JOUFF

Members-

Posts

98 -

Joined

-

Last visited

About JOUFF

- Birthday 05/12/1953

Profile Information

-

Gender

Male

-

Location

France

Recent Profile Visitors

-

JOUFF reacted to a post in a topic:

MONTAÑES by Amalio

JOUFF reacted to a post in a topic:

MONTAÑES by Amalio

-

JOUFF reacted to a post in a topic:

La Créole 1827 by archjofo - Scale 1/48 - French corvette

JOUFF reacted to a post in a topic:

La Créole 1827 by archjofo - Scale 1/48 - French corvette

-

JOUFF reacted to a post in a topic:

La Créole 1827 by archjofo - Scale 1/48 - French corvette

JOUFF reacted to a post in a topic:

La Créole 1827 by archjofo - Scale 1/48 - French corvette

-

cotrecerf reacted to a post in a topic:

Le Gros Ventre by marsalv - FINISHED - 1:48 - POF

cotrecerf reacted to a post in a topic:

Le Gros Ventre by marsalv - FINISHED - 1:48 - POF

-

mtaylor reacted to a post in a topic:

Le Gros Ventre by marsalv - FINISHED - 1:48 - POF

mtaylor reacted to a post in a topic:

Le Gros Ventre by marsalv - FINISHED - 1:48 - POF

-

Bonjour, Très beau modèle, une réalisation parfaite ! Un très grand "BRAVO" ! Patrick

- 589 replies

-

- le gros ventre

- cargo

-

(and 2 more)

Tagged with:

-

JOUFF reacted to a post in a topic:

La Créole 1827 by archjofo - Scale 1/48 - French corvette

JOUFF reacted to a post in a topic:

La Créole 1827 by archjofo - Scale 1/48 - French corvette

-

JOUFF reacted to a post in a topic:

La Créole 1827 by archjofo - Scale 1/48 - French corvette

JOUFF reacted to a post in a topic:

La Créole 1827 by archjofo - Scale 1/48 - French corvette

-

JOUFF reacted to a post in a topic:

La Créole 1827 by archjofo - Scale 1/48 - French corvette

JOUFF reacted to a post in a topic:

La Créole 1827 by archjofo - Scale 1/48 - French corvette

-

JOUFF reacted to a post in a topic:

Le Gros Ventre by marsalv - FINISHED - 1:48 - POF

JOUFF reacted to a post in a topic:

Le Gros Ventre by marsalv - FINISHED - 1:48 - POF

-

JOUFF reacted to a post in a topic:

Le Gros Ventre by marsalv - FINISHED - 1:48 - POF

JOUFF reacted to a post in a topic:

Le Gros Ventre by marsalv - FINISHED - 1:48 - POF

-

JOUFF reacted to a post in a topic:

Le Gros Ventre by marsalv - FINISHED - 1:48 - POF

JOUFF reacted to a post in a topic:

Le Gros Ventre by marsalv - FINISHED - 1:48 - POF

-

JOUFF reacted to a post in a topic:

Le Gros Ventre by marsalv - FINISHED - 1:48 - POF

JOUFF reacted to a post in a topic:

Le Gros Ventre by marsalv - FINISHED - 1:48 - POF

-

Stefano reacted to a post in a topic:

La Renommée by JOUFF - 1/48 - French Frigate - by Patrick JOUFFRIN

Stefano reacted to a post in a topic:

La Renommée by JOUFF - 1/48 - French Frigate - by Patrick JOUFFRIN

-

robert952 reacted to a post in a topic:

Le Gros Ventre by marsalv - FINISHED - 1:48 - POF

robert952 reacted to a post in a topic:

Le Gros Ventre by marsalv - FINISHED - 1:48 - POF

-

Tobias reacted to a post in a topic:

Le Gros Ventre by ChrisLBren - 1/36

Tobias reacted to a post in a topic:

Le Gros Ventre by ChrisLBren - 1/36

-

mtaylor reacted to a post in a topic:

Le Gros Ventre by marsalv - FINISHED - 1:48 - POF

mtaylor reacted to a post in a topic:

Le Gros Ventre by marsalv - FINISHED - 1:48 - POF

-

Well done, congratulations ! Thank You for the photos. Patrick

- 589 replies

-

- le gros ventre

- cargo

-

(and 2 more)

Tagged with:

-

mtaylor reacted to a post in a topic:

Le Gros Ventre by ChrisLBren - 1/36

mtaylor reacted to a post in a topic:

Le Gros Ventre by ChrisLBren - 1/36

-

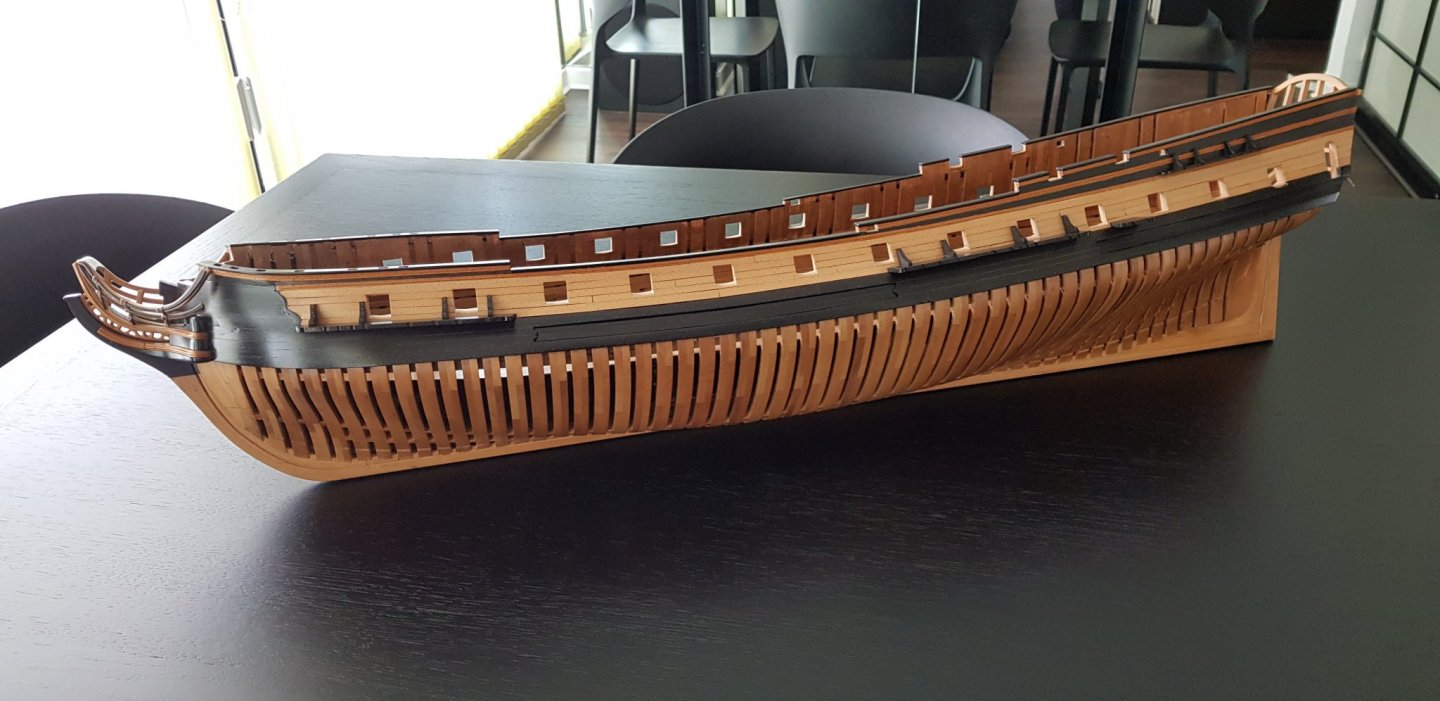

ancre Le Gros Ventre by ChrisLBren - 1/36

JOUFF replied to ChrisLBren's topic in - Build logs for subjects built 1751 - 1800

Hi Chris! Nice work, your construction site seems very well done. You are progressing well and you will achieve a very precise assembly of your frames. Keep it up, it's very promising... Patrick -

Tobias reacted to a post in a topic:

Le Gros Ventre by ChrisLBren - 1/36

Tobias reacted to a post in a topic:

Le Gros Ventre by ChrisLBren - 1/36

-

mtaylor reacted to a post in a topic:

Le Gros Ventre by ChrisLBren - 1/36

mtaylor reacted to a post in a topic:

Le Gros Ventre by ChrisLBren - 1/36

-

No Idea reacted to a post in a topic:

Le Gros Ventre by ChrisLBren - 1/36

No Idea reacted to a post in a topic:

Le Gros Ventre by ChrisLBren - 1/36

-

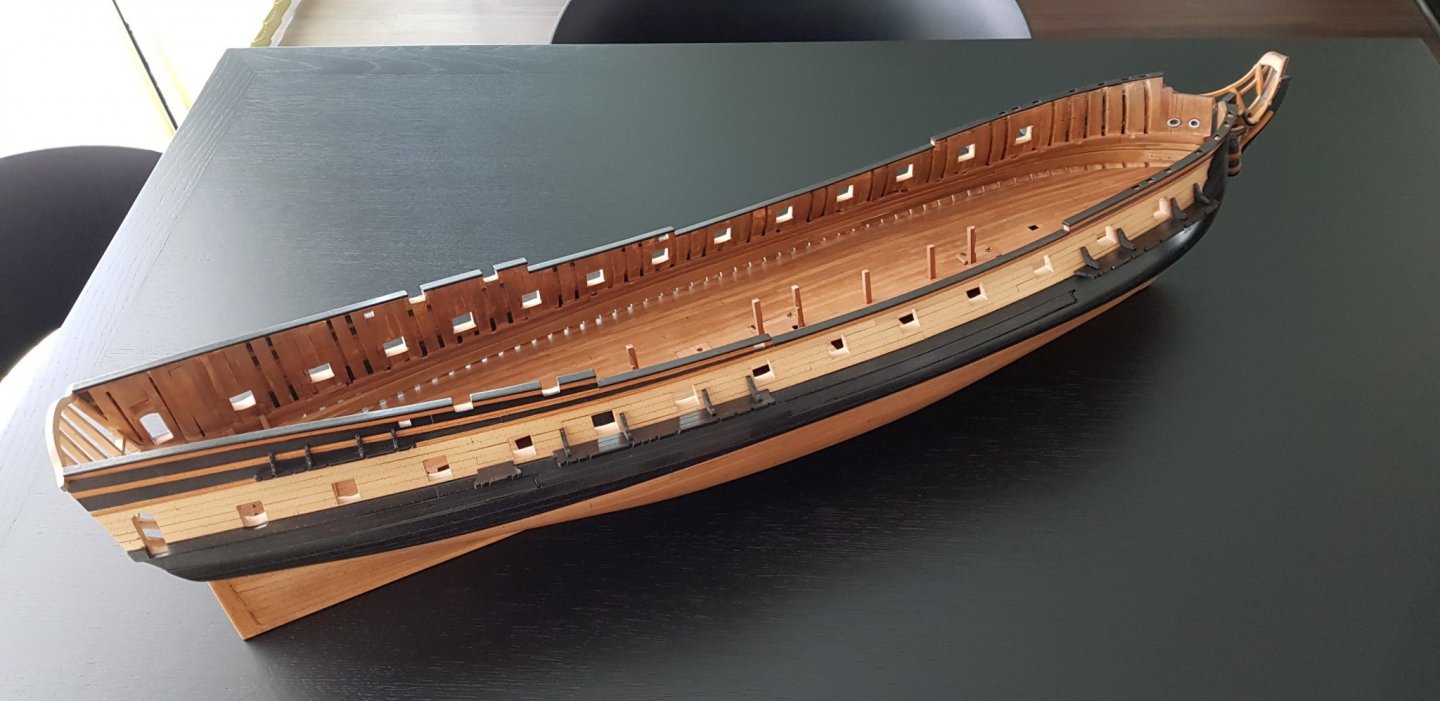

ancre Le Gros Ventre by ChrisLBren - 1/36

JOUFF replied to ChrisLBren's topic in - Build logs for subjects built 1751 - 1800

Hi Chris! This is great progress ! Your work seems very well done and you will take a lot of pleasure in seeing your hull build up... Continue on this path, take maximum pleasure and satisfaction. Patrick -

Hello Gentlemen, Thank you for your feedback. The Leds ramp is now definitely in place : The false deck is glued. Here is a lighting test. The brightness satisfies me : the goal is not to let it light up permanently but to be able to show the inside of the hold on occasion ... So let there be light : So much for this day. I enjoyed myself ... Patrick

-

Hello Gentlemen ! It was a long time ago, wasn't it ! I had "lifted my feet" certainly but despite all the work continued ... A big piece for me: the false deck. I was not sure how to do it. Finally, I decided to do everything by hand : cutting the slats, adjusting them, sanding etc ... Some photos of the successive stages : A small patina, nails : I decided to make openings in different places where there is something to see. The upper decks will also be opened to show the structure ... To summarize : the wedge will be visible through the frames and on the opposite side we will see the structure in "plunging" mode. I make the openings : The false deck in place - not glued - to see what it gives : I also wanted a lighting system for the hold and the deck. I had not shown you these photos where I installed some micro-leds in the bilge to start : All this being practically invisible from above : I continue the lighting work with a whole ramp of leds, embedded in a slat, so that they are not visible when we look between the frames : That's it for the moment. The continuation next time ! I wish you a good day ! Patrick

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.