FlounderFillet5

Members-

Posts

139 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by FlounderFillet5

-

In my experience, I didn't normally get a response, but a package with the requested parts just showed up a handful of days later. I would wait a week or so to see if they arrive in the mail before purchasing elsewhere. Is there another part of the build you can work on in the meantime? Maybe a lifeboat or similar to keep you occupied while you wait? I hope this helps and good luck getting it resolved!

-

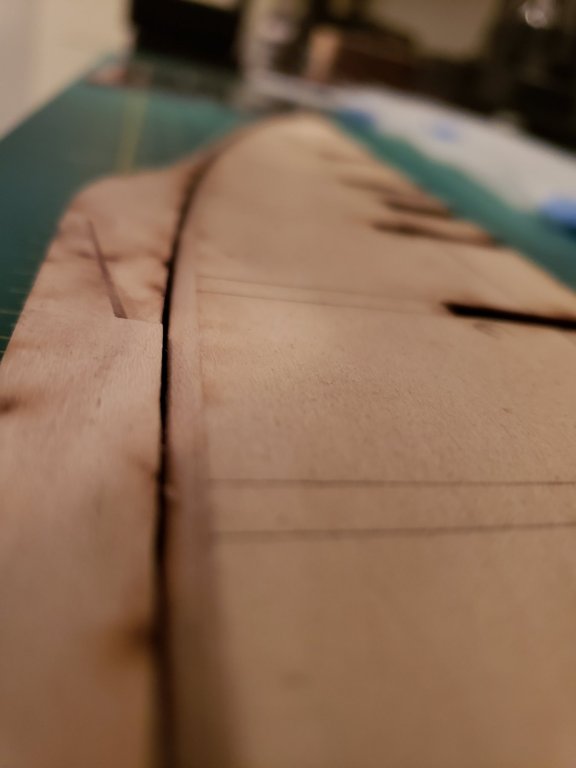

Thanks Wayne, and Happy New Year to you as well! Upon a close (not that it needed to be that close) inspection a few days ago, I noticed that the garboard strake was very wavy and wouldn't be able to be resolved with some sanding as I originally thought. I decided to tear the planking out and restart on it. This took some very careful chisel work to maintain the sharp edges on the keel. I have seen people mention that they have the set of mini tools from veritas and basically never use the chisel set, but I have found them to be very helpful in the nibbing process as well as the cleanup of the rework I did here. I used my full size chisels for the rough work, but the little guys really helped get into some tight spots. I have already done the rework to get the first 2 1/2 planks on each side back in place and they look much better and I am now happy with my technique of planking this portion of the hull. I will have pictures of the new planks in my next update. I am running into a little difficulty with the third plank up from the keel though; I placed the forward most plank, the one with the nib(or hook) and it fits great on both sides, but the middle plank that runs between bulkheads F and K is difficult to clamp properly. I have twisted the plank to fit pretty closely to the transition between planks, but my first attempt at making this plank was done in such a way that the bottom edge that runs along the second plank seems to be too straight and thus needs to be edge bent slightly to have it fit tightly along the second run of planks. This wouldn't be an issue, but I don't seem to have a clamping setup that allows me to put pressure on the plank to both hold it down flush with the bulkheads and hold the edge of the plank tight against the existing plank below it. I am going to try and remake these planks, edge bend the tapered planks using Chuck's video tutorial that is posted here on MSW, and then twist the bent planks to the proper shape to match the changing profile of the hull along its length. If this doesn't work, I would be at a loss on how to hold the planks while the wood glue dries. I did just have a thought that I could do something along the lines of making a small block of softer wood with a hole in it that will fit a small nail, then I could drive the nail into the side of the bulkhead at a location that would put pressure on the plank via the small wood block so as not to dent the top edge of the new plank. I realize that that description is probably hard to follow, but I think that will be my plan to try and get this next plank in place. The planking process is kind of fun, definitely challenging this first time, and also very slow going. It seems that I have the time and mental fortitude to cut and try to secure one plank on each side of the hull each evening, but that means that the planking will take around 3 weeks not even including the fact that I plan on complicating things more than I should around the waterline by transitioning between the pear below the waterline and ebony above it and possibly adding a very thin strip of holly at the transition to accentuate the waterline slightly. I am looking forward to seeing this portion of the build come together, because just seeing a couple/few planks on the hull is a little daunting considering the amount of time I have already investing in learning to plank, trial and error, and rework. Until next time... Cheers!

-

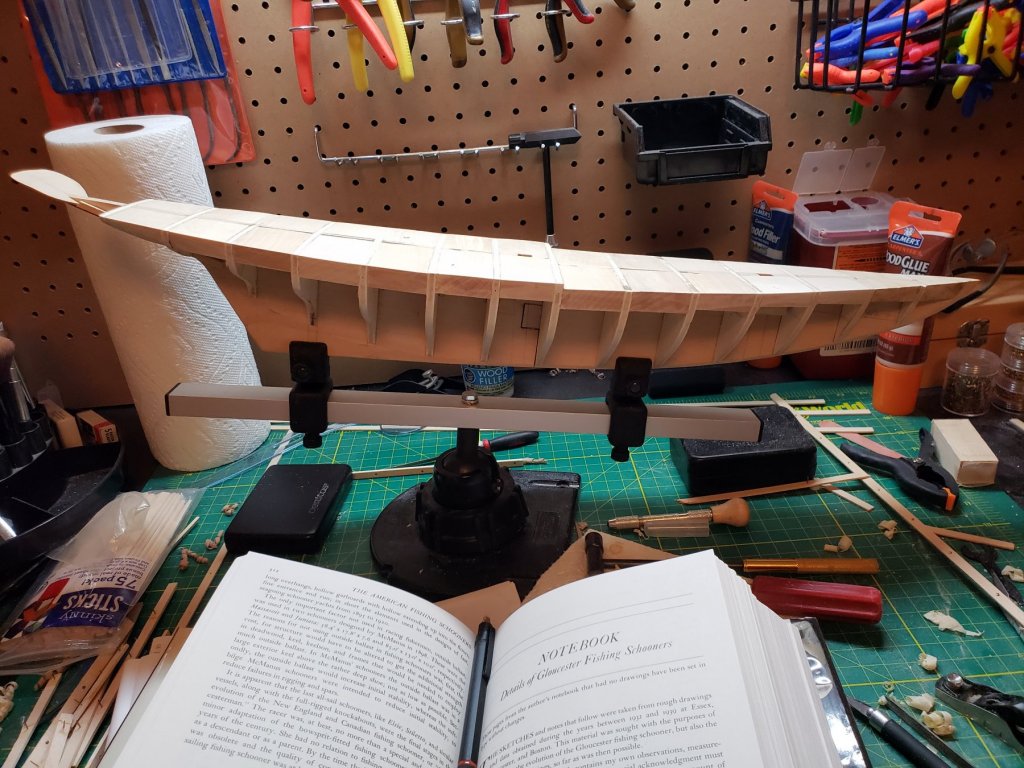

Time for another update, got a little work done over the New Years holiday. I lined out the hull and started laying my first hull planks ever. I think I mentioned this in my previous post, but I am using Swiss Pear for the hull planking below the waterline as well as for the keel, stern post, and (eventually) the rudder. Also note that I added a strip of Swiss Pear to the false keel where the planking will butt up to the sides. I do realize that the majority of this will be above the waterline, so they will be ebony planks butting up against it, but I think it will look fine with the Swiss Pear being constant along the length of the keel. As I said, got the first couple planks laid.

-

Hey everyone, Wanted to come back for another quick update on milling the wood for the planking portion of this build which will get us just about caught up. I started with rough boards of swiss pear and american holly, and then the castello boxwood and malagasy ebony both came from Gilmor wood company and they provide blanks that are fairly flat and square, which is pretty convenient, but an expensive convenience. Anyway, I am getting an error when uploading pictures of the rough stock and planing process, but I used one of my block planes to plane the rough boards. I do have some larger planes that I purchased second hand and that would have been better suited for jointing these boards, but I have yet to get to restoring them, so the block plane was the best tool for the job here. I was able to get the Holly almost perfectly flat according to my straight edge, but had a tough time getting the slight twist out of the swiss pear. I decided to just rip the 2-3" blanks from the slightly warped pear wood, which reduced the twist because of the reduced width. Then I used the Byrnes thickness sander to give me parallel faces and used the block plane again for jointing the edge of the boards and making sure they were perpendicular to the faces. I then started resawing boards which were thicker than the final dimensions needed and used the thickness sander between resawing in order to produce the boards you see in the following photo which all have one flat side and one with bandsaw marks. I then ran all the boards through the thickness sander until they were the appropriate thicknesses and then cut planks according to the dimensions in the parts list that came with the kit. The swiss pear strips are for the hull planking below the waterline and probably the great beam at the deck step level, the ebony will be used above the waterline, the boxwood will be used for the waterway a small bit of deck planking and probably the deck houses' roofs, and the holly will be used for the majority of the deck planking and possibly the deck houses' walls. I am undecided on which wood I am going to use for the deck housing coamings, I am trying to decide between the pear and boxwood, but that decision will come a little bit later in the build. I also wanted to try something of an experiment: I needed 1/32" thick and 1/16" thick planks for the bulwark planking, but since I would like to keep paint off of this ship and use wood to get the colors I would like, I decided to try and laminate some holly and ebony for the bulwark planks so that the outside will be ebony to match the upper hull planking and the inside will be holly to match the color scheme of the deck and accompaniments. First, I cut the holly and ebony to both 1/64" and 1/32" thicknesses, laid them on the table as shown in the picture below, spread glue only on the faces that were up and sandwhiched them together and clamped them the best I could with clamps and calls to try and keep them lined up pretty well. The planks to the left (with the blue painters tape) are 1/32" thick and the ones to the right are 1/16" thick. Here is the result of the glue up, now just need to plane the edges flush and plane the faces slightly to get the glue and blade marks off the faces which are the important sides. A view of the side of the glued up bulwark planks, I think this might just work! If I were doing this again, and I might need to because I may have not cut enough of these planks, then I would cut the planks about 1/8" oversized on the width to give me a little margin to plane down one edge and rip the other edge to the final plank width. You live, you learn, but maybe these will be just enough and I'll be able to get them to a consistent enough width to be usable. I have been reading up on planking strategies and methods, so hopefully I will be able to do all of this fancy wood justice and not waste it. My biggest concern with planking the hull is the garboard strake, but that may just be because it is one of the first planks I need to make and there aren't any really defined rules for its size or location, only loose guidelines. Thanks for stopping by and, as always, constructive criticism or wisdom is always appreciated!

-

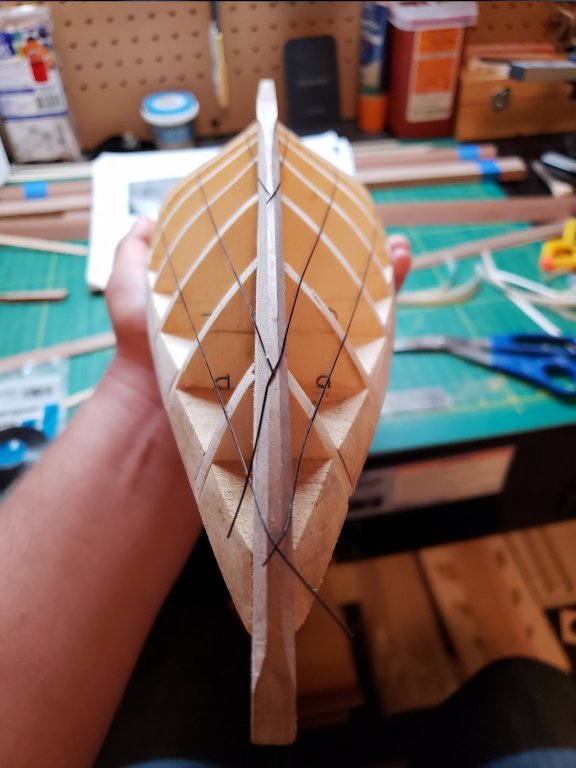

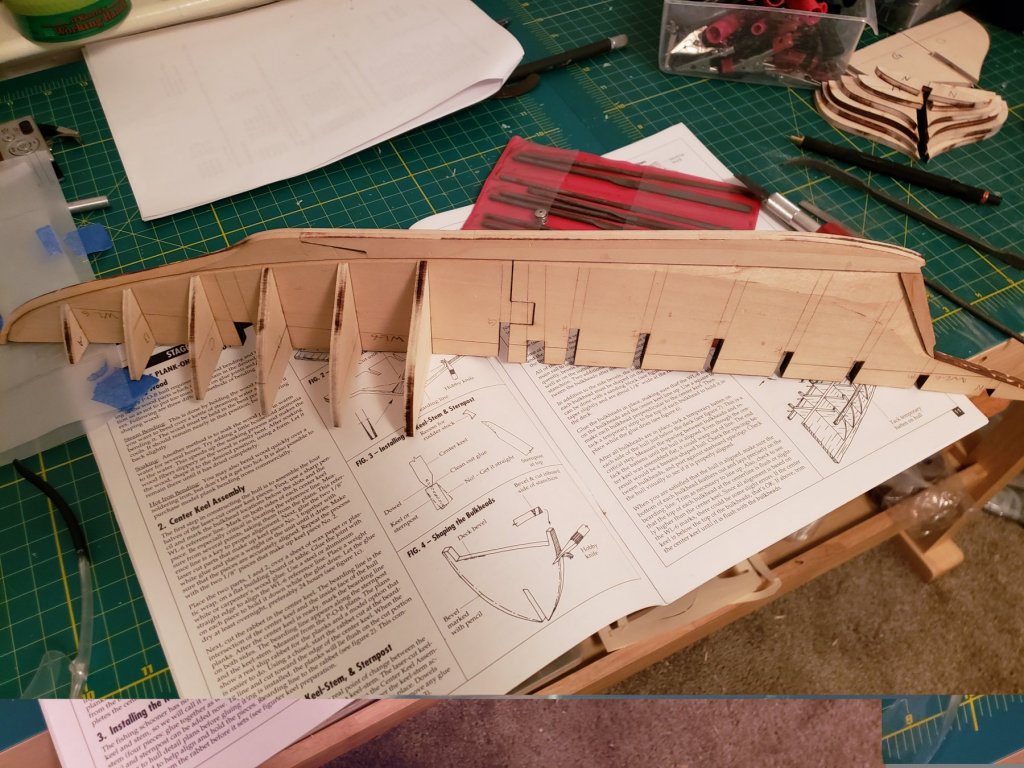

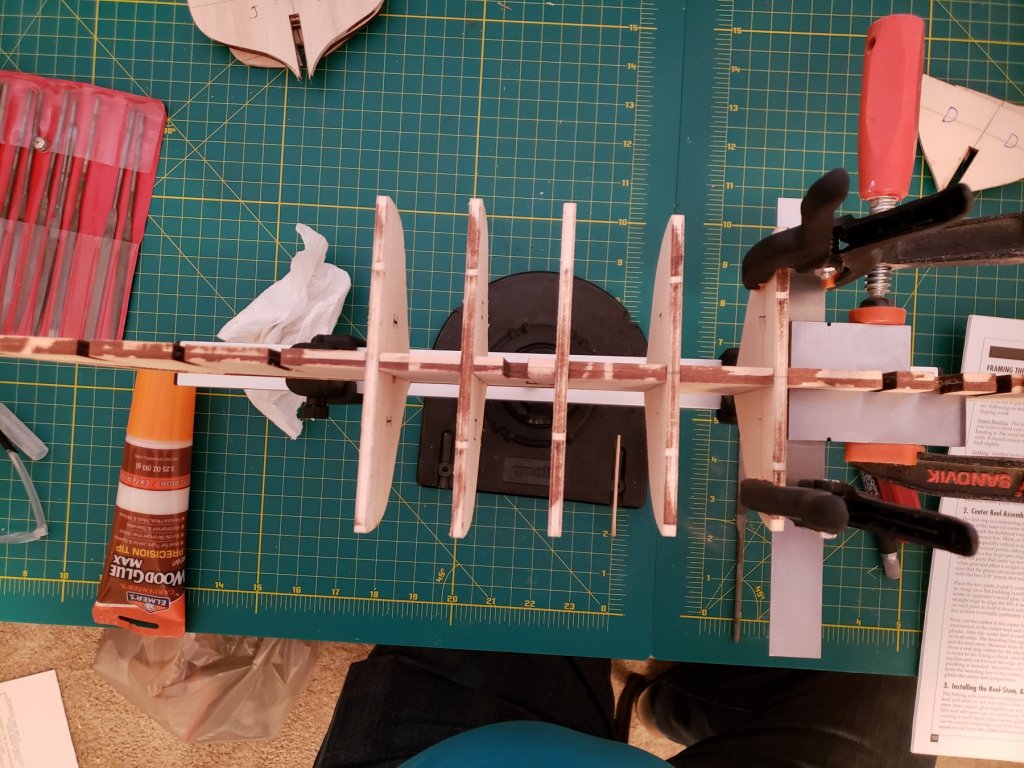

Hello again, It has been far too long since my last update and I am glad to say that my schedule finally calmed down enough to make some progress on this build. I have been having a great time with this build, although, fairing... and fairing... and more fairing! I am hoping it has been enough on the fairing front, but we will soon find that out. First, I needed to attach the bulkheads to the false keel. I wanted to do my best to get these as square as possible, so I used some small squares and clamps to accomplish that. Here are a few different views of the setup for any other fledgling ship builders like me. Side View: View from the bow: Top view: This was kinda slow going, because I was using wood glue instead of CA, but I figure this will result in a stronger backbone of the ship, at least that was my hypothesis. Here is a photo of the bow end of the ship complete: And all of the bulkheads attached: In this photo, you can see that there is a fair bit of fairing needed on the tops of the bulkheads, but I did learn to pay more attention to the tops of the bulkheads in the attachment process. Also note that the carving of the keel is a little messed up, I ended up tearing the keel & stem off the model and fabricated them out of swiss pear, but that will be shown in a future update. Doing a little reinforcement of the structure for faring: After MUCH fairing, I decided to place some filler blocks at the deck level in order to have a solid surface to lay the deck planking. I cannot stress how long this fairing process took, I couldn't believe it, but hopefully I have gotten the fairing to an acceptable level for hull planking. After reviewing the photo below, I have realized that this was not the final state of fairing, I have sanded this puppy a bit more still! Also note the transom secured in place, this was fabricated with a profile block and clamping the trimmed transom piece to it to dry, which worked pretty well. I am excited to finally be done with fairing the hull and moving on to something new. I remember fairing the hull for my solid hull Phantom build and thought that was going to be more time consuming than a POB build, but I don't think that was actually true, seems to be the same regardless and possibly even more important on the POB model since it will be planked. Up next, milling some wood for planking and related items!

-

Thanks everyone for the informative posts! Bill, that is interesting, I have never seen end grain flooring, but I absolutely love my home made end grain cutting board I made with scrap cutoffs! Very durable in that configuration, but like you said, I don't think end grain would be suitable for planking the hull haha.

-

Thank you both for the replies! To clarify, I am currently working at 1/48 scale, but plan on doing 1/64 going forward. The species in question are Swiss pear and Castello boxwood, the boxwood is what I was looking at primarily when I asked the question, but I'll probably use Swiss pear below the waterline and boxwood above it, with ebony for the wales. I plan on using Holly for the decks, but I don't think it matters much for the ebony or Holly, only the pear and boxwood.

-

Hey everyone, Quick question about milling my own planks. I have some different species of wood that I would like to mill into planks, but I'm unsure of which face to cut them from. I have already searched and I feel as though I've gotten some conflicting information. For example and explanation going forward, I have wood that is 2" x 4", so the 2" side has very straight grain and is the edge and the 4" side is more wavy in its grain pattern and is the face. I would like to end up with 1/8" x 1/16" planks. Some people say to cut the boards that will be ripped into planks from face grain and that the boards should be the thickness that the finished planks are wide. So this would mean cutting 1/8" thick boards (oversized to be finished to 1/8" thick) that would be 4" wide. Then I would cut 1/16" planks from that board resulting in having the 1/8" side being edge grain with straight, but more pronounced, grain. I have also seen advice to cut the 1/8" thick boards from the edge of the original stock, which would result in 1/8" x 2" wide boards that would get ripped into planks with the 1/8" side being face grain of the original stock which shows less defined, but wavy, grain. Lastly, I have seen the suggestion that you should cut 1/16" thick boards from the face grain of the original stock and rip the planks to the 1/8" width which would result, again, in face grain on the 1/8" side. What type of grain should I be looking to get on the larger dimension (1/8") of the finished planks? Should this be the straight and more obvious edge grain, or the harder to see, but kinda wavy face grain? Any help would be appreciated here. Thank you in advance for your help! Best Regards, Max

-

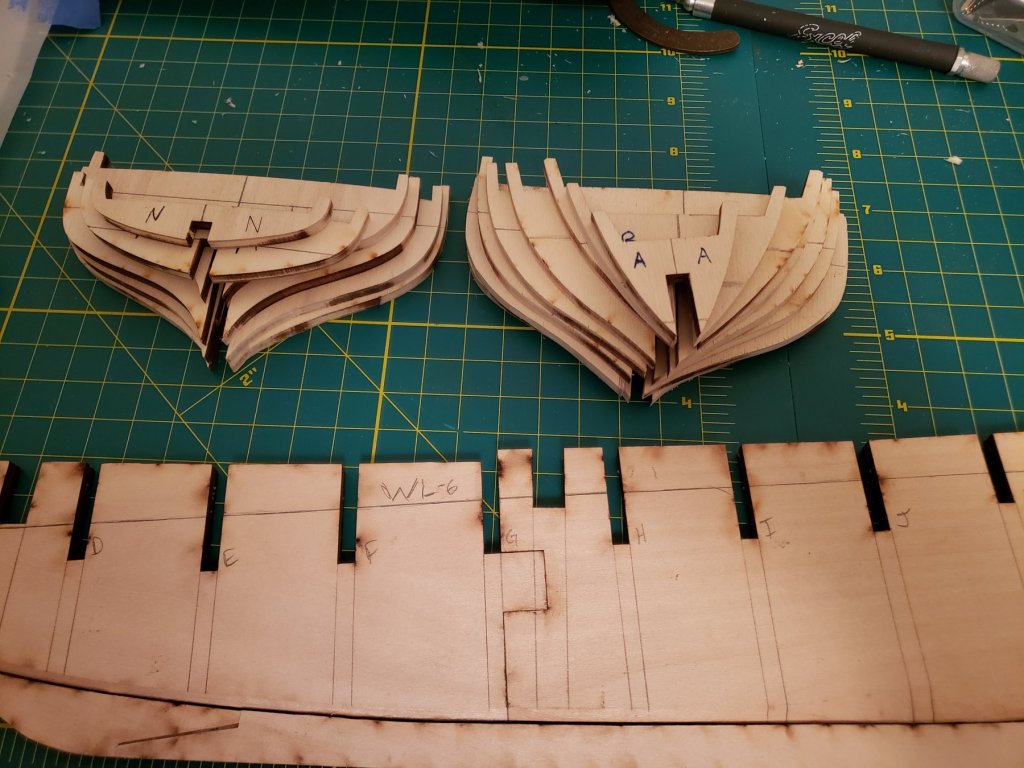

Ahoy there! This is the beginning of my build log of the Model Shipways Benjamin Latham POB kit. DISCLAIMER: This is my first POB kit, so this is not the place to come to learn best practices, but maybe I can offer a little insight between my stumbling through like a blindfolded elephant in a china shop! It's been a while since I have been active on this forum, but now I have my degree, have a job, have an extra bedroom to set up my workshop, and have a little extra time to do some modelling. Many many big life events ago, I had a build log for the Model Shipways Pilot Boat Phantom, which you can find in my signature, but about 5 moves later, she is in rough shape and I would like to start with something fresh and get back to her sometime in the future. Anyway, I have had the Banjamin Latham kit since I started my Phantom all those years ago and have always been drawn to her lines. I finally mustered up the courage to crack open that kit and try to tackle my first plank on bulkhead kit. This first post will just be a quick catch up to show the little progress I made before starting this log. I am looking forward to this build and excited to be an active member of MSW again, please feel free to pull up a chair and get comfortable, because I am sure I will need your help along the way and it is sure to be a long endeavor. Here are the obligatory photos of the box and its contents: <Placeholder> I broke out my trusty Stanley no. 12-101 and Veritas chisel to carve the simulated rabbet in the marked up false keel. Here is a picture showing the false keel and a few shavings. Oh, did I mention that this was take two? I accidentally carved the wrong taper in the first keel/stem assembly and Model Shipways was kind enough to send me replacements, as always. I love the support they offer for their kits! You can see the old false keel in the bottom right of this photo. Next, I completed the construction of the keel/stem assembly which consists of two pairs of two parts all glued together, carved the tapers near the bow, and glued her to the false keel. All in all, it came out okay, but I can definitely tell that I am a little rusty. As you can see in the second photo below, the glue joint for the keel/stem assembly is a bit off, but I made sure to make it as flush as possible on both sides, so hopefully it will not be noticed once the hull is painted. I think the rabbet came out pretty well! If I can find the old photo, I will post it, but I used tracing paper to transfer the profile of each bulkhead to some manila folder material to use as a template for shaping them and making sure that they are symmetrical. In the meantime, here is a photo of all the bulkheads shaped and ready for fitting to the false keel. I drew the WL-6 line on both sides of each bulkhead as well as the appropriate letter designations. Following the lead of others, I decided to trim off the bulkhead stanchions from each bulkhead so that they can all be installed at once later in the build and this should make them all match better since they will all have the same fabrication and installation method. Well, that is it for now, just wanted to get this build log started and quickly up to date so that I can post progress as I go. I remember getting a lot of helpful tips, insight, and knowledge from everyone who stopped by my Phantom log, so I would like to say thank you in advance to everyone for the great ideas and encouragement along the way. I am very much looking forward to taking this journey with you all. Cheers, Max

-

Scale Hardware back in business

FlounderFillet5 replied to jhearl's topic in Metal Work, Soldering and Metal Fittings

Fantastic news! -

Here is what I currently see offered: 1/8” (0.125”) 4-flute square end 1/8” (0.125”) 2-flute ball end 1/8” (0.125”) 2-flute 90 degree point end 3/32” (0.09375”) 4-flute square end long (1/2”) length of cut 3/32” (0.09375”) 4-flute ball end 1/16” (0.062”) 2-flute square end 1/16” (0.062”) 4-flute square end 1/16” (0.062”) 2-flute ball end 1/16” (0.062”) 4-flute ball end 3/64” (0.046875”) 4-flute square end 0.040” 2-flute square end 0.040” 2-flute ball end 1/32” (0.03125”) 2-flute square end 1/32” (0.03125”) 4-flute square end 1/32” (0.03125”) 2-flute ball end 1/32” (0.03125”) 4-flute ball end 0.024” 2-flute square end 0.010” 2-flute square end 1/8” 2-flute 90 degree chamfer #000 (0.020”) Center Drill #00 (0.025”) Center Drill

-

Chuck, thanks for the input. That makes complete sense, I hadn't realized that. Per, I agree with you about Chuck's products. I bought some blocks and line from chuck for my Phantom, although I haven't gotten to too much of the rigging, only rigging the deadeyes and a few blocks, but they were very high quality from what I could tell. I just figured that I could save a little cash and get a bit of a modelling fix by making my own since I have the tools to make them now. I will compare them to Chuck's blocks to see if the quality of my home made ones is acceptable.

-

Hey all, I found a good deal on some small size end mills with two and four flute varieties as well as square and ball end varieties in 5-10 packs and was wondering if anyone would be interested in a set of one - two of various types and sizes for a bundle price. They work out to be around $5 each, much cheaper than the $10-$20 dollars on most sites. They are carbide cutters made in the U.S.A. and I am very interested in purchasing some, but don't need so many of each size and variety. If there is some interest here, we can talk about what you ask want included and I can purchase the mills and make sets to put up for sale here. Just gauging if there is interest in something like this, if there is, I'll go ahead and make some purchases. I hope you all are having a wonderful day.

-

Thanks for the responses! I know how to convert scale, but guess I don't really know where to find sizing of the original rigging components to scale down. @Chuck: would you say that most model expo kits show accurate sizing of blocks in the materials lists? Or should I only trust the ones you have worked on? Thanks again!

-

Hey guys, Great topic here, very useful information! I have been looking for some small size end mills and have had trouble finding them for reasonable prices or in decent sets. My question is if anyone knows of a good source for these. I have found some on ebay and micrommark has a few, but just wanted to know if there is a hidden gem out there for them. Size of shank doesn't really matter as I have a 3/8" end mill holder as well as a set of collets that go down to nearly 0 gap. Thanks in advance for your input.

-

Hello out there! I am currently living in an apartment where room is scarce and build space is almost non existent, but I have a space to set up my mill. I am planning on building a ship in 1:64 scale once I move after graduation, probably the Syren. I wanted to know what the typical sizes of blocks, deadeyes, etc are so that I can make a bunch out of some spare boxwood I have laying around in the meantime. I figure that it will save me some cost on my next build(s) by making them myself, not to mention I will know that they were my blocks and get some satisfaction from that later on. If you guys could chime in on what size blocks and the like I should mass produce, I would appreciate it. If you also have information on the dimensions of them, like a diagram of the layout or the like, that would save me a little time as well, but that is information that I'm sure I can find somewhere on my own. Any information would be greatly appreciated and would get me back into doing what little I can related to model ship building in my current place. Thanks in advance! Best Regards, Max

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.