-

Posts

248 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by dashi

-

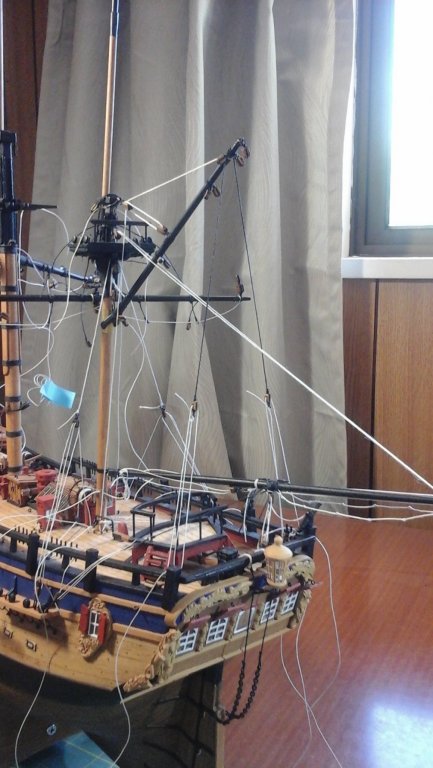

With the exception of sails, name plate and case this build is finished to my best ability and interpretation of contemporary drafts, shipwright practices, drawings/paintings, british naval ship building practices, and Cooks log with special attention to the tiller support built by Cook while in Queen Charlotte Sound New Zealand, and the mizzen driver/spanker boom. I wanted to make sails and even bought the cloth, but unfortunately due to declining health cannot make them, so have run the sail rigging with the exception of bowlines. The nameplate is in the winds and a case at this stage is outside my budget, so a can of compressed air will have to suffice to keep the dust from collecting. I bashed the bouys and in lue of sails the port anchor and pinnace are shown in the process of being raised using relevant fish/yard/hatch and stay tackles. As there were several methods of tackle used to raise the anchor I went with the simplest which was suggested for small ships. Only the pinnace hull was painted white as an experiment to test the effectiveness of white lead paint against sea worm, so the ship and rest of the boat hulls were protected using 'brown stuff' as Cook refers to it. I'd like to thank everyone here for their build logs, support and encouragement in helping me over the 4 years it's taken to complete this build. Cheers and safe sailing Dashi

-

Thanks for all the likes and Chris and Dave for comments, yes more ropes and blocks with some rework to the top and lower sail sheet quarter and yard blocks swapping them out for 6mm which better fit 1/64 scale 14-16 inch blocks. The kit only supplied 5mm so had to purchase approx 26 x 6mm single blocks plus some doubles for top yard ties. Also while doing this corrected the lift block lashing to the yard sheet blocks as per Steel. Chris I hope my photos are some help, I have followed as best I could David Steel 1794 and made the gallant topping lift shroud thimbles where required using a small brass rod with a lower seizing pushed up tight to the shroud seizing then fixed with ca glue twisting the rod so it doesn't stick while the glue sets and then removing it to form the thimbles. Udate: Yard running rigging complete, next the sail running rigging without sails.

-

Hi Pat, just found your build and she's coming along nicely, looking very neat and clean. Dashi

- 111 replies

-

- artesania latina

- finished

-

(and 1 more)

Tagged with:

-

She's looking great. This was my first build and I think you are doing a much better job than I did, well done.

- 12 replies

-

- artesania latina

- Virginia

-

(and 1 more)

Tagged with:

-

Thanks for the likes and comments. Update: Standing rigging completed and now onto fitting the yards. To keep the ratlines level and even I used 5mm graph paper which I pegged and leveled to the shrouds. 5mm works out to about the 13inch gap required. Also I interpreted Steel as having the upper and lower 6 ratlines only tied to the shrouds that are futtocked (the futtock staves being only across the lower shrouds for the above futtock shrouds) then the ratlines are tied to all the shrouds in between.

-

Mast Lengths and their above deck heights for HMB Endeavour

dashi replied to dashi's topic in Masting, rigging and sails

'Ship-builder's Assistant by William Sutherland London 1726' Druxey this pushes the practice of stepping the mizen mast in the lower deck instead of the keelson back to at least 1726, the early 18th century. Therefore IMHO when considering the evidence to hand I don't think it unreasonable to conclude that due to the stated length of Endeavour's standing mizen mast that it was indeed stepped in the lower hold instead of the keelson! Ship builder's assistant by William Sutherland London 1726 Cheers Dashi- 63 replies

-

- HMB Endeavour mast lengths

- above deck mast heights

- (and 3 more)

-

Thanks for the likes, and thanks Sam, do you have a build log for your Bounty? Updates: Jeer blocks and Corrections. Jeer blocks: Here are the photos showing the re run of the stays around the head [as stated in previous post] along with the first jeer block lashed to the head. The strapping for the jeer block according to Steel is 5" so used 0.75 black thread doubled and made it's length 1 fathom [6ft] so the blocks sit at a nice height below the stays and above the yard. The lashing around the mast is 3" and 28 fathoms long or 14 fathoms per side until it's used up and well stopped, so used 0.25 caldercraft black cord which wasn't supplied in the kit. I basically clamped the jeer block in position with the strapping eye touch the base of the jeer cleat and held the lashing in place above the opposite cleat with my finger as I passed the cord around keeping it pulled firm and even. I will fix it all in place with diluted white glue when done. Corrections: A major oversight of mine early on was to have the main stay collar too close in to the fore bits which resulted in the preventer stay collar around the fore mast being below the height of the stowed boats which would fowl the mid/main stay sail if used. So moved the main stay collar up the bowsprit to give enough clearance for the preventor stay and mid stay sail. Where the main stay passes the fore mast was exactly on the preventor collar cleat so filed an angle groove for the stay to rest in. Fortunately I used white glue for the collar cleats so used water to soften the glue and cleanly removed them from the mast for repositioning. Main and fore shrouds: Before adding the jeer blocks I thought it best to review my lower rigging as I don't want to be removing them. I wasn't comfortable with the first top mast standing back stay on a large dead eye and the after standing back stay on a small dead eye on the channels, when they are both the same size rope. It seems more likely with the dead eye configuration that there was only one pair of standing back stays for the top masts on the small dead eye at the aft end of the channel, because in addition to these on the topmasts there are the breast back stay and shifting or 'weather back stay' as Cook refers to it, which still leaves 3 pair of top mast back stays. Endeavour did have problems with the top mast back stays. The sheer plan of the 'Wasp 1812 in the National Maritime Museum' http://collections.rmg.co.uk/collections/objects/84386.html which is close in size to Endeavour, seems to bear this configuration out with one pair of standing back stays for the topmasts and two pair of standing back stays to thimbles for the top gallant masts [which I will do]. So have added the extra shrouds to the fore and main masts on the large deadeyes as can be seen. Cheers dashi

-

Thanks for the likes and kind comments. For me it's very much 2 steps forward and 1 step backward because not only am I making more mistakes (like accidentally cutting my main stay in half... eyes not so good some days) It's a very steep learning curve for me also as I'm slowly getting familiar with Steel and Lever and having to re do a lot of my earlier work. So Dave I think you might cross the finish before me and Thunder that's very kind of you, but please don't take what I've done or written to be correct as I may have mistakenly misinterpreted, or overlooked something. Currently I'm redoing the blocks that hang under the tops inline with the replica top photo Dave provided on his build log, which accords with Steel's discriptions. And whilst looking at the replica and Victory tops noticed I had the stays wrong around the head's so a simple fix to correct. I'll post some pics soon I hope. Cheers dashi

-

Dave I was researching the blocks under the fore and main caps and found your log to be a great help especially the photos of the replica's tops. Then I noticed how you have the stays over the heads so after some more research found a clear picture of HMS Victory which has it the same with the jeer pendants running down between the mast and stay, so I've corrected my stays to match. Thanks for a great log, Cheers dashi

-

Thanks for the likes and thanks Pat, yes just enough room to fire those guns and slide the boat skids in and out I think. Lower standing rigging: Shrouds, stays and futtoc staffs all fitted. Since I'm following the rigging tables from Steel 1794 I've had to deviate from the kit for the Mizen. The kits Mizen shrouds were 0.75 mm which at 1/64 scale would be just under 6 inches and the stay the same. According to Steel the shrouds are 4.5 inches @ 1/64 = 0.56 mm and the stay 5.5 inches so as per the kit. This correction also applies to the fore and main top mast shrouds and consequently reduces the gallant and mizen top mast shrouds from the kit which uses 0.70 mm for the mizen and 0.5mm for the gallants. According to Steel the gallant shrouds are 2.5 inch and the mizen top mast shrouds 3 inch, so down to approx 0.35 mm cord from the kits 0.5 mm cord. I bought a roll of caldercraft 0.25 black cord for the job as non is supplied in the kit, and which under magnifying glass looks to be more like 0.35 mm so should be good and look more to scale. So here's some pics of where I'm at, as can be seen the mizen shrouds are well clear of the rail and swivel gun. At this stage Steel says to do the ratlings, but I don't want to limit my tweezer access to the deck so might leave those for later. I might carry on with with the fore and main jeer block pendants, catharpins, tops, futtoc shrouds and any other collars or blocks I need to fit to the lower heads, then rig the top masts (subject to change). Also I might change out the buoy cord on the anchors since I now have more caldercraft cord as what I've used doesn't look right. Cheers dashi

-

Yards: Here's a pic of all the yards complete with blocks and parrels showing the relationship to each other in their respective order from driver boom/left to top sprit yard/right. Since this pic I've increased the length of the brace pendants slightly using Steel's length formula for each yard which is a fraction of the given yard in feet then converted to fathoms. If 2 pendants then divide that number by two which allows enough length for strapping of the block and thimble around the yard. As per a previous post the jeer and tye blocks are according to Steel's description and tables for a ship of 400 to 450 tons. The topmast tye blocks should be 6 mm so have trimmed two doubles for the yard and ordered more along with more 3 mm blocks which I need to complete the build. Parrels are of 4 different types according to Steel, changing in size respective to their yards, it seems there is some lee way especially regarding the top gallants which can either be truck and rib or rope. Because according to Seel's tables the size of the gallant parrels are so small at only 8 inch which translates at 1/64 scale to 3mm I decided to opt for rope parrels. I would have done the same for the top sprit yard but it seems they are farely insistent that this be truck and rib so have used the kit supplied parts even though they are slightly over sized as I couldn't find or make anything smaller. Because the mizen top yard is on a pole it seems to be treated much the same as a gallant so am in 2 minds as to the parrel type, the size should be 11 inch which at 1/64 scale = 4.5 mm, the kit ribs are 7 mm so for now have gone with a rope parrel in keeping with the gallants. Standing Rigging: I've re done the collars on the lower masts to bring it all inline with Steel as I did for the bowsprit. The fore mast shrouds, stays and futtoc staffs are fitted. The futtoc staff is made from .75 black cord put on the stretch and painted. These are then lashed below shrouds to where the catharpins will be lashed, the same distance below the top of the cross trees to the bottom of the cap. The futtoc staff does not extend to the fore most shroud due to it being abreast the mast and consequently not catherpinned. The fore most catharpin looks like it will chaff the mast and pull the shroud out of line so I might cross the first two catharpins so they clear the mast, however I can't find any reference to this being done! Because I'm following the 'As fitted draft of 1768' Greenwich National Maritime Museum zaz7844, then the size and number of deadeyes on the channels differs from the kit and AOTS. The last two dead eyes on the fore and main channels I've reserved for the top mast back stays following Steels drawings; in the case of the fore mast my interpretation is: 2 pair of shrouds and one swifter per side; the main 3 pair of shrouds per side and the futtoc staff not extending to the aft most shroud as it has 4 catharpins and 6 shrouds. Hope this makes sense as it took a lot to nut out but once I got my eye in reading Steel's descriptions and tables then for the most part it started to make sense. I still might have overlooked or misinterpreted something for which I apologize in advance. Cheers dashi

-

Thanks for the likes and for checking out the driver boom Dave. I must admit I was in 2 minds about installing the driver boom. What tipped my hand was that Endeavour did actually have one according to contemporary accounts, which to my limited knowledge I haven't seen fitted before so was curious and wanted to show it. As to the sail it carried there seems to be several options of which I'm yet to decide. 😀

-

She looks great, well done and thanks for the tip on those flags which I might look into as I was wondering what do and they look good. Cheers dashi

- 108 replies

-

- endeavour

- caldercraft

-

(and 1 more)

Tagged with:

-

HMCSS Victoria 1855 by Banyan - 1:72

dashi replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

Very impressive Pat..- 973 replies

-

- screw

- gun dispatch vessel

- (and 5 more)

-

Thanks Pat Bowsprit: Time to take a closer look at my rigging and make corrections according to contemporary sources. Moved the collars and sprityard sling cleat as they were too close in toward the bow and placed them in order as best to my interpretation of Steel. The new positions give a straighter line on the fore top stay and fore stay and a little more space for the spritsail. The size in Steels tables for the shroud hearts or dead eyes is 7 inch so 3mm which I think looks more to scale. So replaced the kit supplied 7mm hearts to 3mm deadeyes as there seem to be plenty spare in the kit and according to Steel both hearts or dead eyes can be used here. Doubled the bobstays inline with Steel and contemporary Navy regs, and replaced the bobstay hearts to 5mm dble and sing blocks with the falls made fast to timber heads as can be seen in the pics. This is according Lever who states in The Young Sea Officer's Sheet Anchor: Boomkins: added 2 inch thimbles to the shrouds inline with Steel. The brass forward of the slingcleat should be lead to protect the bowsprit from wear from the sprityard sling. Cheers Dashi PS. Forgot to mention at this scale to make thimbles I simply seize the cord around a rod of the size thimble I require and set it with ca glue and sometimes finish it with a little black paint.

-

Driver boom and gaff: Have bashed the driver boom and dry rigged it and the gaff to ensure belay points and clear rope runs (lost count of how many attemts and corrections it took, dry assembling and taking down to redo). I used the following resources as the basis of the construction of the driver boom and rigging: The Art of Rigging by D Steel 1806, The Elements and Practice of Rigging And Seamanship, 1794, by David Steel, and The Young Sea Officer's Sheet Anchor by Darcy Lever 1835 which although later has some wonderful illustrations and discriptions; and of course the aforementioned painting by Atkins and log entry by Cook. It's worth noting that when using Steel I needed to cross reference his tables for the sizes of rope and blocks etc for each part as they can change relative to the ships tonnage. It wasn't easy as there are several ways and combinations of rigging the mizen, each being correct given the situation whilst following certain criteria. For example you can rig a square cut mizen course without the driver boom, or with a driver boom to stretch the foot; the square cut course furled with the driver boom, and full driver sail temporarily rigged using halyards and a short yard at the gaff peak laced to the driver sail; the driver boom with driver sail laced to the gaff replacing the square mizen course completely (spanker?); and even a narrow temporary driver sail laced to a short yard at the gaff peak abaft of the square mizen course with a short footing boom going from the square mizen clue and projecting abaft over the tafferel as illustrated by Lever and which I think is what the AOTS mizen driver might be attempting or interpreting? As to the different ways of running the rigging there were many and where possible I have followed Steel except for the run of the sheet and the luff tackle cats clawed to it which instead of hooking to the tafferel, is hooked into an eye bolt through the boom abaft the it's goose neck and opposite it's belay cleat on the boom because of the light on the tafferel. This illustrated by Lever and functions as an outhauler but without an inhauler. Also Lever states that if a driver boom be fitted the the gaff should traverse up and down the mast, but this appears to be contradicted in one of his illustrations. I've run the sheet from the luff tackle up through a sheave in the end of the boom and temporarily made fast around the boom forward of the inner cleat. There were 2 options for attaching the driver boom to the mast: with jaws and parrel like the gaff resting on a timber abaft the mast around 6 to 7 ft off the deck or goose neck to an eye bolt banded around the mast which I've gone with 7 ft off the deck which clears everything with a slight upward angle. I discovered that the hooks are to long to fit the gutter eyebolts if they are fitted lengthwise, so I'm needing to twist each eyebolt 90 degs to the gutter or opject it might be close to. Having said and done all that, this of course is just my amateurish interpretation and so there are numerous other ways as I've mentioned and most likely some I don't know about yet of rigging the mizen. So much for a short discription but since this isn't described in the kit I wanted to share as much information I could. cheers Dashi

-

Thanks Pat. Looking into this further I think if the driver boom were lost and both a driver boom sail and mizzen course we're carried then swap the driver sail out with the mizzen course, in which case exhibiting either sail configuration with or without the driver boom as described by Steel wouldn't be at odds. So either a copper sheet to stop jaw chafing or iorn band with hook for a driver boom as Steel describes needs to be fitted to the mizen mast and possibly the driver boom stowed or fitted accordingly. Cheers☺

-

(cheers Dave) Another question regarding the driver or spanker boom which is not indicated in the Woolwich yard draught of 1771: (see edit below) http://collections.rmg.co.uk/collections/objects/86385.html However the driver boom washed overboard according to Cook's log entry of 16 Feb 1769 The driver/spanker boom is clearly evident in Samuel Atkins water colour of Endeavour off the coast of New Holland possibly painted in 1794. http://nla.gov.au/nla.obj-135273911/view Edit... Excerpt from D Steel 1794 which defines the proportions of a driver boom agrees with the driver boom depicted in Atkins water colour mentioned above. Also because it is the same length as the main topsail yard and diameter of the fore topsail yard then there might be no need to mention it on the Woolwich draught of 1771? https://archive.hnsa.org/doc/steel/part1.htm#pg40 The AOTS seems to be at odds with the above evidence and indicates a different interpretation on p 113 which shows a separate sail as the driver hung from a small yard at the gaff peak after the mizen stay sail and stretched by short booms lashed to the rail at it's foot which KM interprets as the driver booms. A later entry in the log when masts and a steering boom were lost Cook states they were easily replaced by others (spares). So after reviewing the above evidence, should we assume the driver boom was replaced with a spare (simplest option), or the AOTS interpretation of a driver boom and mizzen course which are at odds with Steel's discription and Atkins painting?

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.