-

Posts

1,171 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by jud

-

a drafting tool or paper weight

jud replied to garyshipwright's topic in Modeling tools and Workshop Equipment

Google flexible curve. The one I have had for 25 years is a STAEDTLER. Have not used it since I started using CAD, but it worked well for those pesky Highway Spirals I once had to draw and later stake out on the ground. Did on occasion need to use drafting paperweights to keep it stationary on large curves. Those weights were shot or sand filled round shaped leather pads we used for keeping plans flat, still available, also easy to make but an old boot in a plastic bag, bulky, but would do the job. -

Fine picture, they were busy ships in all their rolls. Thanks for the posting your work, all of it and especially this, you must have covered most of the ships of WW2 and many under sail. Couple of photos of USS LST 44 on the net, your work portrays her better.

-

Winston Churchill stated: " The destinies of two great empires seemed to be tied up on some God damned things called LST's." Over 1150 were built, kind of important ships that received little glory, yet did a big and diversified job.. Make my request for your efforts depicting an image and the role of the LST. Yes, I rode 3 of them in the Vietnam war.

-

As the hanging ropes are depicted, they are used to mask the location to an approaching foe. The Eyes on both ends would allow for a bar or pole to be inserted through all, restricting their movement and preventing twisting and tangling while they were being trained to hang properly. They were also probably used with a bar or secured pole to restrict movement and tangling during high wind conditions. What you see is what you get, they are not Mantlet's or intended to mimic them.

-

They were called mantlets as the article says, it also states that they were woven rope, not hanging rope and intended to stop projectiles and at Gibraltar flame from setting off unprotected powder. The hanging ropes in the original photo are not mantlets and would fail to stop shot or flame. When I was doing a lot of archery, to extend the life of my backstop bales of hay, I would hang a piece of old carpet, about a 6' X 6' piece, in front of the bales to stop the arrows, they never reached the hay. Was shooting an 80 pound compound bow, the arrows would strike the carpet and as it was free hanging from the top, it would rise and bunch up absorbing the energy, much as a true manliet would do. Replacing the target area was a simple matter of attaching another piece of carpet over the shot up main carpet.

-

Thanks for that, have used painted canvas for siding and roofs on canopies and on small sheds, the boiling water I missed, sounds like an improvement. Canvas shrinks when wet without help, so maybe 2 or 3 coats of wet latex would accomplish the shrinking with better penetration for my occasional needs.

-

Swivel guns

jud replied to tlevine's topic in Discussion for a Ship's Deck Furniture, Guns, boats and other Fittings

I suspect there was no hard and fast rule on mounting height of swivel guns that was not related to location and intended target. If mounted aloft and sighting down the gun to a neighboring ship, close enough to justify shooting, knee high would be about right, If mounted on the bulwarks and the intended target was the upper works of you enemy then head high would work, allowing the gunner to squat to aim. If intended for a horizontal slugfest, then mount a Quaker and ambush your foe while their attention is on the dummy. Swivel guns are intended to be pointed and aimed quickly so mounting height is considered when placing them. An adjustable mounting for height would be nice, the 20MM Oerlikon was basically a Swivel gun and the mount permited the height of the gun trunnions to be varied easily and rapidly for any sight angle, to suit the convenience of the gunner. This is done by the column raising handwheel mounted on the pedestal head. -

Steam Gratings

jud replied to barkeater's topic in Discussion for a Ship's Deck Furniture, Guns, boats and other Fittings

Wood clad in sheet metal would encourage rot, so I suspect it was not the practice. Cast Iron or bronze gratings would withstand the heat, steam and greasy smoke they would be subject to and also be reasonably easy to remove for cleaning. -

Mini spot welder to weld railing

jud replied to modeller_masa's topic in Modeling tools and Workshop Equipment

Put the arc welder away and use a gas torch to weld with if you must weld, be better to braze the joints. From the net; A brazed joint is made in a completely different manner from a welded joint. The first big difference is in temperature – brazing does not melt the base metals. -

Rattlesnake was built as a Privateer, 'civilian warship', ornate carvings are not fragile and were relative cheap at the time, can become splinter hazards if hit with a round cannon shot. There was no safety glass in those days and broken glass cuts today, just as it did then, we go to great effort to prevent it from flying around in large chunks when broken. Small ships with large crews needed to fight and provide for Prize Crews, could not stay at sea long before provisions were used up, those provisions would have filled every available space, leaving no free space to strike glass below or carry safety covers for it, heck the crews probably slept in every corner around the weather decks and in every cranny below. I don't believe glass was used at all in these ships, except for perhaps to pass light into a magazine, because of its danger and the cost in a vessel built strictly for going into harms way for profit. Often showing a light at night was dangerous for small vessels. We live in a well lit word, in Rattlesnake's day, they had learned to do well with little artificial light or windows.

-

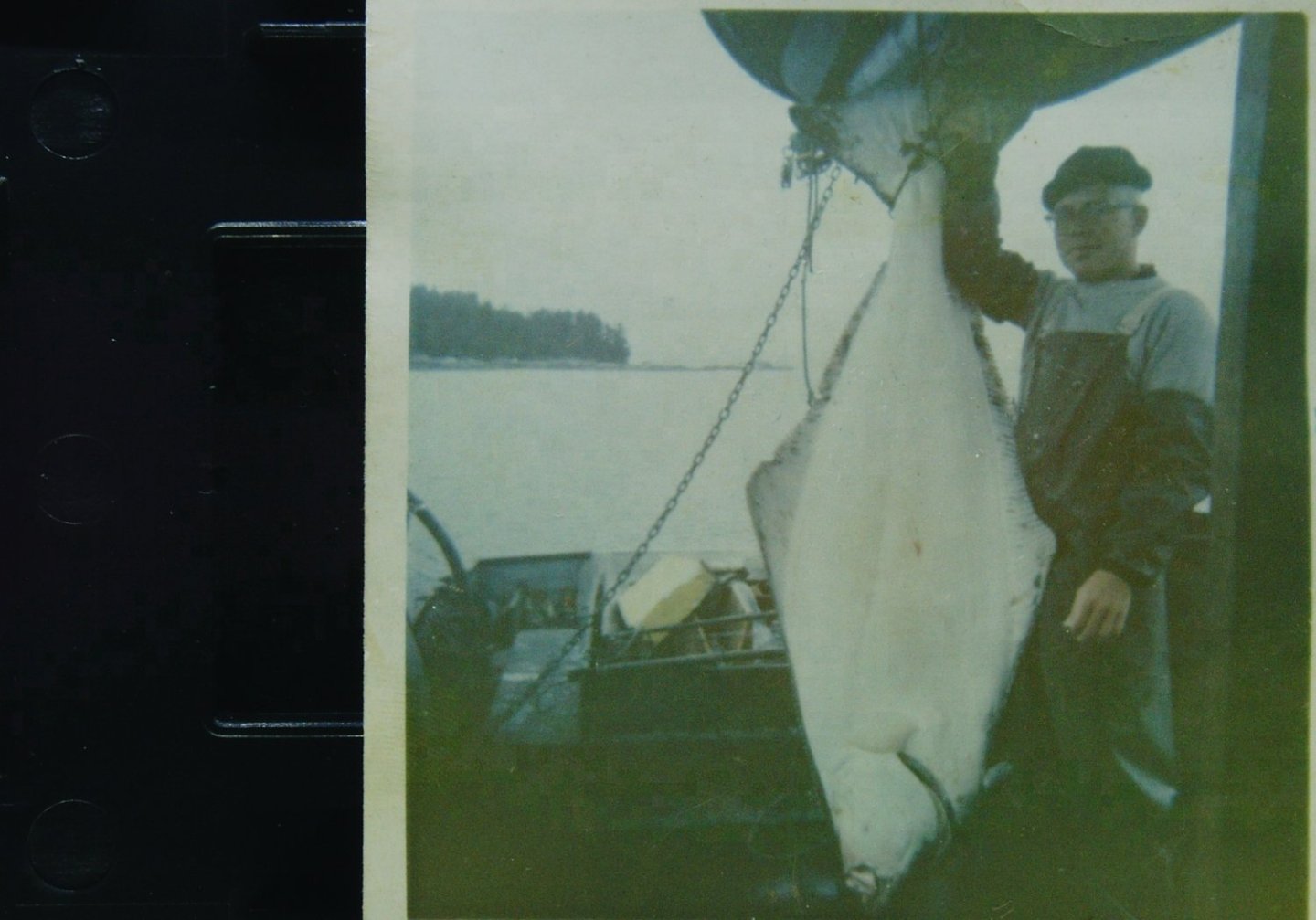

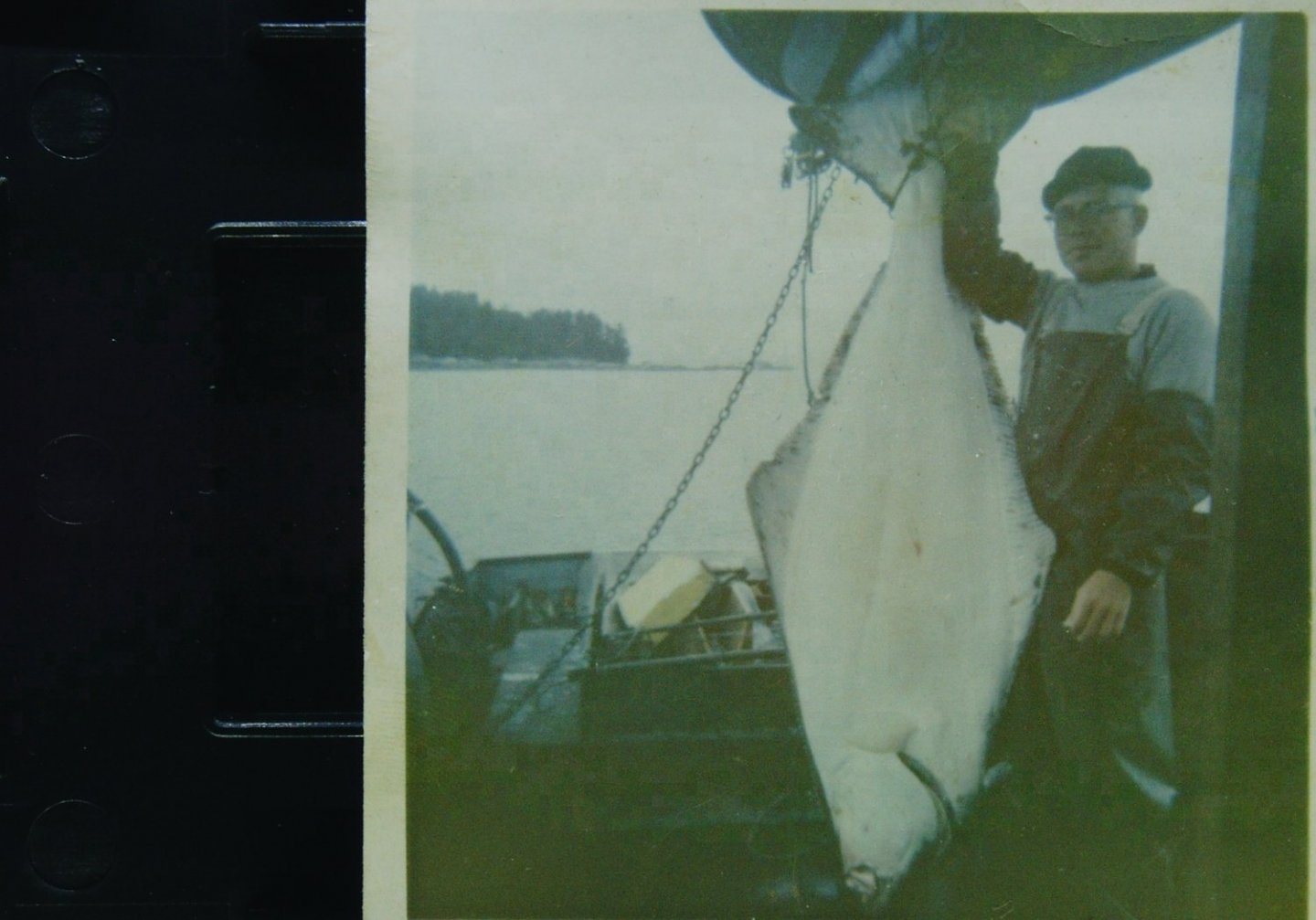

Not a ratline, but spacing is wrong, it stayed wrong, never wore it out because of a collision at sea 19 July 1960. Me, 1960 when still on Deck Force leaving the Whale Boat after a run. I, being a newbie was the Bow Hook.

-

Suspect that the cargo was manhandled to the main deck using carts, 2 wheeled trucks and slides, then block and tackles or slides were used to move it below, where manhandling was again used to secure it for sea. When the sails were replaced with steam power, there was room previously not available to rig windless with swinging booms to move cargo directly from dockside directly into the holds where manpower was used to stack and secure for sea.. Think the hand powered windless seen about he decks were primarily used to manage the needs of the ship and her sails. Took a long time to load a ship in those days and large Stevedore gangs were common.

-

Fishermen who spend their lives afloat would figure it out and each solution and the details would vary from boat to boat, man to man and from each type of container. It's contents and intended use would dictate the where. You need to make a decision on contents and intended use to make a good decision on location. Having chased 8" projectile's, a fork lift and hundreds of random items around the decks of rolling modern ships I have learned something about securing for sea. Movement of any kind is the killer, no matter how small it may be, it will grow and if not stopped will break out. However you chose to secure the barrels they must be hard against a structural part of the ship or the lines, straps or chains secured directly to the ship and need to be easily adjusted. Make your choice on the reason for the barrels being there in the first place then secure them for sea where they can be used for their intended purpose or leave them in a box near your work bench.

-

Being an X Navy Gunners Mate, I like Guns, Lots of Guns, but why would a perfectly good Schooner need Chase Guns? If pursued, steer upwind and run off over the horizon if over gunned. Also guns and carriages are heavy, the stern of a schooner is a poor place to be adding the weight of guns, carriages and crews that can only be fired aft and those guns and carriages would be the devil to move elsewhere to trim the ship or to store amidships and move them into an position if needed. Forget the Ports, not a logical place for an armed schooner to have guns, just the additional structure to handle the weight cantilevered aft, would handicap the ship and slow her down.

-

Boathook history

jud replied to Michelnou's topic in Discussion for a Ship's Deck Furniture, Guns, boats and other Fittings

The book is worth reading anyway to get a flavour of serving on an American merchant ship and sailing round the Horn to what became San Francisco. //////// -

The whole arraignment looks suspicious to me. Stove sits on a brick bed, an approved and practical safety precaution, then that built in safety consideration was overcame and made moot by the placement of flammable and well dried wood so close to a hot iron surface radiating heat. There are good reasons to maintain space between stoves and flammable surfaces. Then there are the considerations of actual use of the stove for cooking for a large crew and the space needed to do so. Something is very wrong with this picture.

-

Waterways

jud replied to Ron B's topic in Building, Framing, Planking and plating a ships hull and deck

Amidships, Port side, USS Helena CA 75, 1961. Wood Deck laid over steel and waterway. Whaleboat visible, rigged for quick deployment, we had two and rubber rafts were used for Life Rafts. -

Thought some might find this link interesting, near the end you can see clearly the delay after the shot leaves the bore and the remaing energy after overcoming the mass of the gun and carriage results in movement. https://l.facebook.com/l.php?u=https%3A%2F%2Fyoutu.be%2FWSXaCkQ9sF8%3Ffbclid%3DIwAR2_jageataBz8xSUo-6A9s3GRBT-1LH8659E9XbNK-fB-x5g0jO0eX5lIQ&h=AT0xInmSvJNLmqPpMy3aL6CFU_BmCU3pC7zvwp-lWxUNzSNCDhbVqM9SoUkWqutvh8VyafbMhELs9fNC5jEpZRwRRQzvuKBR73Gs__Nf3hMiVquWh4uMvlaDv9uw43oQytiMUXgHI2FSB4BJJa0&__tn__=H-R&c[0]=AT052FpwOe6xVjYlypq6Ix-aaIks1ECHaDlMSPOZiX1_jjKG4aVjZ_uS5uqwNg46qGNIiOWxzJTWGxJeWHFJ7hVUe05XqacKDLDg9ckKtOrVKAB1XlqVH1pU3woLIJlYN8F-kbv-hZi11V8iUOsHldNT37ss40MGYNuvZ3W13aIc2bLgt-f7hWYF-xFNg7-5jcADAnbX7IJJBtyX45c

-

Ladder steps

jud replied to allanyed's topic in Discussion for a Ship's Deck Furniture, Guns, boats and other Fittings

Only one way to adhere to a lift per step standard without having an odd step at the top or bottom is to adjust the length of the slope. Many times that option is not available and step height must be adjusted, not a problem for an experienced seaman to adjust to, it is the odd height at the top or bottom that causes problems, so keep them all the same, those using them will adjust.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.