-

Posts

59 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Bundaberg

Recent Profile Visitors

-

ccoyle reacted to a post in a topic:

HM Cutter Mermaid 1817 by bundybear1981 - FINISHED - Modellers Shipyard - Scale 1:48

ccoyle reacted to a post in a topic:

HM Cutter Mermaid 1817 by bundybear1981 - FINISHED - Modellers Shipyard - Scale 1:48

-

GrandpaPhil reacted to a post in a topic:

Colonial Schooner for Port Jackson 1803 by bundybear1981 - Modellers Shipyard - Scale 1:50

GrandpaPhil reacted to a post in a topic:

Colonial Schooner for Port Jackson 1803 by bundybear1981 - Modellers Shipyard - Scale 1:50

-

GrandpaPhil reacted to a post in a topic:

HM Cutter Mermaid 1817 by bundybear1981 - FINISHED - Modellers Shipyard - Scale 1:48

GrandpaPhil reacted to a post in a topic:

HM Cutter Mermaid 1817 by bundybear1981 - FINISHED - Modellers Shipyard - Scale 1:48

-

GrandpaPhil reacted to a post in a topic:

Longboat HMS Sirius 1786 by bundybear1981 - Modellers Shipyard - 1:24

GrandpaPhil reacted to a post in a topic:

Longboat HMS Sirius 1786 by bundybear1981 - Modellers Shipyard - 1:24

-

Jobbie reacted to a post in a topic:

Colonial Schooner for Port Jackson 1803 by bundybear1981 - Modellers Shipyard - Scale 1:50

Jobbie reacted to a post in a topic:

Colonial Schooner for Port Jackson 1803 by bundybear1981 - Modellers Shipyard - Scale 1:50

-

Jobbie reacted to a post in a topic:

Colonial Schooner for Port Jackson 1803 by bundybear1981 - Modellers Shipyard - Scale 1:50

Jobbie reacted to a post in a topic:

Colonial Schooner for Port Jackson 1803 by bundybear1981 - Modellers Shipyard - Scale 1:50

-

thanks for all the comments! I started on the rigging today, its coming along nicely. Still got a bit of rigging to go yet but taking shape now!

- 13 replies

-

thankyou for your kind words Scott. This is my 3rd build of a Modellers Shipyard (now Modellers Central) kit and I have been happy so far with the quality of their kits. I'm up to a point where I can either finish it and leave it as a row type or continue on to add the rigging. I plan on doing all the rigging on her.

- 13 replies

-

Around the time cyclone debbie was hiiting far north queensland we were hitting 95 to 99% humidity. Nothing was drying then! Seems to be a lot better now its dropped off again.

- 13 replies

-

bundybear1981 reacted to a post in a topic:

Longboat HMS Sirius 1786 by bundybear1981 - Modellers Shipyard - 1:24

bundybear1981 reacted to a post in a topic:

Longboat HMS Sirius 1786 by bundybear1981 - Modellers Shipyard - 1:24

-

Time for the next update! Next I laid the boards inside the hull and the cap rails. Once the glue had set I cut the row locks in the cap rails and stained them with golden oak stain. After that I put the benches in then put the supports under them. Next was to fit the rudder. I had a materials issue here, the instructions had the same 3x3mm timber that was used for the seat supports for the rudder handle, however there was not enough length left to do so. The supplied strip was 250mm long. There was 220mm needed for the bench supports, with the rudder requiring a piece at 10mm and another at 60mm. To get around this I used one of the spare planks from the first run of planking cut in half and glued together then sanded to 3x3mm. This was stained teak when it was fitted to the rudder. I then put the rudder brackets on the rudders and fitted the rudder to the transom.

- 13 replies

-

Over the last 10 days I've been slowly working on the longboat (however I have been a bit slack on taking progress pictures) The next step was to do the 2nd layer of planking. After the main planking was completed rowlocks were cut out, then a timber strip fitted over the rowlock strip and another one just under it to trim it. Once all the planking was completed it was stained with a teak stain, and a coat of varnish applied (this was later removed with some turps, very wet weather prevent it from properly drying and was still tacky 2 days after application) Next step was to remove the hull from the build frame and remove the bulkheads from the hull. Thanks to the sticky tape this was easily completed. Once they were all removed I sanded the inside of the hull, clearing excessive glue and smoothing the inside. Some marks remained from the plank bender, if I were to redo the model I would use heat to bend the planks so it didn't have the markings from the bends. Once I was happy with the sanding the inside of the hull was painted white, I applied 3 coats to get a good coverage. Next step was to install the strip below the rowlock inside the hull. In hindsight this should have been fitted prior to painting (the instructions are out of order here too, they show this being fitted after the painting but later show it painted white with no mention of painting it). Once this was in place I then cut the timber strip off the rowlocks. I then filed these with the square needle file to tidy the sides and make sure it was square. After this I proceeded to fit the ribs of the hull. I drifted from the instructions here a little. When fitting them I pushed them hard up on the rowlock strip, pushing them out against the hull down to the keel. I used a sharp cutter to cut them tightly in to place (they were tight enough to remain in place on their own) When I had them all in place I diluted some PVA glue and applied a light coat over the ribs, which then fixed them in place. The instructions showed each strip (inefficiently) being glued and pinned with map pins to allow the glue to dry. When I worked up to the bow some bulldog clips were used to hold the ribs in place where they bunched at the front. Following the completion of the ribs being placed, the grating that fits under the bench at the transom was fitted in place. The rear bench was then planked, stained teak and fitted in place. You'll see two ribs slightly moved in the picture, the glue had not fully dried at this time. They were placed back in position and clipped in place to fully dry.

- 13 replies

-

This is my rotary drill in the drill press the I used to taper the planks before laying them. It is currently fitted with a sanding disc, this made the shaping of planks fast, easy and accurate. Next the tapered planks were fitting to the hull,working toward the temporary plank. As I worked toward the centre the clamps became less practical, having planks only glued to each other and not the frame it was much slower so I reverted to map pins to allow more planks to be laid at a time, running a thin bead of glue on the faces of the planks being joined each time. To help with shaping and holding the planks together while the glue dried I got out my forceps clamps and applied light pressure on the planks. Once all the planks are in place I trimmed the overhang planks flush with the transom then any gaps filled with wood filler, holes and marks. This was followed by sanding the planks smooth, removing excess filler and giving a good surface ready for the next stage. After I was satisfied with the sanding job the next step was to fit the washboards strip. This was 2mm laser cut ply. It needed to be shaped to follow the curve of the bow. Using a hand held plank bending tool (incidentally the same tool as in the diagram provided with the model) was quite difficult. The laser marks for the oar locks cut-outs gave significant weak points while the ply sheet itself was very hard. It took several attempts to get the shape right, many times re-shaping previously crimped marks. I would use another method to shape it should I re-visit this build in the future. (as a scratch build) As a side note the picture showing this process must have been from an earlier version as it wasn't laser cut ply but rather a standard plank marked and shaped. This was then glued to the 1st plank run that was done. I used a combination of pins and rubber bands to hold it in place to dry overnight.

- 13 replies

-

Today I started to run the first set of planks. Firstly the bulkheads 1 through 9 are taped to prevent the glue and planks from binding to it (as mentioned earlier they will be removed later to give the hull its internal shape) The bow was too sharp an angle with too little timber for the clamps to grip so a map pin was pushed through. The bow and stern are glued in place. The next step was to calculate the taper on the 1st run of planks, these run from the first plank 45mm up the bulkhead where the 2nd run begins. After the angle was calculated the boards were marked for tapering, bundled into groups of 5 planks and sanded on the rotary drill.

- 13 replies

-

Both the bow blocks shaped ready to be fitted to the keel. The bow blocks are then glued on to the keel Now to wait for the glue to dry before I do the fairing on the frames.

- 13 replies

-

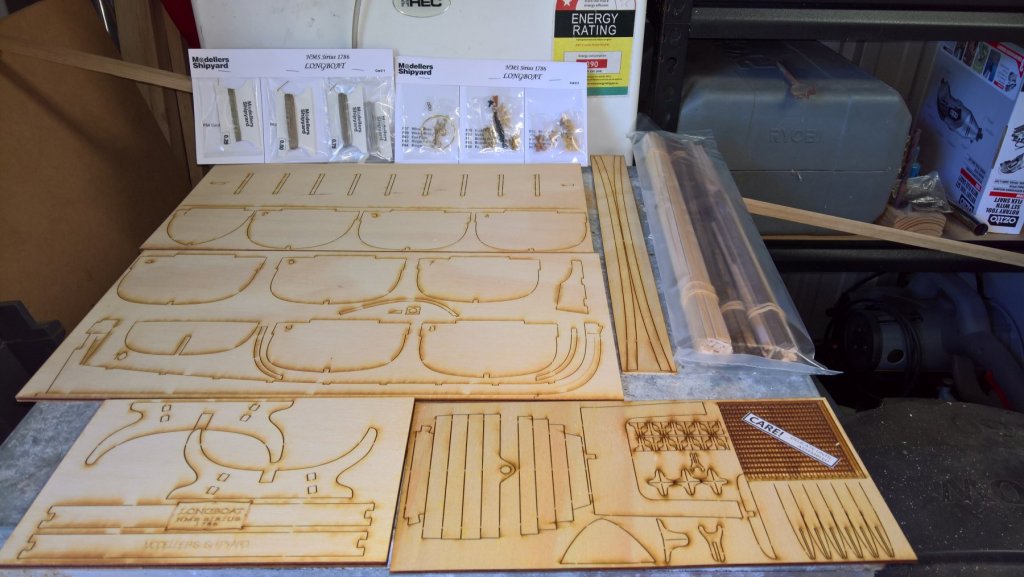

Good day all! After an extended hiatus I'm back in the shipyard! Today I received my next project, the longboat from HMS Sirius, one of the first fleet ships. The box in which she came! Next is the contents of the kit spread out. First step was to lay out the frames and put the keel in place. The frames aren't glued to the baseboard so once planked it can be removed from the internals of the longboat, it is there to provide the framework to build on to. The transom is glued on to the keel however. Next was to shape the bow blocks with a 45 degree bevel. To do this I used my rotary tool in the Dremel drill press with a sanding disc on it. It made the job faster, easier and did a great job!

- 13 replies

-

bundybear1981 changed their profile photo

-

Hi phiSuter Sorry, I have been away from the forum for a period (and changed emails, hence didnt get any notifications) How are you going with your build? If you have and questions please send a message and I'll help where I can! Cheers Jason

- 25 replies

-

- mermaid

- modellers shipyard

-

(and 1 more)

Tagged with:

-

Absolutely beautiful work! She is looking amazing

- 98 replies

-

- norfolk

- modellers shipyard

-

(and 1 more)

Tagged with:

-

Looking very nice! Shes coming along nicely. Won't be long till you're on to the rigging work. I've had to delay mine, fish tank sprung a leak so had to spend my new model fund on fixing it Oh well, I'll get there Can't wait to see more pics!

- 98 replies

-

- norfolk

- modellers shipyard

-

(and 1 more)

Tagged with:

-

An interesting side note on this subject, 3D printers are coming down in price. Earlier this year I read and article about 3D printers that suggests within the next 12 months (I thinks they are a bit optimistic here) they will be down to the price of a quality inkjet printer. You can currently buy a 3D printer for about A$2500 that uses the Objet/Polyjet/Multijet method of printing capable of printing objects up to 200mm x 200mm x 170mm. Something worth watching if you want to make scaled people for your ships, be able to print out the scale you need in what ever pose or rank you need!

-

Looking very nice! Great job on the first planking run. Looking forward to seeing your next work Keep up the great job! Also, with the balsa fillers you installed in the stern, are they to help give more binding for the rear planks or for another purpose?

- 98 replies

-

- norfolk

- modellers shipyard

-

(and 1 more)

Tagged with:

-

I haven't yet. Going to have a few really busy weeks at work. I'll probably order it later this month. I'm guessing the plans will be like for the Mermaid and Port Jackson builds, color in A3 size with full size plans. Should be a fun build.

- 98 replies

-

- norfolk

- modellers shipyard

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.