-

Posts

1,394 -

Joined

-

Last visited

About archjofo

- Currently Viewing Forum: - Build logs for subjects built 1801 - 1850

- Birthday 03/17/1958

Contact Methods

-

Website URL

http://www.segelschiffsmodellbau.com/t643f358-Franzoesische-Korvette-quot-La-Cr-eacute-ole-quot.html

Profile Information

-

Gender

Male

-

Location

Germany, Münchsmünster

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

CiscoH reacted to a post in a topic:

La Créole 1827 by archjofo - Scale 1/48 - French corvette

CiscoH reacted to a post in a topic:

La Créole 1827 by archjofo - Scale 1/48 - French corvette

-

CiscoH reacted to a post in a topic:

La Créole 1827 by archjofo - Scale 1/48 - French corvette

CiscoH reacted to a post in a topic:

La Créole 1827 by archjofo - Scale 1/48 - French corvette

-

CiscoH reacted to a post in a topic:

La Créole 1827 by archjofo - Scale 1/48 - French corvette

CiscoH reacted to a post in a topic:

La Créole 1827 by archjofo - Scale 1/48 - French corvette

-

giampieroricci reacted to a post in a topic:

La Créole 1827 by archjofo - Scale 1/48 - French corvette

giampieroricci reacted to a post in a topic:

La Créole 1827 by archjofo - Scale 1/48 - French corvette

-

Speedy reacted to a post in a topic:

La Créole 1827 by archjofo - Scale 1/48 - French corvette

Speedy reacted to a post in a topic:

La Créole 1827 by archjofo - Scale 1/48 - French corvette

-

Speedy reacted to a post in a topic:

La Créole 1827 by archjofo - Scale 1/48 - French corvette

Speedy reacted to a post in a topic:

La Créole 1827 by archjofo - Scale 1/48 - French corvette

-

Speedy reacted to a post in a topic:

La Créole 1827 by archjofo - Scale 1/48 - French corvette

Speedy reacted to a post in a topic:

La Créole 1827 by archjofo - Scale 1/48 - French corvette

-

Speedy reacted to a post in a topic:

La Créole 1827 by archjofo - Scale 1/48 - French corvette

Speedy reacted to a post in a topic:

La Créole 1827 by archjofo - Scale 1/48 - French corvette

-

jfhealey reacted to a post in a topic:

La Créole 1827 by archjofo - Scale 1/48 - French corvette

jfhealey reacted to a post in a topic:

La Créole 1827 by archjofo - Scale 1/48 - French corvette

-

mtaylor reacted to a post in a topic:

La Créole 1827 by archjofo - Scale 1/48 - French corvette

mtaylor reacted to a post in a topic:

La Créole 1827 by archjofo - Scale 1/48 - French corvette

-

archjofo reacted to a post in a topic:

La Créole 1827 by archjofo - Scale 1/48 - French corvette

archjofo reacted to a post in a topic:

La Créole 1827 by archjofo - Scale 1/48 - French corvette

-

archjofo reacted to a post in a topic:

La Créole 1827 by archjofo - Scale 1/48 - French corvette

archjofo reacted to a post in a topic:

La Créole 1827 by archjofo - Scale 1/48 - French corvette

-

Perhaps I might add, basically there are quarter blocks with one disc, so-called single blocks, and with two discs, so-called double blocks. In the lower yards, the quarter blocks were large single blocks to guide the sheets. The clew lines were managed in separate blocks. In the topsail and topgallant yards, quarter blocks were arranged as double blocks to guide the clewlines and sheets together approximately in the middle of the yard. Since the clew lines are usually thinner than the sheets, these double blocks usually also have different disc gates. Therefore, these blocks are also called thick-and-thin blocks.

-

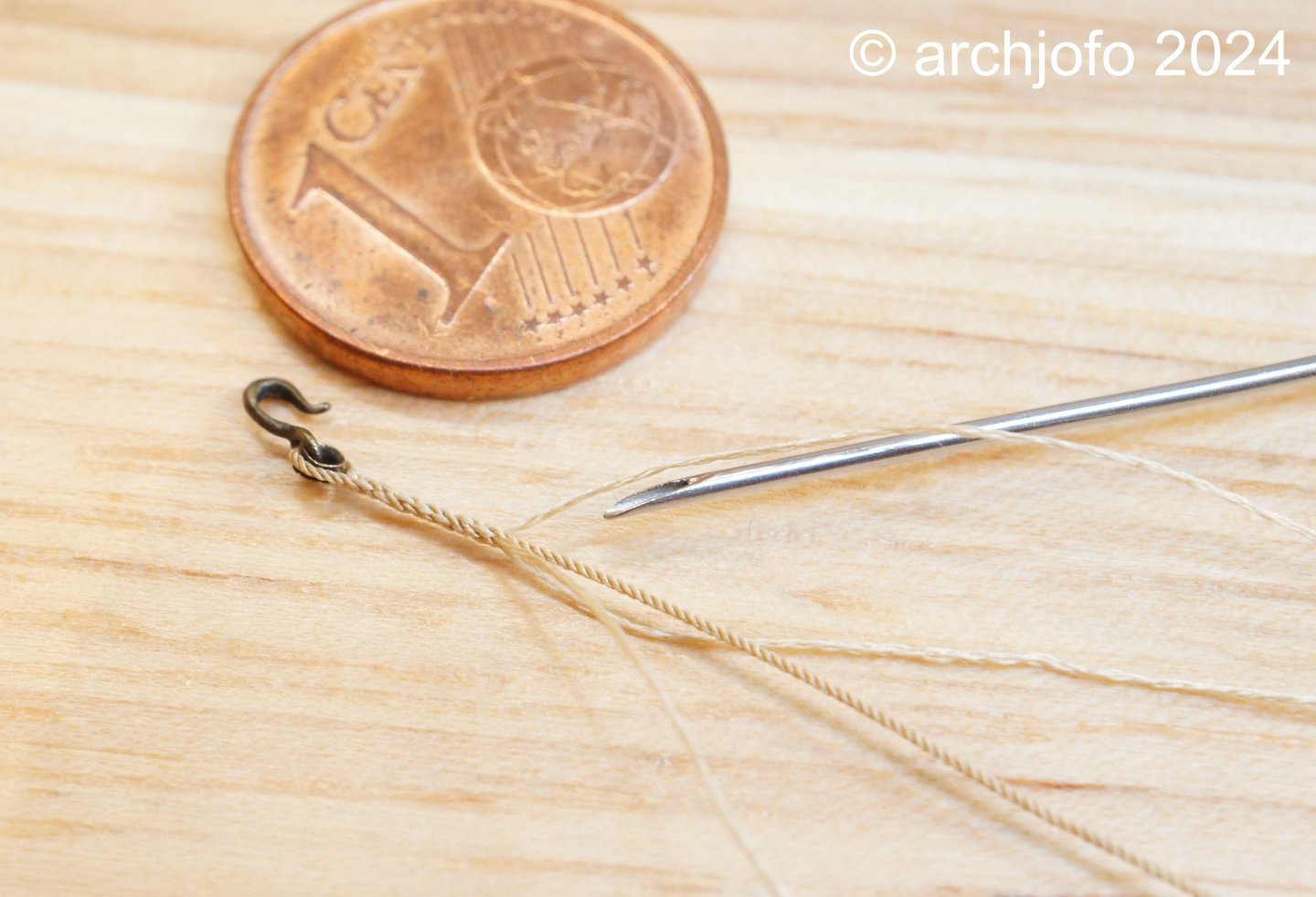

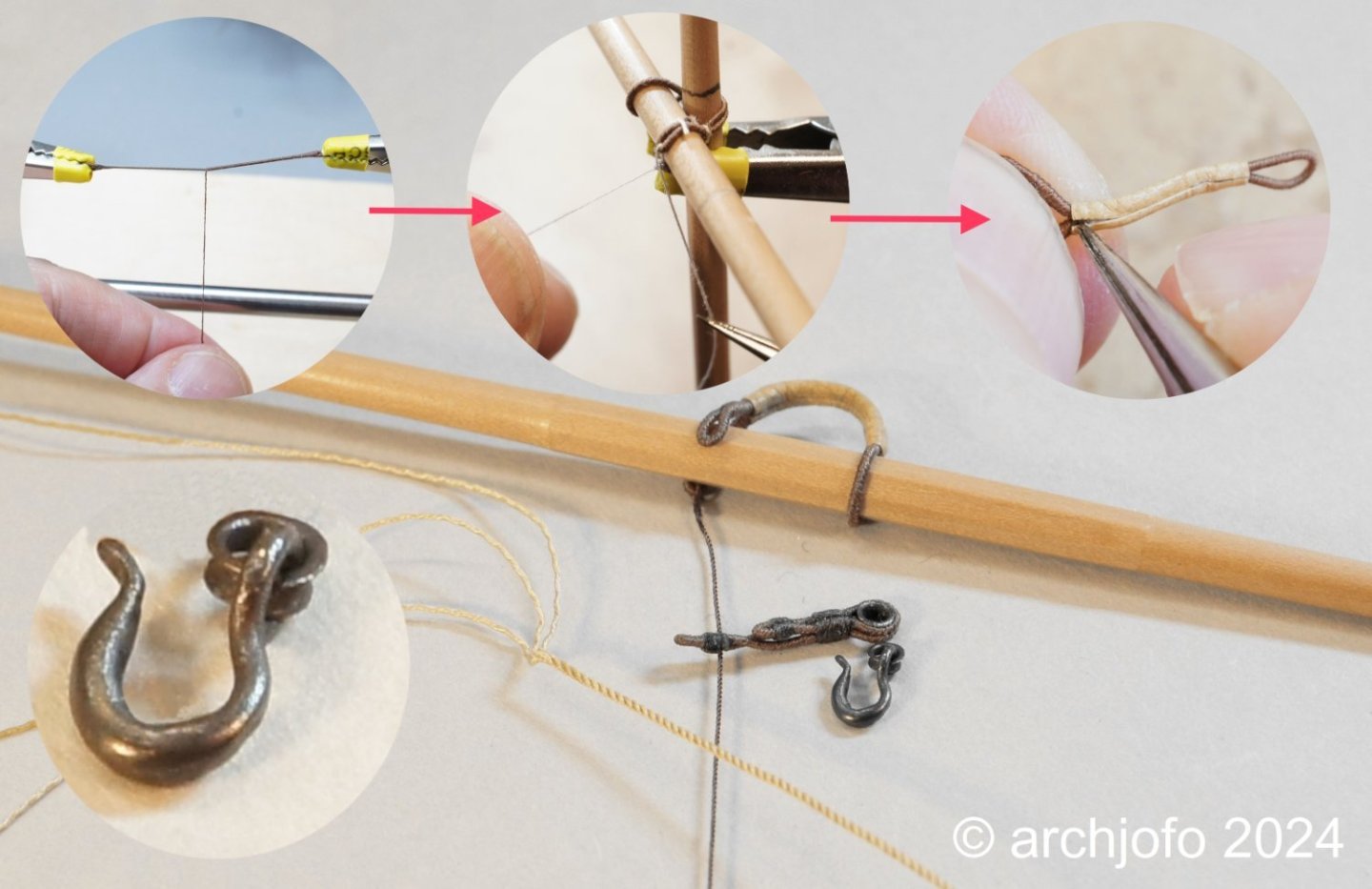

@druxey Hello, I'm glad you like it. Thanks ! I would also like to thank everyone else for the LIKES. Continuation: Equipment of the mizzen topgallant yard – Vergue de perruche After a suggestion from model building colleagues, I secured the mousing of the hook for the tye with a thinner three strand rope with a diameter of 0.15 mm that was specially made for this purpose. We then continued with the quarter blocks (clew lines and sheets), which are among the smallest double blocks on the model. For the block ropes I used ropes with a diameter of 0.25 mm, which were served with silk yarn. The last two pictures show the arrangement of the quarter blocks with the truss already attached. Up soon …

-

archjofo reacted to a post in a topic:

La Créole 1827 by archjofo - Scale 1/48 - French corvette

archjofo reacted to a post in a topic:

La Créole 1827 by archjofo - Scale 1/48 - French corvette

-

Continuation: Equipment of the mizzen topgallant yard – Vergue de perruche After a short creative break, we continue with the equipment of the mizzen topgallant yard. The equipment and rigging elements basically correspond to those of the fore topgallant yard, but again with correspondingly smaller dimensions. The mizzen topgallant tye is also equipped with a hook. At around 4 mm long, this is even smaller than the hook for the tye of the fore topgallant yard. Of course, the eye splice couldn't be missing either. With a rope with a diameter of 0.35 mm (2x3 Japanese silk thread - rope in the original ø 17 mm) this is a difficult matter, but after some practice it is definitely doable. It just looks better and corresponds to the original design. As already described several times, I use an injection needle as a hollow spike for splicing, with a diameter of 0.8 mm for the thin ropes. In the next picture you can see the mizzen topgallant tye with the double strop and the thimble already tied on to guide the simple clueline. Sequel follows …

-

archjofo reacted to a post in a topic:

La Créole 1827 by archjofo - Scale 1/48 - French corvette

archjofo reacted to a post in a topic:

La Créole 1827 by archjofo - Scale 1/48 - French corvette

-

archjofo reacted to a post in a topic:

NRG Rigging Project by tlevine

archjofo reacted to a post in a topic:

NRG Rigging Project by tlevine

-

archjofo reacted to a post in a topic:

HM Cutter Cheerful 1806 by Erik W - 1:48 scale

archjofo reacted to a post in a topic:

HM Cutter Cheerful 1806 by Erik W - 1:48 scale

-

archjofo reacted to a post in a topic:

La Créole 1827 by archjofo - Scale 1/48 - French corvette

archjofo reacted to a post in a topic:

La Créole 1827 by archjofo - Scale 1/48 - French corvette

-

archjofo reacted to a post in a topic:

La Créole 1827 by archjofo - Scale 1/48 - French corvette

archjofo reacted to a post in a topic:

La Créole 1827 by archjofo - Scale 1/48 - French corvette

-

archjofo reacted to a post in a topic:

La Créole 1827 by archjofo - Scale 1/48 - French corvette

archjofo reacted to a post in a topic:

La Créole 1827 by archjofo - Scale 1/48 - French corvette

-

archjofo reacted to a post in a topic:

La Créole 1827 by archjofo - Scale 1/48 - French corvette

archjofo reacted to a post in a topic:

La Créole 1827 by archjofo - Scale 1/48 - French corvette

-

@Gregory @Keith Black Hello, thank you very much for your kind words. Musée national de la Marine in Paris Today I have to get the following off my chest. As you all know, the Musée national de la Marine in Paris reopened its doors some time ago after many years of renovation and modernization. Our forum colleague Eberhard @wefalck reported on this with impressive photos. I actually planned to visit the reopened museum later this year and in particular to view and photograph my "object of desire", the original model of "La Créole", in order to, among other things, to explore unclear details of the upper rigging. After his first visit, Eberhard indicated that he was not sure whether “La Créole” could still be seen in the permanent exhibition. After contacting the museum, I was informed that this was indeed the case and that the "La Créole" had ended up in storage, like many other models. When I asked if it would be possible to take a few photos of the upper rigging (topgallant yards and royal yards), I was referred to the restorers. A very friendly restorer then went to the depot especially for me and took a whole series of pictures of the rigging. Regardless of the fact that these recordings are very valuable for my project, I am shocked by the fact that this beautiful model has now become the victim of a new museum education. Apparently the aim is to reach a wider audience. The German Museum is also apparently following this trend. As I found out, for example, the beautiful 74 model after Boudriot by our forum colleague Robert @tarjack can no longer be seen in the permanent exhibition. Is this the future of cultural-historical and artistic creation? Here is a picture from the depot of the Paris museum, where the "La Créole" will now eke out its future existence alongside many other models. It almost looks like a prison, which makes me a little sad. Previously proudly presented in the permanent exhibition, published with glossy photos, among other things, by J. Boudriot and now in the depot without protection. Hopefully the air in the depot is dust-free. I'm still hoping that one of the restorers will remember the model and fix the already partially dilapidated rigging.

-

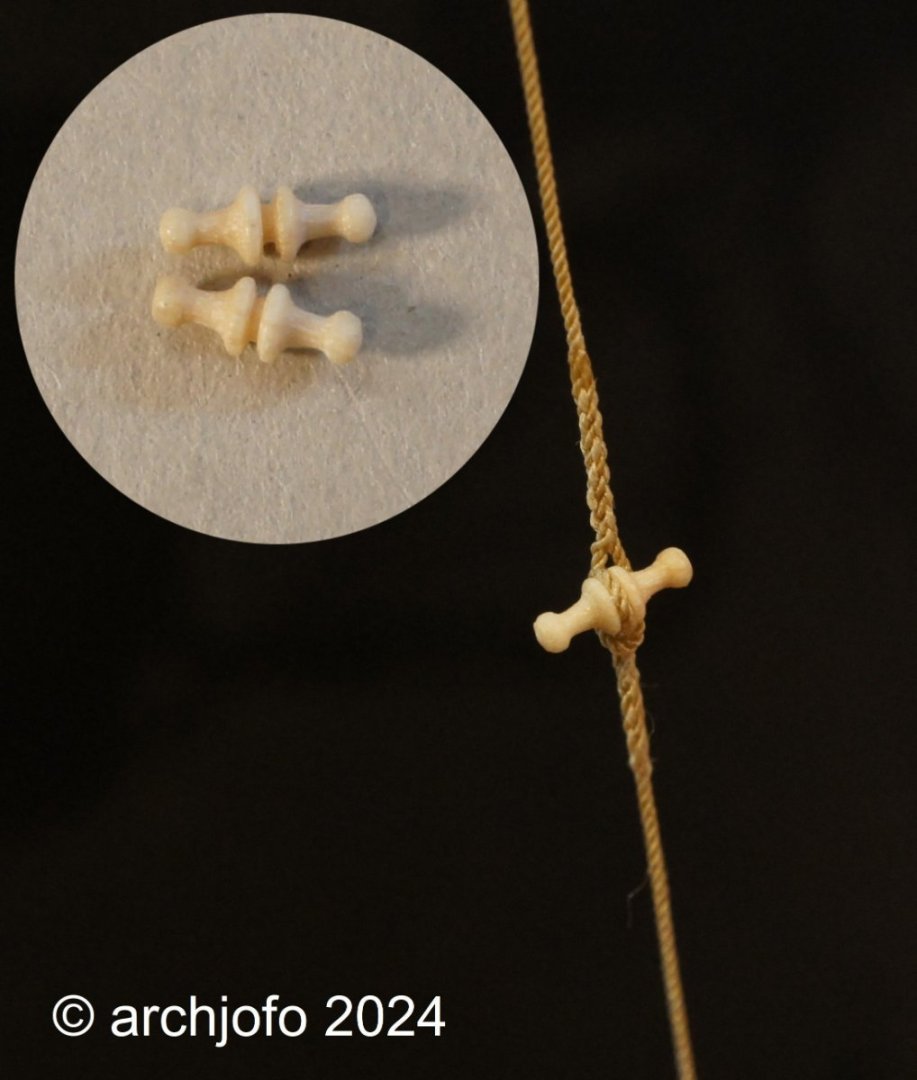

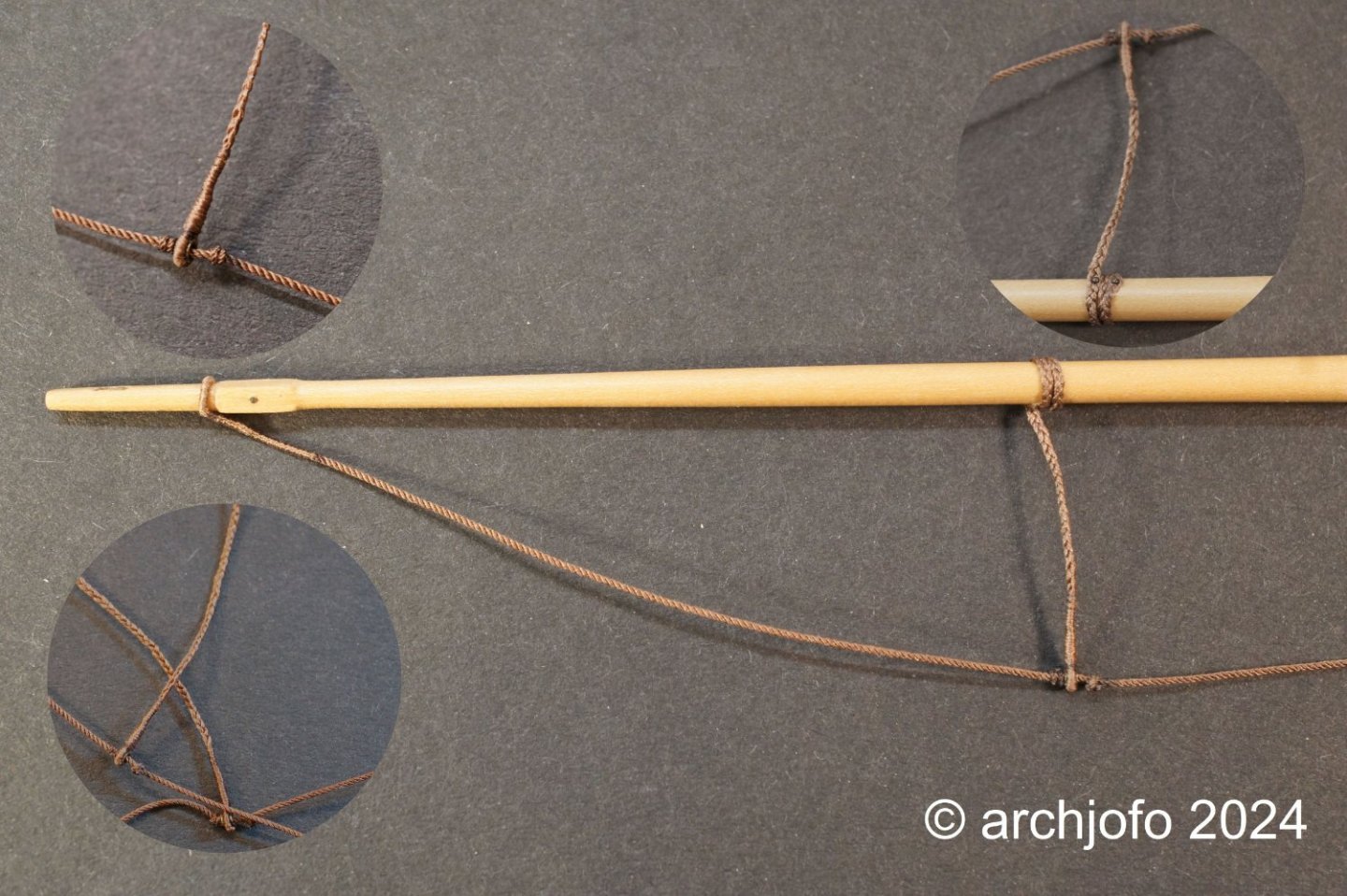

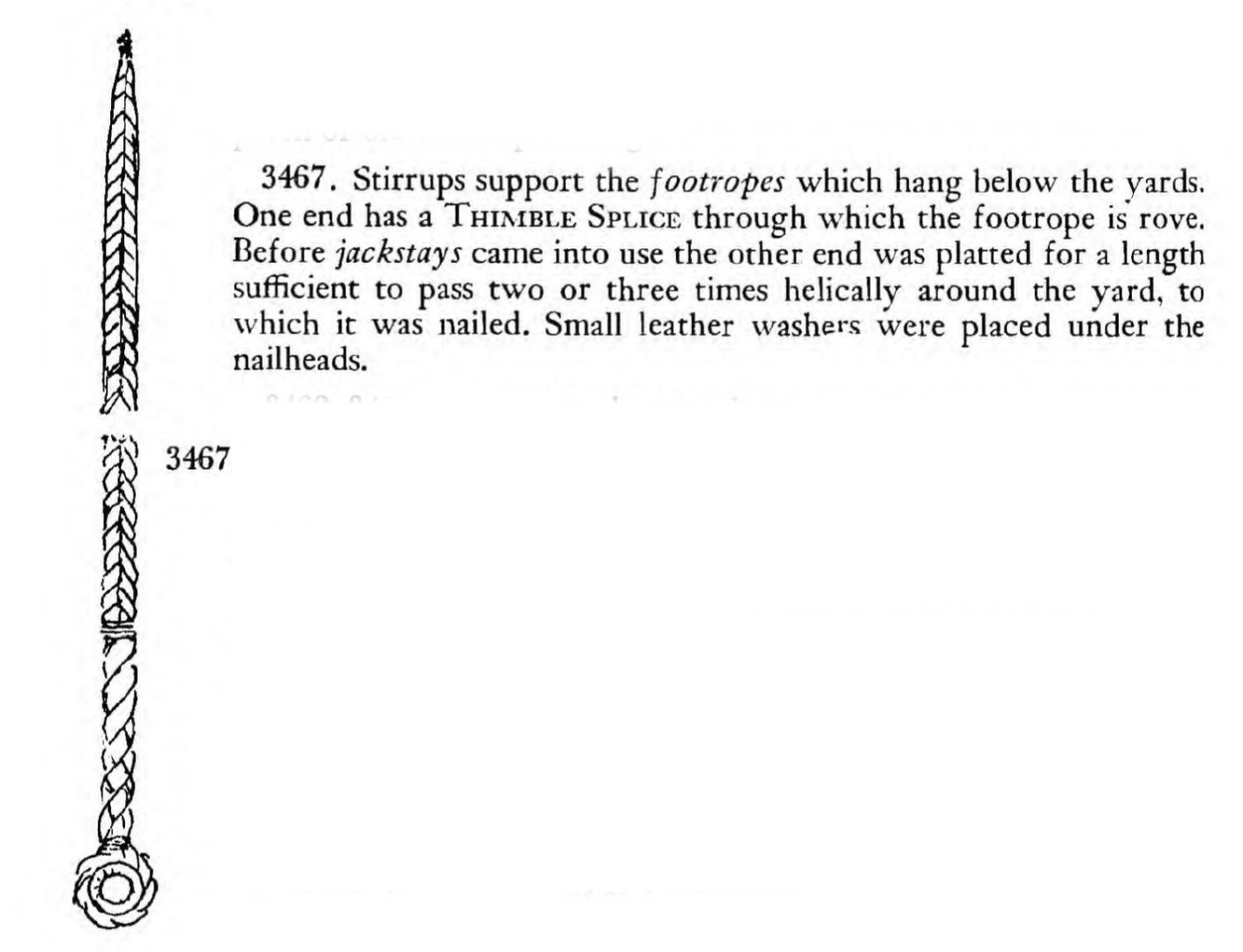

Continuation: Equipment of the fore topgallant yard – Vergue de petit perroquet As announced a long time ago, I started to equip the fore topgallant yard. In principle it is the same rigging elements and accessories as the main topgallant yard, just with reduced dimensions. In this respect, I don't want to repeat myself and let the pictures speak for themselves. The double blocks for the royal sheets and the single cluelines are also a little smaller. Here is a direct comparison of a quarter block for the main top gallant yard with those of the fore top gallant yard. Unfortunately, at this size you can already see some irregularities. In the next photo I show, among other things: an already made strop for a double block with my scale man, which I've been neglecting a bit lately. Actually a loyal companion at the model building yard for more than 10 years now. And here's another picture of the stirrups. On the one hand you can see the unraveled rope and on the other hand the finished braided plating. The sheets are connected to the cluelines in the usual way when no sails were attached. Finally, here is a picture of the entire fore topgallant yard, but still without lifts. Sequel follows …

-

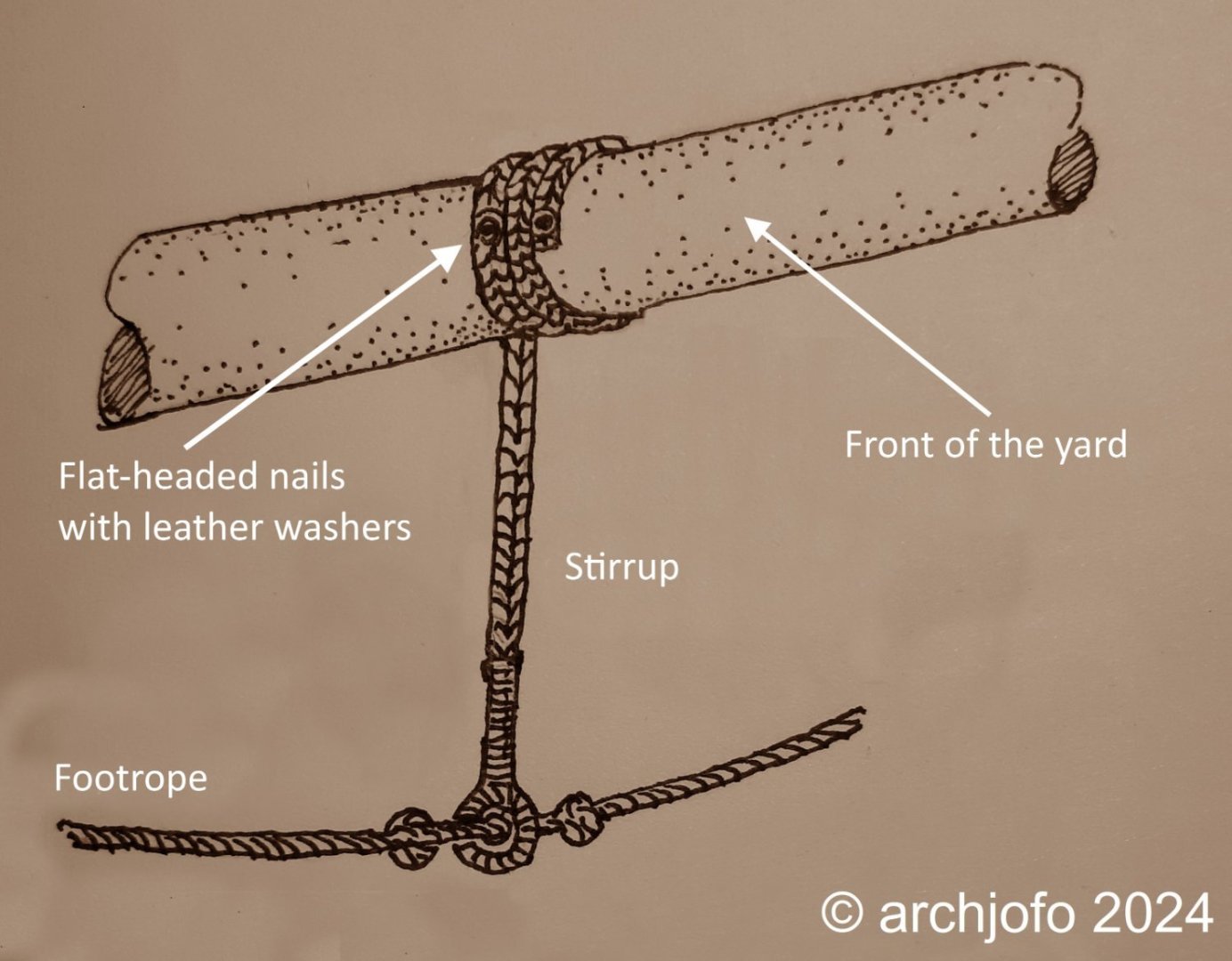

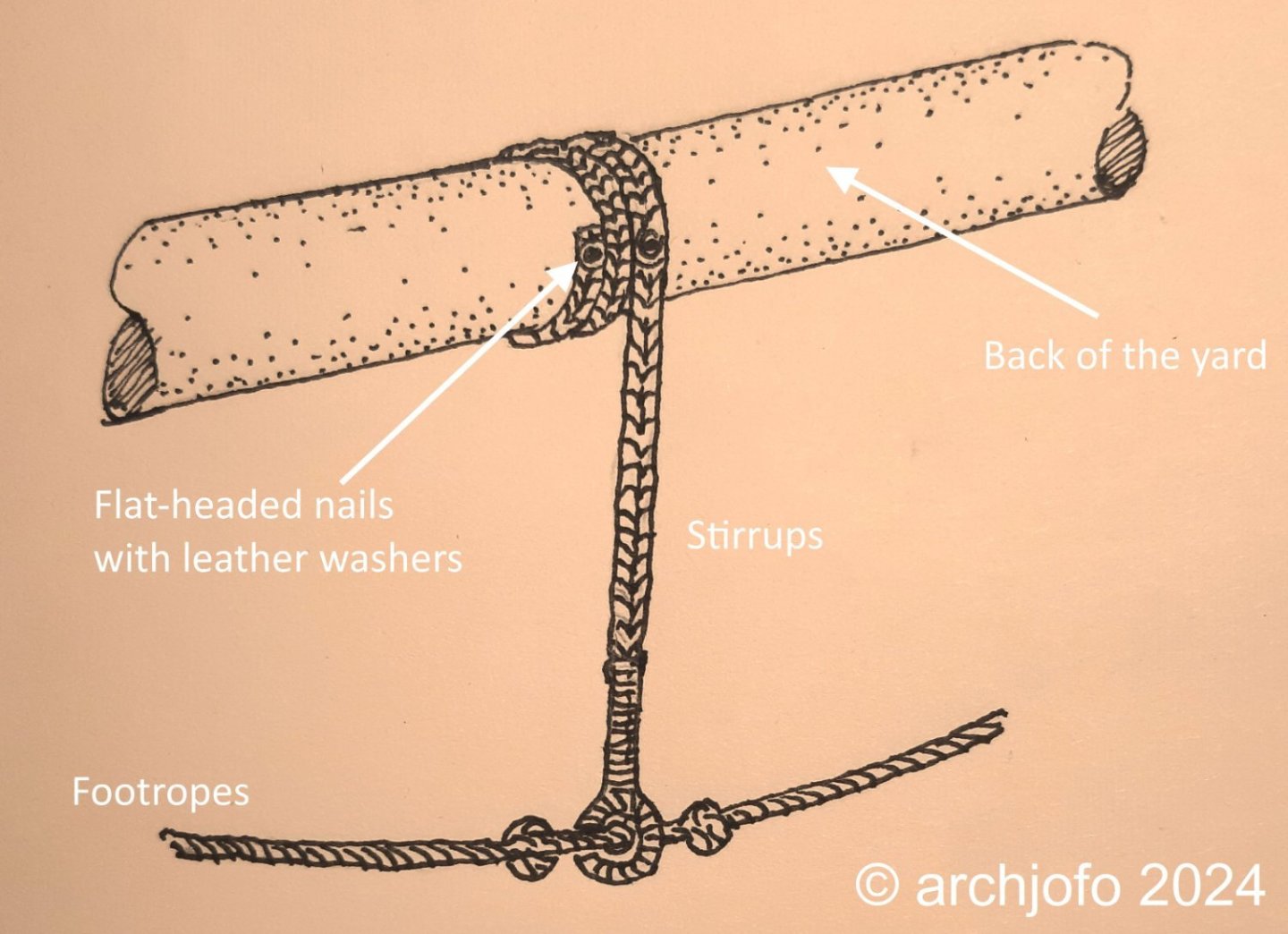

Hello, Based on Eberhard @welfalck's advice and further consideration, this seems to be the better and probably correct solution for attaching the stirrups. The reverse arrangement ensures better drainage of rainwater. I have now also found an illustration of this in "Rundhölzer, Tauwerk und Segel" by K. Schrage.

-

Hello dear colleagues, I wanted to provide an additional explanation about the braided stirrups. In various publications I was able to read how the braids were looped and secured around the yards, but I have not yet found a picture of it. According to these descriptions, I implemented it for my model at the main topgallant yard and now quickly made a drawing at Eberhard's @wefalck request. I think it might have looked like this: Of course I can't be absolutely sure about this.

-

@albert Thanks for your interest and the nice comment. @giampieroricci Hello, This illustration is from the book “Takelung und Ankerkunde” by Freiherr v. Sterneck, published in 1873. Can be downloaded as a PDF from Google Books. This is not quite the time of my corvette, but in conjunction with descriptions from contemporary French specialist literature, these depictions are often a good starting point.

-

Hello Jerry, as explained earlier in my report, the topgallant yards and the royals of my model do not receive any jackstays. In the first years of jackstay use at the beginning of the 19th century, only the lower yards and topsail yards were equipped with jackstays. It was only in later years, around the middle of the 19th century, that jackstays were also used in the upper yards. I think the illustrator only turned the jackstay eyes a little so that they could be recognized as such.

-

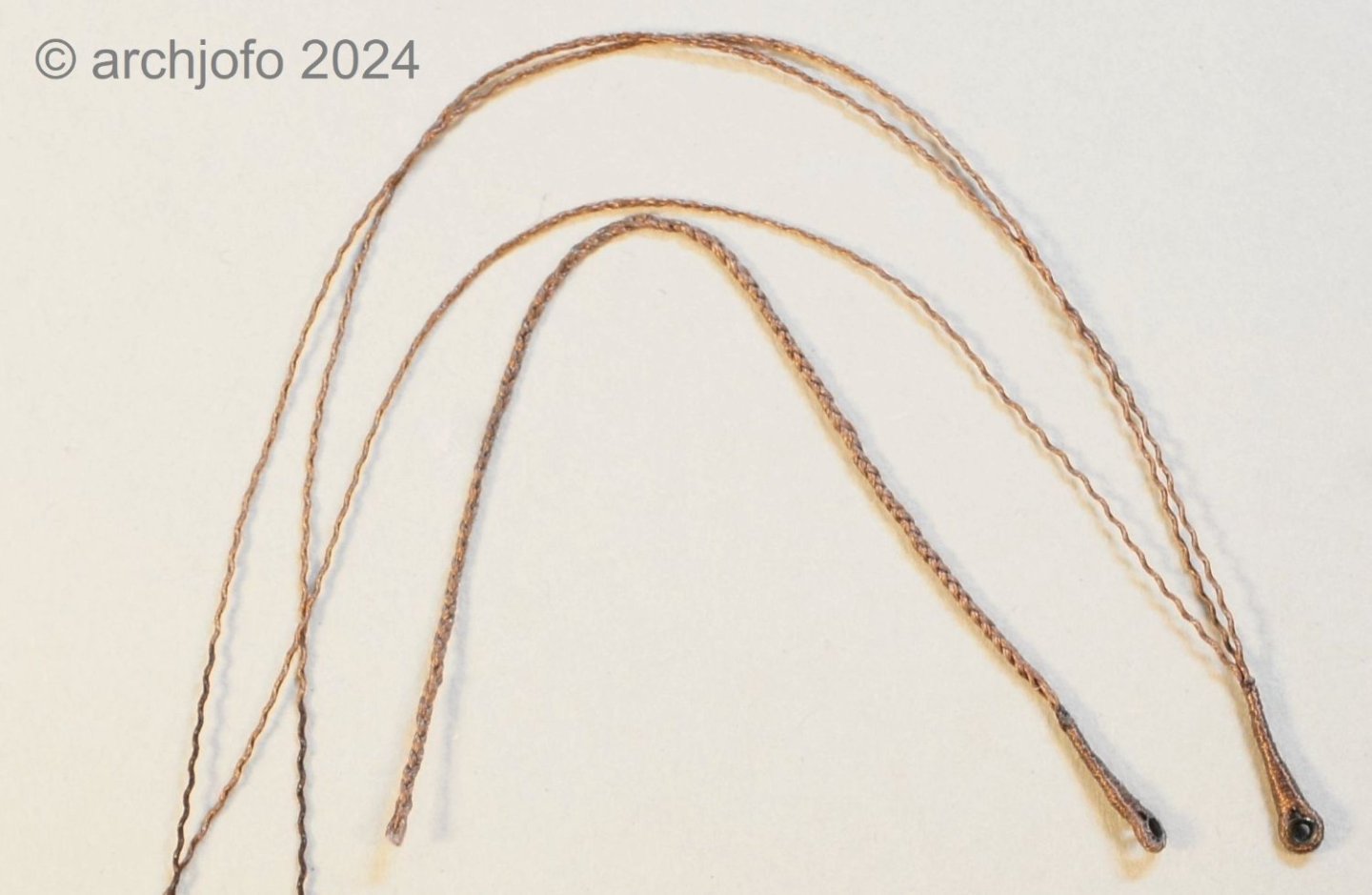

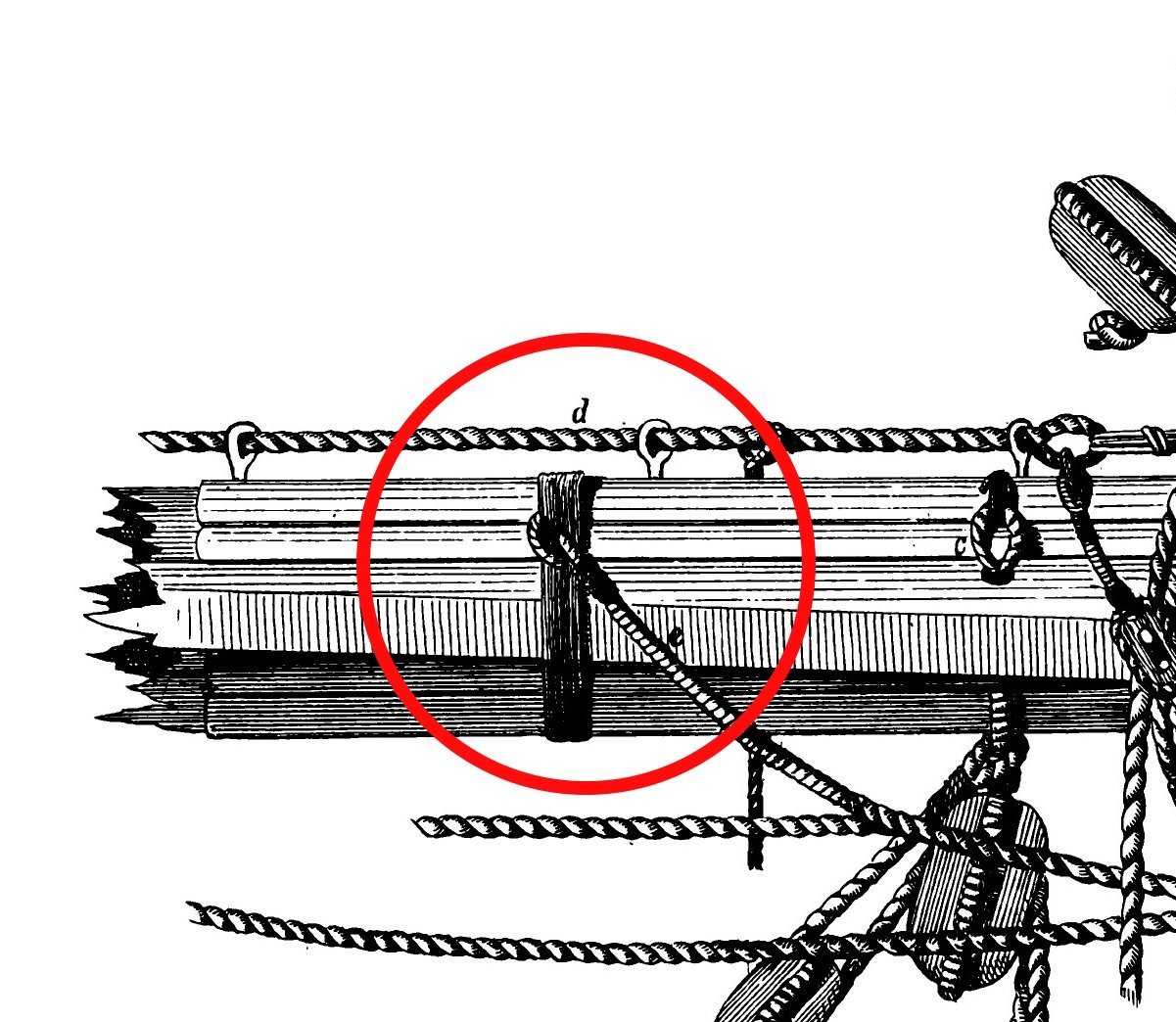

@druxey @Bruma @jdbondy @shipman @giampieroricci Hello friends, thank you very much for your interest in my build report and for the kind words. Also many thanks to all of you for the many LIKES. Continuation: Equipping the main topgallant yard - Vergue de grand perroquet Once I had clarified the details for the footropes with the stirrups, it was time for the implementation. Thanks to the corresponding preliminary work on a test piece, the stirrups were attached to the yard quickly and without any problems. Before the eye splices of the footropes could be pulled over the yardarms, the prepared grommets were first put on as chafe protection. When attaching the footropes in the center of the yard, I used the following example as a guide. Source: Freiherr v. Sterneck, "Takelung und Ankerkunde", 1873 This is what the realization for the model looks like: I have now also made the mousing to secure the hook for the tye: The simple buntlines were guided in thimbles at the topgallant yards of the French corvette. These buntlines branched out in the lower area onto two ropes, which were attached to the leeches of the sail. I therefore attached a thimble directly to the tye, as seen on the original Parisian model. The clewlines for the topgallant sails were normally connected to the clews by means of toggles. Without sails, the clewlines are connected directly to the topgallant sheets. The single-guided lifts, the braces attached directly with eye splices and the aforementioned sheets complete the equipment of the main topgallant yard. These ropes have a diameter of ø 0.25 mm and served eye splices for laying on the yardarms. The last two pictures give an overview of the main topgallant yard with all equipment elements and ropes. I will continue with the fore topgallant yard. More about that soon ...

-

Hello, the rigging with the sails looks very realistic. A really very nice model.

- 397 replies

-

- cutty sark

- revell

-

(and 2 more)

Tagged with:

-

Continuation: Equipment of the main topgallant yard – Vergue de grand perroquet The next step was the production of the quarter blocks. In the first picture you can see the quarter blocks with a length of 3.0 mm that have already been provided with strops. At the top left of this picture I show these double blocks compared to a guide block that is used on the deck to redirect the topsail sheets. Here the assembly of the quarter blocks is nearing completion. Before I started making the footropes for the main topgallant yards, I tried to fundamentally clarify the execution details for the topgallant yards. In this context, I found what I was looking for in the contemporary specialist literature “Manuel de Greement” by F. A. Coste from 1829 on pages 120/121. Accordingly, the footropes of the top gallantyards of the yardarms each extended slightly beyond the center of the yard, where they were then attached. These footropes could not be tensioned with lanyards like those of the lower yards and topsail yards. Since the brams of the La Créole did not yet have a jackstays, unlike the lower yards and topsail yards, the stirrups were designed and attached in the conventional manner. This means that the ropes of the stirrups were braided and looped around the yard with two to three turns. The ends of the braids, also known as plating (in German, I don't know the English name), were fastened with flat-headed nails with leather washers. As F. A. Coste describes, the number of stirrups in the topgallant yards must be chosen depending on the yard length. For a corvette like the La Créole, one stirrup per half of the yard should be sufficient. To make the stirrups, I was able to find the following in the specialist book “The Ashley Books of Knots” by C. W. Ashley: Of course I had the ambition to implement this detail for my Corvette too. After tying in the thimble, the braid was made after unraveling the rope of the stirrup. This is how the meaning of the braid became clear to me. Since these were no longer round but flat, they could be wrapped very well and tightly around the yard and securely nailed down. Since I still had a main topgallant yard as scrap from making the yards, I was able to try out attaching the braids to it. The result can be seen in the next picture. I think that's how I'll ultimately implement it at the topgallant yards. Sequel follows …

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.