-

Posts

16 -

Joined

-

Last visited

-

etubino reacted to a post in a topic:

US Brig Syren by VasaRodin - Model Shipways - Scale 1:64

etubino reacted to a post in a topic:

US Brig Syren by VasaRodin - Model Shipways - Scale 1:64

-

etubino reacted to a post in a topic:

US Brig Syren by VasaRodin - Model Shipways - Scale 1:64

etubino reacted to a post in a topic:

US Brig Syren by VasaRodin - Model Shipways - Scale 1:64

-

etubino reacted to a post in a topic:

US Brig Syren by VasaRodin - Model Shipways - Scale 1:64

etubino reacted to a post in a topic:

US Brig Syren by VasaRodin - Model Shipways - Scale 1:64

-

fatih79 reacted to a post in a topic:

US Brig Syren by VasaRodin - Model Shipways - Scale 1:64

fatih79 reacted to a post in a topic:

US Brig Syren by VasaRodin - Model Shipways - Scale 1:64

-

fatih79 reacted to a post in a topic:

US Brig Syren by VasaRodin - Model Shipways - Scale 1:64

fatih79 reacted to a post in a topic:

US Brig Syren by VasaRodin - Model Shipways - Scale 1:64

-

fatih79 reacted to a post in a topic:

US Brig Syren by VasaRodin - Model Shipways - Scale 1:64

fatih79 reacted to a post in a topic:

US Brig Syren by VasaRodin - Model Shipways - Scale 1:64

-

fatih79 reacted to a post in a topic:

US Brig Syren by VasaRodin - Model Shipways - Scale 1:64

fatih79 reacted to a post in a topic:

US Brig Syren by VasaRodin - Model Shipways - Scale 1:64

-

fatih79 reacted to a post in a topic:

US Brig Syren by VasaRodin - Model Shipways - Scale 1:64

fatih79 reacted to a post in a topic:

US Brig Syren by VasaRodin - Model Shipways - Scale 1:64

-

VasaRodin reacted to a post in a topic:

US Brig Syren by Gahm - Model Shipways

VasaRodin reacted to a post in a topic:

US Brig Syren by Gahm - Model Shipways

-

VasaRodin reacted to a post in a topic:

US Brig Syren by Gahm - Model Shipways

VasaRodin reacted to a post in a topic:

US Brig Syren by Gahm - Model Shipways

-

VasaRodin reacted to a post in a topic:

US Brig Syren by Gahm - Model Shipways

VasaRodin reacted to a post in a topic:

US Brig Syren by Gahm - Model Shipways

-

VasaRodin reacted to a post in a topic:

US Brig Syren by Gahm - Model Shipways

VasaRodin reacted to a post in a topic:

US Brig Syren by Gahm - Model Shipways

-

VasaRodin reacted to a post in a topic:

US Brig Syren by Gahm - Model Shipways

VasaRodin reacted to a post in a topic:

US Brig Syren by Gahm - Model Shipways

-

egkb reacted to a post in a topic:

US Brig Syren by VasaRodin - Model Shipways - Scale 1:64

egkb reacted to a post in a topic:

US Brig Syren by VasaRodin - Model Shipways - Scale 1:64

-

VasaRodin reacted to a post in a topic:

US Brig Syren by Gahm - Model Shipways

VasaRodin reacted to a post in a topic:

US Brig Syren by Gahm - Model Shipways

-

WackoWolf reacted to a post in a topic:

US Brig Syren by VasaRodin - Model Shipways - Scale 1:64

WackoWolf reacted to a post in a topic:

US Brig Syren by VasaRodin - Model Shipways - Scale 1:64

-

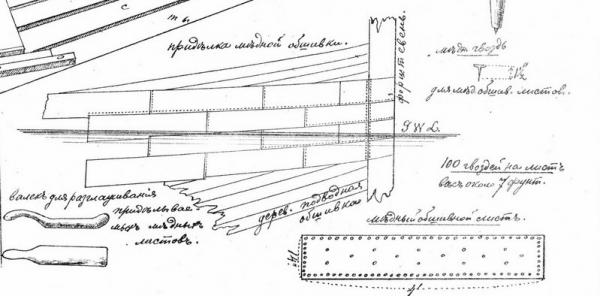

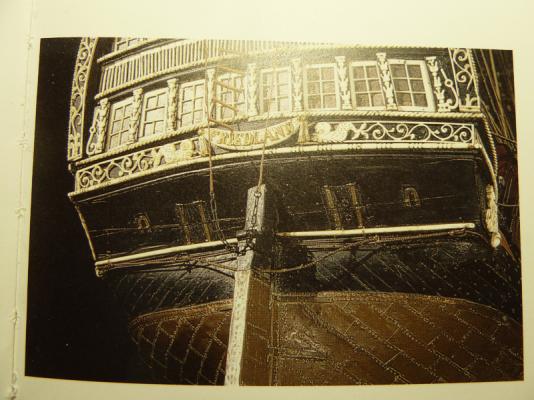

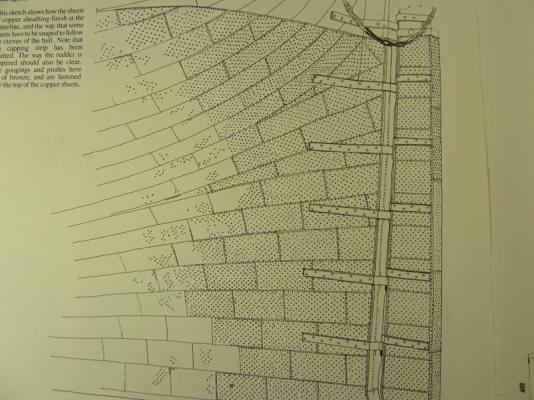

I have a first big question. According to the plans the first row of the copper plates starts from the keel and goes up to the waterline. But I've studied different sources and saw that the first row started from the waterline and went down to the keel everywhere. Does our Syren has her own way of coppering?

-

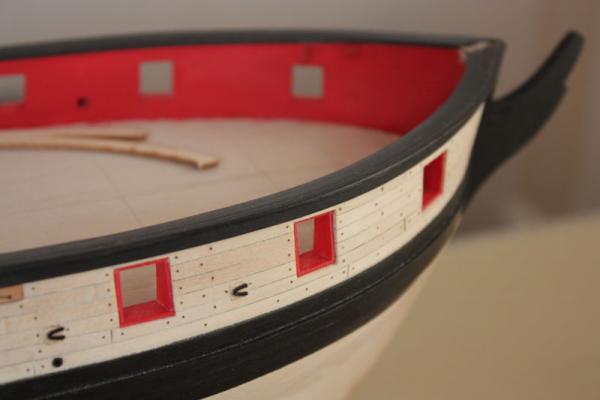

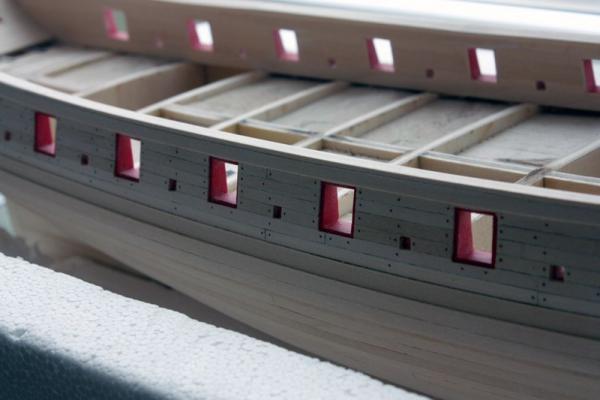

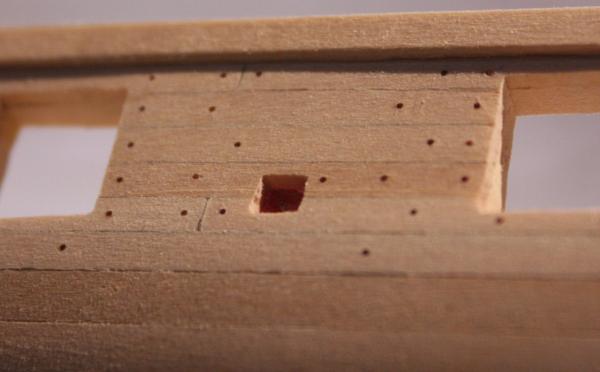

Ready with paintings and think there will be more coats of black. Different details are finnished such as ladders, simulated sheaves and so on. The 0,6 mm plywood list was installed on to the deck. Also testing how the deck should look like. Next steps are the deck and copper plates so it'll take muuuuch time. Perhaps I'll leave the hull without copper plates cause the wood looks fine for me. But I didn't decide yet.

-

VasaRodin reacted to a post in a topic:

US Brig Syren by Gahm - Model Shipways

VasaRodin reacted to a post in a topic:

US Brig Syren by Gahm - Model Shipways

-

VasaRodin reacted to a post in a topic:

US Brig Syren by Gahm - Model Shipways

VasaRodin reacted to a post in a topic:

US Brig Syren by Gahm - Model Shipways

-

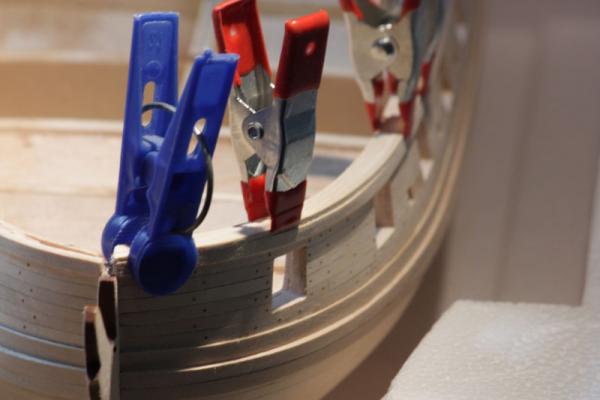

Thank you Mr. Helmsman. I think preparation work makes the difference. Will always recomend using balsa on POB models. Dust is the only problem with this sort of tree. I've learned many new words when my wife found the dust even in the soup. He-he. Making the cap rail is a serious problem as it needs edge bending. My solution was to create cap rail in the bow part from separate planks. When glued and sanded they look like one solid wood. Black paint will finish the process. Transom cap rail made of special wood which bends easily. I'm not sure what kind of wood it is. Just bought it in a hobby shop.

-

Sincere thanks for your warm comments. This is my very first experience in the shipmodelling. Chuck Passaro did the great job. All I need is to follow his instructions. Posting more pictures and preparing myself for the deck construction. Treenails were made of brown fishing line 0.55 in diameter. Then the wales were fixed.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.