Roks82

Members-

Posts

38 -

Joined

-

Last visited

About Roks82

- Birthday 09/30/1982

Profile Information

-

Gender

Not Telling

-

Location

Slovenia

Recent Profile Visitors

-

Captain Poison reacted to a post in a topic:

H.M.S. Triton Cross Section by roks82 - 1:48

Captain Poison reacted to a post in a topic:

H.M.S. Triton Cross Section by roks82 - 1:48

-

Gabek reacted to a post in a topic:

H.M.S. Triton Cross Section by roks82 - 1:48

Gabek reacted to a post in a topic:

H.M.S. Triton Cross Section by roks82 - 1:48

-

Gabek reacted to a post in a topic:

H.M.S. Triton Cross Section by roks82 - 1:48

Gabek reacted to a post in a topic:

H.M.S. Triton Cross Section by roks82 - 1:48

-

mtaylor reacted to a post in a topic:

H.M.S. Triton Cross Section by roks82 - 1:48

mtaylor reacted to a post in a topic:

H.M.S. Triton Cross Section by roks82 - 1:48

-

mtaylor reacted to a post in a topic:

H.M.S. Triton Cross Section by roks82 - 1:48

mtaylor reacted to a post in a topic:

H.M.S. Triton Cross Section by roks82 - 1:48

-

mtaylor reacted to a post in a topic:

H.M.S. Triton Cross Section by roks82 - 1:48

mtaylor reacted to a post in a topic:

H.M.S. Triton Cross Section by roks82 - 1:48

-

mtaylor reacted to a post in a topic:

H.M.S. Triton Cross Section by roks82 - 1:48

mtaylor reacted to a post in a topic:

H.M.S. Triton Cross Section by roks82 - 1:48

-

mtaylor reacted to a post in a topic:

H.M.S. Triton Cross Section by roks82 - 1:48

mtaylor reacted to a post in a topic:

H.M.S. Triton Cross Section by roks82 - 1:48

-

GrandpaPhil reacted to a post in a topic:

H.M.S. Triton Cross Section by roks82 - 1:48

GrandpaPhil reacted to a post in a topic:

H.M.S. Triton Cross Section by roks82 - 1:48

-

Roks82 reacted to a post in a topic:

H.M.S. Triton Cross Section by roks82 - 1:48

Roks82 reacted to a post in a topic:

H.M.S. Triton Cross Section by roks82 - 1:48

-

Roks82 reacted to a post in a topic:

H.M.S. Triton Cross Section by roks82 - 1:48

Roks82 reacted to a post in a topic:

H.M.S. Triton Cross Section by roks82 - 1:48

-

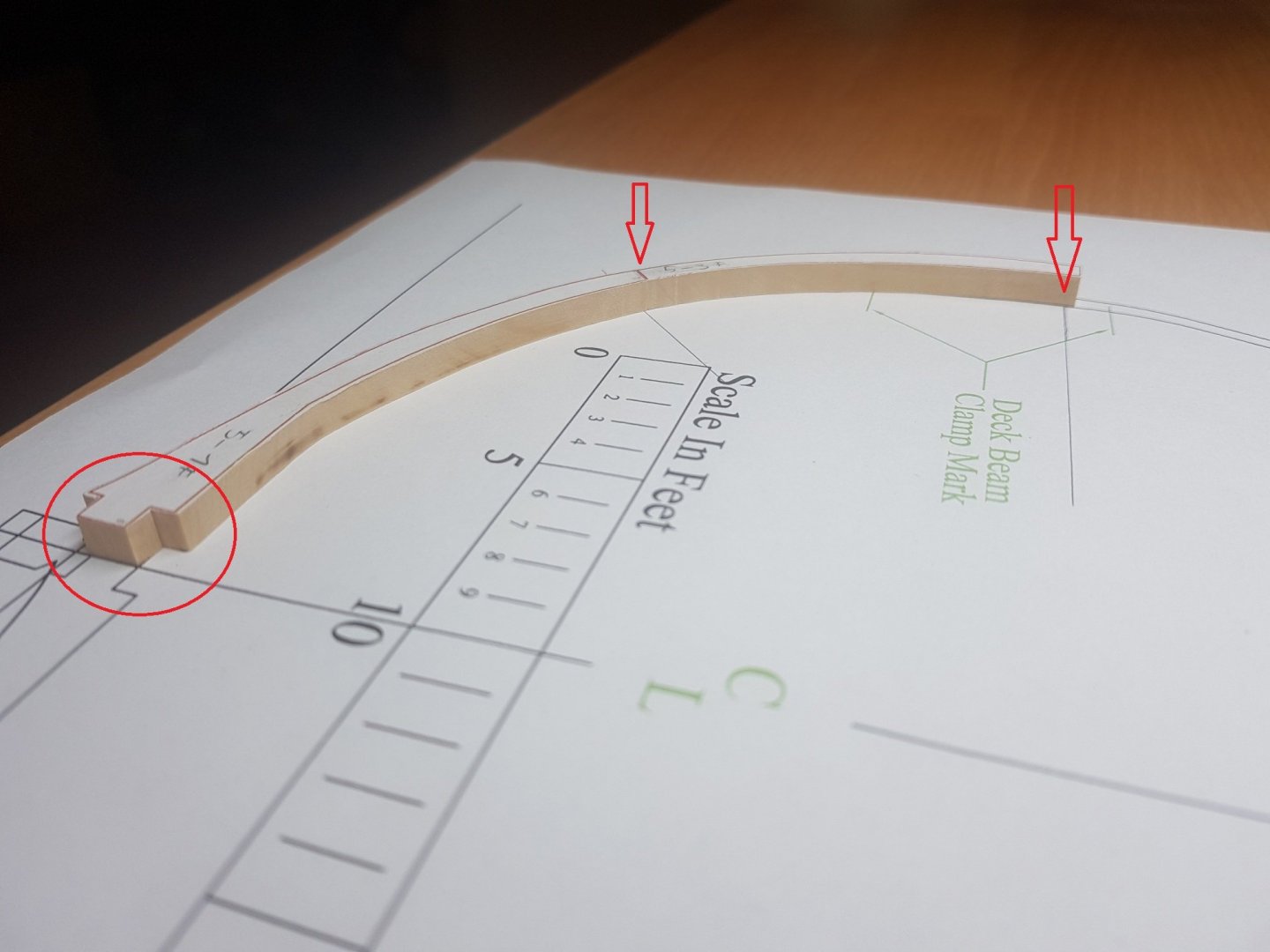

I need some help from you fellow Triton builders. I've sanded the frames up to the line and they fit in perfectly however while checking the assembly drawings it looks like the frame parts are slightly too long. I've also checked the that the scale printed correctly and can confirm it is ok... So the only logic solution to me is to sand the frames further (over the line), has anyone else experienced this issue?

-

Roks82 reacted to a post in a topic:

H.M.S. Triton Cross Section by Ainars Apalais - 1:48

Roks82 reacted to a post in a topic:

H.M.S. Triton Cross Section by Ainars Apalais - 1:48

-

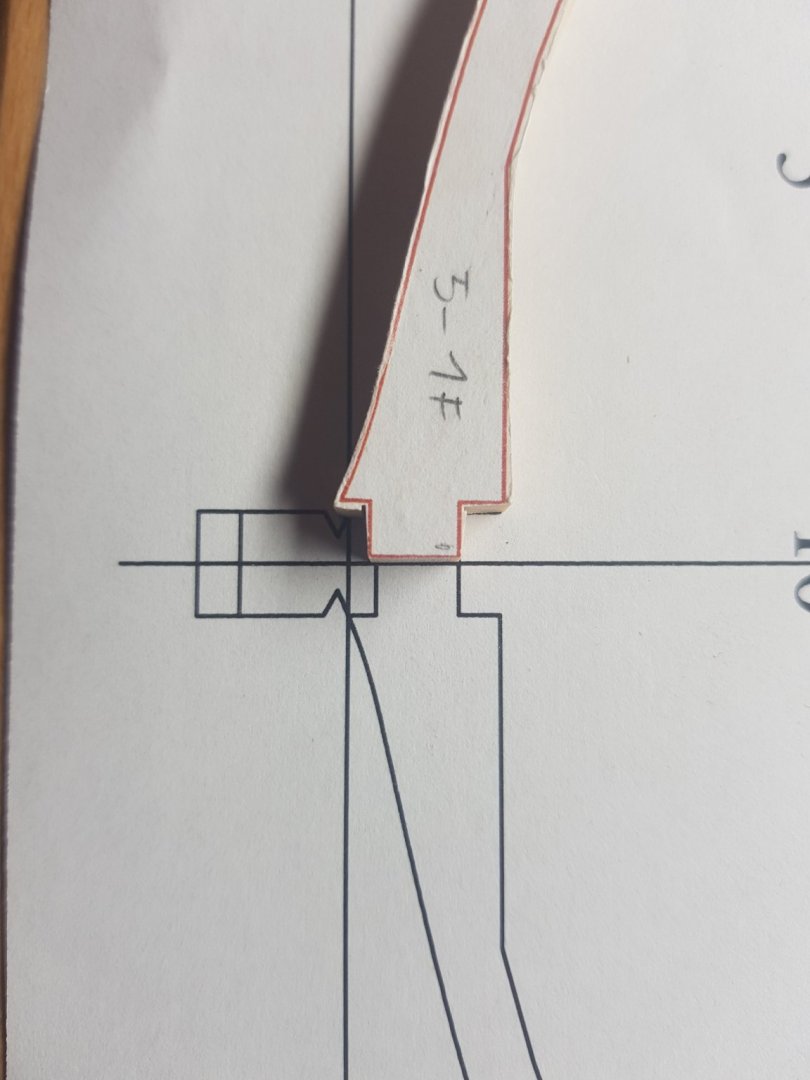

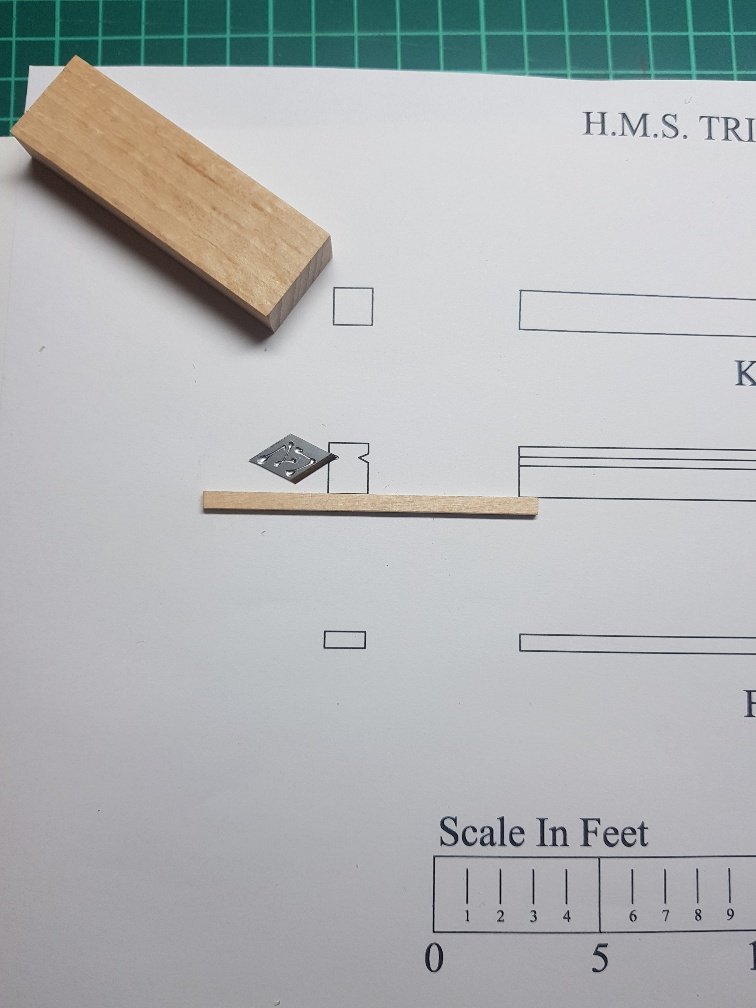

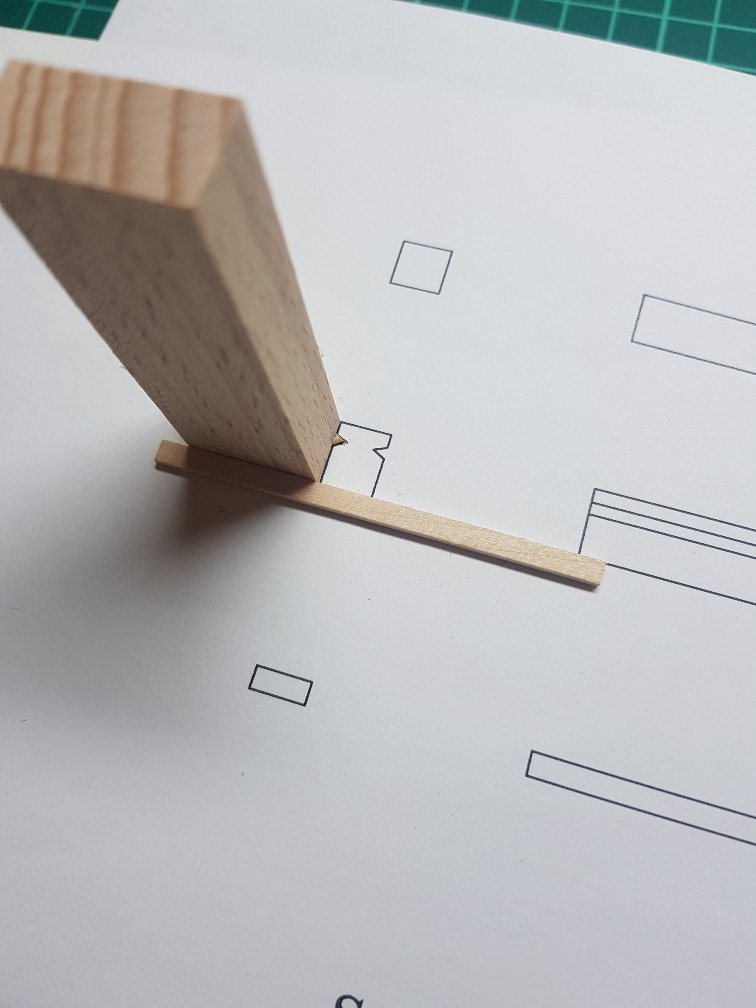

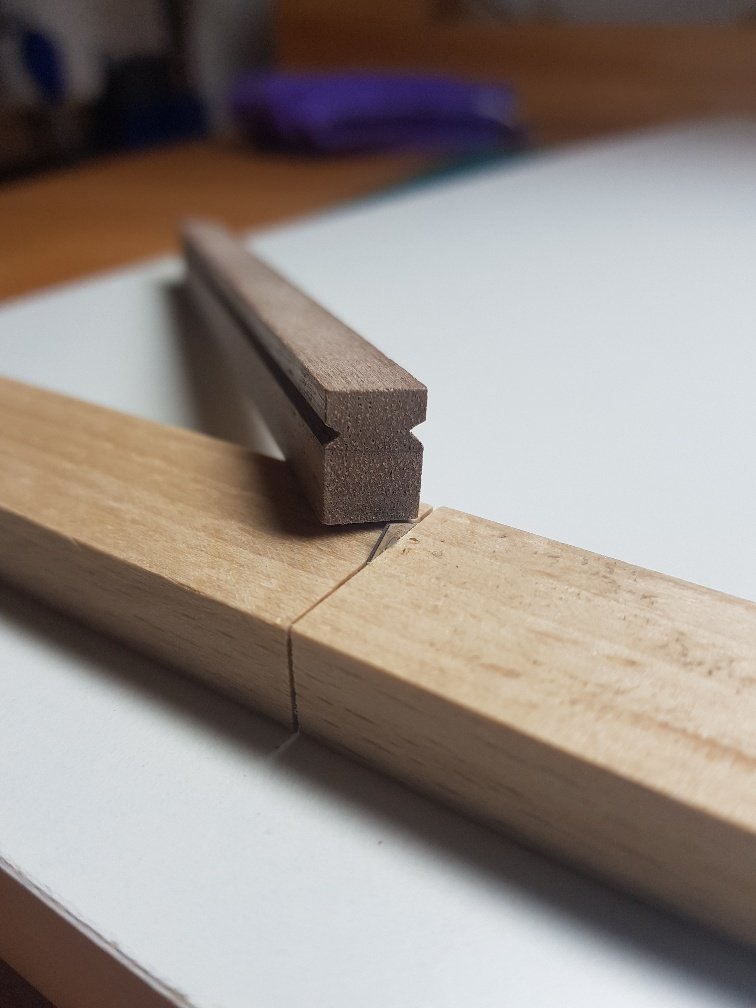

Thanks Christian for the welcome! I've taken the liberty to use Chad's approach for cutting out the rabbet line on the keel. First I glued the razor blade on the plan with a very small amount of CA glue, I then glued the guide scrap piece on the blade and finally glued it all together on a flat surface. I then scraped off each side of the keel....

-

Roks82 reacted to a post in a topic:

H.M.S. Triton Cross Section by roks82 - 1:48

Roks82 reacted to a post in a topic:

H.M.S. Triton Cross Section by roks82 - 1:48

-

Roks82 reacted to a post in a topic:

H.M.S. Triton Cross Section by roks82 - 1:48

Roks82 reacted to a post in a topic:

H.M.S. Triton Cross Section by roks82 - 1:48

-

This time I'd like to share with you my method of bending/twisting the planks. First I just slightly wet the plank with some tap water - wetting the fingers and passing on the area that I intend to bend. I then position the plank in the vise and with the help of some clamps twist it in position (actually just slightly over bend). I then use a normal hairdryer to heat up a plank and woila...in 3 minutes you have your fully bent plank Hope this helps someone. Rok

-

Hello comrades! I have some questions for you which hope you can answer and perhaps help some of us newbies: - After finishing the planking what is your fairing procedure? - Which sandpaper’s grits do you use? Are you using files too? - How do you protect the keel/stem/sternpost from being scratched? - Any tips for fairing tight corners? Thanks in advance!

-

The shipyard re-opened! The upper planking has been completed with some issues however. I've been using very thin black paper to simulate the caulking which did not allow me to bevel some of the edges causing minor gaps in the planking. Now it's time for some sanding to make it smooth. Could some of you guys advise how do you perform the caulking (except for the pencil method)? For the lower planking I'll go without the caulking simulation so I am aiming for some better results

-

It's been a while since my last post - the shipyard has been closed for a while due to lack of motivation Anyway some upgrades have been done this year so work has now resumed and hopefully will continue till finishing this interesting project. I've upgraded the workshop with a Byrnes table saw, a Proxxon DSH 2 scrall saw and an Optimill which might seem a bit exaggerated for our hobby but the reason I bought it instead of a smaller Proxxon is that I could now use it for other projects/materials. Not clearly seen but on the picture is also a extremely useful electrically adjustable table - I've bought the base in Ikea and fitted it with a custom top...it really helps to lift it and work while standing from time to time!

-

Like many of you I have also chosen the cross section as my first scratch build. I’ll be building it simultaneously with by Confederacy so maybe some steps will proceed slower then expected. The first step for me was choosing the wood...I’ve decided for a combination of boxwood and walnut, maybe I’ll also use some pear but haven’t fully decided yet as I am a bit concerned about a conflicting color scheme. I am really looking forward to this build and your comments and suggestions!

-

Work continued in the shipyard... The lower counter has been planked, I've added some thin lawyer of paper in between to simulate the caulking however seems that it was too thin so some of it tear apart and is not visible throughout the whole length of the planks...lesson learned! Exact sanding on the port and starboard side will be done at a later stage once the side planks are positioned. I had some spare time and decided to make the doors for the beakhead. I think it was easier to make them now considering that the cut out doors on the bulkhead G are much shorter then the pre-cut doors so some careful sanding is required. PS: I am not sure why some pictures are not rotated properly, I am posting the URL from Google Drive and they all look formatted properly there?!

-

Hi Jim, Thank you so much! Seems that we are both having some issues with emails. I’ve sent one email last week and another one this week....maybe it ended somewhere in the spam folder. I will resend it also from my business email so hopefully you should get it. Anyway I am very happy that you are still in business and that the magic saws are still available

-

Hello everyone, Does anyone (especially the US colleagues on this forum) know whether Jim Byrnes is still in business? I have placed an order for his magic table saw almost two weeks ago but did not receive any feedback on the shipping charges. I’ve also sent a couple of emails just to make sure that everything is in order but didn’t get any reply either... Rok

-

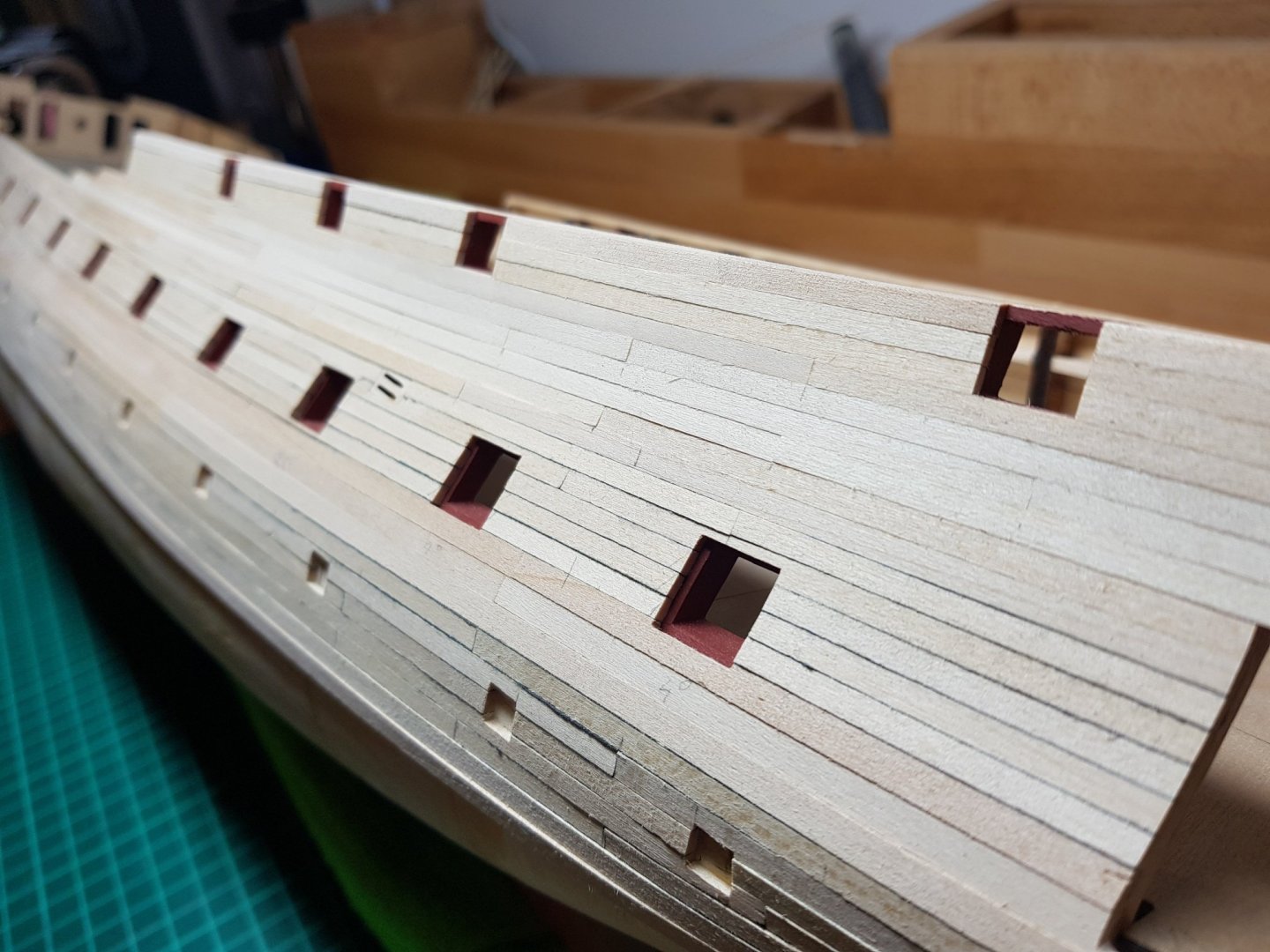

After almost a year I have resumed work on my Confederacy in January. Unfortunately I did not have much time to update each single step up to now as I have managed to complete the gunports and beakhead planking (treenailing still to be done). The jig that you see in the below picture is made of scrap MDF that I had at home and was used just for aligning the ports perpendicular to the hull. For the gunports I've decided to go with a red ochre colour as to me looks a bit more authentic for the ships of that era. The first coat was undiluted paint, followed by another 3 coats of diluted paint with some fine sanding between each coat.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.