-

Posts

1,171 -

Joined

-

Last visited

-

Scottish Guy reacted to a post in a topic:

For Beginners -- A Cautionary Tale

Scottish Guy reacted to a post in a topic:

For Beginners -- A Cautionary Tale

-

Archi reacted to a post in a topic:

Stairs on the hull planking and on the wale

Archi reacted to a post in a topic:

Stairs on the hull planking and on the wale

-

DaveBaxt reacted to a post in a topic:

Stairs on the hull planking and on the wale

DaveBaxt reacted to a post in a topic:

Stairs on the hull planking and on the wale

-

Old Collingwood reacted to a post in a topic:

Cowboy Chuck Wagon 1860 by JohnB40 - FINISHED - Model Trailways - 1:12 Scale

Old Collingwood reacted to a post in a topic:

Cowboy Chuck Wagon 1860 by JohnB40 - FINISHED - Model Trailways - 1:12 Scale

-

jud reacted to a post in a topic:

How hairy are ropes?

jud reacted to a post in a topic:

How hairy are ropes?

-

Hubac's Historian reacted to a post in a topic:

William Sutherland's concept of ship hull design, 1711

Hubac's Historian reacted to a post in a topic:

William Sutherland's concept of ship hull design, 1711

-

Hubac's Historian reacted to a post in a topic:

William Sutherland's concept of ship hull design, 1711

Hubac's Historian reacted to a post in a topic:

William Sutherland's concept of ship hull design, 1711

-

jud reacted to a post in a topic:

Making scupper

jud reacted to a post in a topic:

Making scupper

-

jud reacted to a post in a topic:

Syren Ship Model Company News, Updates and Info.....(part 2)

jud reacted to a post in a topic:

Syren Ship Model Company News, Updates and Info.....(part 2)

-

jud reacted to a post in a topic:

Need Help Identify Model Battleship / Recently Saved From The Curbside

jud reacted to a post in a topic:

Need Help Identify Model Battleship / Recently Saved From The Curbside

-

Mark P reacted to a post in a topic:

William Sutherland's concept of ship hull design, 1711

Mark P reacted to a post in a topic:

William Sutherland's concept of ship hull design, 1711

-

jud reacted to a post in a topic:

Repairing the bow on an unknown model boat

jud reacted to a post in a topic:

Repairing the bow on an unknown model boat

-

mtaylor reacted to a post in a topic:

Question about tholes

mtaylor reacted to a post in a topic:

Question about tholes

-

mtaylor reacted to a post in a topic:

Gunnery tools - ramrods, sponges - how were they stored on the spar deck?

mtaylor reacted to a post in a topic:

Gunnery tools - ramrods, sponges - how were they stored on the spar deck?

-

SIDEWAYS SAM reacted to a post in a topic:

HM Bark Endeavour 1758-61 by DaveBaxt - Caldercraft - 1:64

SIDEWAYS SAM reacted to a post in a topic:

HM Bark Endeavour 1758-61 by DaveBaxt - Caldercraft - 1:64

-

jud reacted to a post in a topic:

HM Bark Endeavour 1758-61 by DaveBaxt - Caldercraft - 1:64

jud reacted to a post in a topic:

HM Bark Endeavour 1758-61 by DaveBaxt - Caldercraft - 1:64

-

Spare spars and masts supported and secured near the ends only, then boats placed on the unsupported center and lashed down to the deck with any device that creates tension, would warp the spare spars. Support your spars in the center or lash your boats to the spars only and rotate them frequently. Any unsupported pole will sag without proper spacing of support and load.

-

jud reacted to a post in a topic:

Gunnery tools - ramrods, sponges - how were they stored on the spar deck?

jud reacted to a post in a topic:

Gunnery tools - ramrods, sponges - how were they stored on the spar deck?

-

jud reacted to a post in a topic:

Gunnery tools - ramrods, sponges - how were they stored on the spar deck?

jud reacted to a post in a topic:

Gunnery tools - ramrods, sponges - how were they stored on the spar deck?

-

jud reacted to a post in a topic:

Gunnery tools - ramrods, sponges - how were they stored on the spar deck?

jud reacted to a post in a topic:

Gunnery tools - ramrods, sponges - how were they stored on the spar deck?

-

In my second photo, notice the rag tied to the rail behind Hughes.' first loader', There to wipe the sweat out of his eyes and the oil and sweat off his hands, a kind of a tool that most never think about, but curses on anyone who wanted to removed it, there was another for the other loader. Flack jackets became tools when the steam and scalding water came bouncing up off the top of the water cooler tanks, throw a flack jacket over it and keep on shooting, someone will drag a water hose up and take care of it. If a short boil, could be toped off using another tool, the steel pot had a good water spout built in. Right gun is being cooled off, it's loader is assisting the loading of the left gun, position of the clip and operating lever give it away. Keep what you need on the gun to keep it going.

-

jud reacted to a post in a topic:

Gunnery tools - ramrods, sponges - how were they stored on the spar deck?

jud reacted to a post in a topic:

Gunnery tools - ramrods, sponges - how were they stored on the spar deck?

-

Keep the tools to work the gun, on the gun, not a problem for those with the ability to hang such things up, secure and out of the way using hooks, straps, line, knots and hitches daily. In the days of sail, space below decks, then, as it is today on the ships that I rode was at a premium, ladders few and space was used for stores needed to sail and maintain the ship and crew for months at a time, Those sailors were the same type of human we have today, so they were capable of storing their tools safely and out of the way on or near their guns out of the way of hundreds of men in a confined space getting to their battle stations. You wonder about the weeks and months with no contact being idle times so be a neat nick and stow such tools below during those times, you forget about the drills and gun exercises that keep men busy and the ship capable of fighting and surviving if needed, those tools were there for training and combat. Keep them on or handy to the gun where they were used. A model depicting ordnance without the tools to operate that ordnance is not finished in the mind of this Old Gunner.

-

Varied by ship, her job and job of each individual, in a combat Zone or not and the experience of the Skipper and crew. On LST 821 we operated in a combat zone constantly month in and month out supporting SEALS, PBR's and HAL 3, were kept busy just doing our thing without GQ on top of it, so we minimized that and had a ready gun always manned with enough to fire one gun, two men on roving patrol with grenades and a M16 as defense against swimmers and floating mines while we went on about our business, some got more sleep than others but it was those who got the most that the months on station bothered the most, one shot himself because he wanted no more of it and he was a E6 Store keeper, exhausted enough to sleep on anything and take power naps is good thing on extended operations, just as important or even more so, is the ability to remain alert in spite of it all, when others are relying on you doing your job.

-

Quote from Srodbro, ( I wonder whether the water course was less intended to protect the deck from heat than from fat/grease leaking thru the layers of brick ( due to cracks in the masonry and joints ) from the burning of blubber scraps as fuel and spreading fire to the deck below ). Suspect this is the correct reason for the water. Used as a barrier to the oil preventing the decks and supporting timbers from becoming soaked in oil and a stinking messy fire hazard later.

-

Before GPS but Loran was in use on larger vessels, all we had was a chart, magnetic compass and a fathometer to navigate from Bellingham, Washington to SE Alaska and back with a King Salmon Season between. We used the compass and visual cues to steer by, paid close attention to the chart and water depth, verified by the fathometer, to verify where we were while running or fishing. When caught by fog, we listened for horns and followed a bottom contour chosen from the chart to find our way in to a place to anchor. We had no Binnacle but there was a gimbaled Nautical Compass mounted which was adjusted to the magnetic field it occupied with tested and certified correction tables at hand. All forward of the wheel of the 34 foot King Salmon Troller, Cape Race,1965. Don't remember needing the correction tables, would pick a course, get on it and visually correct if necessary, we were running the Inland Passage or when fishing, had islands in sight most of the time. Did have Binnacle's, Engine Order Telegraphs, Gyro Repeaters and of course Radar, on every Navy Ship I rode, they were a Fletcher Class Destroyer; a Baltimore Class Heavy Cruiser; 3, 542 Class LSTs and some others doing my reserve time.

-

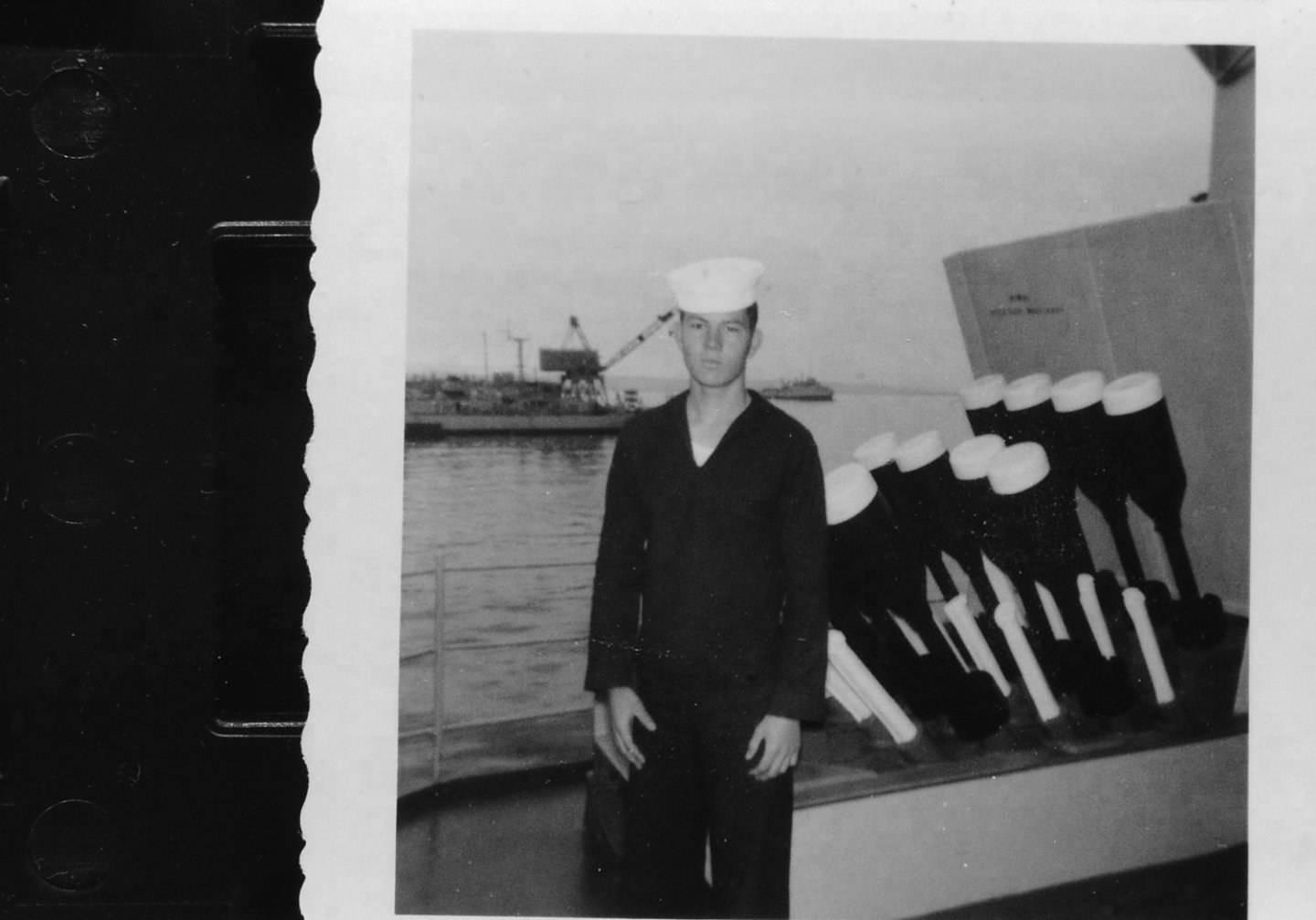

Starboard Hedge Hog Projector, 01 Level USS Ammen DD 527. Sailor was named Lyle, a buddy I went through Boot Camp with, he was killed during the 19 July 1960 collision. I was part of the crew that fired this projector on 2 occasions, as a crew member of Mount 31, a 3"50 Dual Propose Gun Starboard side, between the stacks. When at GQ, ASW, some of us manned this projector. Those modeling this thing, don't forget the big red 'safety firing circuit plug', that would be mounted on a bulkhead, there were two in the circuit, one on the mount and the other in Sonar, they were closely monitored, removed from the circuit for loading, the projector spigots would be centered and locked, before the loader would put one leg inside the frame to load, we never had a problem but rumor was those things broke many a leg, or killed, when a rocket motor would ignite when loading.

-

The Rattlesnake was built as a privateer intended to appear as an English Frigate, so she would have been painted to mimic the English Frigates of the day. She was captured after a short busy career and would have been kept in pristine condition while in American hands to fit that roll, her record indicates that it worked. So look to the British Frigates of the time for your painting scheme.

-

Most models are depictions of Government ships with Captain's, if finically able and for status and promotional reasons used everything they could to gain attention when it came to the appearance of the ship, I suspect prize money finance a lot of that. The Commercial Owner and Skipper were interested in profit and keeping operating costs down, that goal had a lot of impact on appearance unless engaged in a competave trade such as wool and tea, Guano, general cargo and the age of the ship would limit the value of appearance when you could Shanghai a crew.

-

Expect lots of thinned linseed oil and diluted pine tar was used more often than paint on weather deck spaces and furniture. Thinned or diluted for penetration, wood being porous, some areas might have had pigment added to the mix. Get water under painted wood and the paint lifts off, so use proper oils often to protected from water, especially if subject to repeatable dry then wet cycles.

-

Wife asked me to put drain holes in a container she had dragged in to plant something in, used a 22 revolver to make the drain holes. After that she used her own revolver for such chores, might try that, shoot a hole in the bulwarks or side, run a jig saw blade through it, attach the blade to a saw, and have at it. If done carefully, you can do both sides at once and save ammo.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.