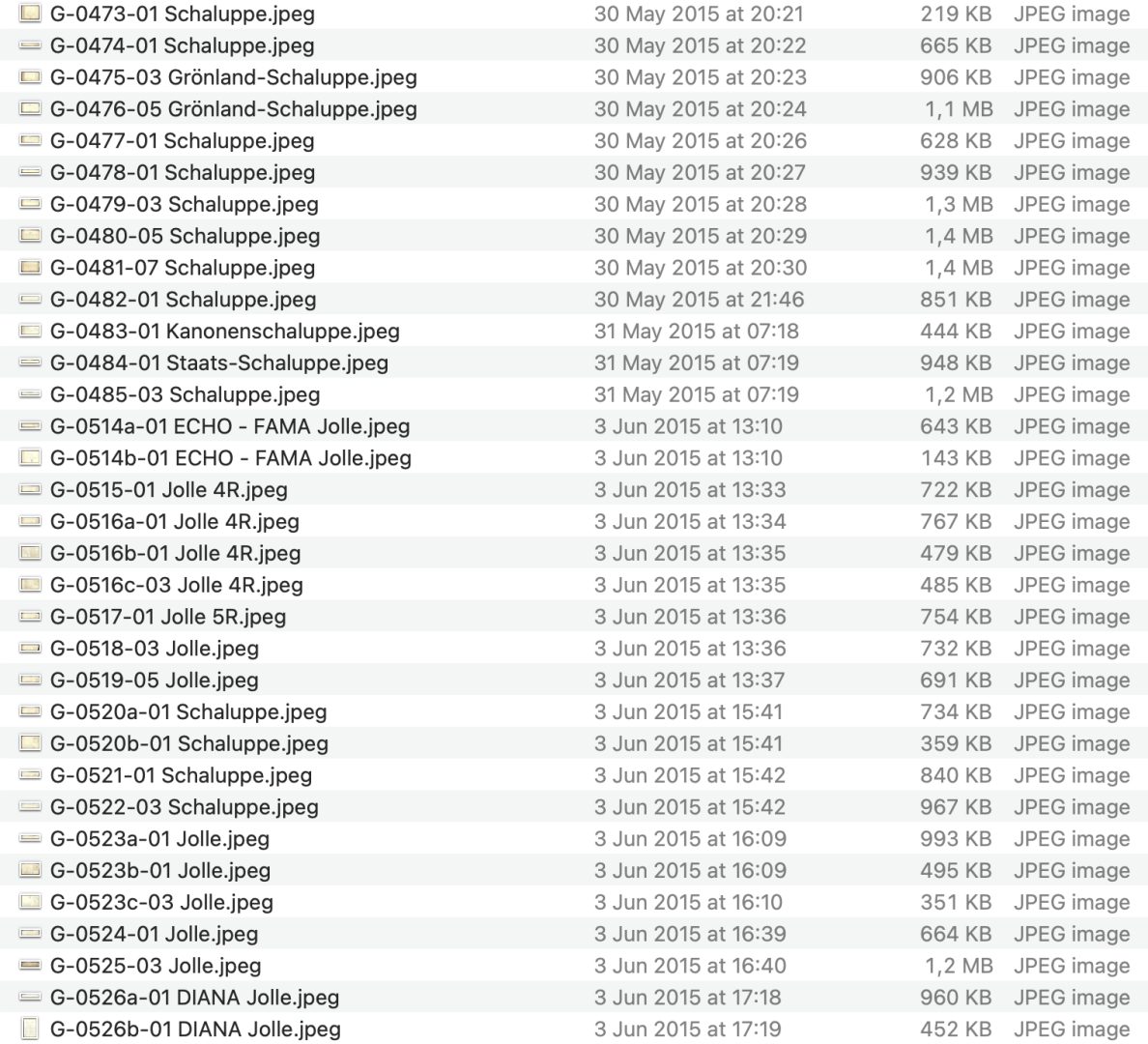

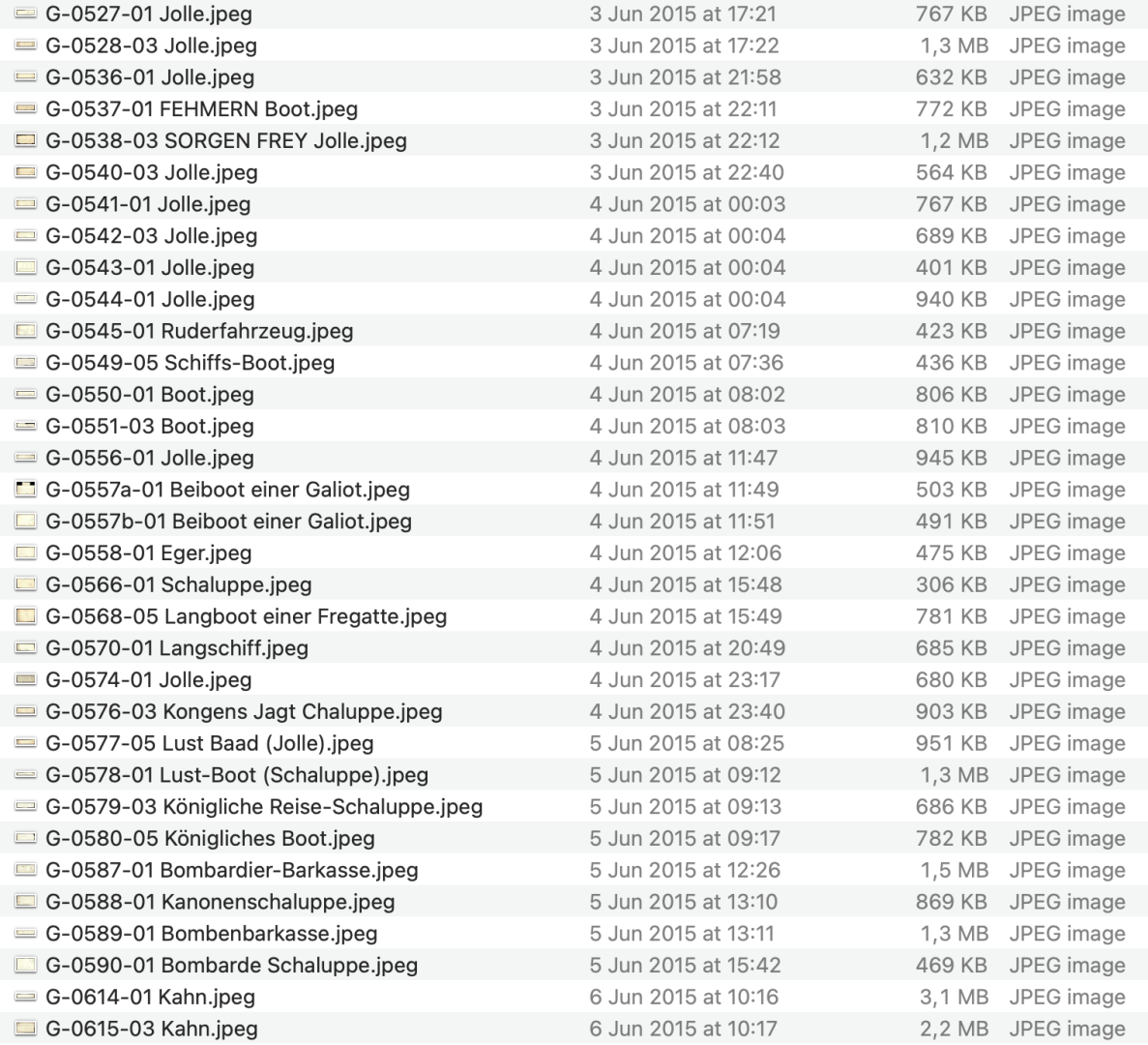

Alllan, unfortunately, there is no easy way to navigate around the site, which is structured exactly as the physical archive is. However, in general terms the archive is structured by subjects, but this doesn't mean necessarily that particularly drawing do not pop up elswehere. Historically, there might have been a logic for this, but this is lost now. A colleague and myself have actually gone through the pains some ten years ago to download the whole archive (I think they have added to it since, but I didn't have time to check ...). So, I have a fairly good overview over what is where. Below is a list under which numbers boats before ca. 1820 (this is an arbitrary date chosen according to my interests) can be found (sorry this is not 'clickable', I had to take screen-shots - and the description is German): Unfortunately, in the navigationsystem for the archive there are no 'thumbnails', so one really has to go through each archive number. I quickly clicked through the previews on my computer and have the impression that in many cases, give the large number of stations drawn, that these correspond to frames. The date of the drawing, or rather of its approval, can be usually found under the legend to the right, but not all drawings are dated.

-

I can only speak about German naval boats, but I think it would be more or less the same for all navies: The bow-oars were indeed shorter than the others, as the boat would be much narrower at the first bench. Some 30 years ago a colleague of mine, who unfortunately died prematurely a couple of years ago, wrote a series of articles on the naval oars of the Imperial German Navy that summarise the knowledge pulled together from various books, naval instruction manuals etc. that are difficult to put your hands on. Although, I do have some of these sources, these articles were extremely helpful, when I worked on my current project. He gives as a rule of thumb the following dimensions/proportions: Length = 3 times largest breadth of the boat, 2/3 outside, 1/3 inside the boat. Max diameter = 0.017 times the length at 1/3 of the length Handle = 0.8 times the larges diameter and about a foot long Length of the blade = 0.27 to 0.3 of the total length of the oar Max breadth of the blade = 1.5 times the max. diameter. Min. thickness of the blade = 0.16 times the max. diameter, at the end. In fact, there are tables with detailed dimensions for all the oars of the Imperial Navy, which were standardised to nine different sizes and matched to the different boat types, which were provided in different size classes. In fact, there were some 20 different boat types in the navy.

-

I think the original question was, what the distance between the frames would be, correct. And I seem to infer that the question concerns 18th century ship's boats? Have you had a look at the images from the Danish archives? There are some very detailed drawings, if I remember correctly, that even show individual frames etc. and not just the stations. For the 19th century, were are better informed, as there are various textbooks from different countries, that have plan views or longitudinal sections of naval boats with all the interior details. There are also few surviving boats that give an idea. At that time most bent frames were used.

-

Sorry, I indeed missed the point with the carpenters' glue. So once trimmed to shape, you lift off the assembly, apply the glue and put it back, right?

- 254 replies

-

I quite like the look of the 'painted canvas' decks. My concern, however, would be how long it stays attached to the decks. These masking tapes are designed to be not too tacky and I know that ordinary painters' masking tape becomes quite brittle with time. Good luck with your lecture and make sure that the audience watches with their eyes and not their fingers 😉

- 254 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.