M.R.Field

Members-

Posts

144 -

Joined

-

Last visited

Recent Profile Visitors

-

Hi, My wife, in about 5 minutes, sadly found that Martin Field has died back in 2021. It was someone from Brit modeller forum that spoke of a wonderful man,

Thanks again for your efforts to help me,

Steve

-

GrandpaPhil reacted to a post in a topic:

Launch Riva Aquarama by WoodButcher - FINISHED - SMALL - popsicle built

GrandpaPhil reacted to a post in a topic:

Launch Riva Aquarama by WoodButcher - FINISHED - SMALL - popsicle built

-

Roger Pellett reacted to a post in a topic:

Launch Riva Aquarama by WoodButcher - FINISHED - SMALL - popsicle built

Roger Pellett reacted to a post in a topic:

Launch Riva Aquarama by WoodButcher - FINISHED - SMALL - popsicle built

-

Duanelaker reacted to a post in a topic:

Ship paintings

Duanelaker reacted to a post in a topic:

Ship paintings

-

Ian_Grant reacted to a post in a topic:

Victorian Racing Cutter Vanity by M.R.Field - scale 1:16 - Radio

Ian_Grant reacted to a post in a topic:

Victorian Racing Cutter Vanity by M.R.Field - scale 1:16 - Radio

-

Roger Pellett reacted to a post in a topic:

Scroll Saw or band saw... help me pick the right one.

Roger Pellett reacted to a post in a topic:

Scroll Saw or band saw... help me pick the right one.

-

yvesvidal reacted to a post in a topic:

Victorian Racing Cutter Vanity by M.R.Field - scale 1:16 - Radio

yvesvidal reacted to a post in a topic:

Victorian Racing Cutter Vanity by M.R.Field - scale 1:16 - Radio

-

mtaylor reacted to a post in a topic:

Victorian Racing Cutter Vanity by M.R.Field - scale 1:16 - Radio

mtaylor reacted to a post in a topic:

Victorian Racing Cutter Vanity by M.R.Field - scale 1:16 - Radio

-

Hi Colin, yes that is very much from the same mould as Vanity. Just a little earlier and perhaps a little smaller. The model has a few more bits on her now, but progress is slow. I have been trying to join a new model flying club as I left the previous one because they were too divided and were not taking training seriously, but the last minute the new one decided to leave it until next year!. So I may be getting rather more done on Vanity now. Cheers, Martin

-

coalman reacted to a post in a topic:

A question about varnish.

coalman reacted to a post in a topic:

A question about varnish.

-

KeithAug reacted to a post in a topic:

Victorian Racing Cutter Vanity by M.R.Field - scale 1:16 - Radio

KeithAug reacted to a post in a topic:

Victorian Racing Cutter Vanity by M.R.Field - scale 1:16 - Radio

-

Thanks, Michael, she's slowly getting there, but I only have weekends and then only if the weather's good which it hasn't been lately much. Martin

-

Well, lovely weather today, so I dragged Vanity out and had a crack at her mast and spars. I'd already made these parts, but a while back I stole the mast to make the handle for my model aeroplane field box that I made. So, another main mast was called for and I found a nice straight grained piece of fine pine at B&Q's. Used my sweet new disc sander that my dear bride bought me for Dad's Day and tapered the foot of the mast till it fitted closely in the step. Then, having made the bowsprit ages ago, I decided to fit the bitts in the deck for holding the inboard end. I'd also already made the strapping irons for the bow support of the bowsprit, so I drilled the hull and epoxied those in after making a suitable hole in the bulwarks with that most useful of tools the drum sander. Finally, drilled the side of the hull for the chain plates and epoxied those in. Photos with the deck furniture just balanced in place for now. Now, time for tea.

-

Jonny, thanks for your comments. It's a very odd thing...I haven't had any new comments for weeks and then there's three in one day and a message! And usually Sunday on the 'net is very quiet. I find the best of the racing yachts to be the most beautiful of craft, if a little narrow in style. I have an excellent book called Traditions and memories of American Yachting, which has photos and lines of many nations' yachts. I think the racers can make a good foil to all the pilot cutters that are made, although they're lovely vessels too. Martin

-

I think she was indeed, one of the slenderest ones. Certainly a successful boat whilst the class rules lasted which was sadly not very long. She was classed as a C class cutter. She went to America and beat the then America's Cup winner on the same course in a friendly, so she was a fast boat. Such a shame she has ended up in Bristol, unloved and falling apart. I hope my model will due her memory some justice. I'm just so damned busy and the weekend weather has not been friendly. I can only do my stuff at the weekend, amongst all the domestic chores that must be done. Martin

-

Thanks, Keith, yes she is a lovely slender lady, which may make her tender in light winds, but she'll stand a blow. I've just been too busy lately to do any more on her, but she will be finished. Martin

-

Mini Table Saw recommendations

M.R.Field replied to captainscott's topic in Modeling tools and Workshop Equipment

Didn't see that. Why price in dollars and have a European voltage motor? Weird. Well, I have to say it. "I'm alright, Jack, pull up the ladder" <G> Martin -

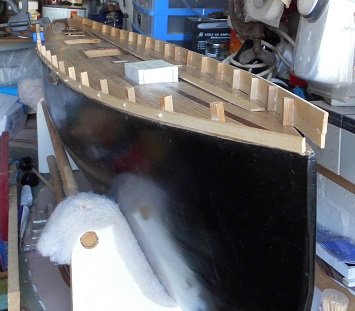

Isn't this weather wonderful? OK, still not allowed to fly when we want (I will NOT plead for a two hour block with the man who thinks he runs the club!), but it does allow me to get on with Vanity in the little bit of shade my shed affords me. Bulwarks on and treenailed and the first capping rails going on, having been band sawed from the same mahogany that I used for the hull, suitably filed to section. Once set they too are treenailed with mahogany pulled through a drawplate to size. Martin

-

Mini Table Saw recommendations

M.R.Field replied to captainscott's topic in Modeling tools and Workshop Equipment

Wefalck, I have no idea of the arbor hole diameter in the blade as I have had no reason to take it apart. It describes itself as German designed, but that never impresses me as I've worked and lived in Germany and was never impressed by purely German design, much of which was appalling. I assumed that was why there were so many foreign contractors there including me and 175 others in just one company! It is what it is. It does not suffer from a fence that isn't locked at the back. It stays put perfectly well, better, for instance, than the Micro craft which I used for decades with, when sometimes necessary, a G clamp on the fence, but rarely. I've read that the mitre fence is no good. Well, erm, it works, so what's no good? I was cutting old, hard 1/8" mahogany tother day and the motor didn't slow at all. I am delighted with it. So far I have cut 3/8th Pirhana pine down to 1/4" square and all I got was a lovely piney smell and very smooth timber heads. Martin -

Mini Table Saw recommendations

M.R.Field replied to captainscott's topic in Modeling tools and Workshop Equipment

I have just found this advert which is the same machine, albeit in dollars. https://joystar.en.made-in-china.com/product/gsrxGvZdMbcN/China-Mini-table-saw-for-woodworking-MTS-3115-.html Hope that helps, Martin -

Mini Table Saw recommendations

M.R.Field replied to captainscott's topic in Modeling tools and Workshop Equipment

Well, I can, but they now say "unavailable". I'm sorry. Looks like I must have got the last one! But I'd keep an eye on the page in case they get more in. My wife paid just under £60 for it. It came with tools and a spare belt. https://www.amazon.co.uk/ABEST-Electrical-Bench-Benchtop-Hobby/dp/B07CGBX394 Martin -

Mini Table Saw recommendations

M.R.Field replied to captainscott's topic in Modeling tools and Workshop Equipment

My ancient Minicraft table saw burned out recently after decades of use and they seem to no longer be made, so my wife searched for me and found an Abest on Amazon for £60. I only use a table saw for planks, timber heads etc. So she got it for me. It arrived, after ordering one evening, the very next lunchtime, well packaged! I immediately put it to use and have been using it constantly since. It is billed as German designed (not that that impresses me!) although it is, of course, made in China. I did check the Byrnes price, laughed and let her order the Abest. It appears to be no different from a Proxxon, all of whose tools I have found to be grossly overpriced. The only possible disadvantage to this particular tool is the lack of a tilt table, but I never needed one all the long time I owned the Mini/Maxicraft saw, so I'm sure the lack won't prove a problem with this one. It is belt driven with a geared down ratio so its 480 watts is more than ample for cutting my stuff. I have no need for thick wood in my modelmaking and if I did my full sized table saw would cope, or, I could ask my son to use his slightly more accessible one for me. I do think there's a certain snobbishness on show when it comes to saws and perhaps tools generally. The Byrnes is obviously best, but so it should be at that price! The Proxxon is really no different from my Abest. Just a different, rather billious, colour and up to three times the price. I have no idea about Harbour Freight and Micro Mark as we don't get them in Britain. If I need shapes, I use my £12 fleamarket band saw. When I file stuff, I use the second hand, but previously unusedGenuine Stubbs and Vallorbe Swiss files I buy at fleamarkets, Sunday markets, boot fairs, whatever you want to call them. I buy the best new larger files as I really do give them some stick, although all I can get these days are Nicholson, which do wear out, unlike the old Stubbs of which I still have a few examples. I am and have been for many years a professional modelmaker, but have not found it necessary to go nuts on buying machine tools. The best lathe, for instance, I ever owned, FOR MODELMAKING, is the cheapest by a long way, a Taig/Peatol. American made. English supplied. Martin -

Today I got some treenails in to maximise strength in the bulwarks. Once tother side is done I can trim them off with a new scalpel blade and then cut the capping rails to shape and thin down . They are to be made from the same mahogany as the hull, but all I have left are overly thick strips, so once shaped they can be sawn thinner. Cheers, Martin

-

Bentley 4.5 litre (altered version) by kpnuts 1/12 Airfix

M.R.Field replied to kpnuts's topic in Non-ship/categorised builds

The silversmith actually got the electro-forming process completely wrong and needed to do a vast amount of re-modelling to meet the deadline for the first model. I spent a weekend with him and his father treating sheets of silver as I would brass and making parts from solid silver that couldn't be cast in resin and electro-formed. I figured if I could make stuff an experienced silversmith couldn't and quickly, too, I was worth a Hallmark. So I applied and got one. The silversmith was so put out that he took all his stuff away from my workshop when he knew I wouldn't be there and I never heard from him again. He went broke because he took too much on to do the electro-forming and hadn't learned how to do it. A classic case of over extension, with a good old kick of arrogant ignorance thrown in. I've never used the Hallmark, but it's still valid for a few years more (it lasts an odd 27 years) and if another half useless so called silversmith approaches me I shall wave my personal Hallmark punch under his nose and double my price! Are you going to replace the moulded spokes with fine wire or stretched sprue? Easy, but SO tedious<G> Cheers, Martin

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.