-

Posts

784 -

Joined

-

Last visited

About JerryTodd

- Birthday 09/20/1960

Contact Methods

-

Website URL

http://todd.mainecav.org/model/

-

Skype

geraldatodd

Profile Information

-

Gender

Male

-

Location

Severna Park Maryland USA

-

Interests

Astronomy, sailing, horse riding, motor cycle riding, wood working, living history and reenacting, wargaming, ship modeling, history, maps, reading, ice cream, animals in general but cats especially, a lady named Daphne

Recent Profile Visitors

-

egkb reacted to a post in a topic:

First Class Sloop of War Constellation by Jerry Todd - 1:36 scale - Radio

egkb reacted to a post in a topic:

First Class Sloop of War Constellation by Jerry Todd - 1:36 scale - Radio

-

JerryTodd reacted to a post in a topic:

La Créole 1827 by archjofo - Scale 1/48 - French corvette

JerryTodd reacted to a post in a topic:

La Créole 1827 by archjofo - Scale 1/48 - French corvette

-

mtaylor reacted to a post in a topic:

USS CONSTELLATION by Tschiller - Artesania Latina - Scale 1:85 - Kit Bashed back to 1797

mtaylor reacted to a post in a topic:

USS CONSTELLATION by Tschiller - Artesania Latina - Scale 1:85 - Kit Bashed back to 1797

-

JerryTodd reacted to a post in a topic:

USS CONSTELLATION by Tschiller - Artesania Latina - Scale 1:85 - Kit Bashed back to 1797

JerryTodd reacted to a post in a topic:

USS CONSTELLATION by Tschiller - Artesania Latina - Scale 1:85 - Kit Bashed back to 1797

-

mtaylor reacted to a post in a topic:

First Class Sloop of War Constellation by Jerry Todd - 1:36 scale - Radio

mtaylor reacted to a post in a topic:

First Class Sloop of War Constellation by Jerry Todd - 1:36 scale - Radio

-

Scottish Guy reacted to a post in a topic:

USS CONSTELLATION by Tschiller - Artesania Latina - Scale 1:85 - Kit Bashed back to 1797

Scottish Guy reacted to a post in a topic:

USS CONSTELLATION by Tschiller - Artesania Latina - Scale 1:85 - Kit Bashed back to 1797

-

JerryTodd reacted to a post in a topic:

USS CONSTELLATION by Tschiller - Artesania Latina - Scale 1:85 - Kit Bashed back to 1797

JerryTodd reacted to a post in a topic:

USS CONSTELLATION by Tschiller - Artesania Latina - Scale 1:85 - Kit Bashed back to 1797

-

JerryTodd reacted to a post in a topic:

USS CONSTELLATION by Tschiller - Artesania Latina - Scale 1:85 - Kit Bashed back to 1797

JerryTodd reacted to a post in a topic:

USS CONSTELLATION by Tschiller - Artesania Latina - Scale 1:85 - Kit Bashed back to 1797

-

JerryTodd reacted to a post in a topic:

USS CONSTELLATION by Tschiller - Artesania Latina - Scale 1:85 - Kit Bashed back to 1797

JerryTodd reacted to a post in a topic:

USS CONSTELLATION by Tschiller - Artesania Latina - Scale 1:85 - Kit Bashed back to 1797

-

JerryTodd reacted to a post in a topic:

USS CONSTELLATION by Tschiller - Artesania Latina - Scale 1:85 - Kit Bashed back to 1797

JerryTodd reacted to a post in a topic:

USS CONSTELLATION by Tschiller - Artesania Latina - Scale 1:85 - Kit Bashed back to 1797

-

JerryTodd reacted to a post in a topic:

USS CONSTELLATION by Tschiller - Artesania Latina - Scale 1:85 - Kit Bashed back to 1797

JerryTodd reacted to a post in a topic:

USS CONSTELLATION by Tschiller - Artesania Latina - Scale 1:85 - Kit Bashed back to 1797

-

JerryTodd reacted to a post in a topic:

USS CONSTELLATION by Tschiller - Artesania Latina - Scale 1:85 - Kit Bashed back to 1797

JerryTodd reacted to a post in a topic:

USS CONSTELLATION by Tschiller - Artesania Latina - Scale 1:85 - Kit Bashed back to 1797

-

JerryTodd reacted to a post in a topic:

USS CONSTELLATION by Tschiller - Artesania Latina - Scale 1:85 - Kit Bashed back to 1797

JerryTodd reacted to a post in a topic:

USS CONSTELLATION by Tschiller - Artesania Latina - Scale 1:85 - Kit Bashed back to 1797

-

JerryTodd reacted to a post in a topic:

USS CONSTELLATION by Tschiller - Artesania Latina - Scale 1:85 - Kit Bashed back to 1797

JerryTodd reacted to a post in a topic:

USS CONSTELLATION by Tschiller - Artesania Latina - Scale 1:85 - Kit Bashed back to 1797

-

mtaylor reacted to a post in a topic:

3D Naval Guns 1850s ~ 1870s

mtaylor reacted to a post in a topic:

3D Naval Guns 1850s ~ 1870s

-

3DShipWright reacted to a post in a topic:

3D Naval Guns 1850s ~ 1870s

3DShipWright reacted to a post in a topic:

3D Naval Guns 1850s ~ 1870s

-

GrandpaPhil reacted to a post in a topic:

First Class Sloop of War Constellation by Jerry Todd - 1:36 scale - Radio

GrandpaPhil reacted to a post in a topic:

First Class Sloop of War Constellation by Jerry Todd - 1:36 scale - Radio

-

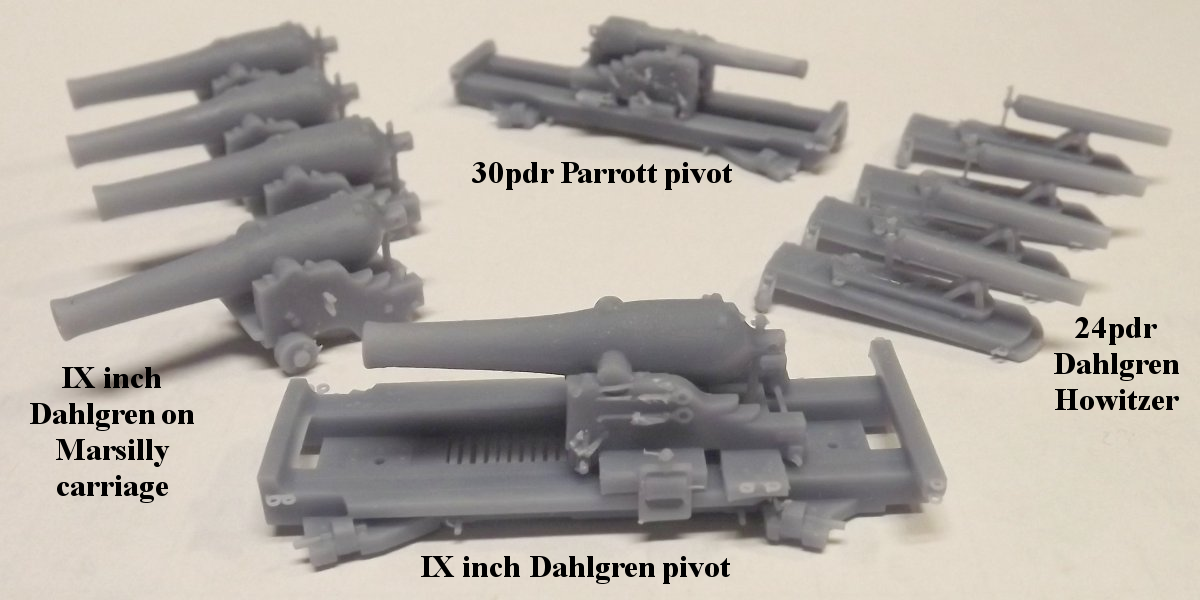

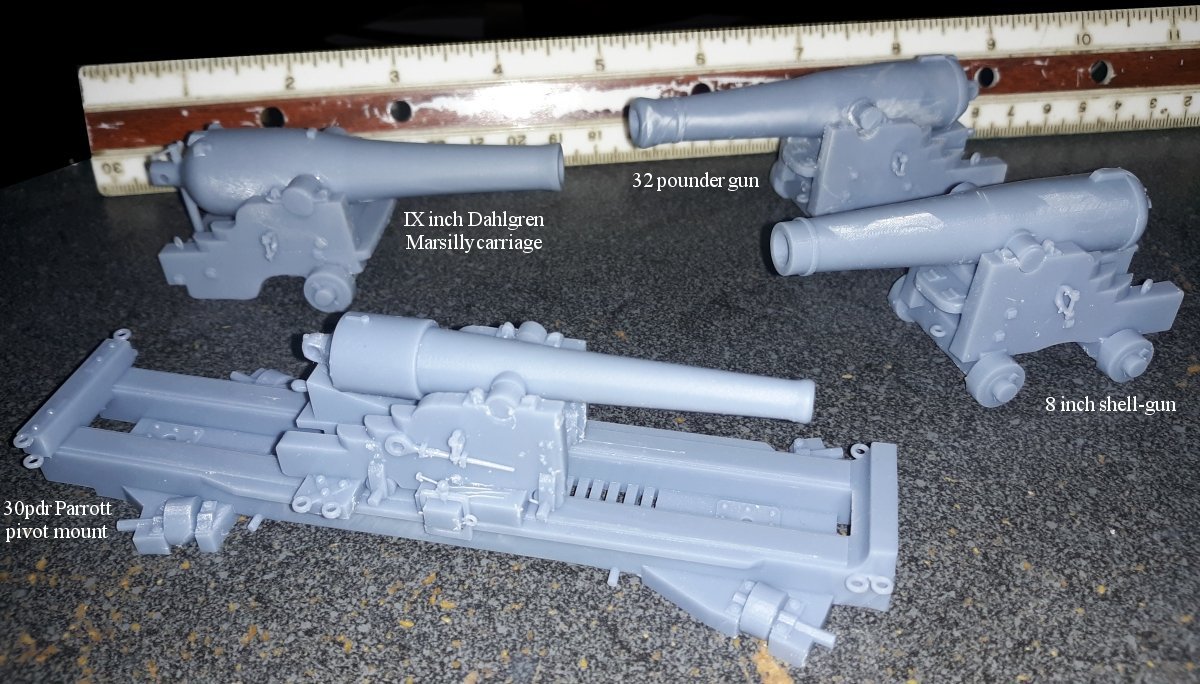

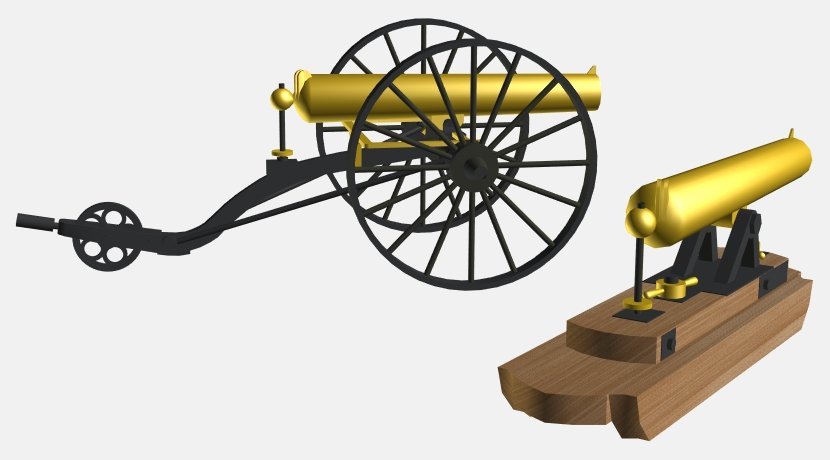

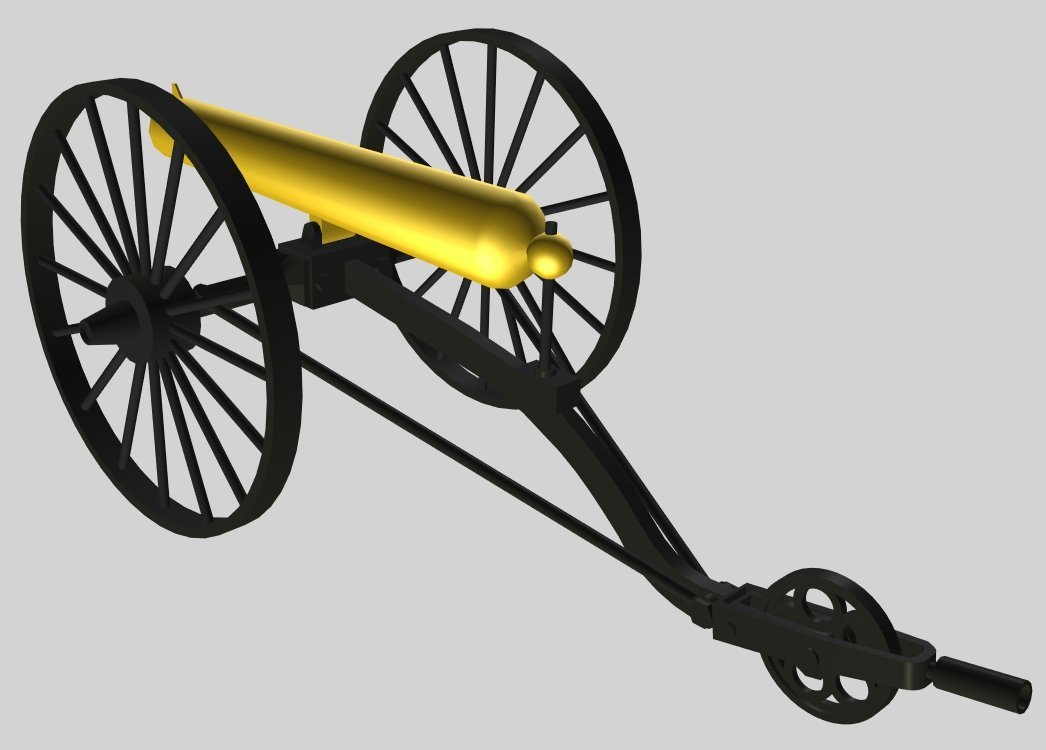

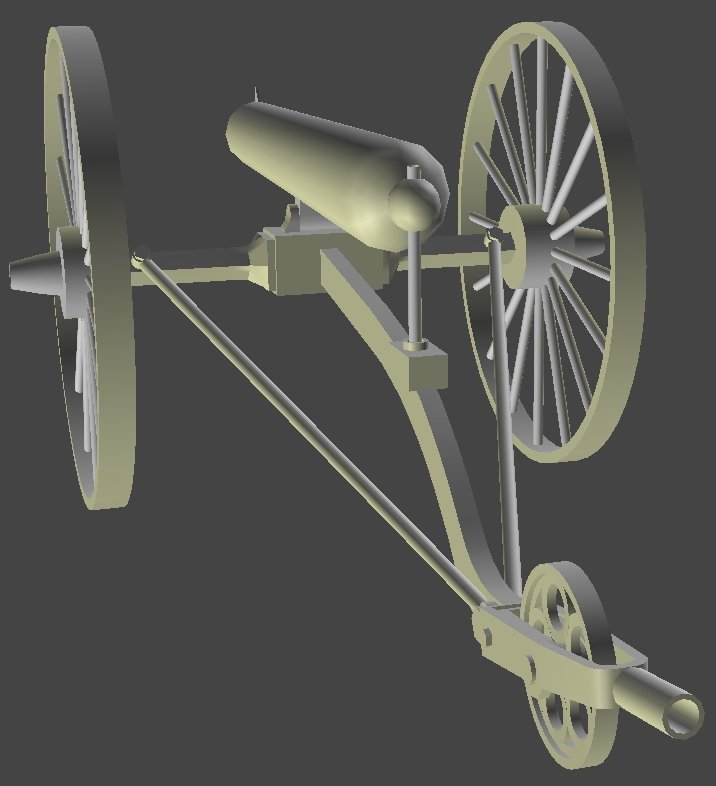

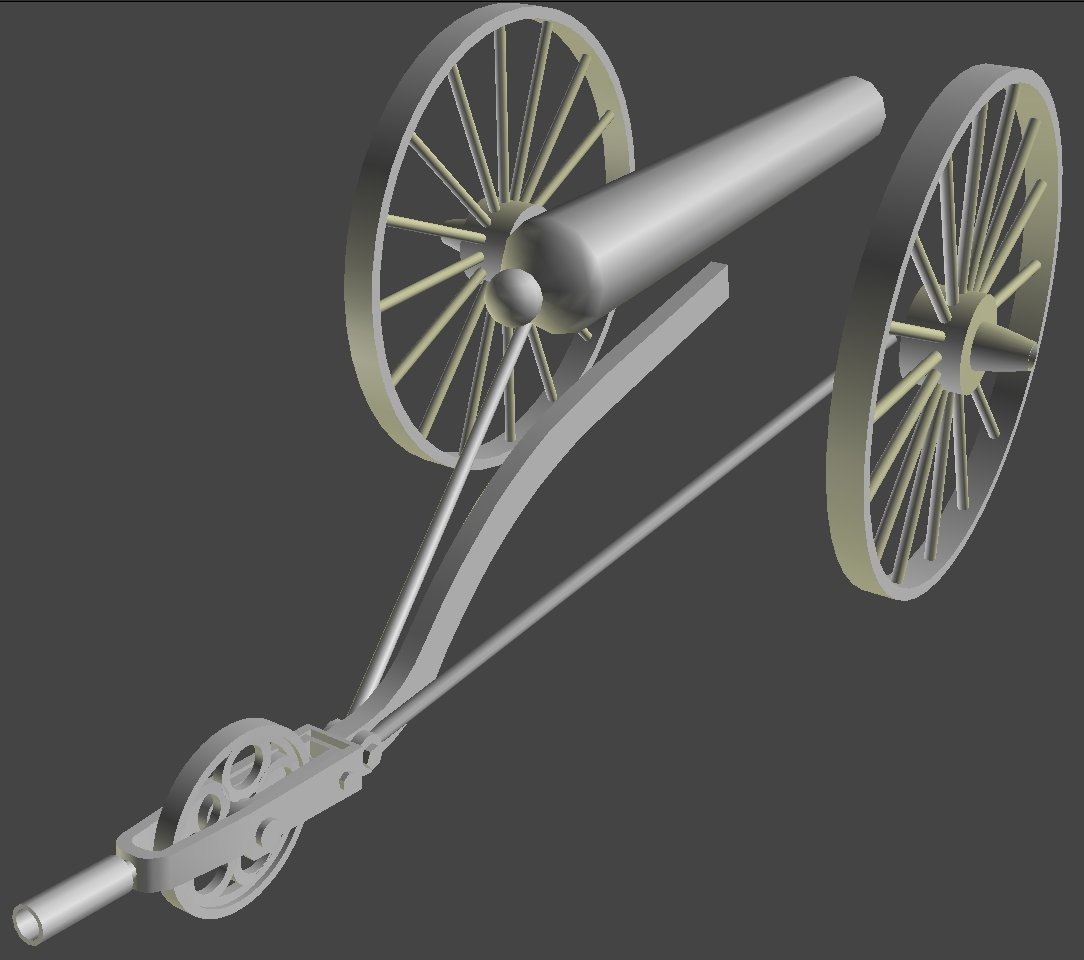

3D Naval Guns 1850s ~ 1870s

JerryTodd replied to JerryTodd's topic in CAD and 3D Modelling/Drafting Plans with Software

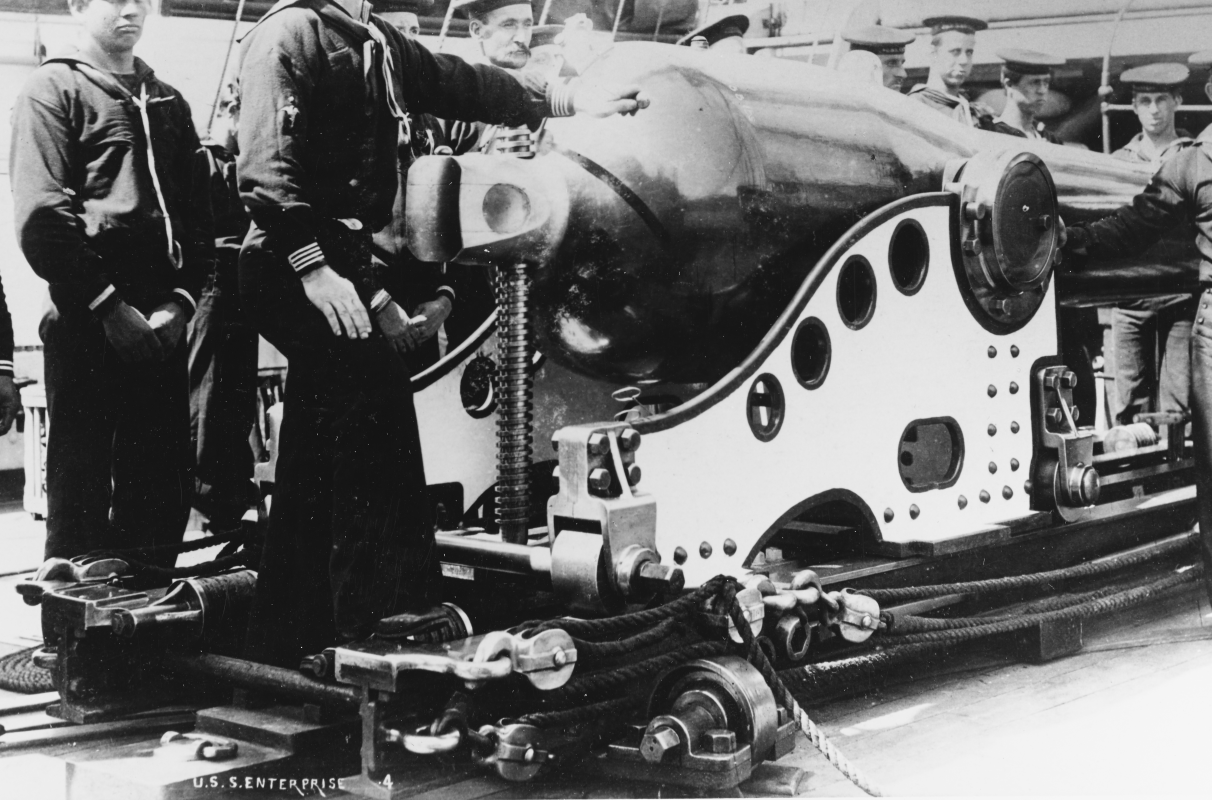

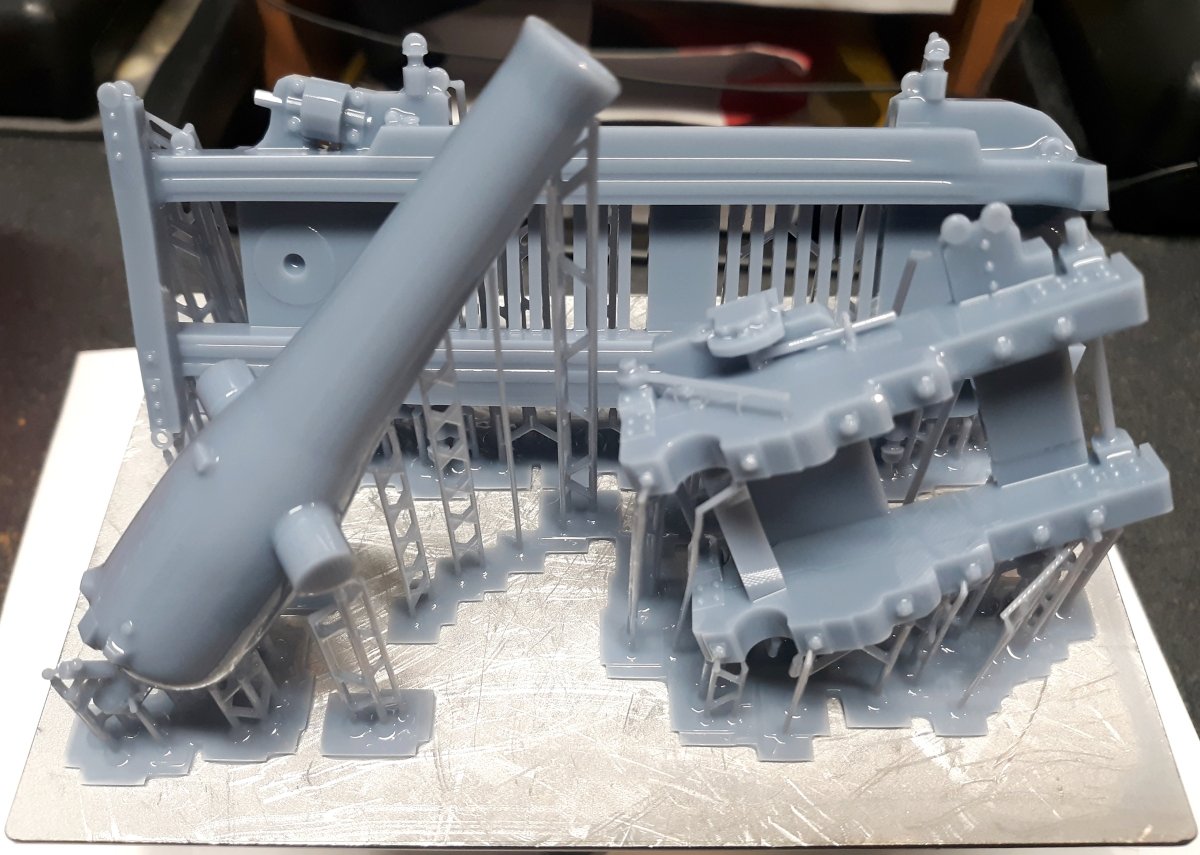

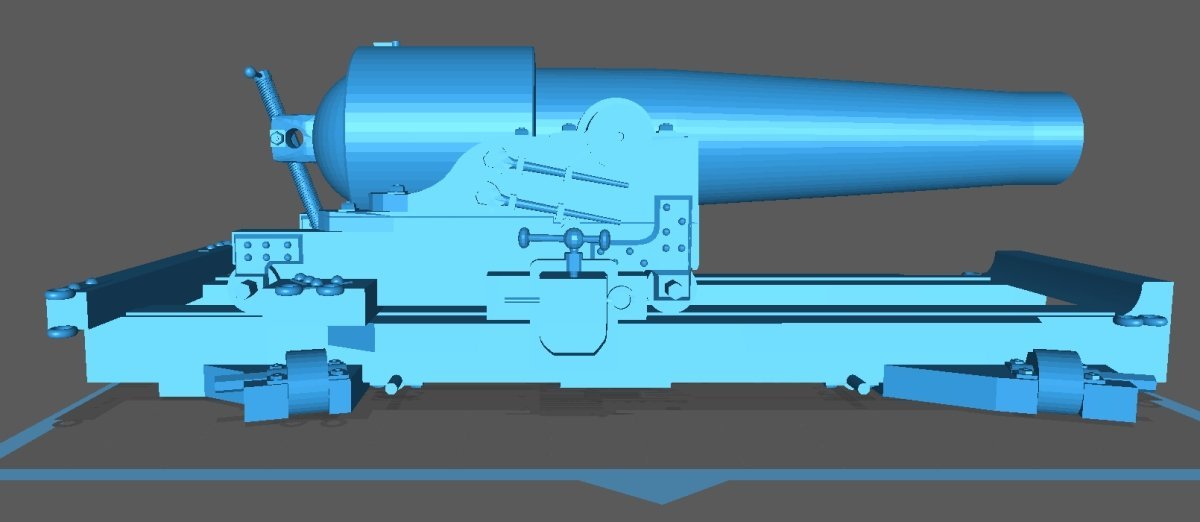

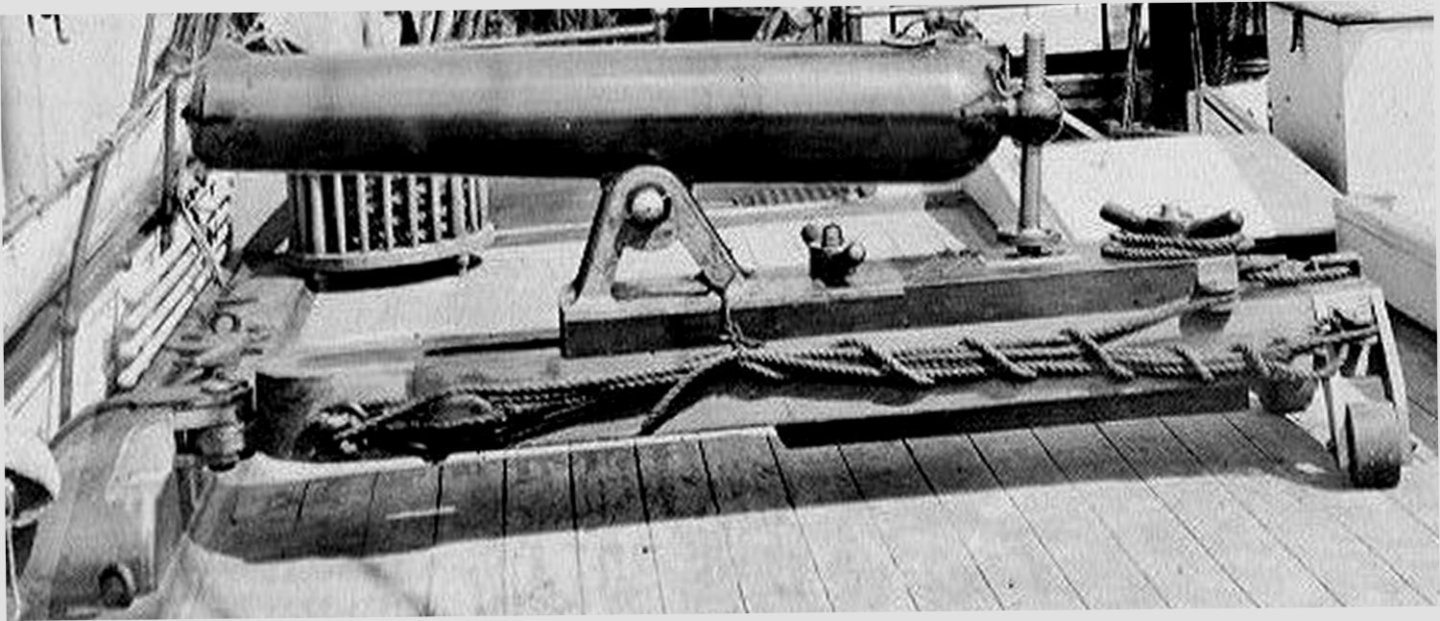

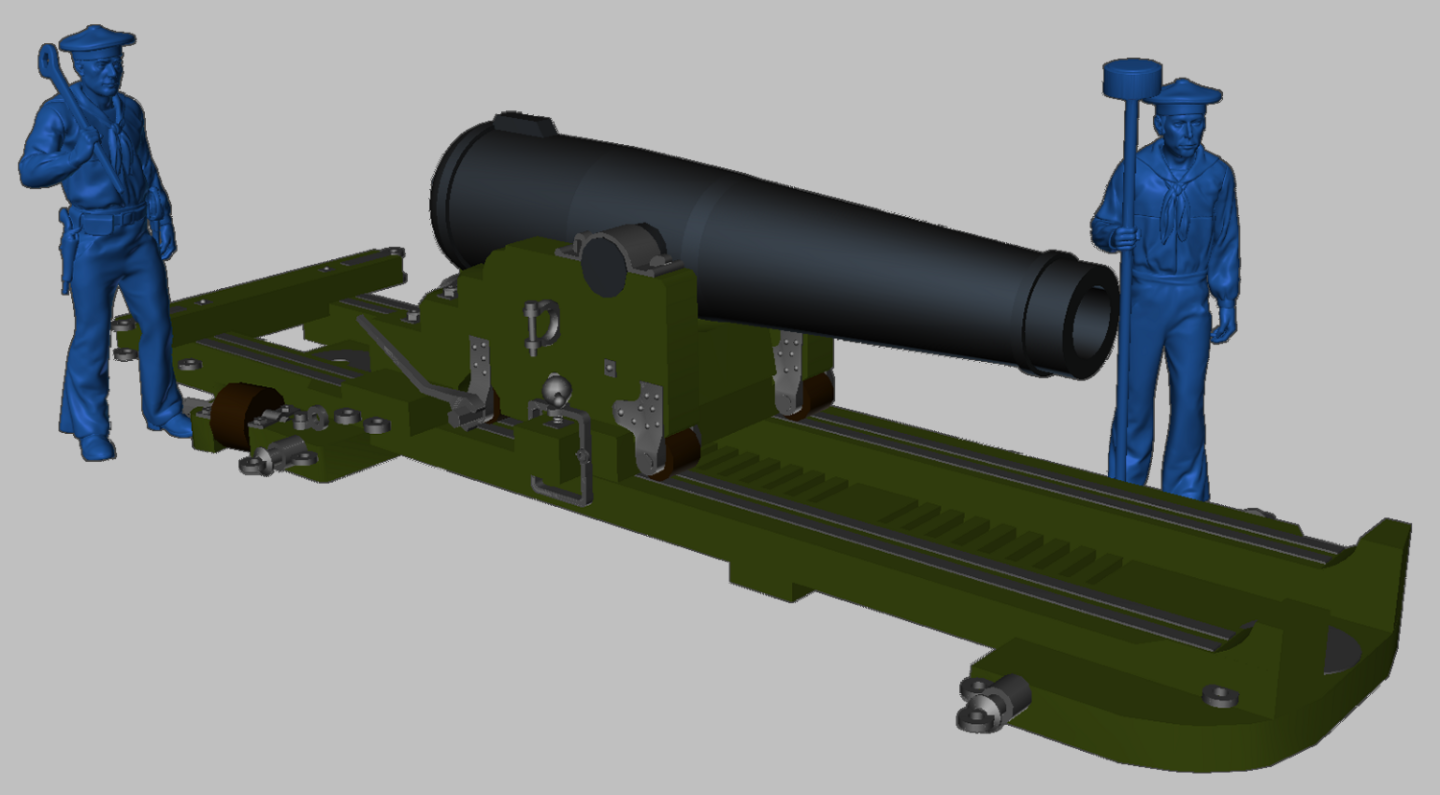

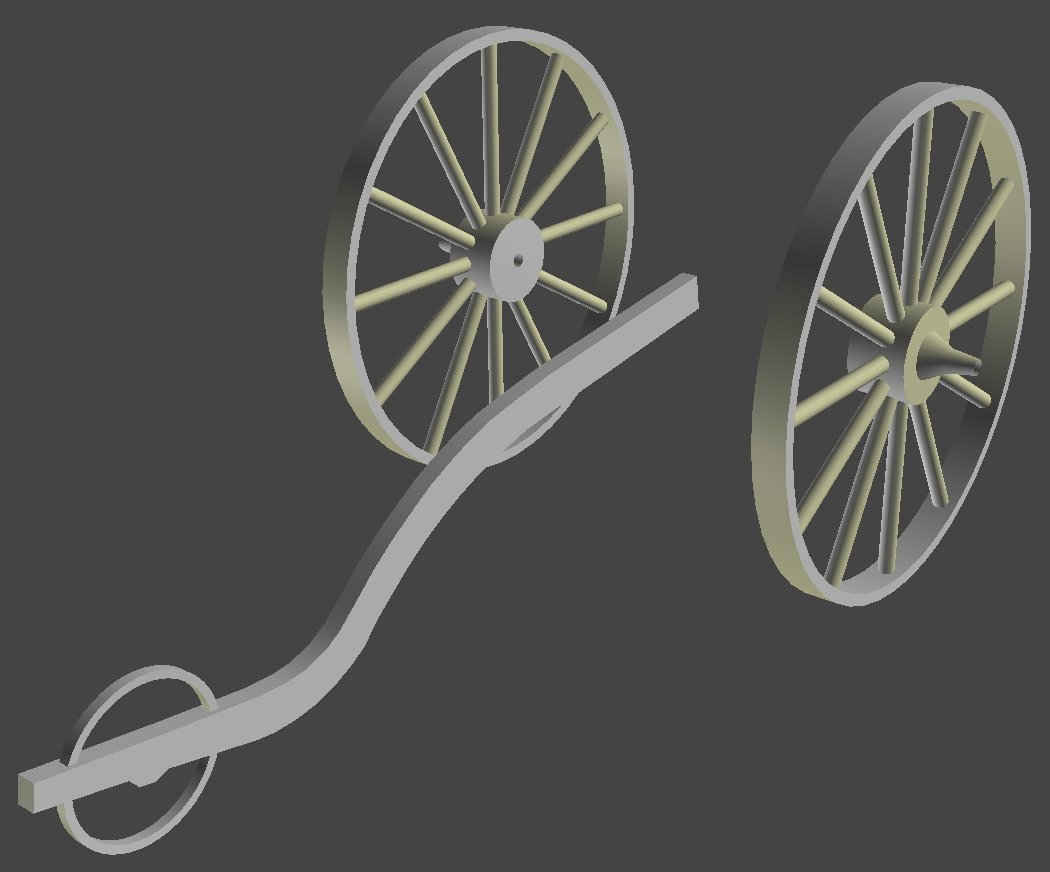

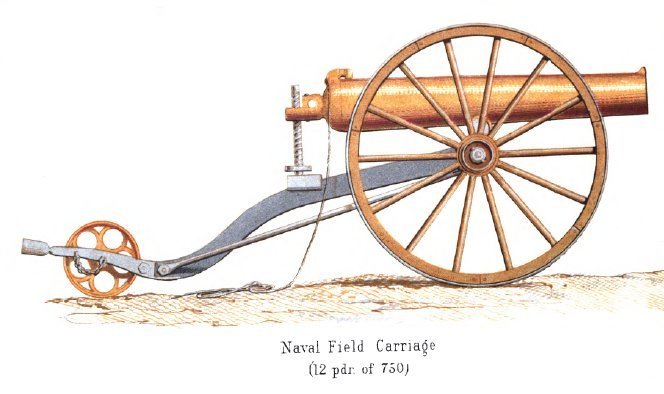

The X inch Dahlgren's and the deck tracks for them are practically done, but that's in my Constellation log. The next WIP is the XI inch on an iron pivot. I've found many images of iron carriages, but all of them are from the 1880's and 1890's when some new technology had been applied, and I'm doing an 1870's version that's basically a war-time wood carriage done in iron. The drawing posted earlier is what I'm working from, but the person that drew it did it as an illustration for a sci-fi story, so I can't be sure of it's authenticity. At any rate, I'm picking a way at it.... Next up I think I'll do Dalhgren's rifle from this image -

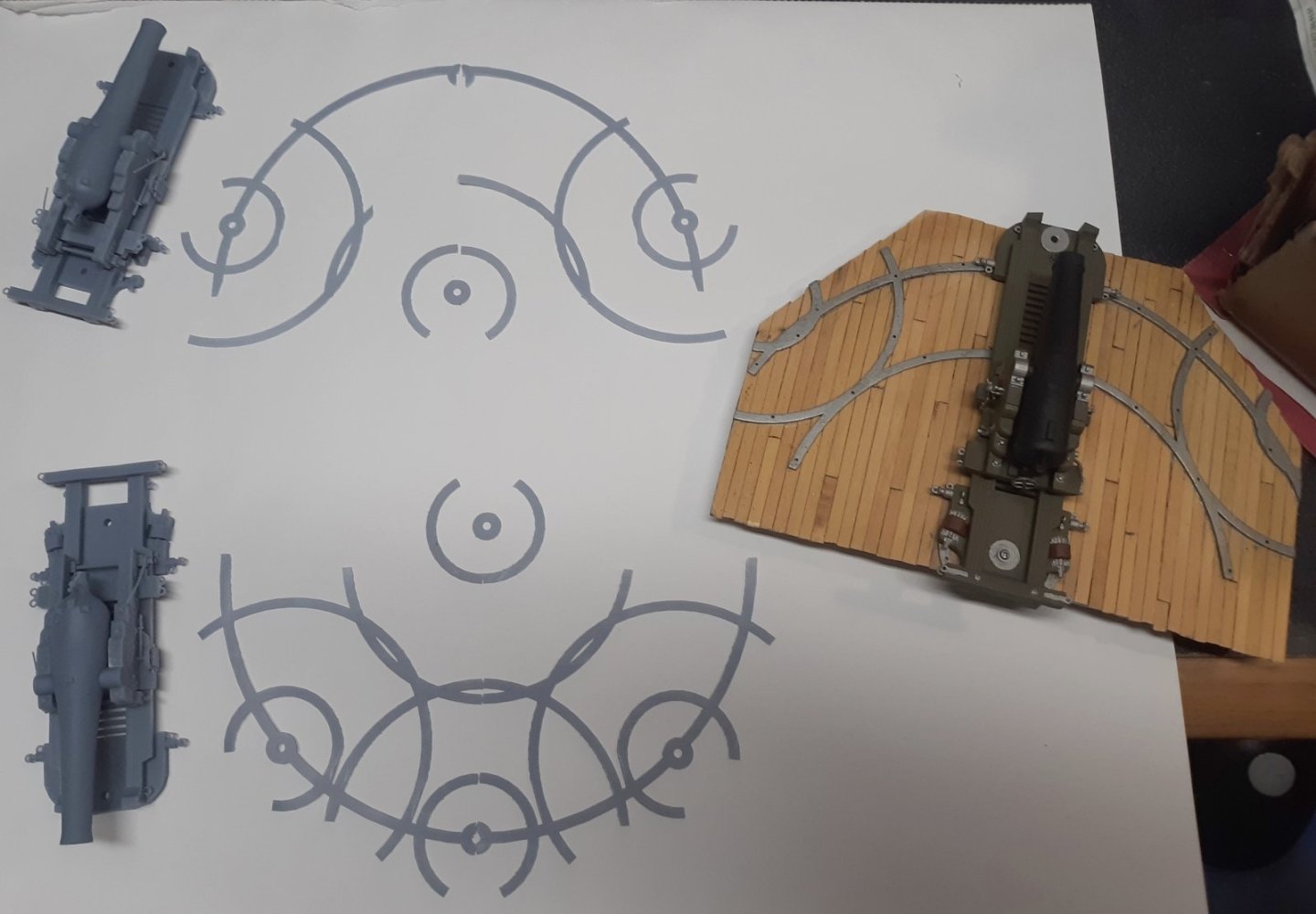

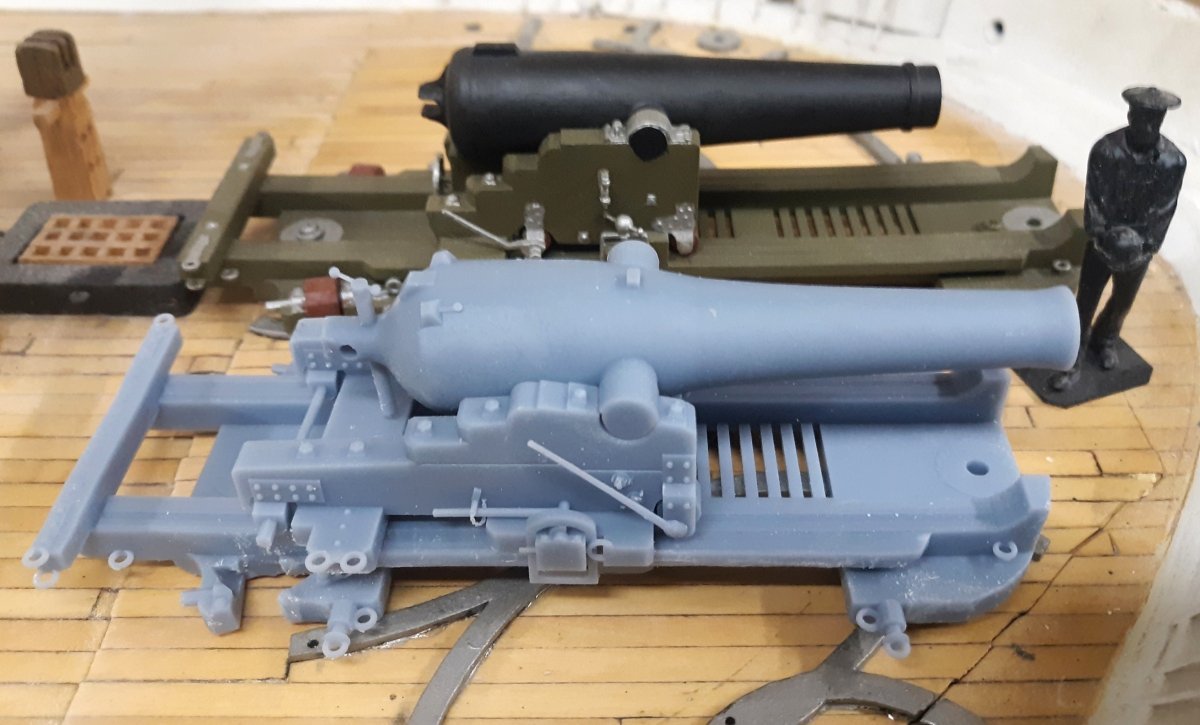

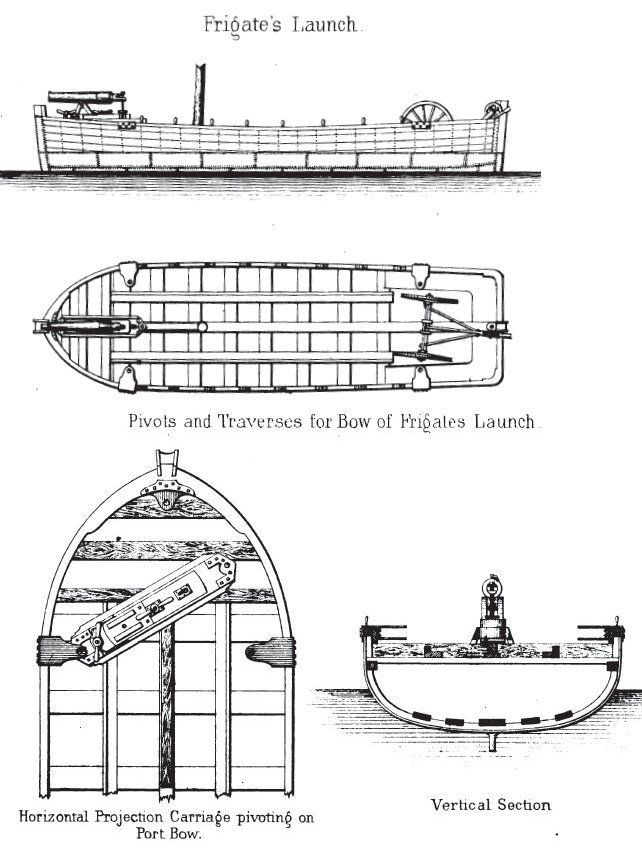

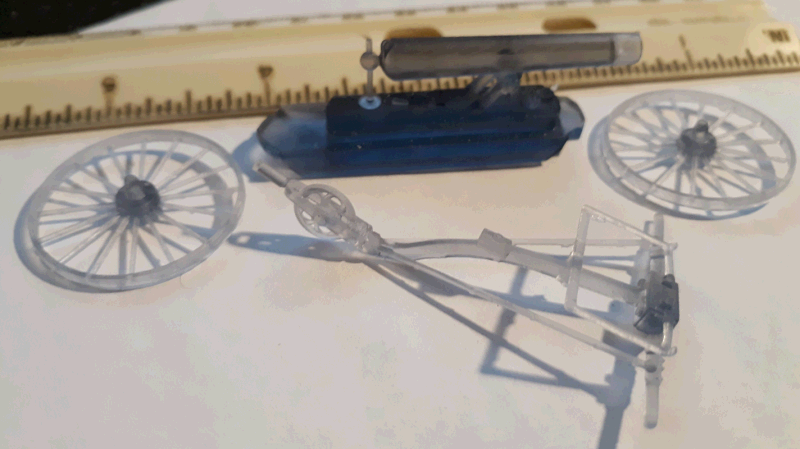

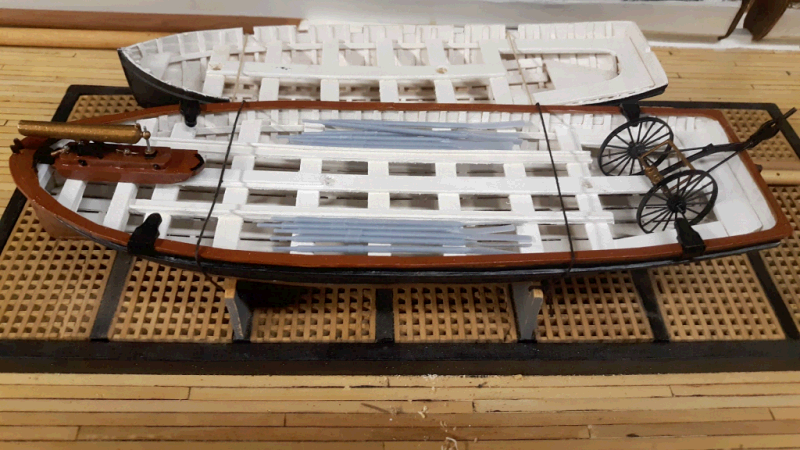

April 8th: The new pivot gun tracks were primed, painted, glued down (had to order a bottle of CA), painted some more. The guns barrels are painted, detailed, and clear-coated (no pic of that yet). The carriages are primed, but not painted yet. They'll be painted olive like the previous set of gun carriages. The new field carriage for the boat-howitzer also got painted, and after some clear-coat, will go to it's home in the stern-sheets of the launch. (sorry for the poor images)

- 524 replies

-

- sloop of war

- constellation

- (and 9 more)

-

egkb reacted to a post in a topic:

First Class Sloop of War Constellation by Jerry Todd - 1:36 scale - Radio

egkb reacted to a post in a topic:

First Class Sloop of War Constellation by Jerry Todd - 1:36 scale - Radio

-

mtaylor reacted to a post in a topic:

First Class Sloop of War Constellation by Jerry Todd - 1:36 scale - Radio

mtaylor reacted to a post in a topic:

First Class Sloop of War Constellation by Jerry Todd - 1:36 scale - Radio

-

3D Naval Guns 1850s ~ 1870s

JerryTodd replied to JerryTodd's topic in CAD and 3D Modelling/Drafting Plans with Software

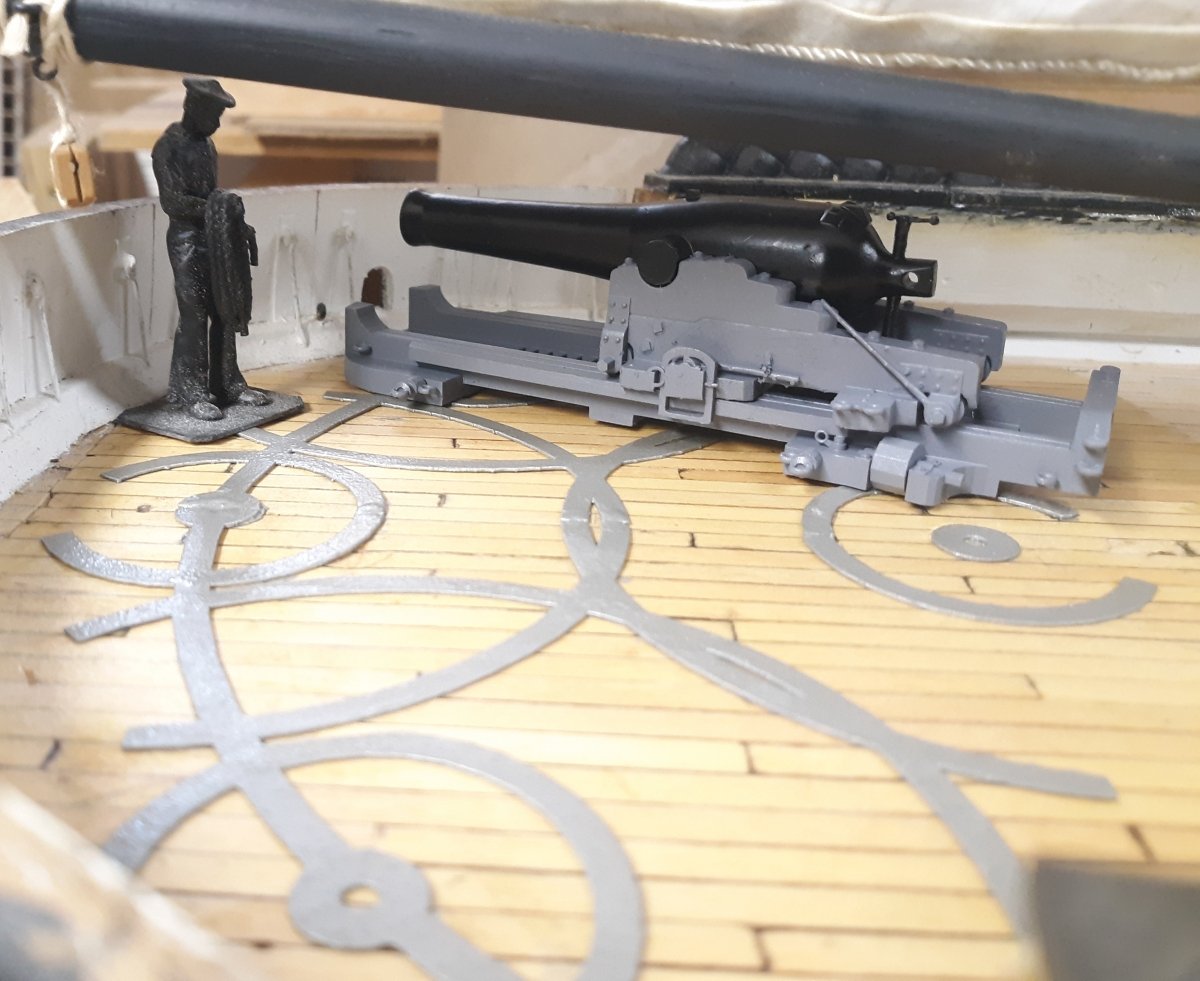

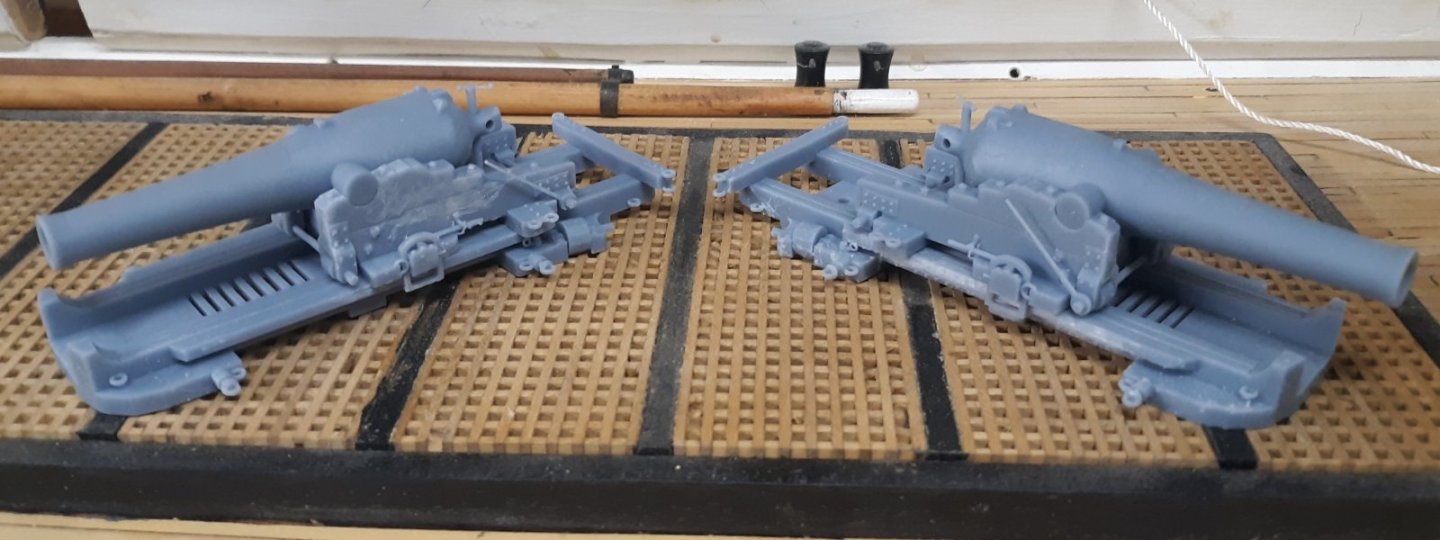

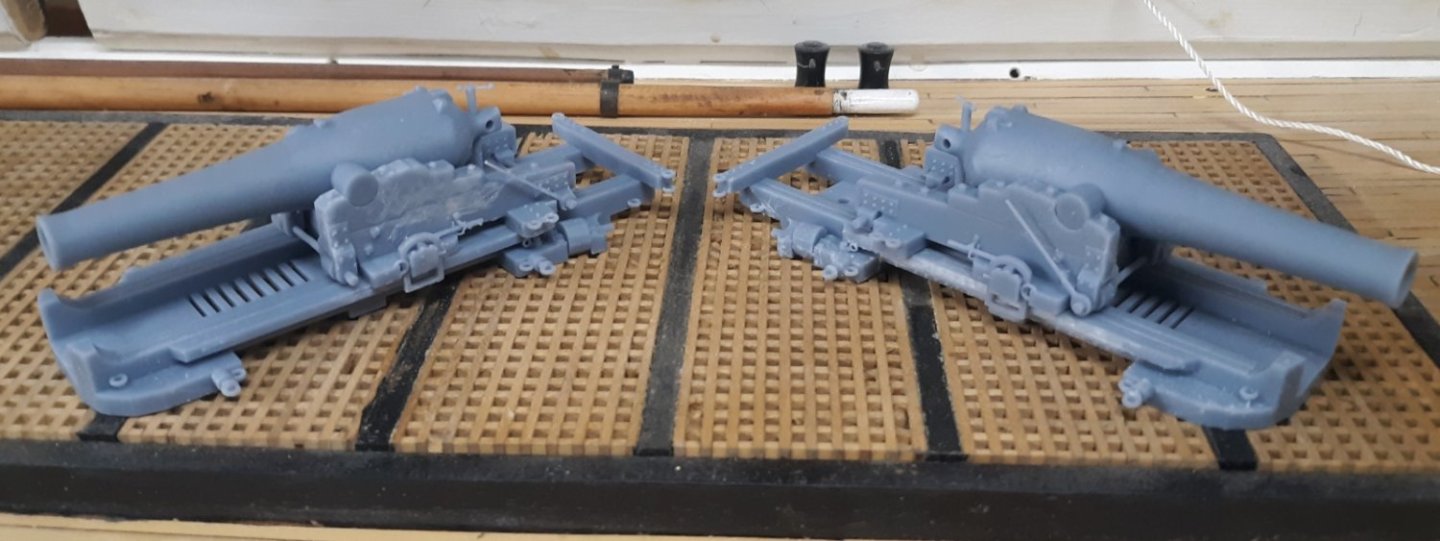

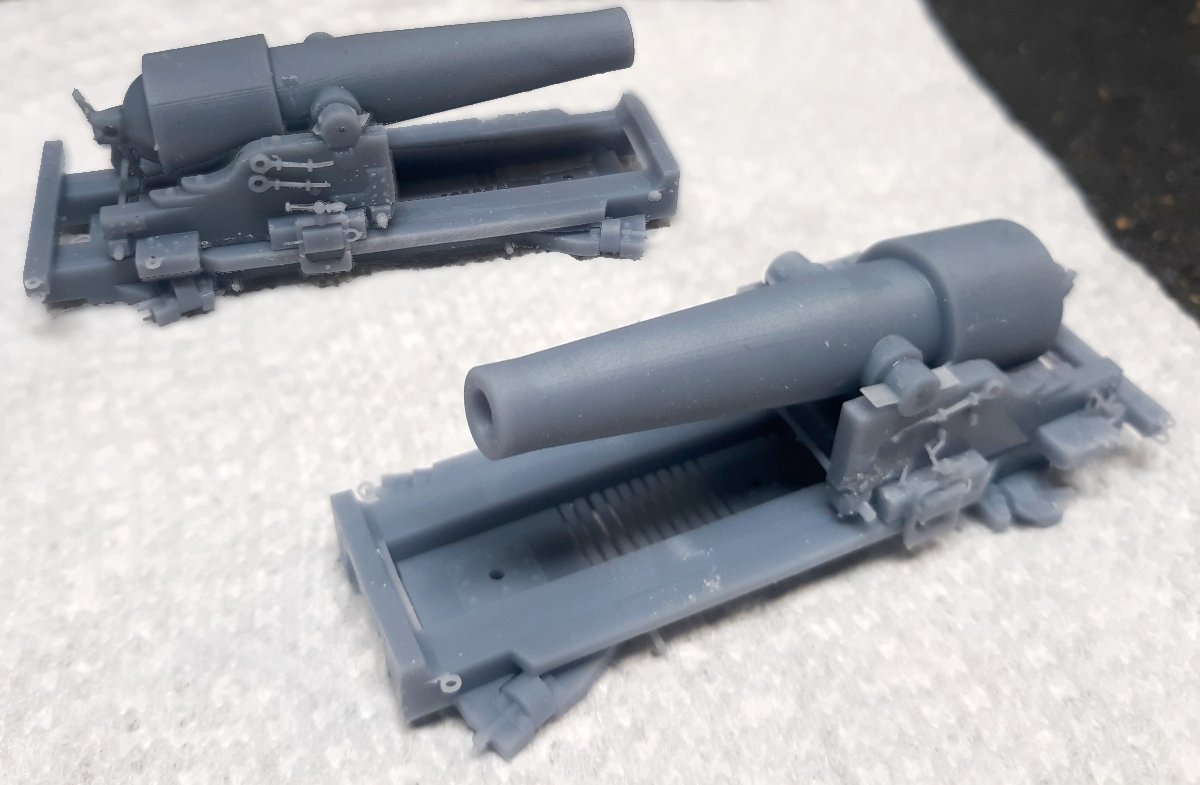

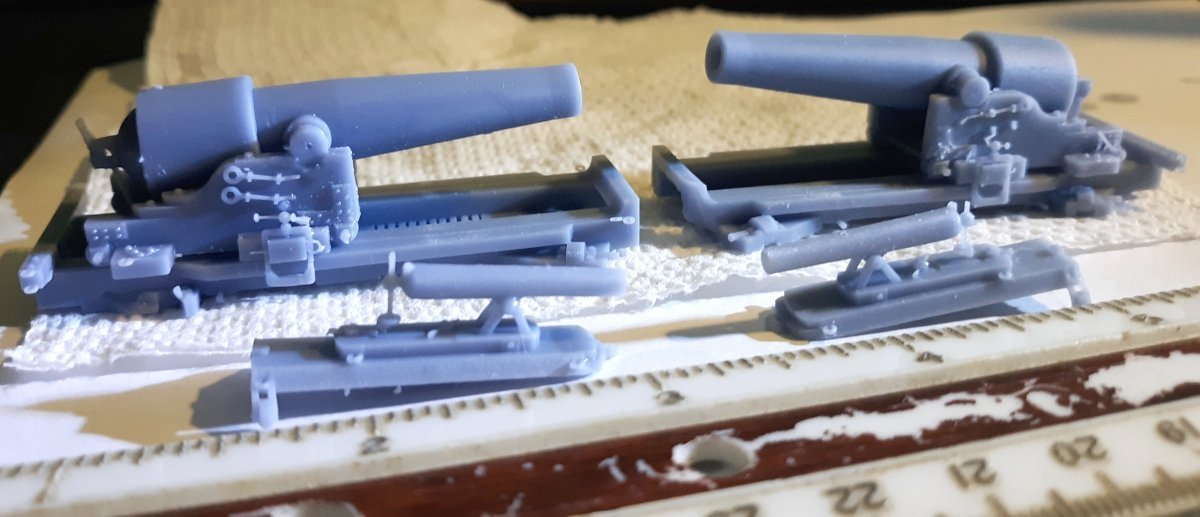

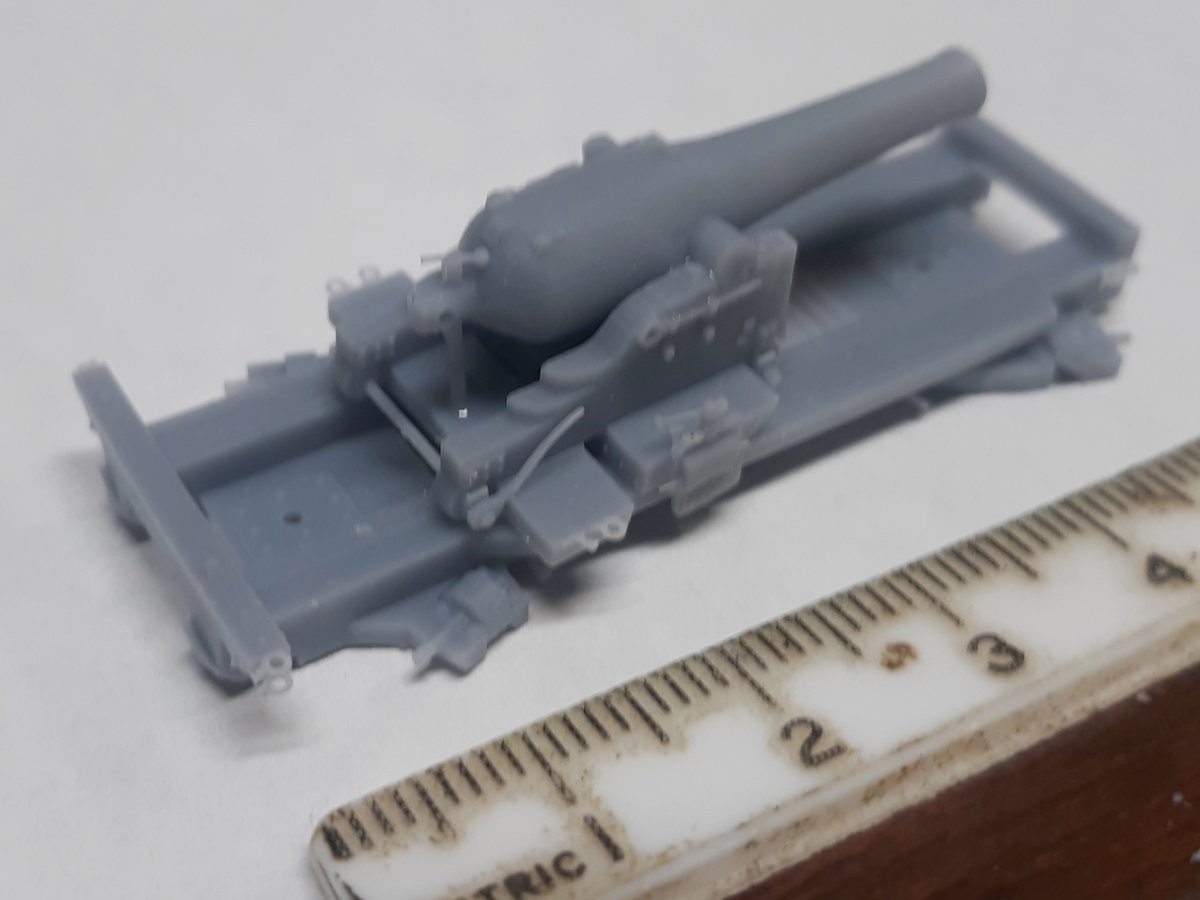

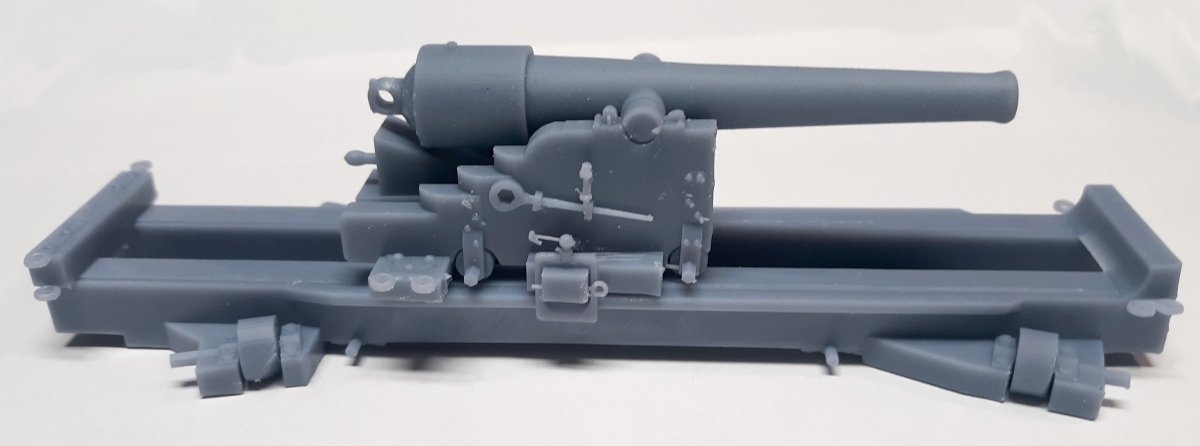

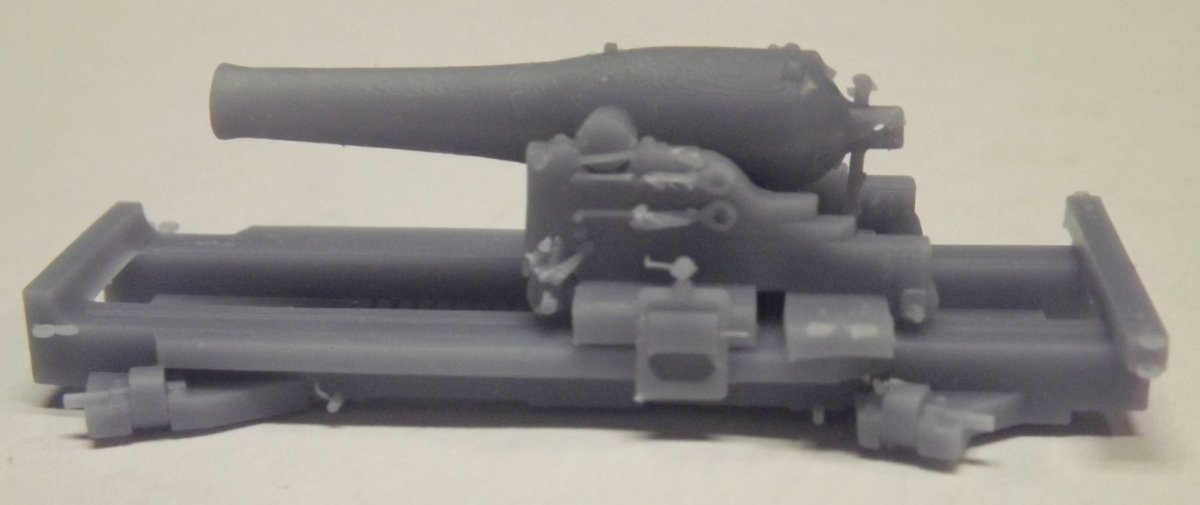

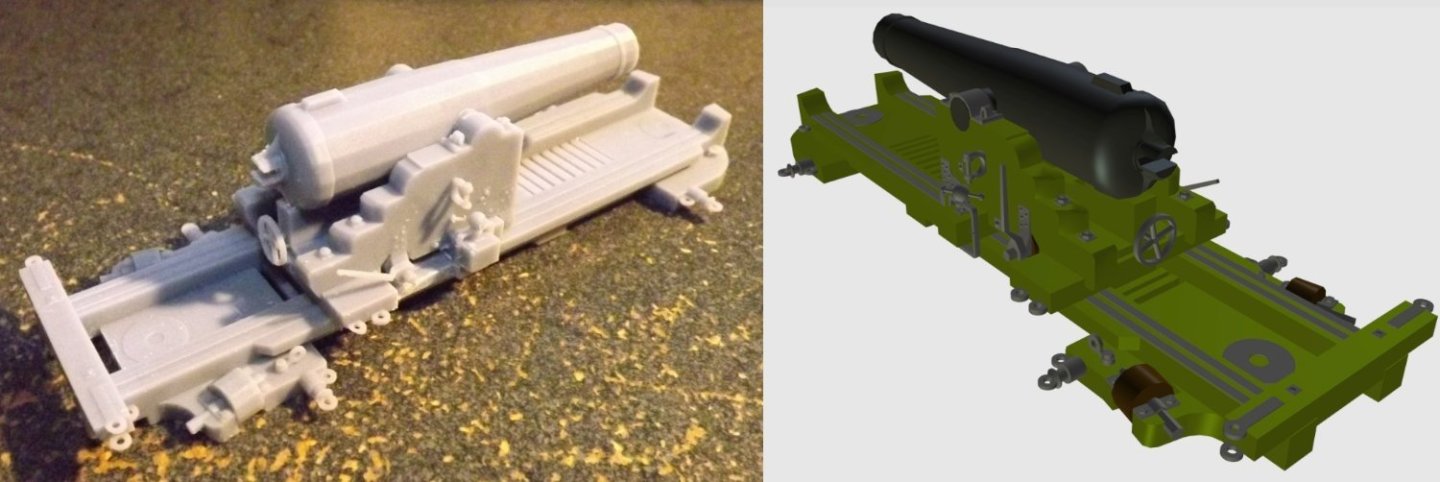

Since I'm replacing the Constellation's pivot guns with this X inch Dahlgren, need to print three of them; 2 for the model, and one for the sampler of Constellation's guns. Here's the second gun fresh off the printer. The first one lost a roller, but that can be fixed. The slide on these gun are shorter than the previous gun's slides, so new deck tracks had to be made to fit. The third gun hasn't been printed yet. The pair sitting on the model's main hatch. The old tracks removed, the access hatches sanded, and refinished with the primed guns and tracks sitting in place. -

Why do the lower dead-eye strops and chains look like rope or cable? They should be iron

- 105 replies

-

- Frigate

- Confederacy

-

(and 1 more)

Tagged with:

-

It's all just sitting there, nothing's glued down yet, until it's actually painted. A pic with, and without flash. I need to watch those white-balance videos someone posted here at MSW.

- 524 replies

-

- sloop of war

- constellation

- (and 9 more)

-

The slides for the new guns are shorter than what was on the model, so new tracks had to be modeled, printed, and reprinted a little. The old tracks had to be removed and the scars sanded off the deck. Then the finish reapplied. Meantime the guns and tracks were primed.

- 524 replies

-

- sloop of war

- constellation

- (and 9 more)

-

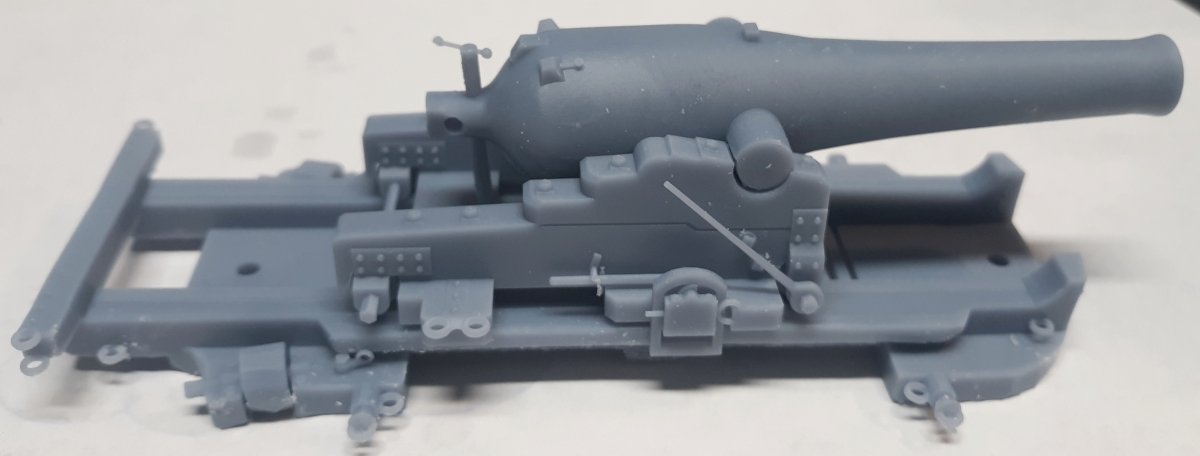

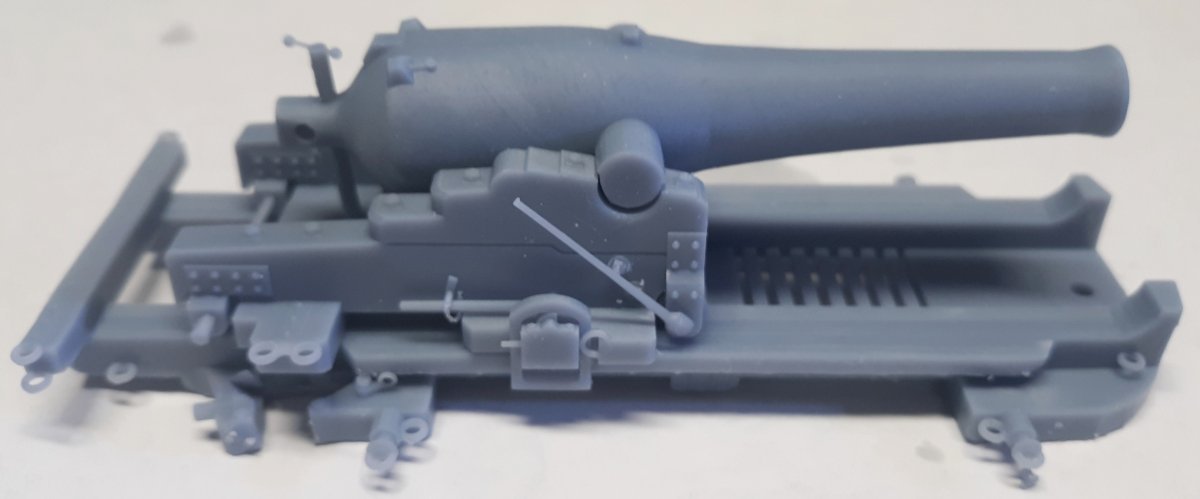

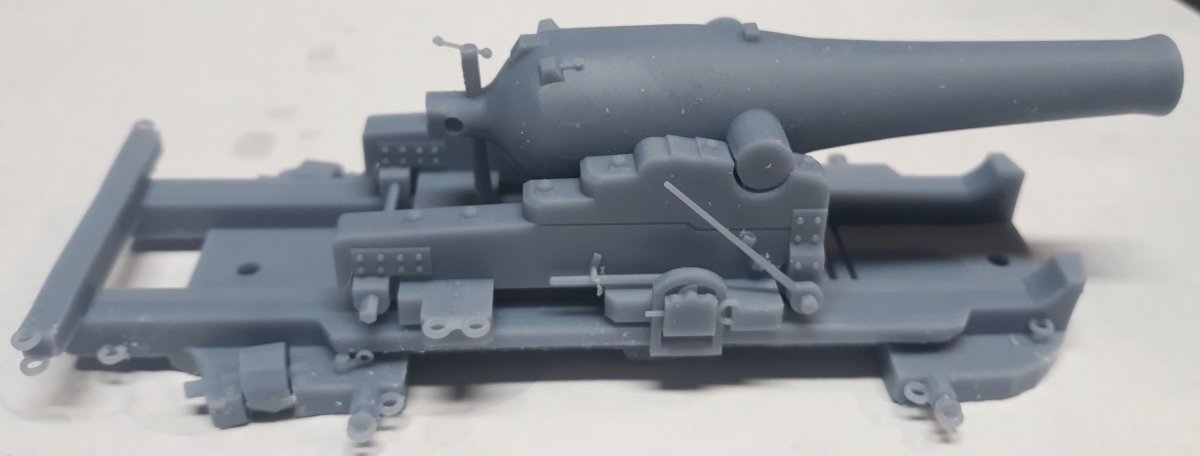

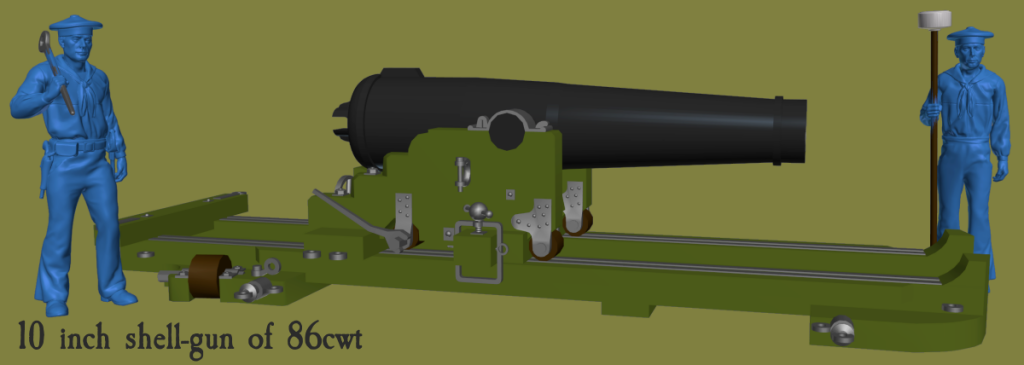

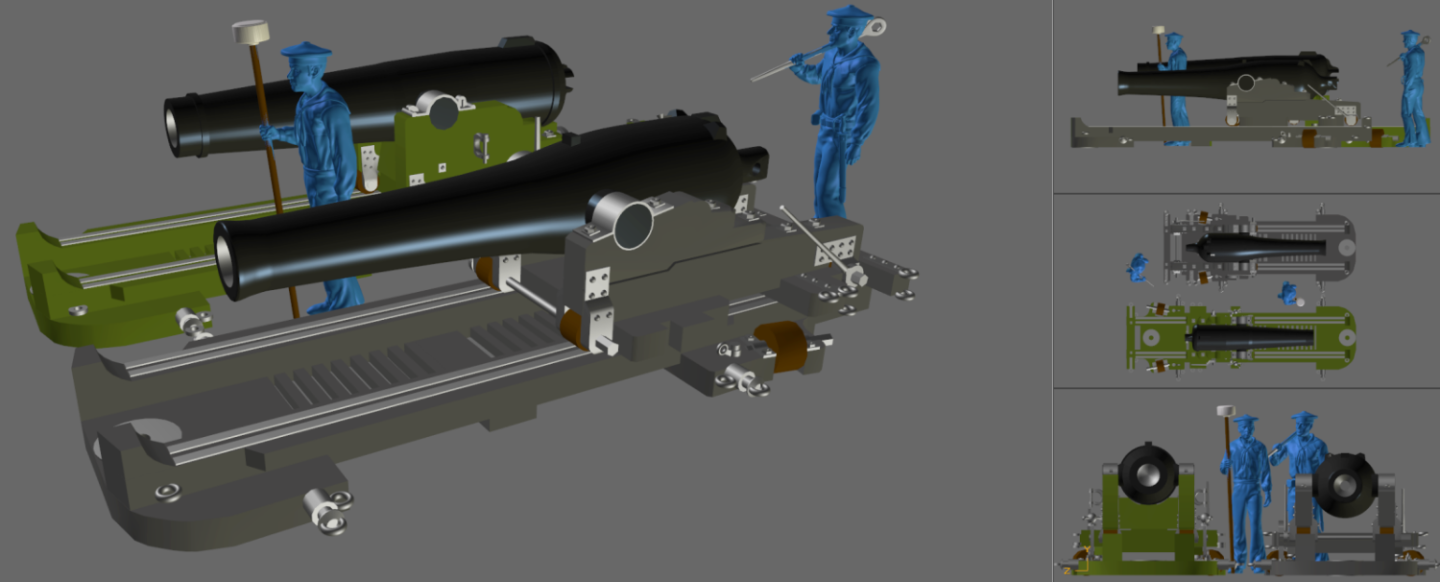

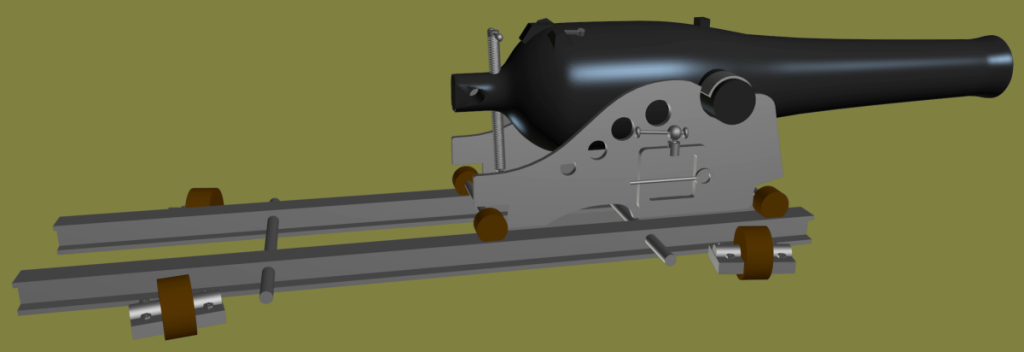

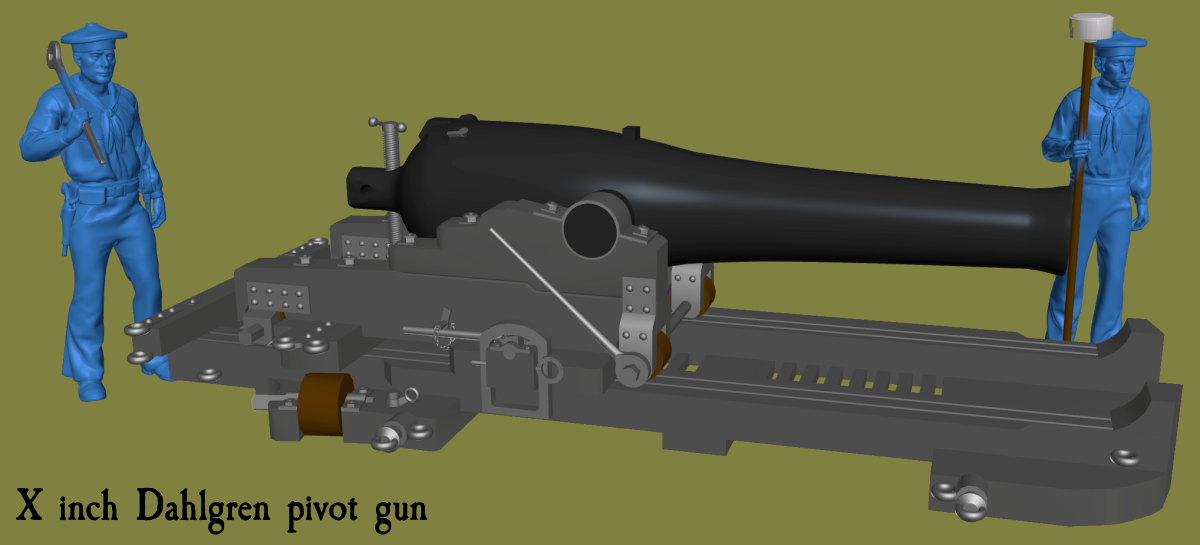

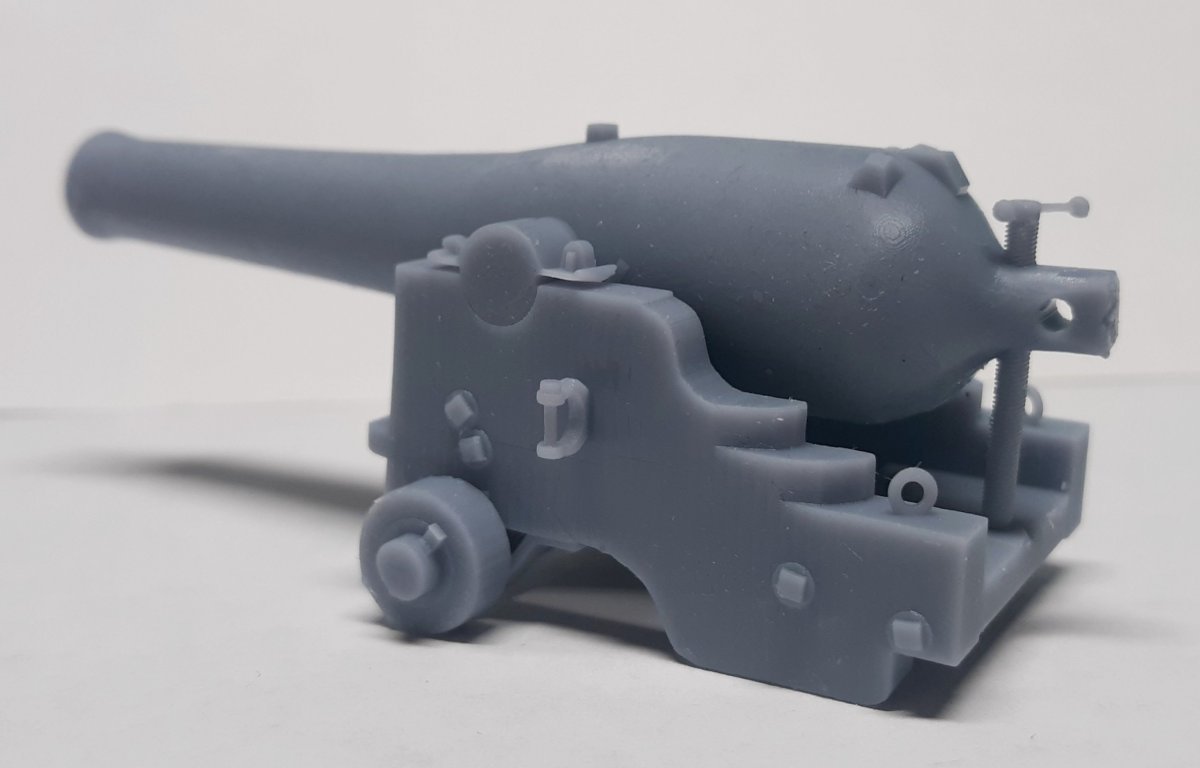

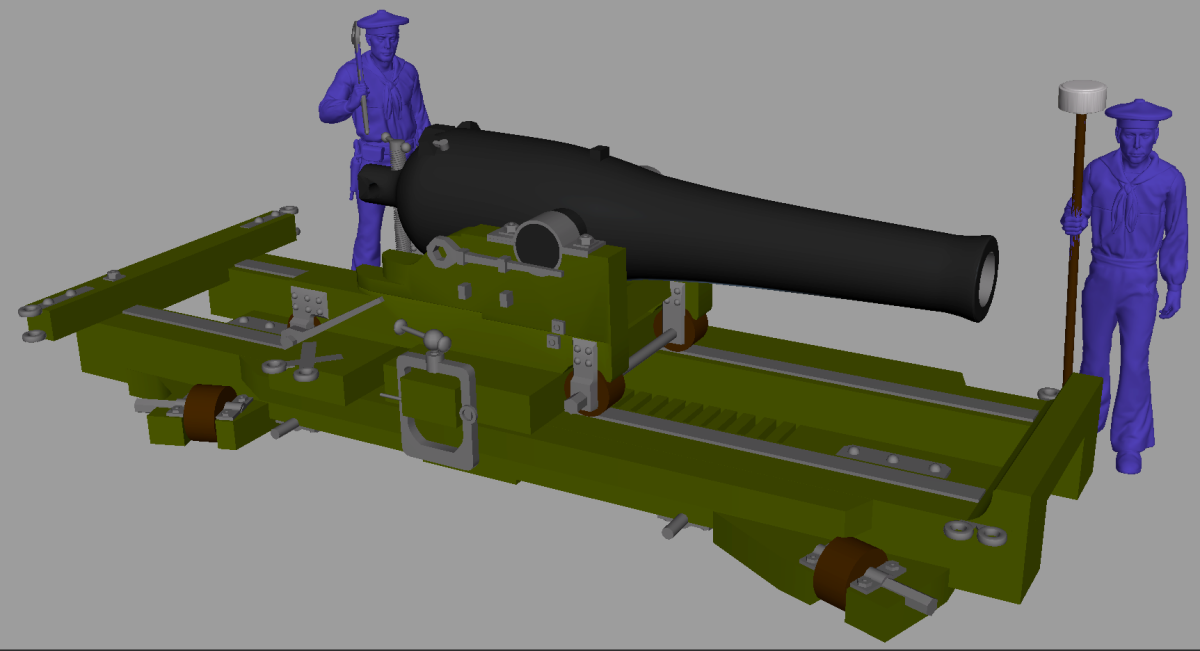

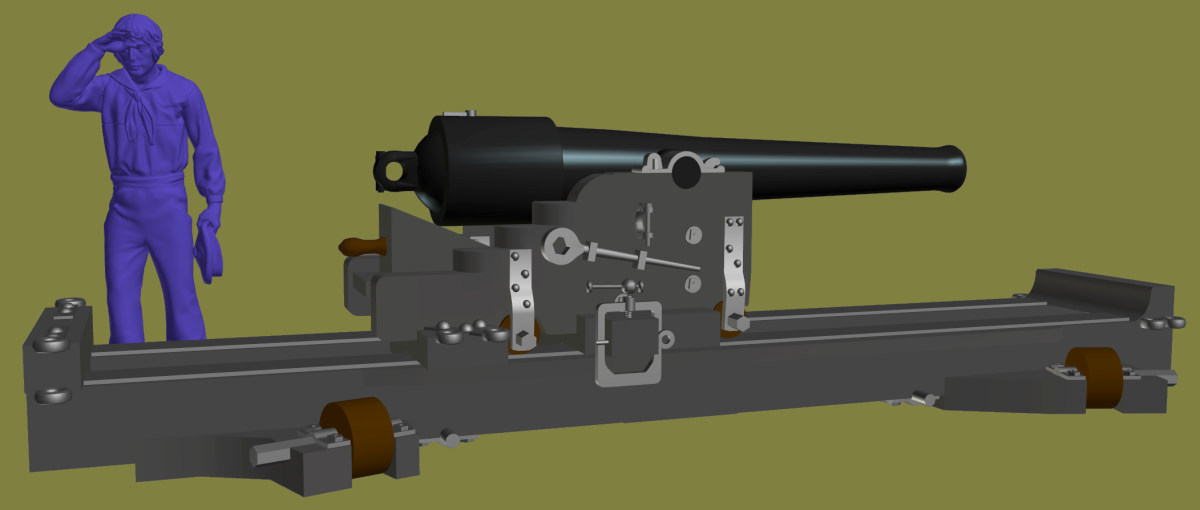

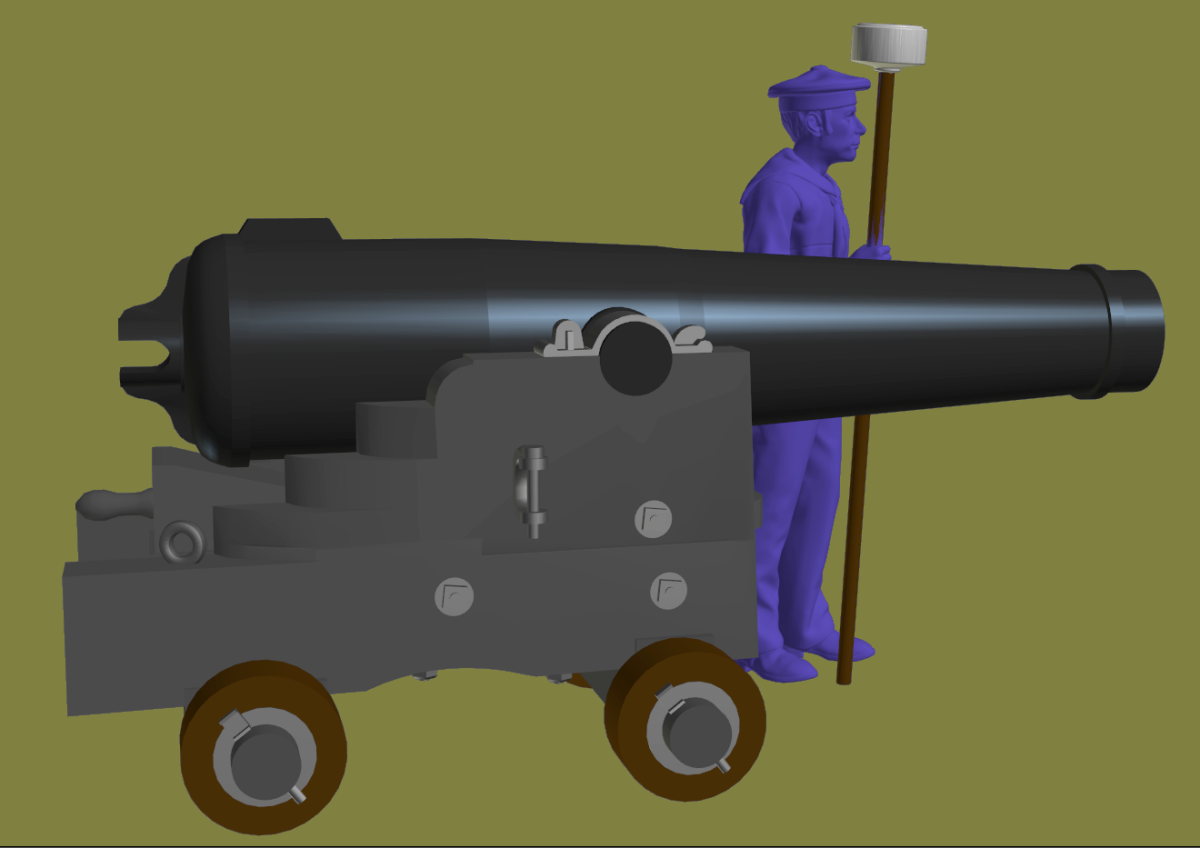

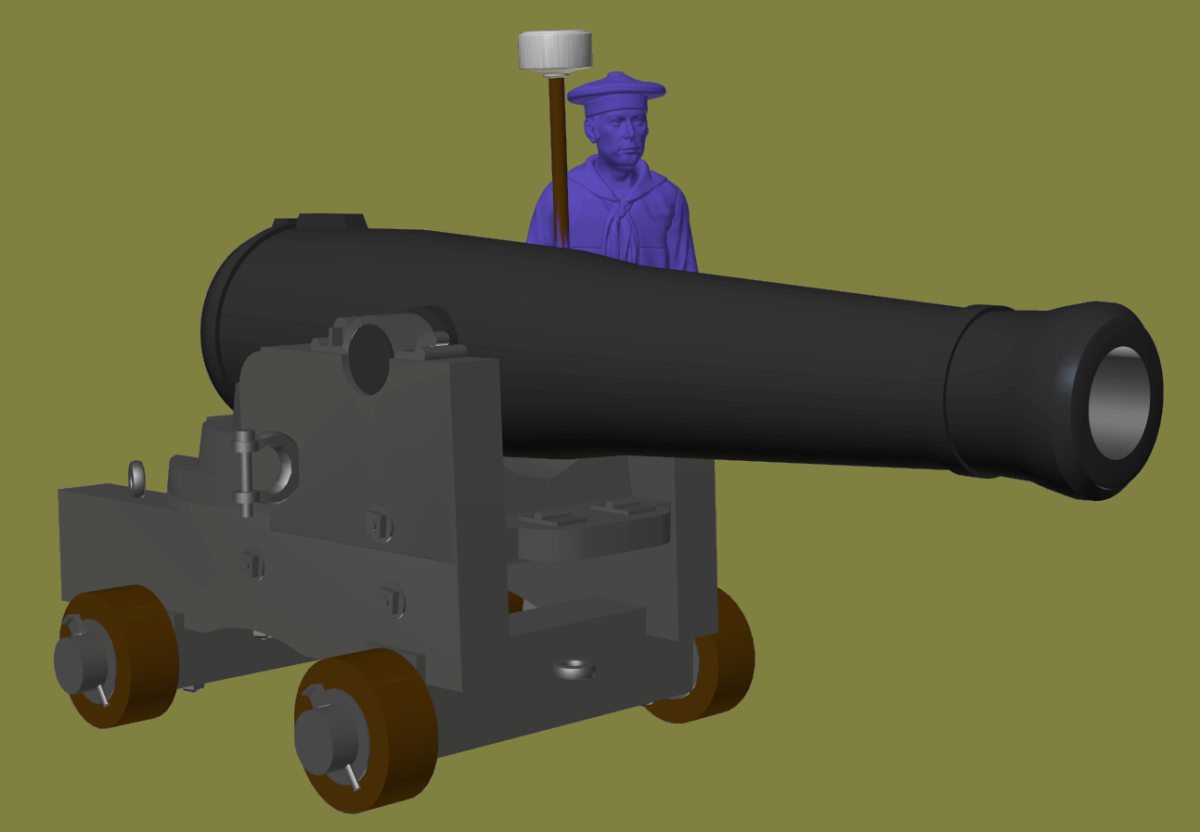

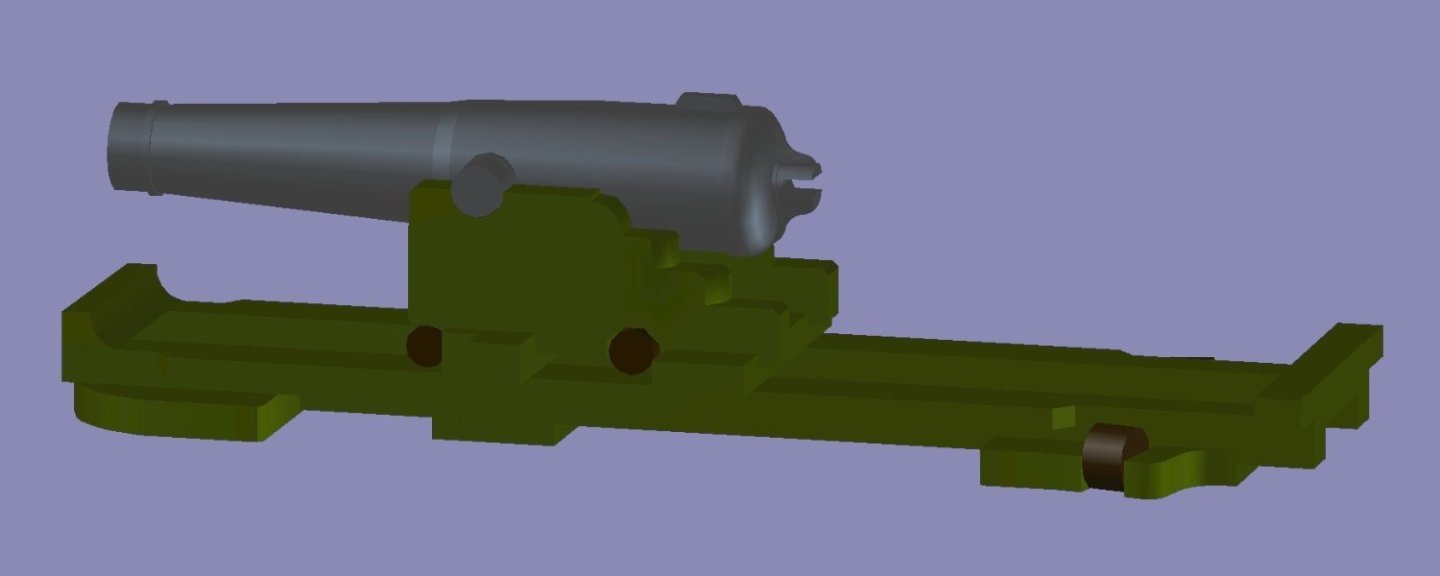

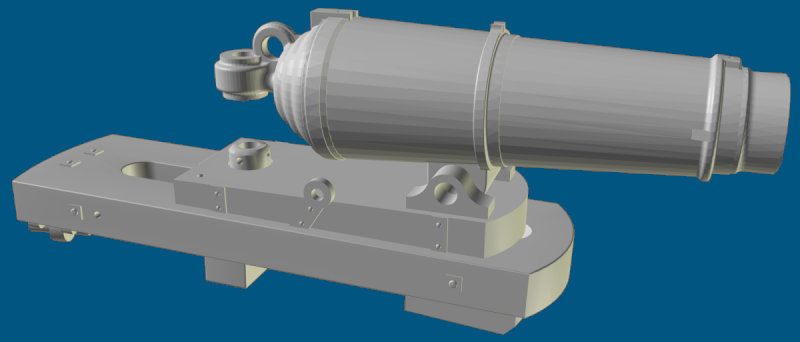

I finished the 10 inch Dahlgren. I didn't model the gun's breech as it was in Dahlgrens drawing. It looked like he left the breech of the Columbiad from the Traverse Carriage drawing and made the rest of it look like his 10" gun. I know Rodman guns were made with that sort of breech, but I can't find drawings of a Dahlgren like that. Dahlgren's patent drawings don't show that sort of breech either. The slide, while just like the one in the Mississippi plan, is shorter and wider; this will mean reworking the deck tracks on Constellation; but It also means it'll fits the space better, with more room for moving the gun about, as well as fitting on my hatches better. The print came out great except for one wheel on the back-left of the slide. I can replace that, and fix the pallet around it easily enough, so it's not a "failed print." The second gun printed better, it didn't lose any wheels

- 524 replies

-

- sloop of war

- constellation

- (and 9 more)

-

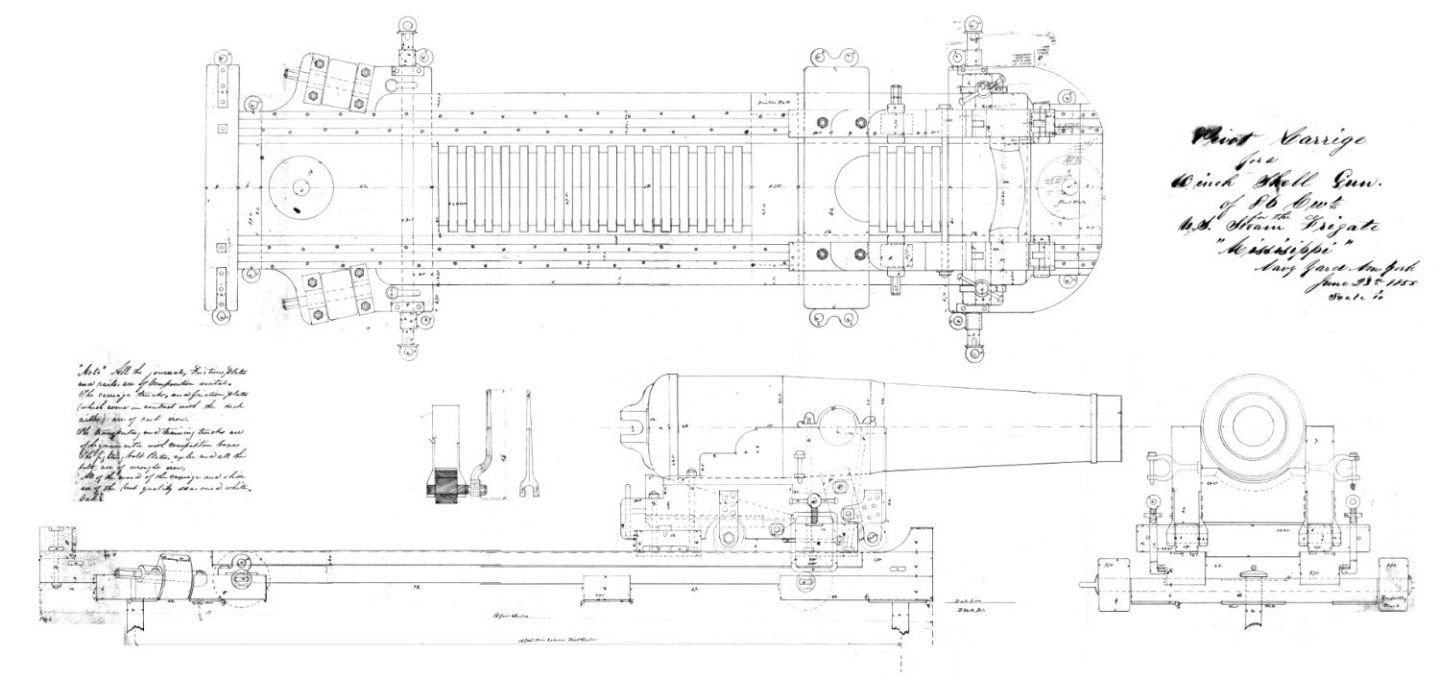

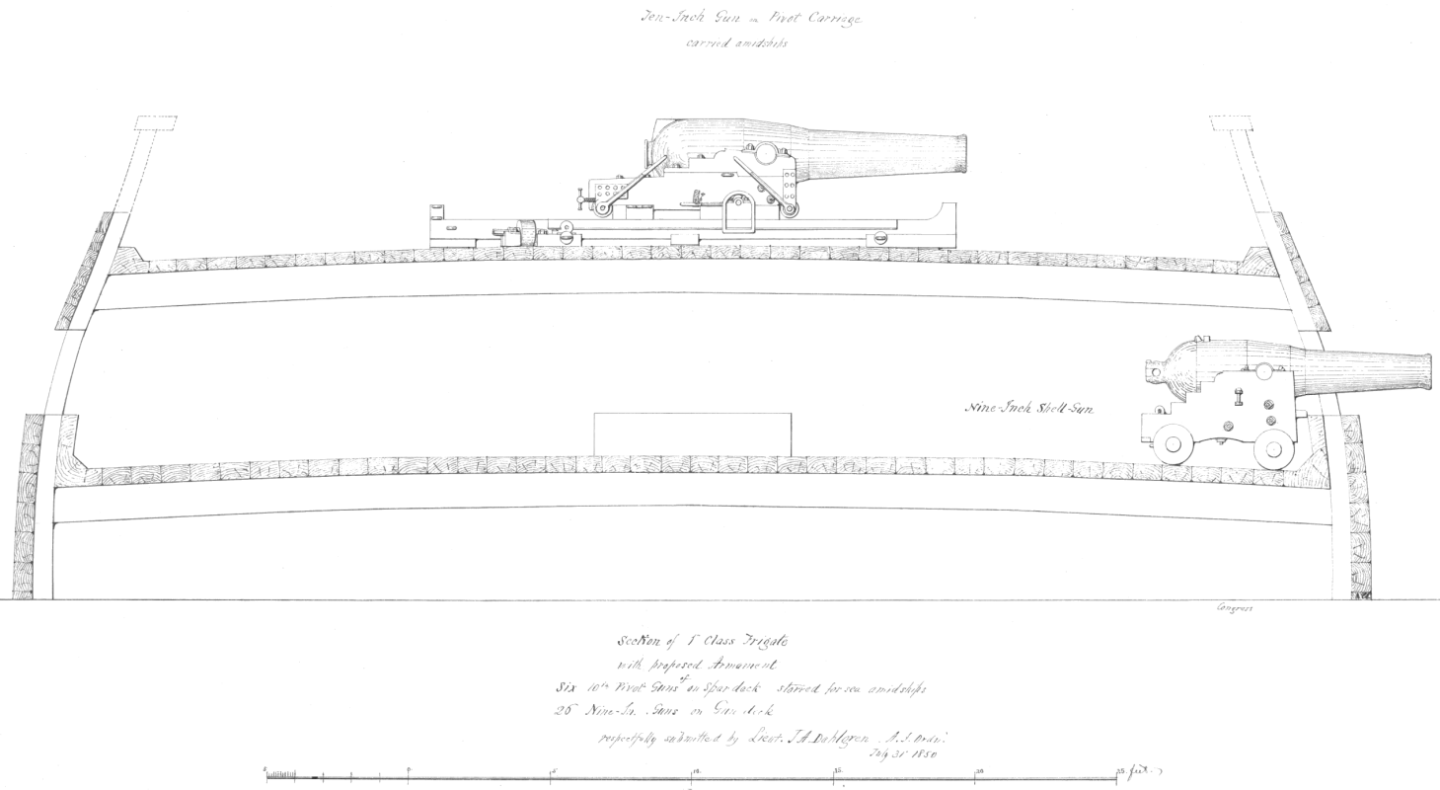

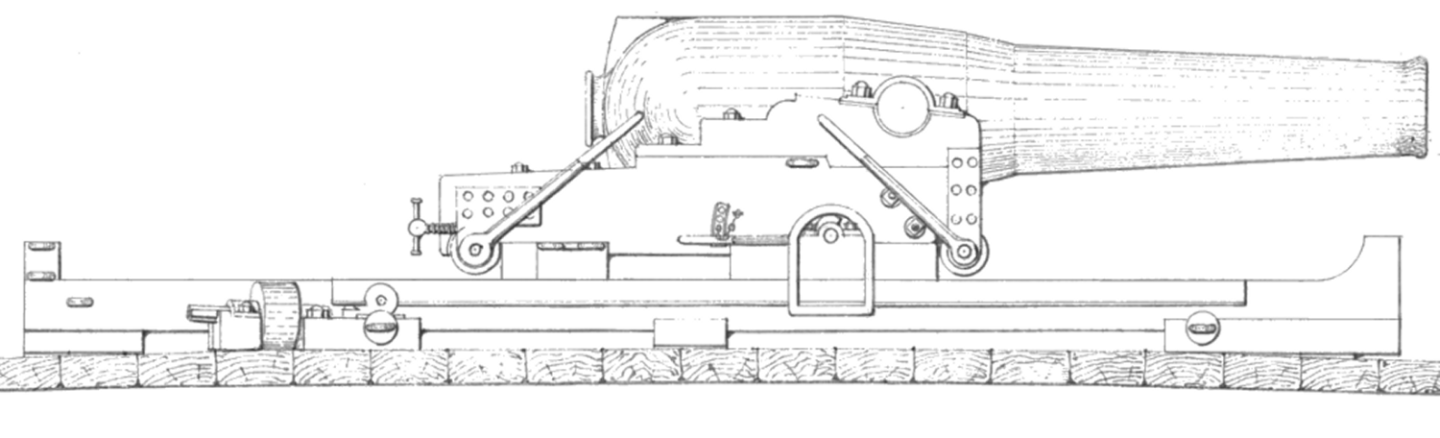

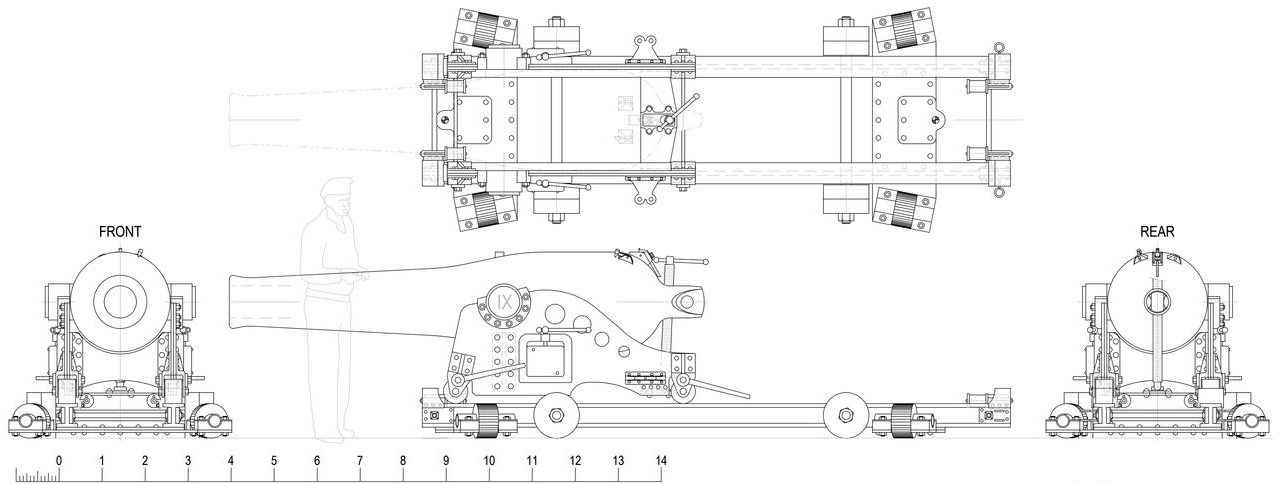

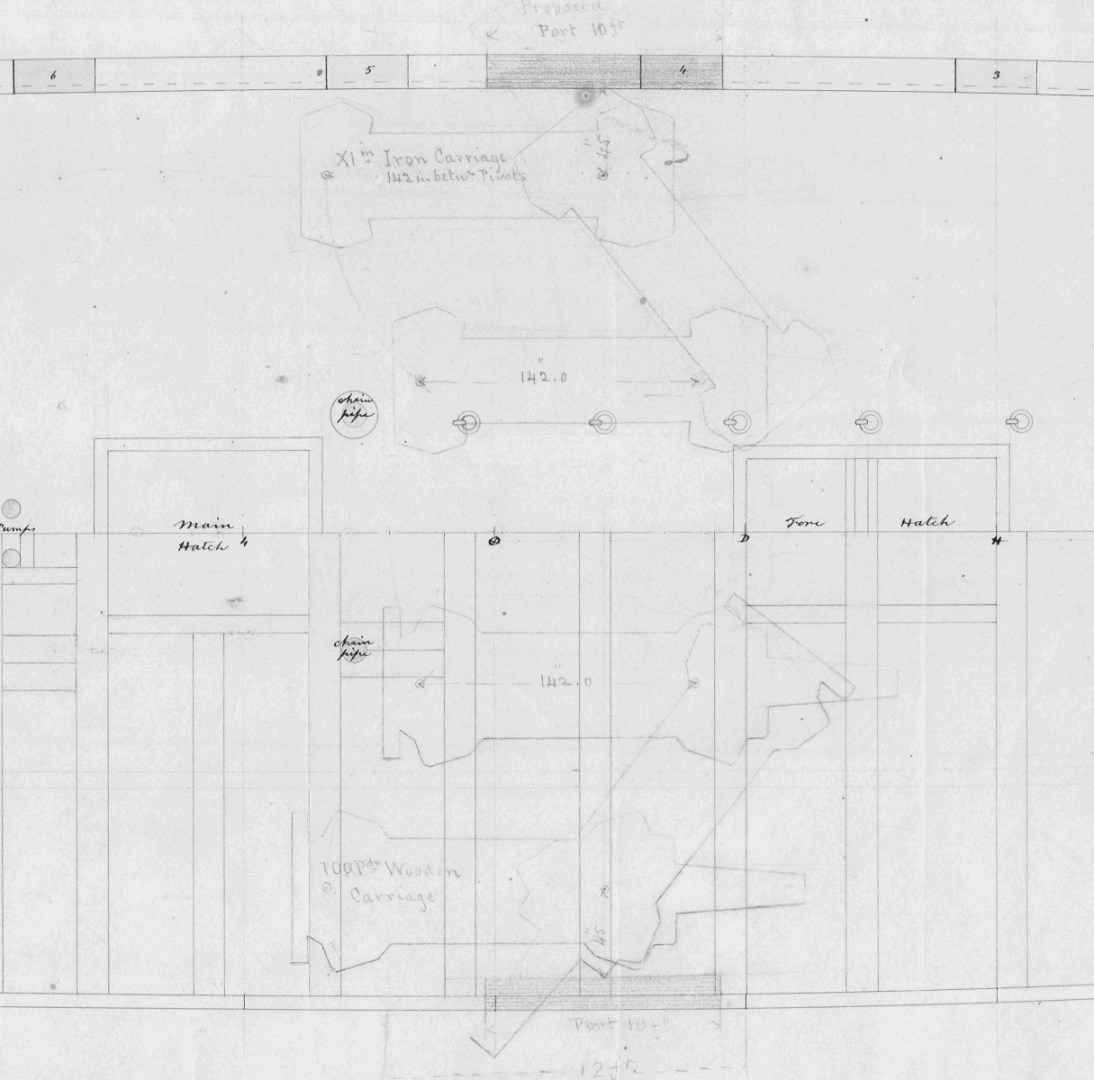

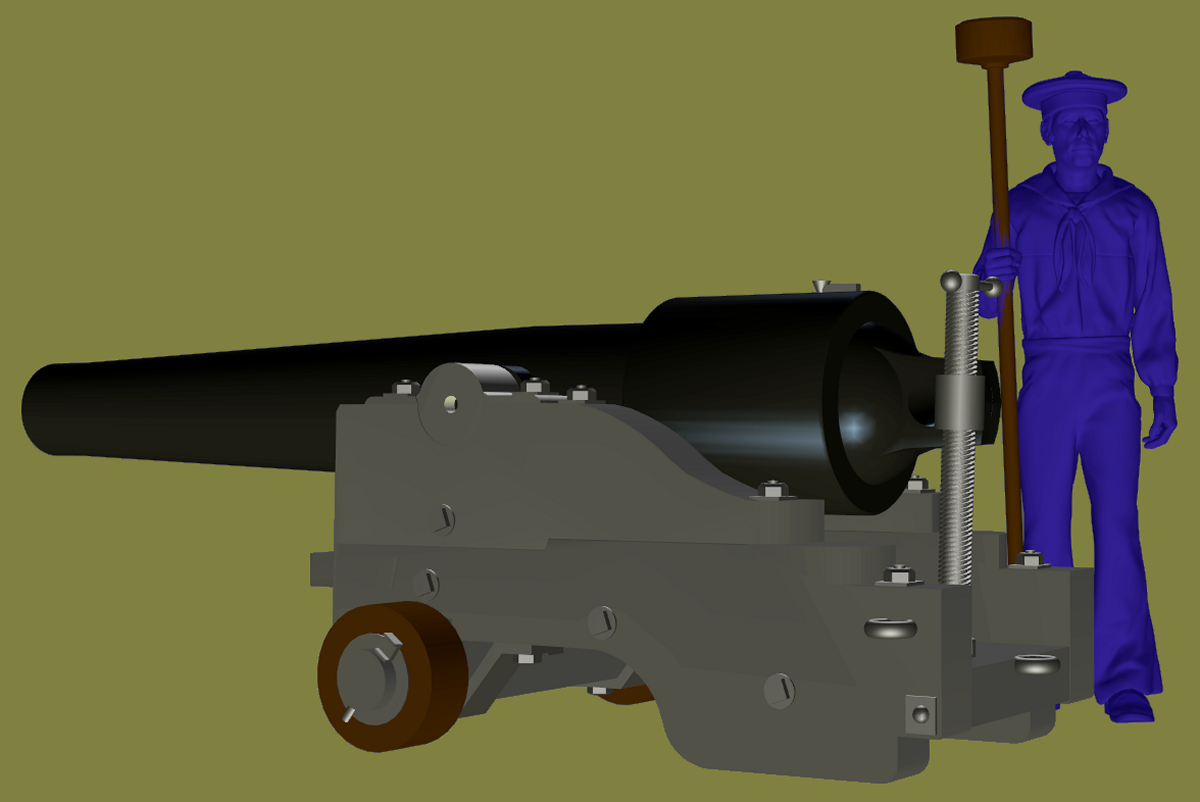

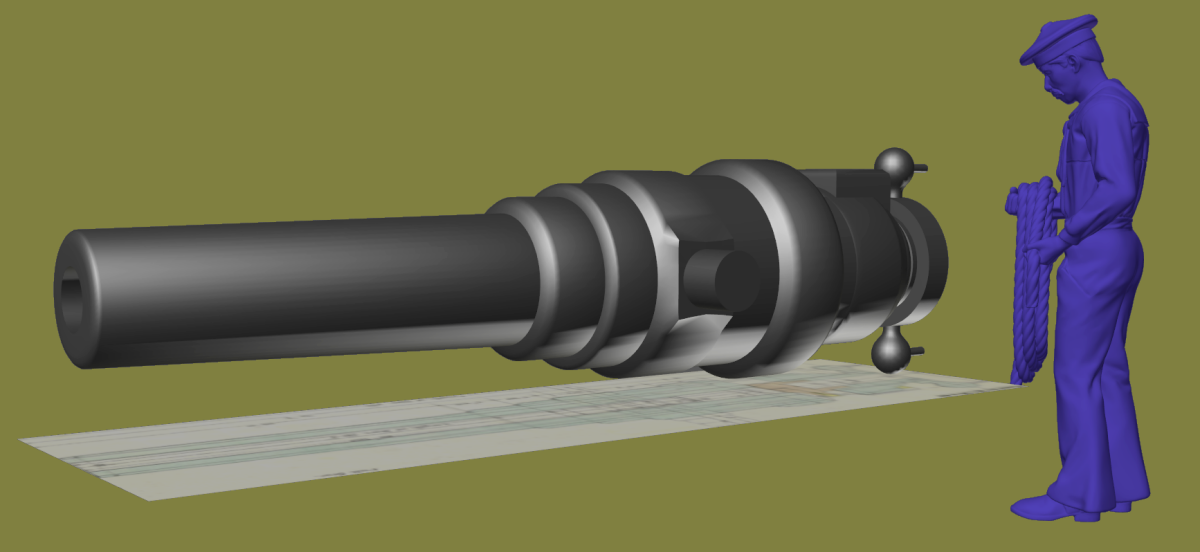

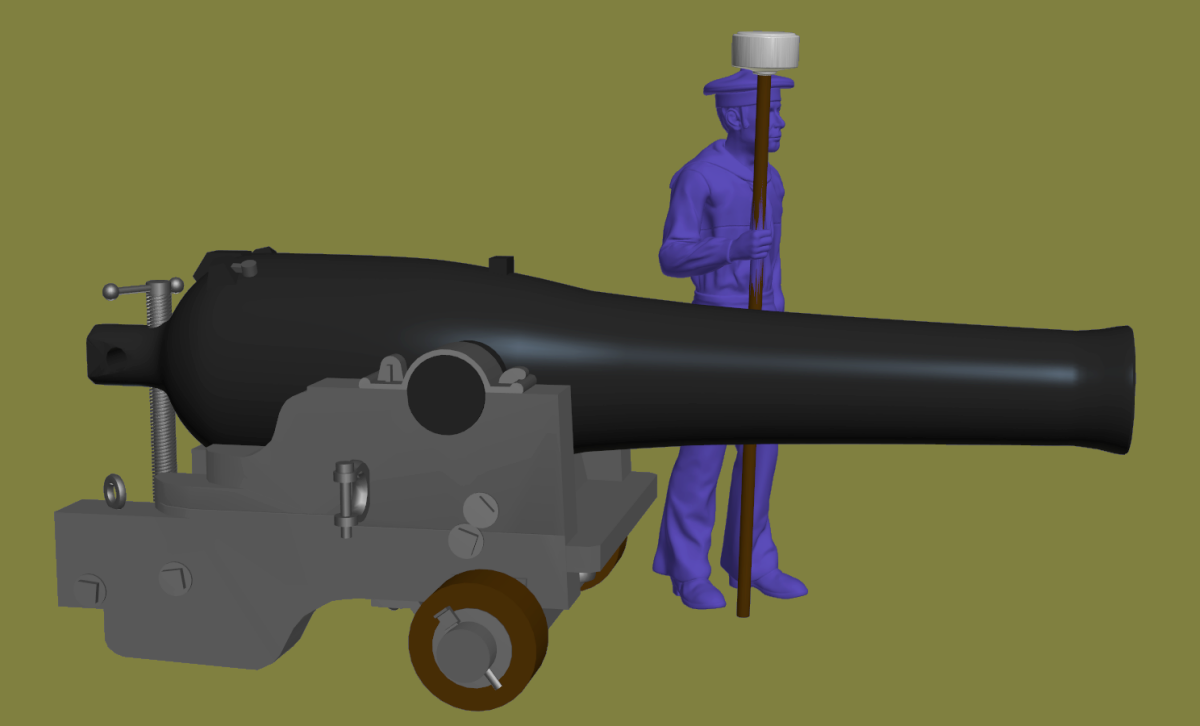

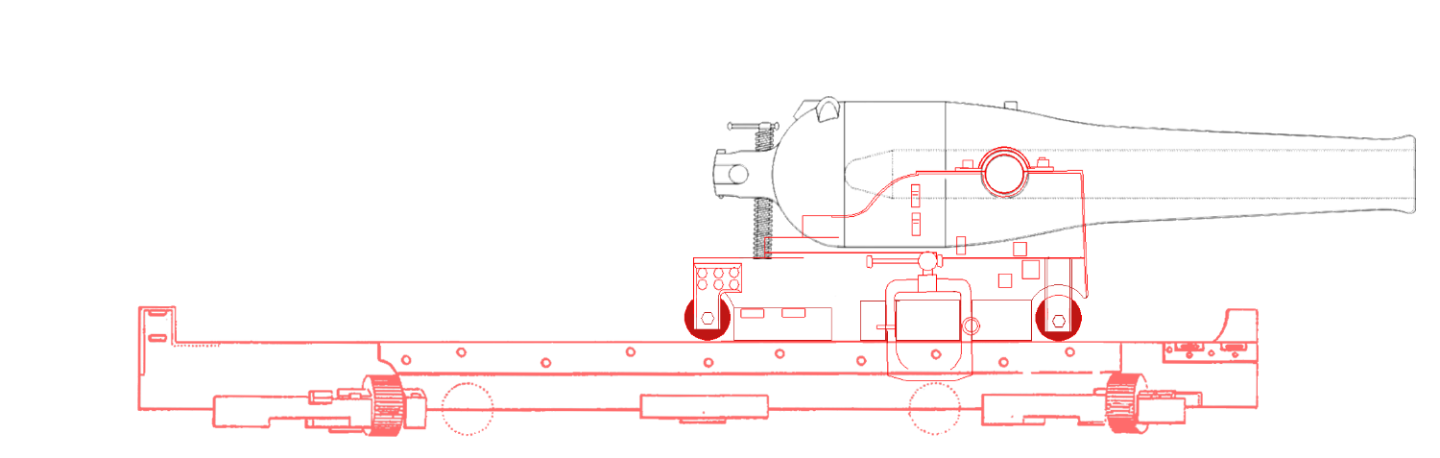

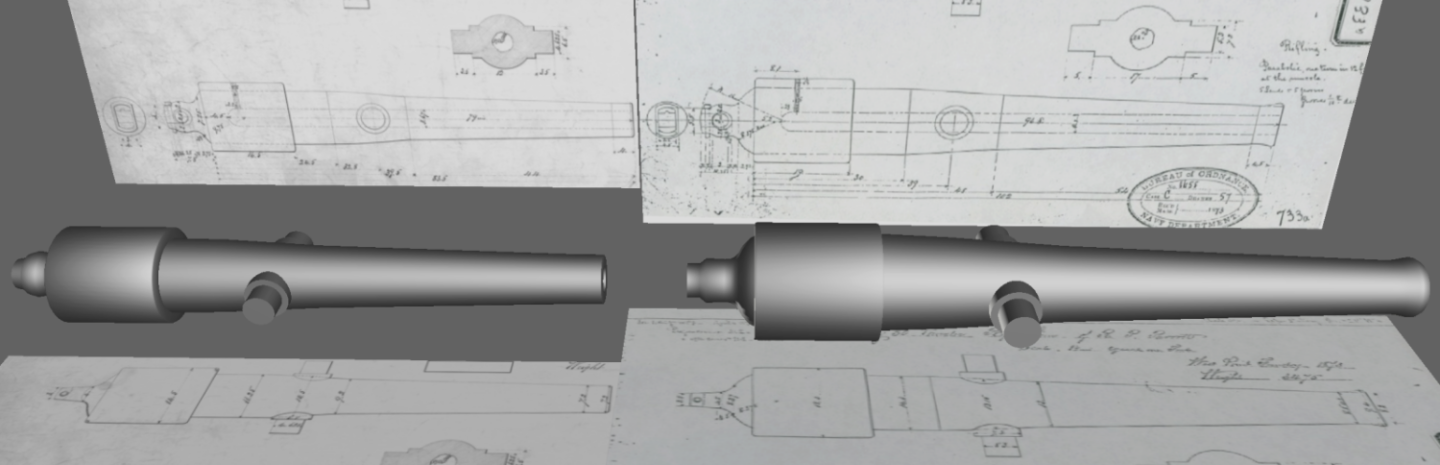

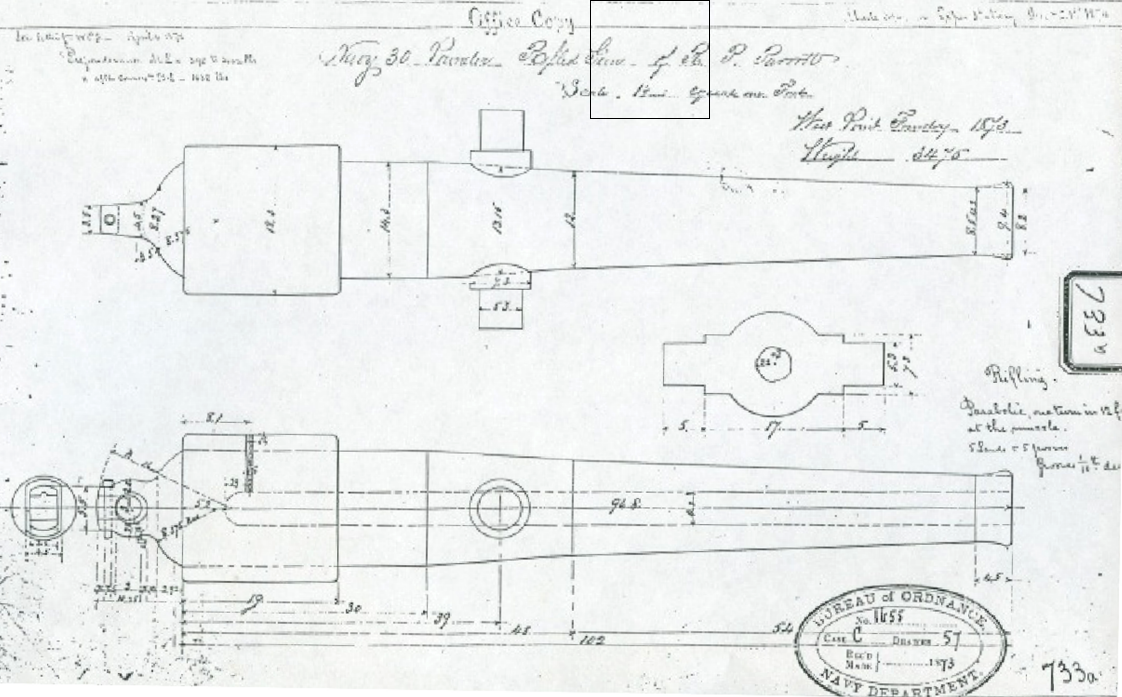

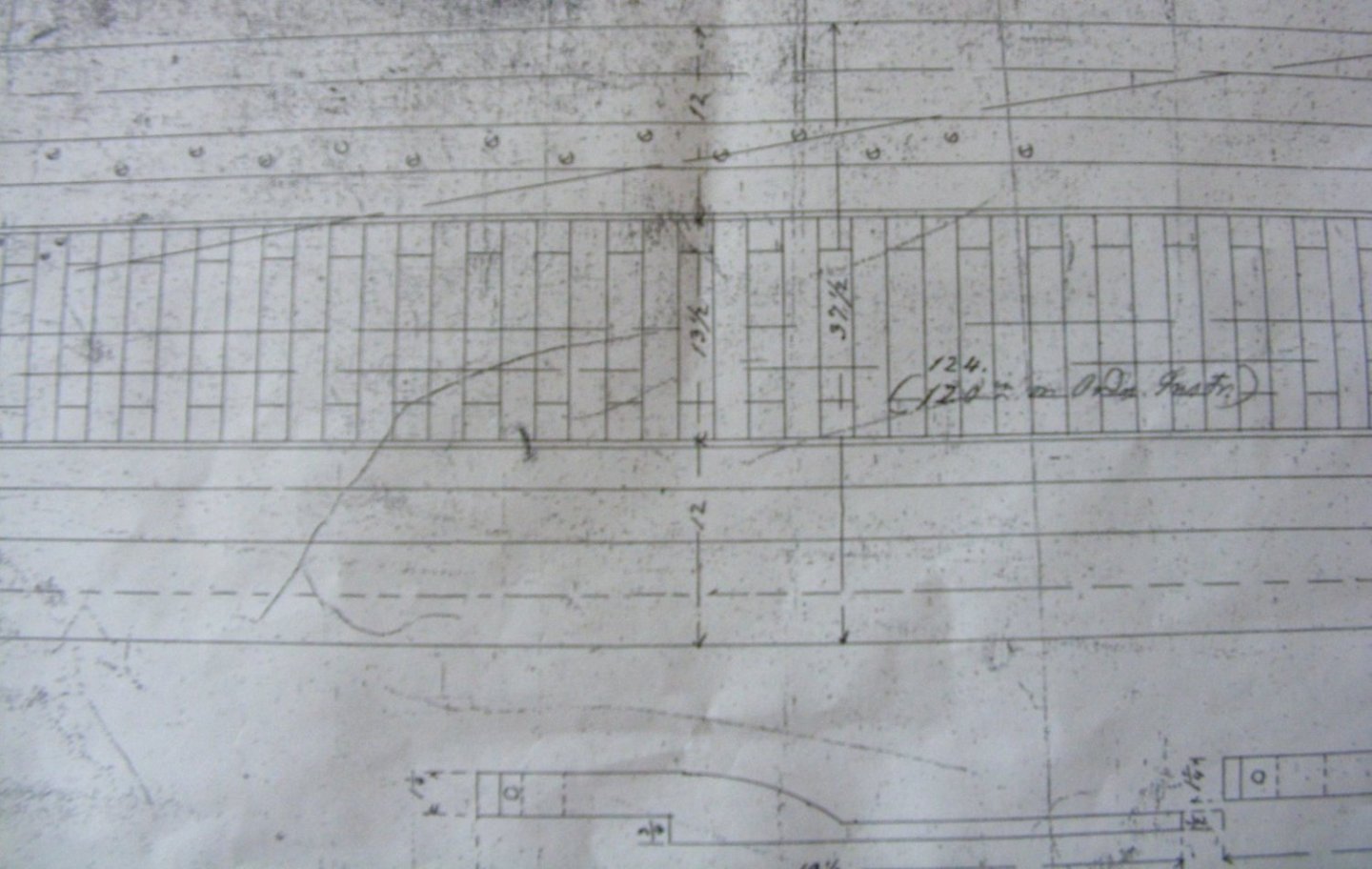

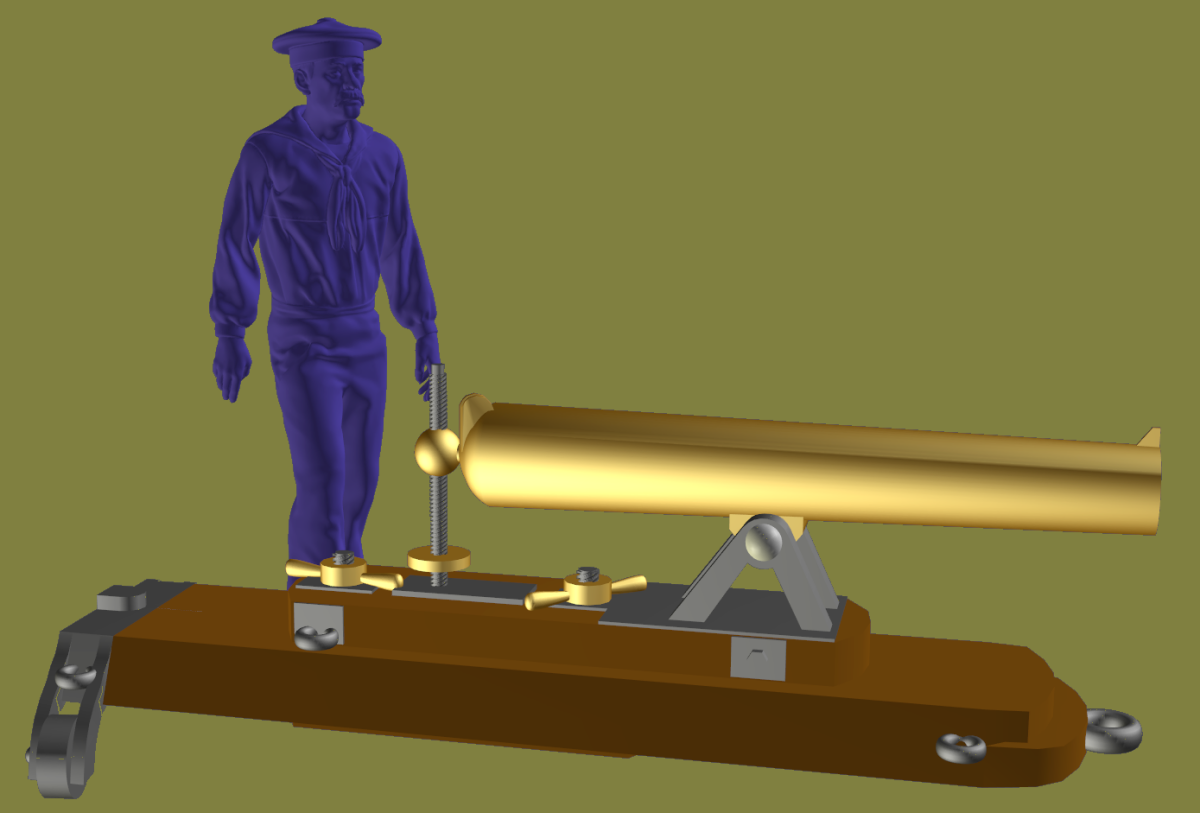

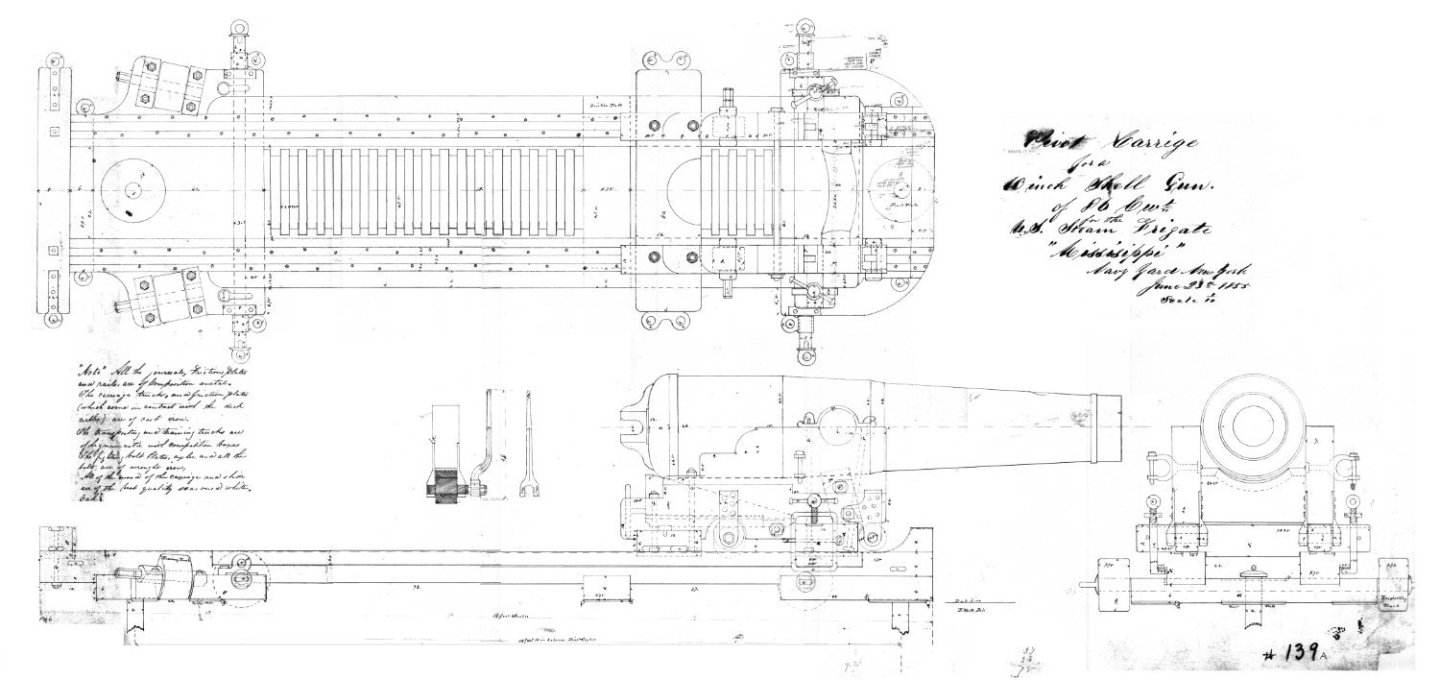

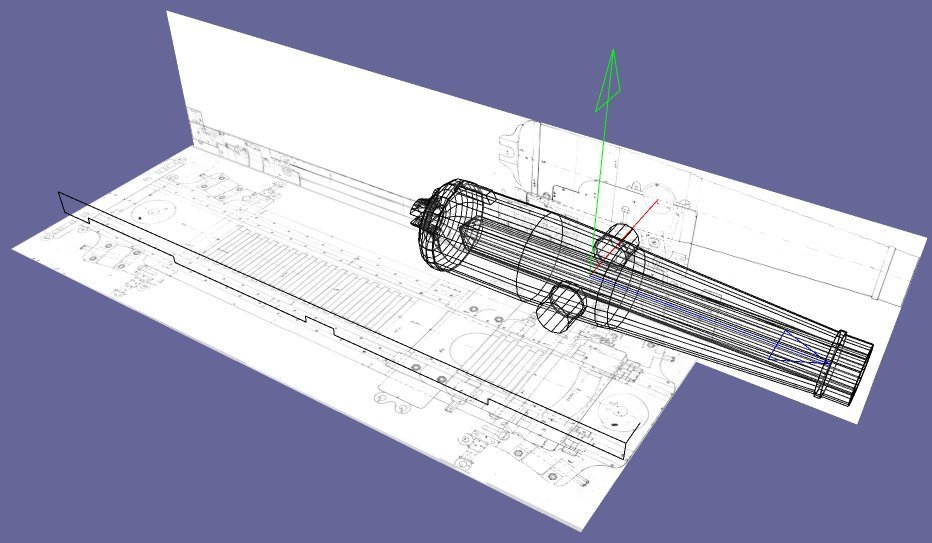

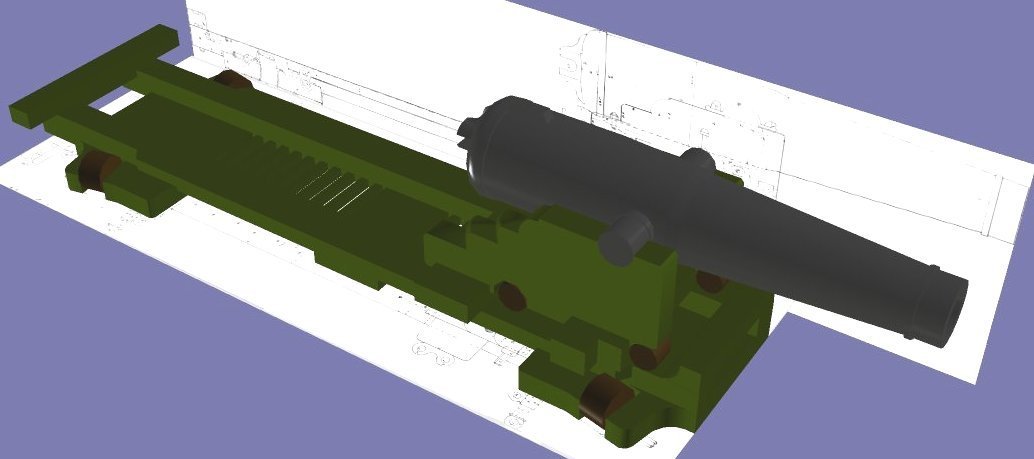

I started a "build log" just for this Naval Gun project, here as well as on my website, mainly to not clutter Constellation's log with all this non-pertinent gun stuff. But one gun I'm working on brings me back here, as it may mean a change to the Constellation model. I'm modeling a 10 inch Dahlgren on a pivot carriage and it got me thinking about Constellation's "10 inch guns on pivot carriages." The Mississippi plan, dated June 23 1855 shows a 10" gun of 86cwt (8600 pounds). The ship's restoration folks presume that Constellation got the same thing because they looked for a 10" pivot gun at the Archives, and that's the plan they found. Constellation was launched on August 26 1854, and commissioned on July 28 1855. Dahlgren's drawing, on-the-other-hand, is from July 31 1850, 5 years prior, and refers to the pivot gun simply as a "10 inch gun on pivot carriage." Without any documentation stating exactly which 10 inch pivot gun the ship was issued, how do I know? Furthermore, a 10 inch Dahlgren tube weighed 12,000 pounds, 3,400 pounds more than the Mississippi gun. When the ship was leaving for the African Station on July 15 1859, her captain felt the pivot guns were too heavy, too high, and made the ship "crank," so had them taken off. I can't help but think that would be a concern regarding a pair of 12,000 pound guns compared to a pair of 8,600 pound guns. I'm trying to find out where any records regarding what guns were issued to what ships would be, and if I can access them, but at the moment, I'm personally leaning toward replacing Constellation's pivot guns with 10 inch Dahlgren pivots. Here's the 3D models of the 10 inch Dahlgren (still a WIP), the Mississippi gun, and both together.

- 524 replies

-

- sloop of war

- constellation

- (and 9 more)

-

3D Naval Guns 1850s ~ 1870s

JerryTodd replied to JerryTodd's topic in CAD and 3D Modelling/Drafting Plans with Software

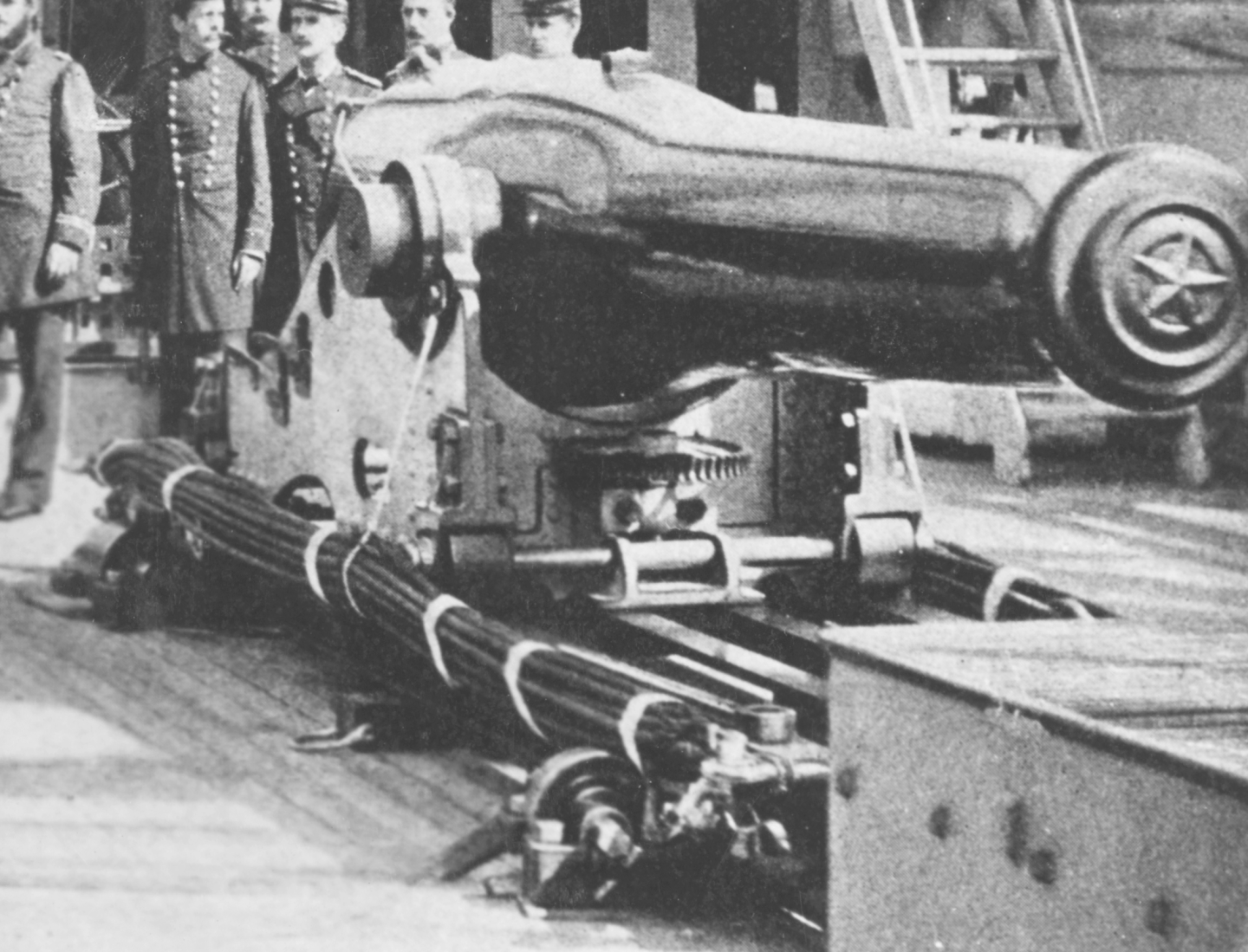

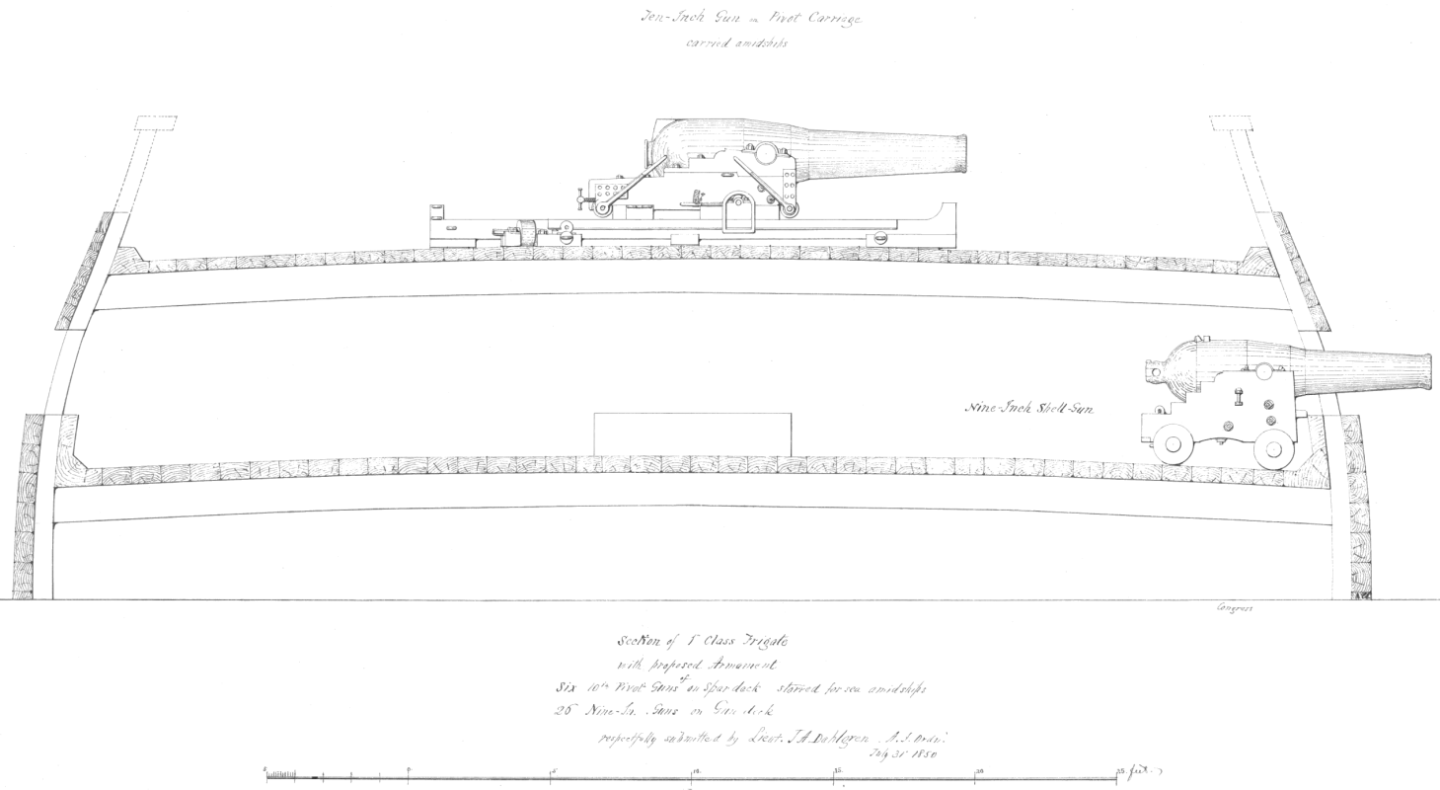

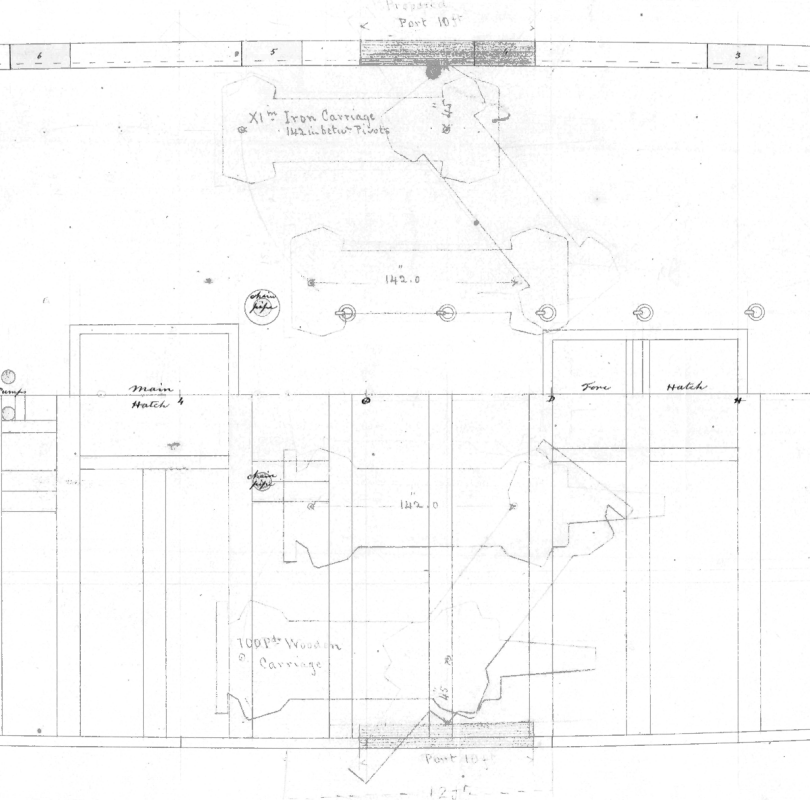

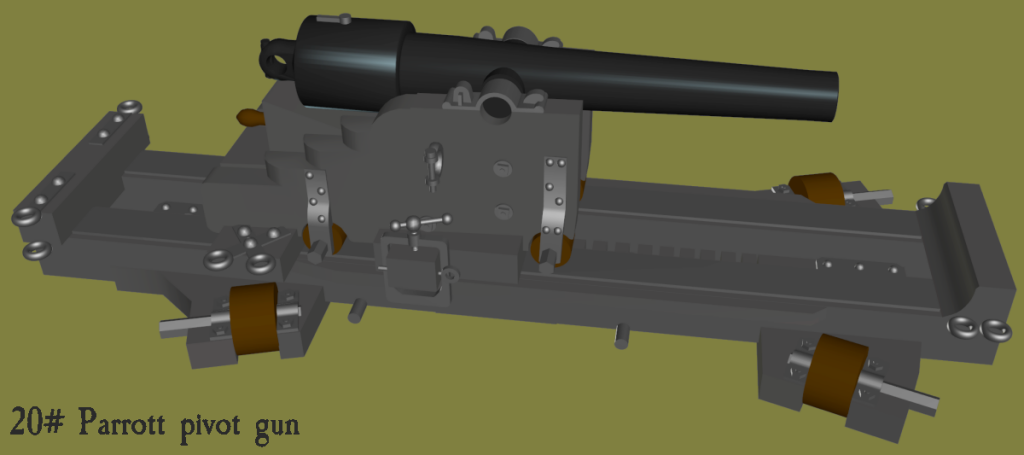

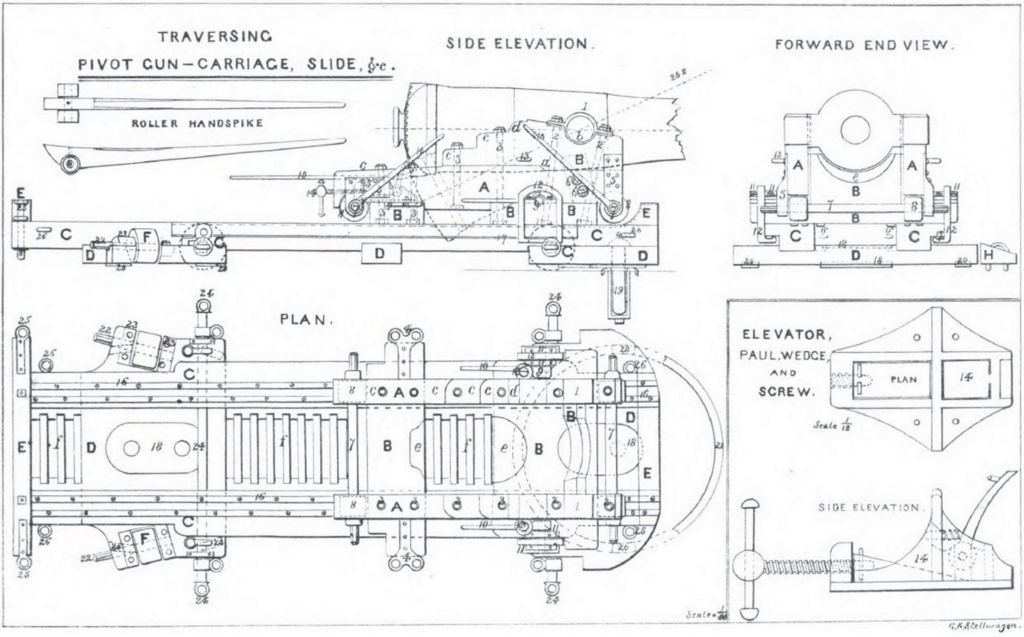

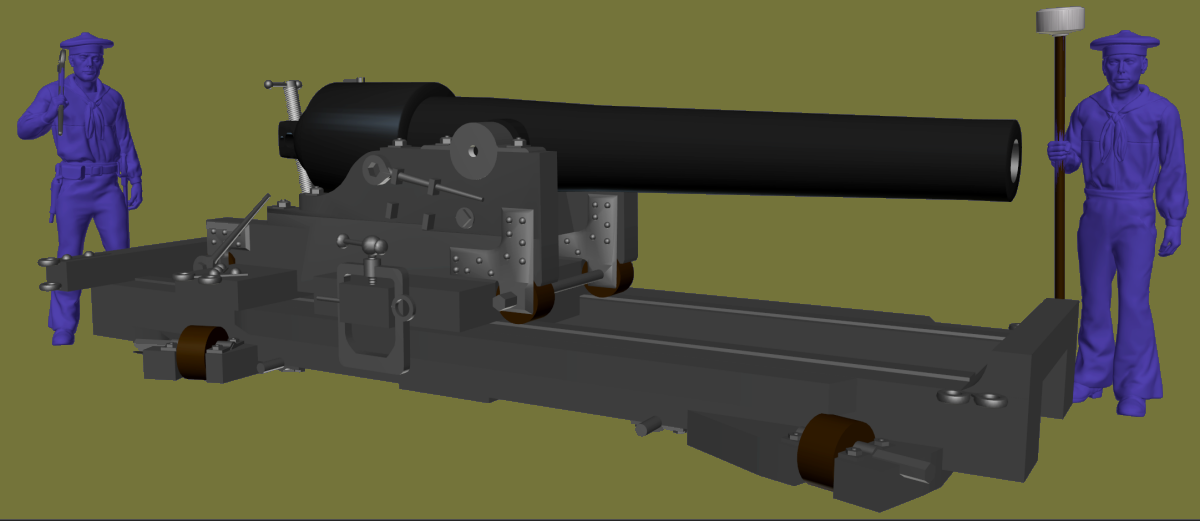

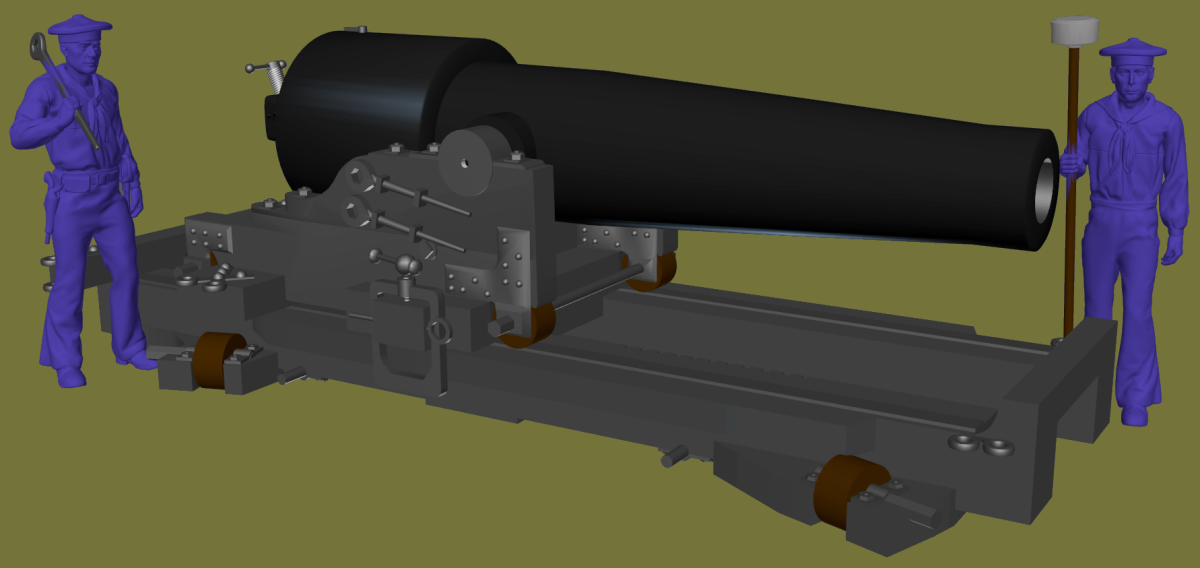

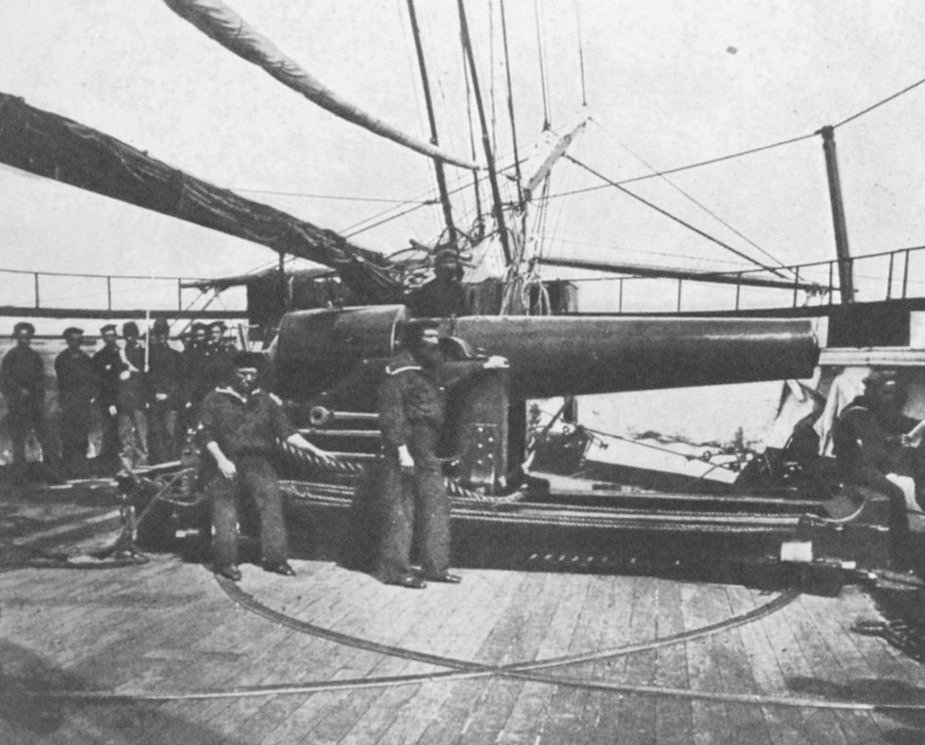

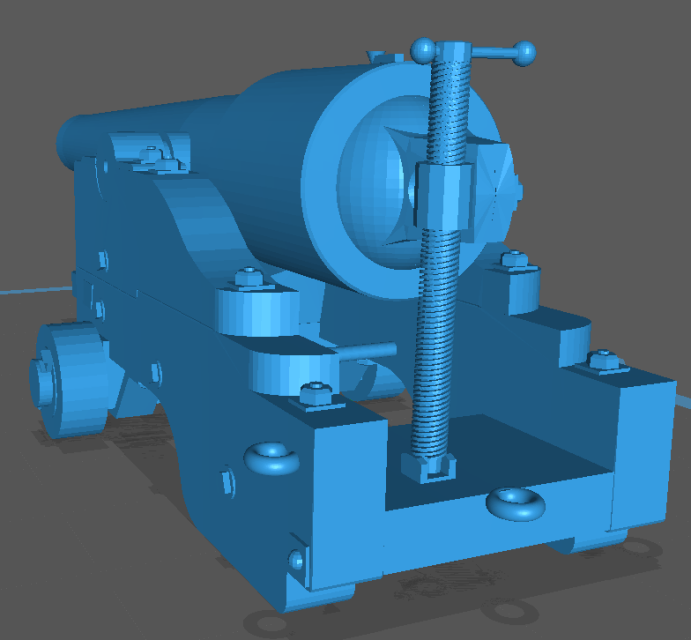

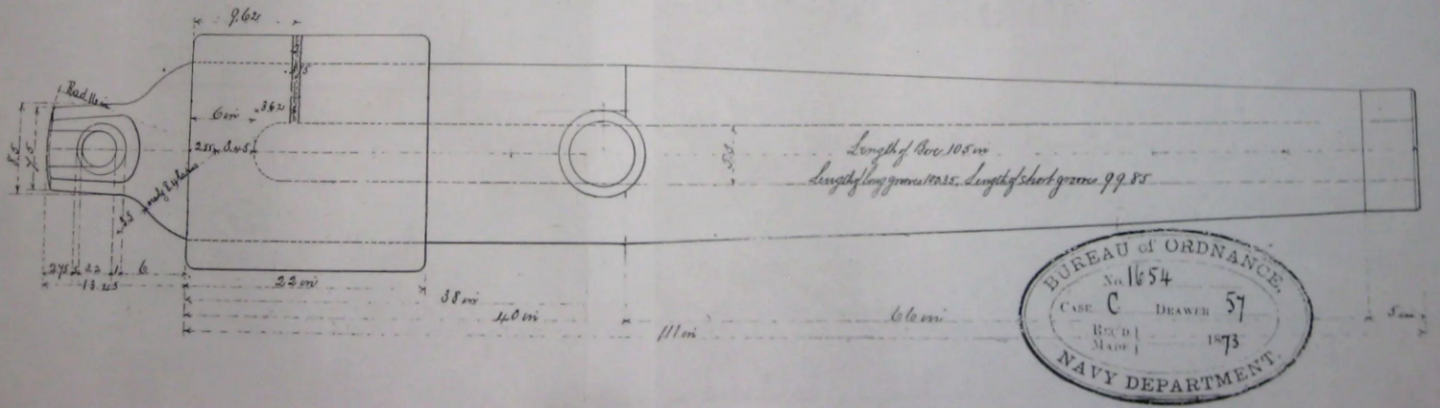

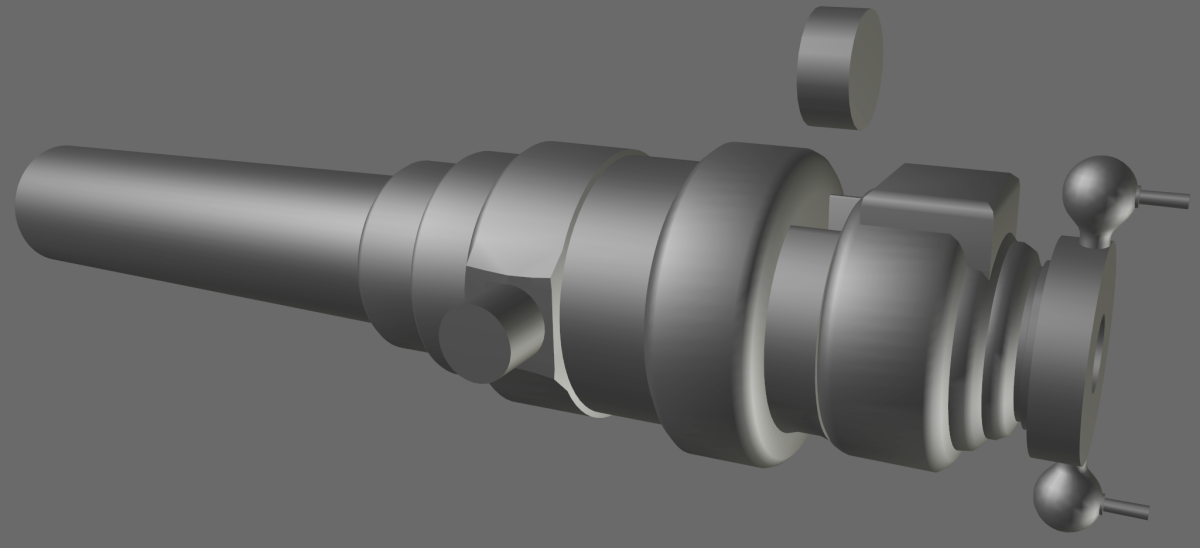

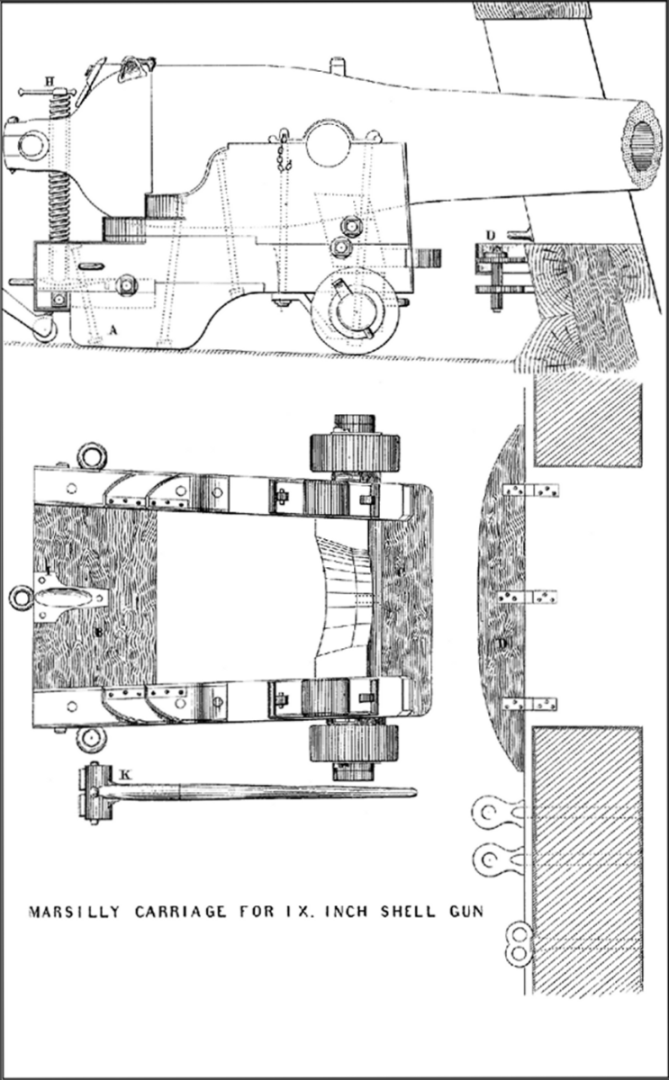

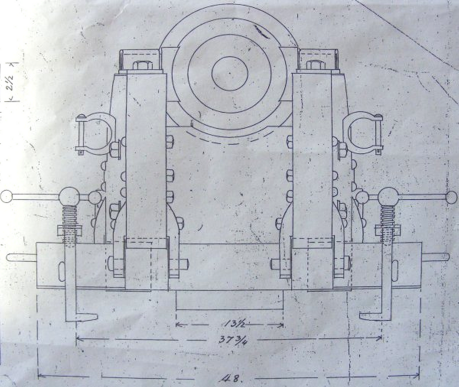

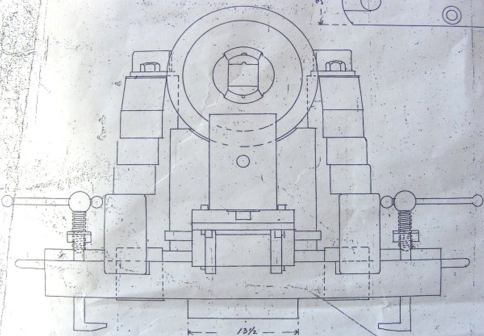

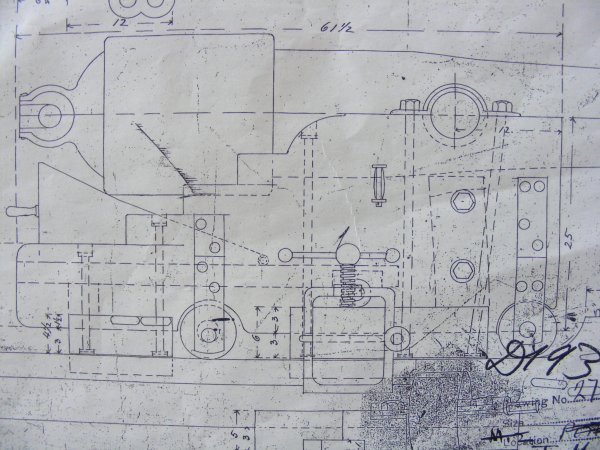

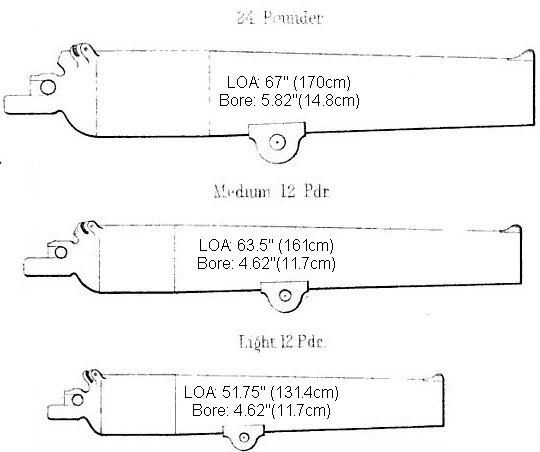

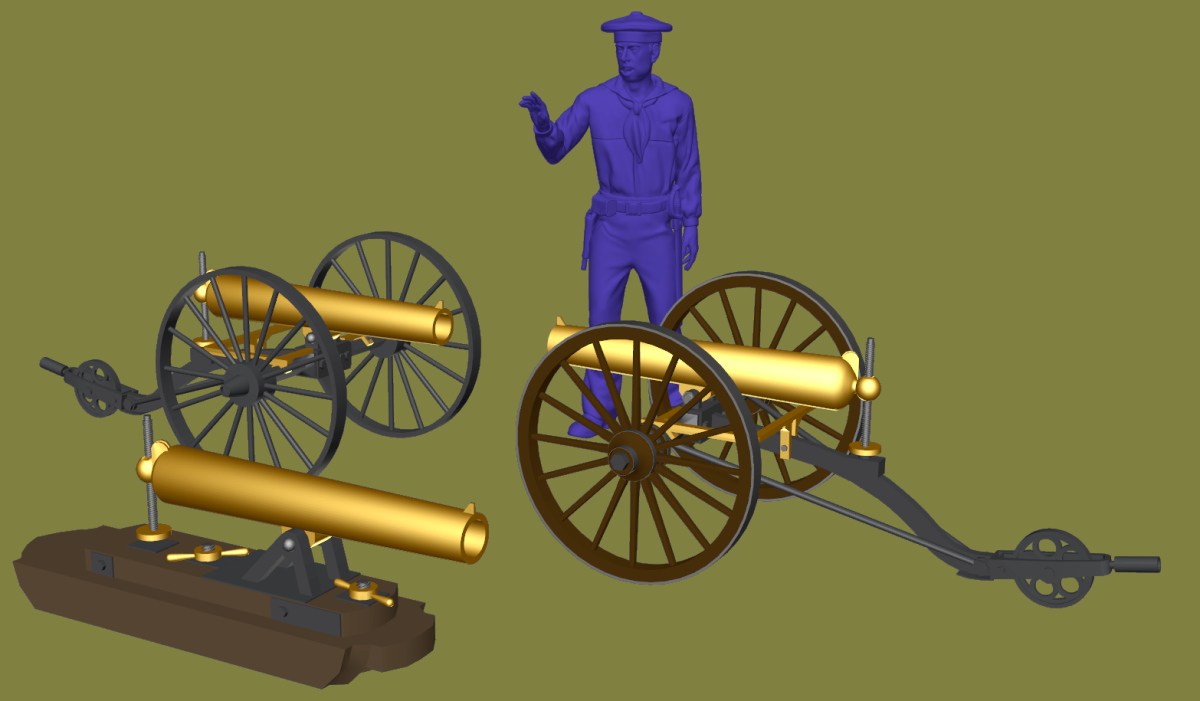

I altered the carriage for the 30# Parrott to fit the 20# gun since I have no data at all what a pivot carriage for the 20# would look like. So, that's that one done. Moving on, I poked at the XI inch Dahlgren on the iron carriage based mostly on a drawing for a sci-fi story on the Deviant Art site. I don't know their source, as most photos I can find are late 1880s, 1890s and the technology had changed some from the 1870s. The carriage looks the same, but there's springs and things the 1870 guns didn't have. It's not done, but it's getting there... This gun's for my list of Constellation's guns, and was mounted on the gun-deck opposite a 100# Parrott on a wooden pivot carriage - each with a their gun-port widened to 10 feet. Making the 60# Parrott pivot got me thinking about the gun at Cumberland's other end, a 10 inch shell-gun. I found a drawing by Dahlgren himself, dated July 1850, with a proposed armament for frigates to mount 6 10 inch shell guns on pivot on the spar deck (the 11 inch hadn't come out yet) and 26 9 inch shell-guns on the gun-deck. The Navy went with two pivots, one fore and one aft, and a mix of 8 inch shell-guns and 32# shot guns on the gun-deck. The 10 inch gun in Dahlgren's drawing is on a Traversing Pivot Gun Carriage and Slide as shown in a diagram in a Navy manual. I then used the Traversing carriage diagram to make the carriage, and took the slide from my 10" shell-gun pivot, and adjusted it to Dahlgrens drawing which was shorter, but it's the same in all other details. Spencer Tucker in his Arming the Fleet says the carriage was the same as that for for the Columbiads (the Traversing Carriage shown), but widened to accommodate the larger Dahlgren gun body. The compressor was different, and a bit fiddly, there's a lever that works it instead of the screw these carriages had later. There's a pin that hold that level connected to the carriage by a chain, and whether it was a good idea or not, I gave it a chain - we'll see how that prints. Now go to my Constellation build log to see the can of worms this opened up... -

3D Naval Guns 1850s ~ 1870s

JerryTodd replied to JerryTodd's topic in CAD and 3D Modelling/Drafting Plans with Software

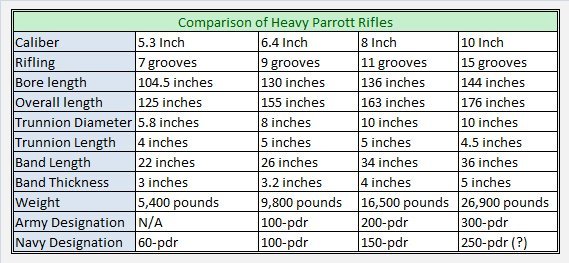

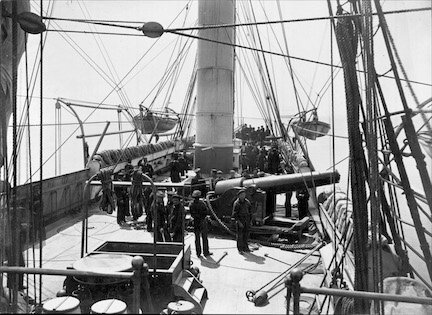

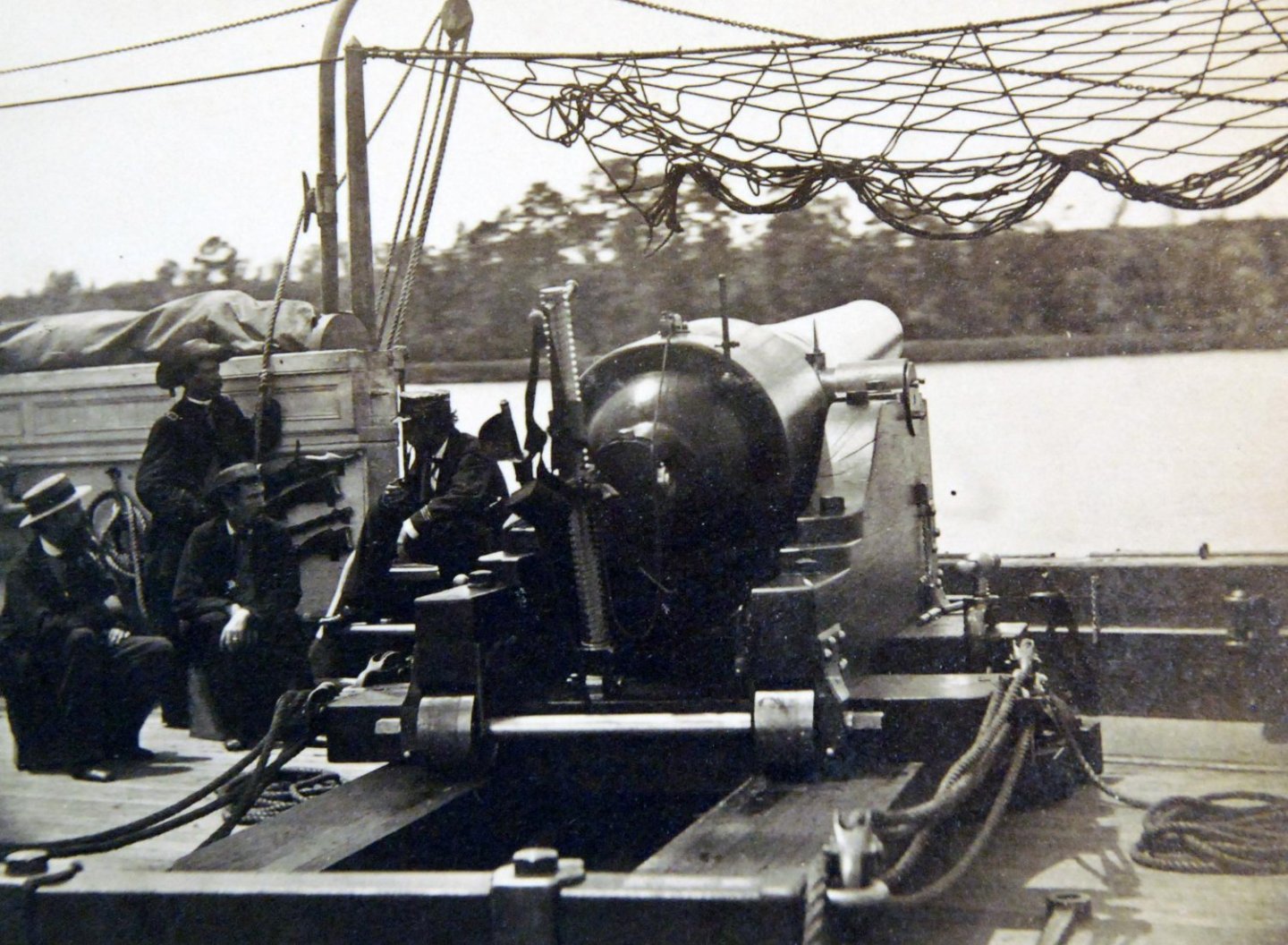

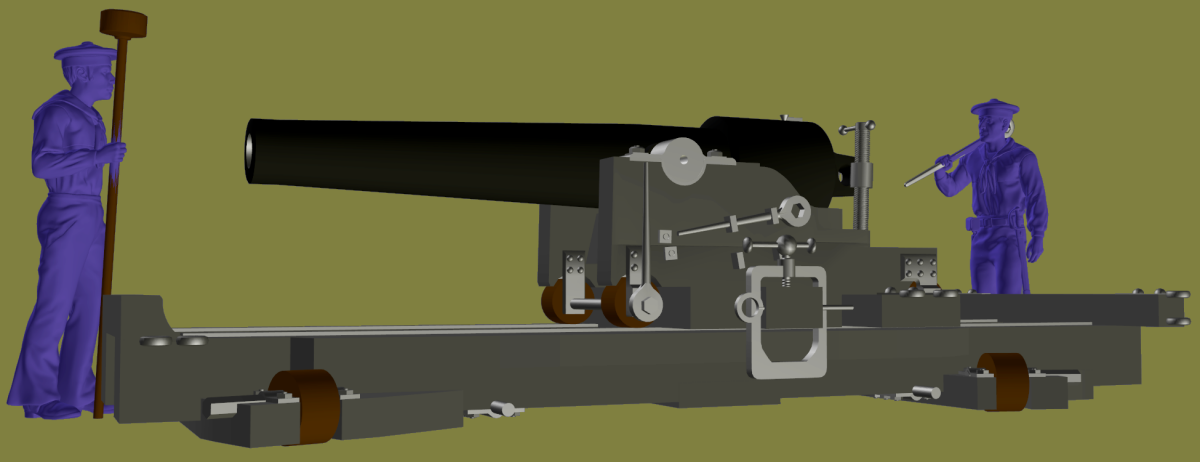

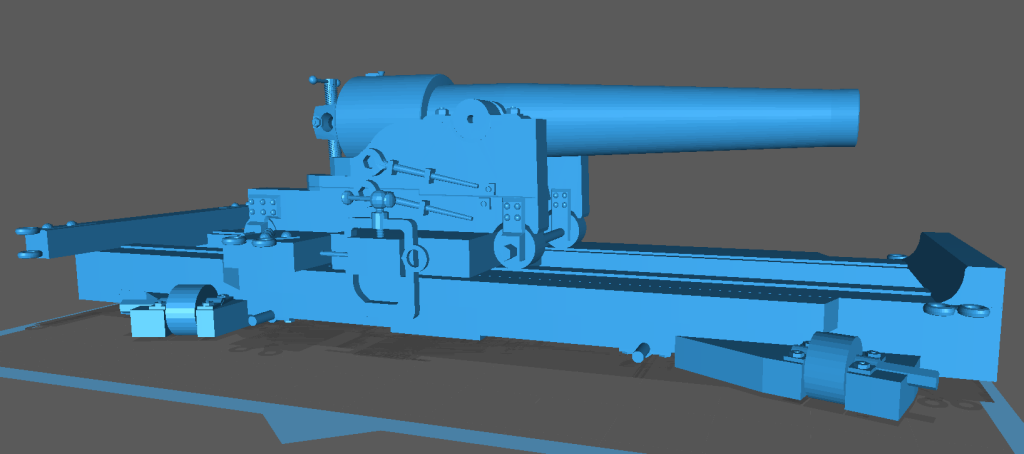

Oops, I skipped over some other Parrotts... I needed a pair of 150# Parrotts on pivots for someone modeling the Susquehanna in 1:72 scale, and I modeled it based on these images: 150# Parrott on the Wabash 150# on the Nipsic, post-war. and the 3D model... The fellow modeling the Susquehanna sent me some helpful data, I printed the 150's he'd need, but they didn't come out very well, though you'd have to know where to look. For my own list of Constellation's guns, I need a 100# Parrott for when she was a training ship in the 1870's. I based that on images of the Mendota's 100# Parrott, which if you look close, is on an identical carriage as the 150# on Wabash. and the 3D model... Unless something else pops out the blue, the only Naval Parrott left to do is the 20 pounder that Constellation had as an aft pivot gun during the war. -

3D Naval Guns 1850s ~ 1870s

JerryTodd replied to JerryTodd's topic in CAD and 3D Modelling/Drafting Plans with Software

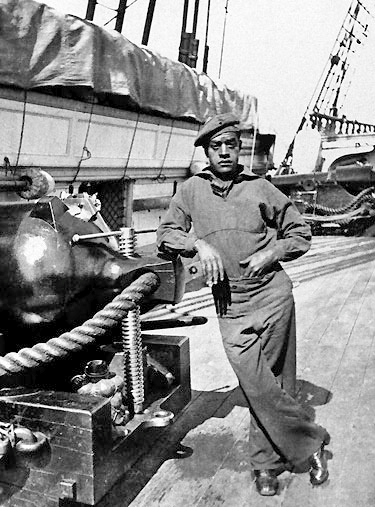

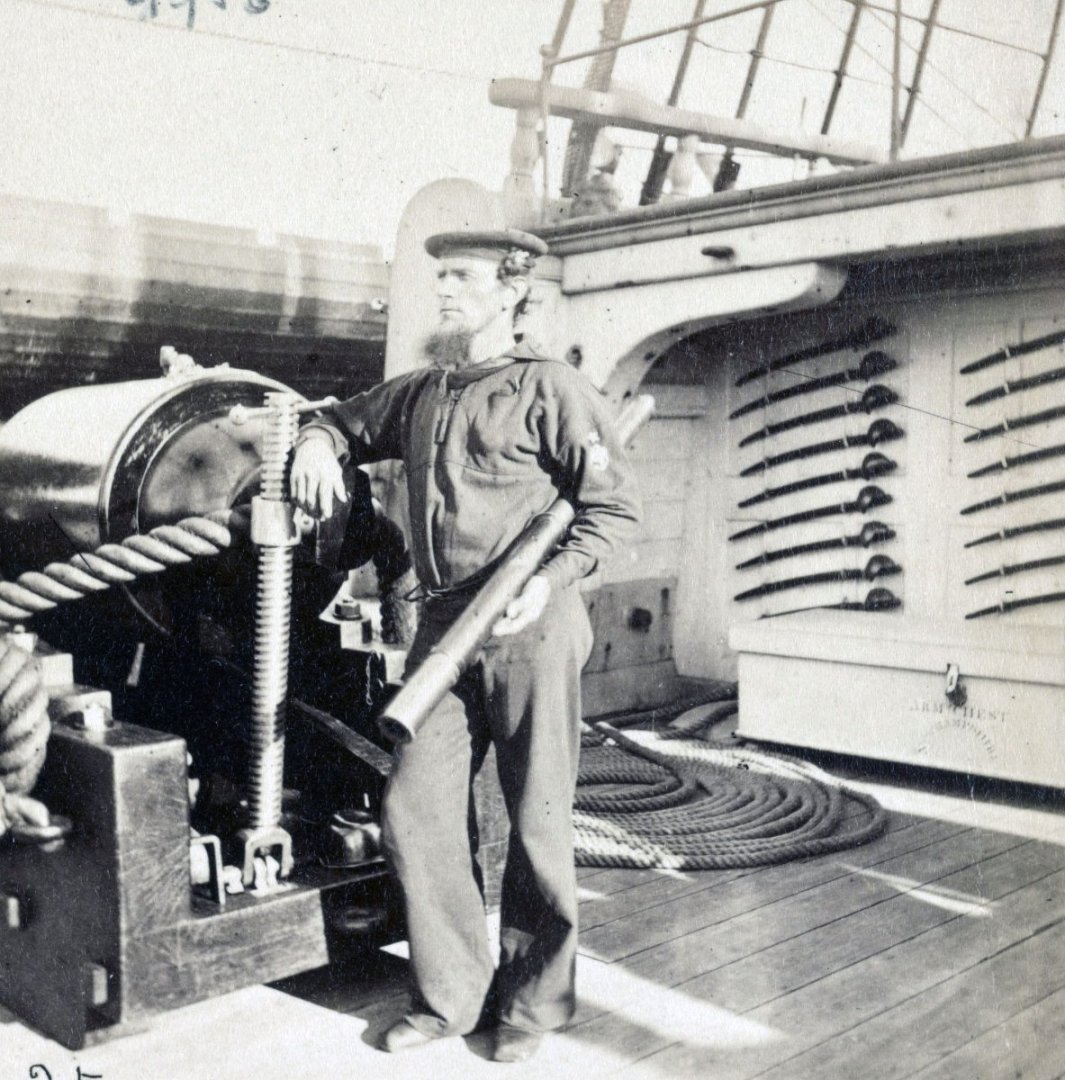

Over on Facebook's Civil War Navies group, a series of photos came up for discussion, one well-known image in this series is the "Powder Monkey," a colorized version shown here... The other images of the series have various sailors posing next to this same gun, and one sailor with a telescope that's more around the rear of the piece, showing some added details. And another with a Black sailor leaning on a IX inch Dahlgren, with this Parrott in the background. Notice in the last image there's a difference in height evident between the Parrott's and Dahlgren's carriages showing the Parrott's Marsilly carriage was fitted to it. (click the pics to see larger versions) Until now, I always figured the gun was a 30# Parrott, but when I put my model of the 30# Parrott on my Marsilly carriage, it didn't match the pictures. I thought I could easily knock out another gun for this project, but it wasn't gonna be that easy. So I put the 100# tube on and that was too big. Knowing the images were taken on board the New Hampshire, I looked into her. I learned she was armed, in addition to her broadside battery, with 4 100# Parrotts. More digging showed she received 60# Parrotts in addition to, or to replace the 100 pounders. So I went looking for data on the 60# gun. I didn't get as lucky as I did with the 20# and 30# guns, but I found a photo of a piece of a similar document from the same original source, and despite the distortion, I could read the measurements. The also had a profile view of a Marsilly type carriage with it, but the drawing of the carriage didn't match the photos, and I don't know the original source of that drawing. So, I added the 60# Parrott to my collection, and modeled my 60# Parrott on a Marsilly carriage. There was another 60# to model. When the Civil War broke out the Navy Yard at Gosport Virginia was abandoned and everything that could leave, was burned, including ships like the 120 gun Pennsylvania, the frigate Merrimack, and others. The sloop of war Cumberland was towed out by a pair of tugs, and escaped. Sent to Boston for repairs, her aft 10 inch Dahlgren was replaced with a 60# Parrott on a pivot carriage. Some reading suggests Buchanan, commanding the former Merrimack, now Virginia, targeted the Cumberland, specifically because she was known to be armed with a rifled gun. I found a reference to that gun in this commemorative item on an auction site. That item aside, I have no clue precisely what her pivot carriage looked like. So I used the carriage from my model of the IX Dahlgren pivot, altered a little to fit the very skinny Parrott rifle, so here's my take on the Cumberland's famous aft pivot. The STLs for both these models have been posted at Thingiverse for those interested. -

3D Naval Guns 1850s ~ 1870s

JerryTodd replied to JerryTodd's topic in CAD and 3D Modelling/Drafting Plans with Software

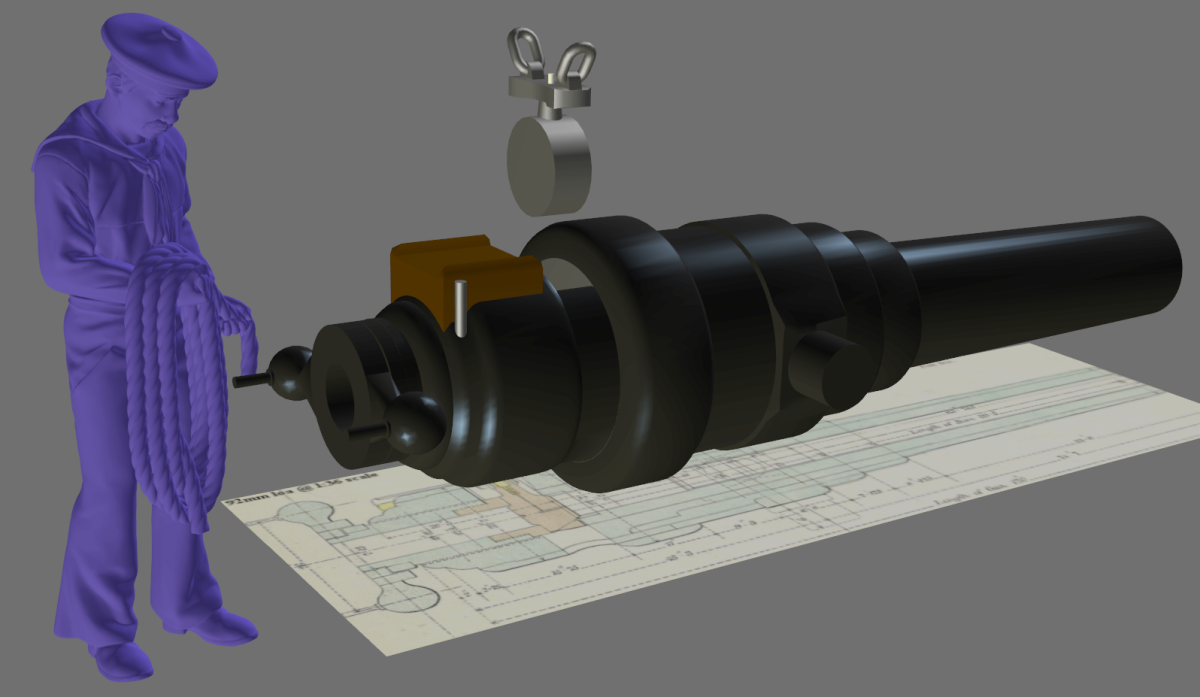

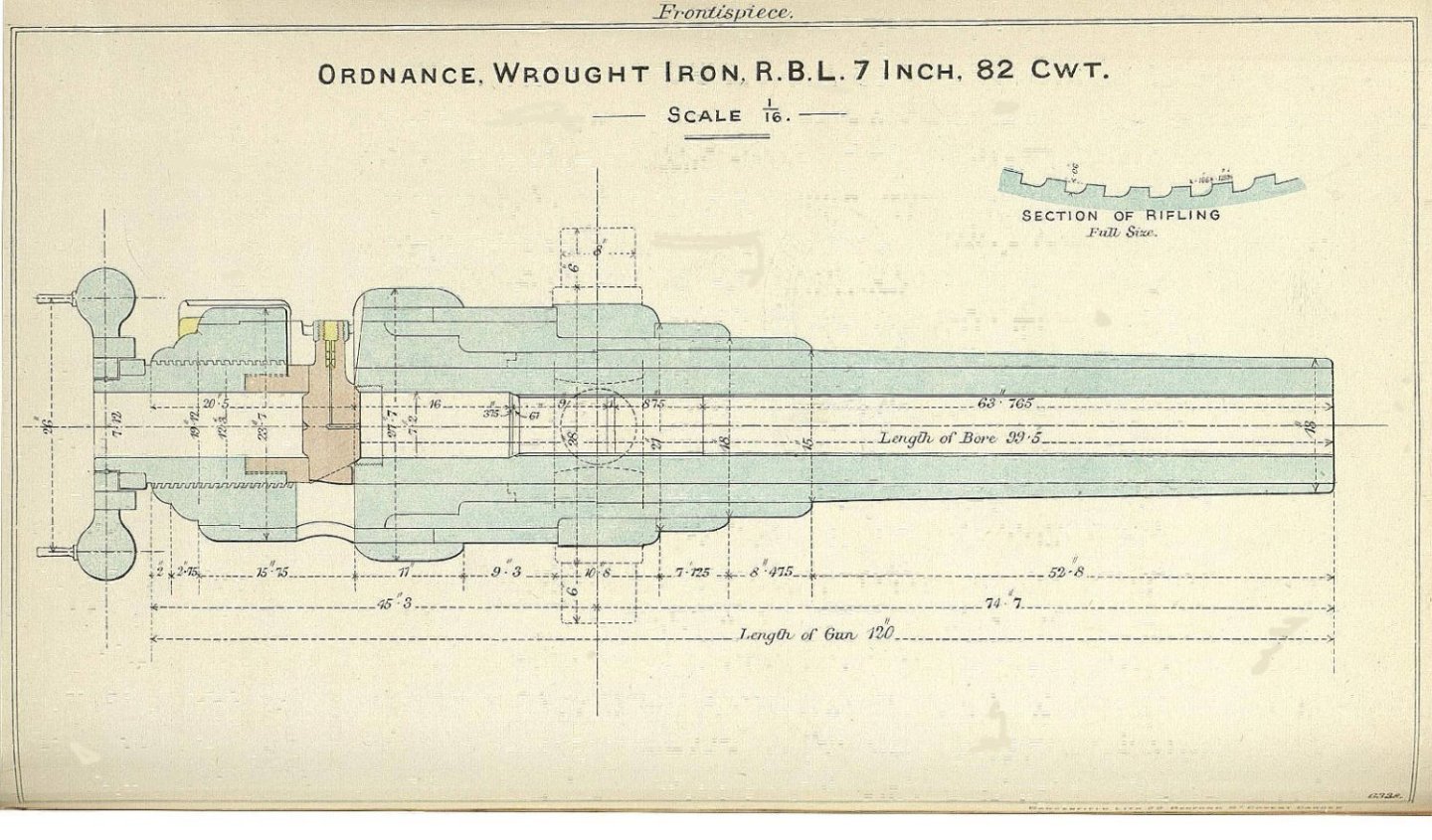

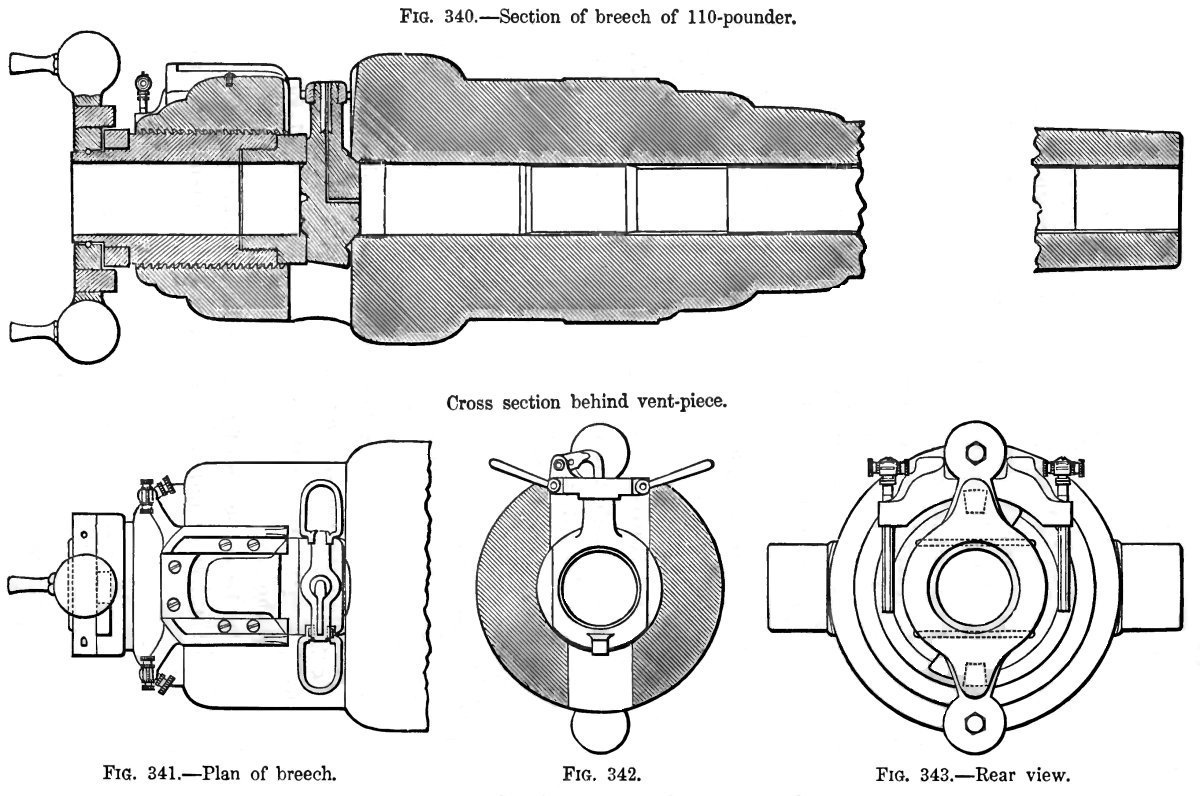

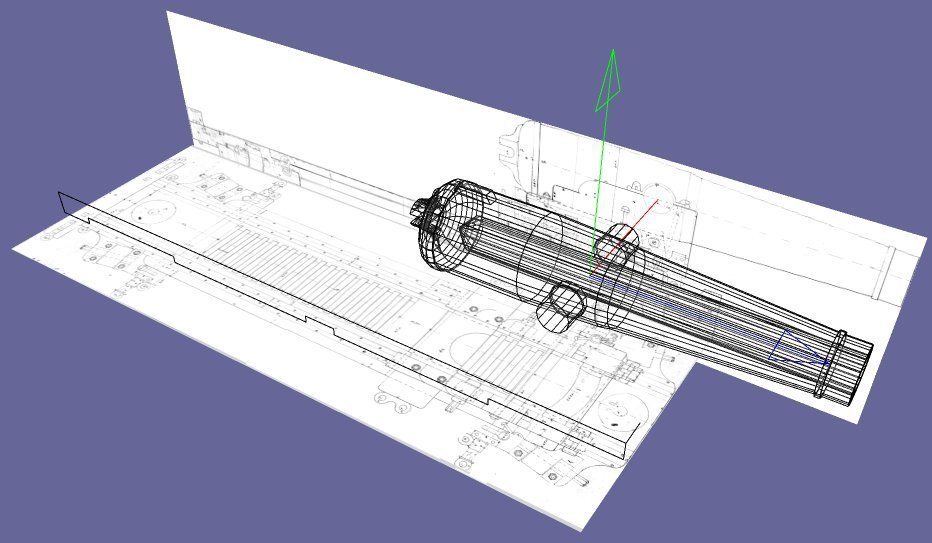

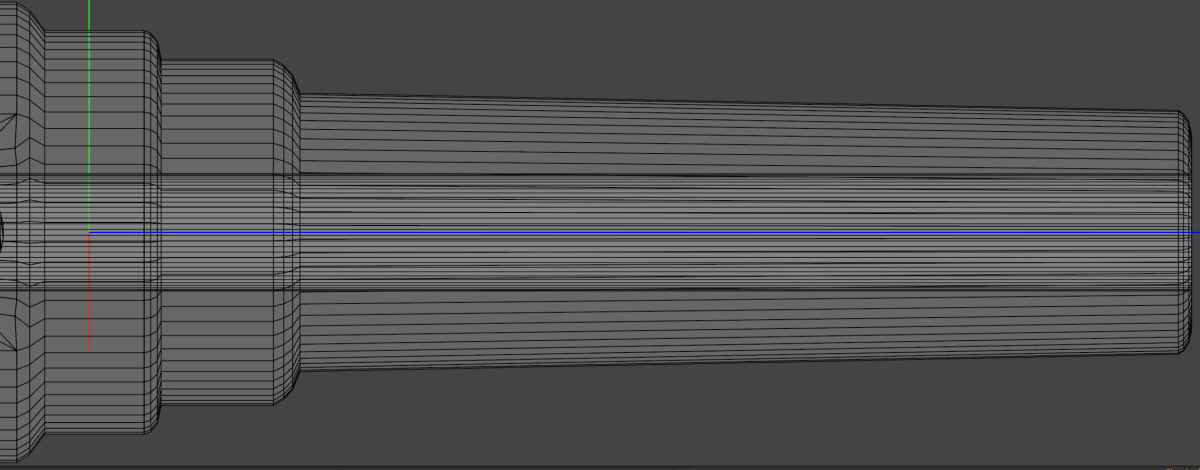

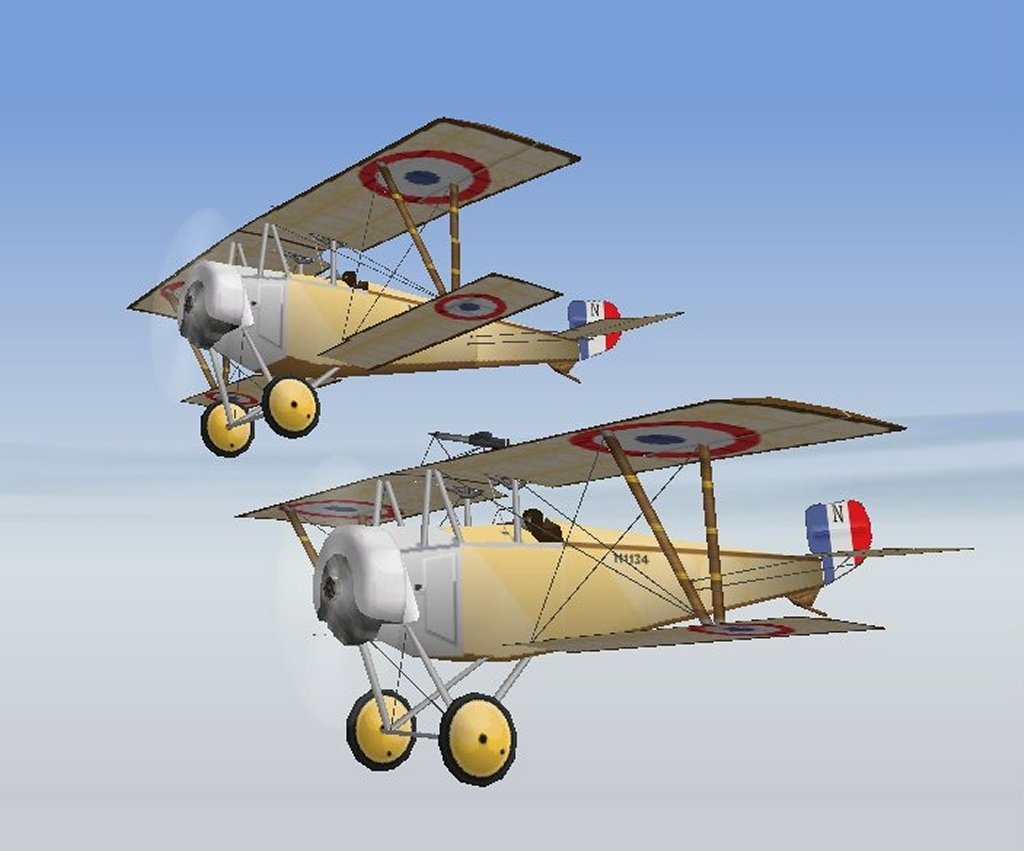

I got a pm on Thingiverse requesting a 7 inch Armstrong breech-loading rifle. I tried to brush it off with "I'm only doing Naval weapons, not fortress or shore batteries," and it was pointed out that HMS Warrior mounts several of these pieces, albeit in fiberglass. It turned out to be interesting enough to want to model, but like everything else so far, getting really solid data to work from was a real pain. Being a British piece, I was surprised by how hard it was to find data, and that on the tube only. Like the American guns, there's even less data to be had regarding carriages and mounts, that is till the 1880's and later, you know, guns I'm not looking for. Anyway, this was the best drawing I was able to find, while the next one helped me wrap my head around the breach mechanism the best, except I didn't find that till I'd pass the model to the requester already. I do the tube in Anim8or starting with what it calls an N-gon. You specify how many points you want and pull what's basically a circle from the center out to the diameter you want - ish. I typically start with 64 points. Then I extrude or extend this into a cylinder with as many segments as the gun has sections, plus a few. I build the gun (or whatever object I'm modeling) in front of one or more Reference Images, as you can see I used with the 10" shell-gun shown in wire-frame. This isn't CAD software, so don't look for measurements. Since then, I smooth the cylinder once or twice, before I start shaping the gun. This gives the object more, but smaller facets, making it look smoother. Notice that faceting on the rear gun's tube compared to the foreground gun's. When I was making airplane for a flight sim back at the turn-of-the-century, using this software, more polygons (facets) meant more work work and memory for the flight sim, so I got in the habit of being frugal with my polygons. I don't need to do that here, and have to remind myself not to. The smoothing does weird things at bends and corners, so I do it before shaping the cylinder to the gun. That includes the ends of the cylinder, so I cut those off like some folk toss the heels of a loaf of bread. I move and resize the segments of the cylinder to each section of the gun's reference image, but on guns like this Armstrong, each section is made of several segments; for instance, the muzzle end of the gun is a ring for the muzzle, a ring for the outer face, the corner is usually chamfered a bit so there's a ring, or two, or more, each a little larger than the one before to make the transition from the flat face of the muzzle to the body of the gun depending on how rounded this corner is. Where the first bulge rounds up from the taper of the barrel takes 3 or 4 segments to make it look rounded, as you can see in this wire-frame view of this same gun. I did this down the length of the tube until it looked like it was supposed to. Sometime I needed to insert or add rings/segments (this gun just ate them up with that Michelin Man shape) and I used a knife tool to just cut a new one near where I needed it, and moved and resized it as usual. This is actually the easier part of modeling a cannon. It's the asymmetrical and added on bits like that box shape at the trunnions that make things interesting. Eventually I got the gun to look right, though it took some time to figure out the breech. Again, none of these models will have moving parts or be functional, and since almost all of them are muzzle-loaders, that's not an issue, but I couldn't resist making the breach-plug removable, or printing one for myself. Yes, the handles on the balls got snipped off after printing, my goof; and no, it's not rifled. The hole for the breach should actually go all the way through. It's a little small at the bottom to make a ledge for the plug to sit on. The way I modeled it, a puddle would form every time they swabbed with no way to drain it. I'll fix the model when I make a carriage for it; one of these, or both? -

3D Naval Guns 1850s ~ 1870s

JerryTodd replied to JerryTodd's topic in CAD and 3D Modelling/Drafting Plans with Software

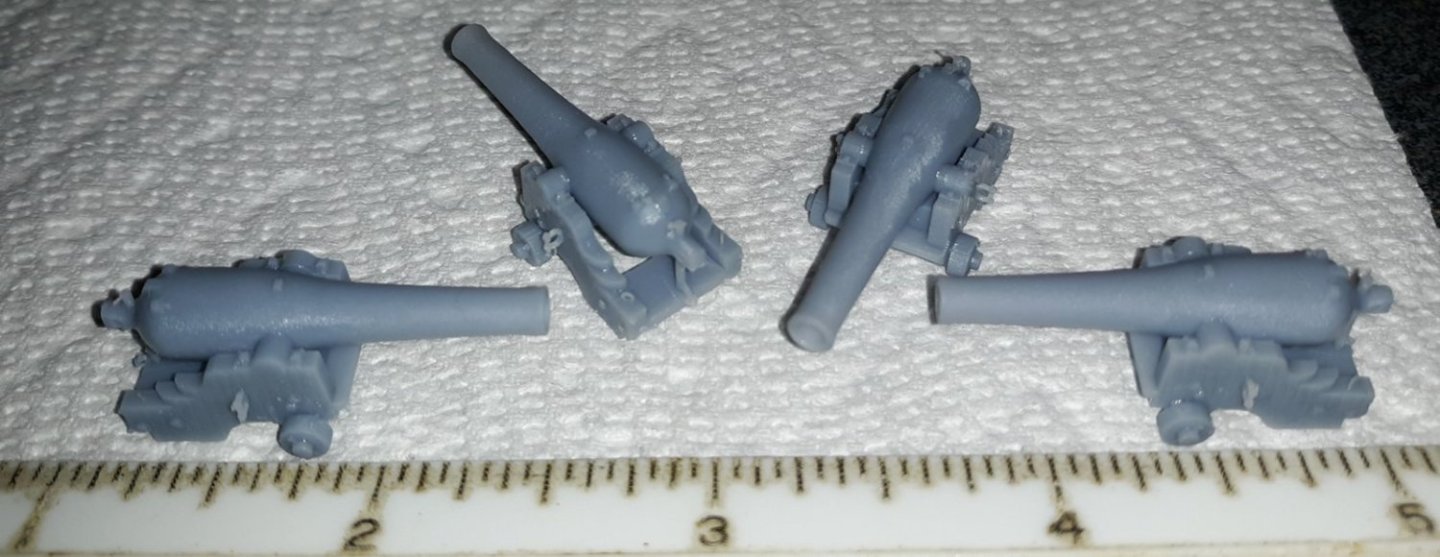

Helping out another modeler with 3D printed guns for his 1:96 scale model of the Harriett Lane I started researching and 3D modeling the guns he would need. In the mean time, I got the idea to make a sampler of one of every gun Constellation ever carried from 1855 to 2024. Those I would print in the model's 1:36 scale and mount on a plank or something to put on display with the ship when I took her to events. Chuck's wanted his model of the Lane to carry the armament she was captured with at Galveston in 1864; which according to Phillip Tucker who was on the ship, and who was published in the Southwestern Historical Quarterly in 1918. as saying: A four-inch rifled Parrot is a 30# Parrott on a pivot carriage; two eight-inch Dahlgren Columbiads folks interpret as being 9 inch Dahlgrens on Marsilly carriages, though there was such a thing as an 8 inch Columbiad, even 8 inch shell-guns. The 24# howitzers seemed pretty straight forward, though I interpret "ship carriages" to mean boat-sleds in their case. Someone made a nice graphic of how they thought this armament may have been organized on on the Lane. My question though, was why they show a 10 inch Dahlgren pivot, when Tucker said it was a 9 inch gun. I found a photo of a 9 inch Dahlgren on a pivot mount on board the Miami (often IDed as the Mendota) that showed it existed and that the 9 inch had it's own carriage, and not just a scaled down XI inch carriage. The Lane's armament was thrown over-board when the ship went aground at Pamlico Sound in August of '61 and she was repaired and rearmed back at Hampton Roads. The 10 inch Dahlgren wasn't as common a gun as the IX's or XI's and those in existence were already on the frigates and razeed sloops, except for one taken off Cumberland at Boston and replaced with a 60# Parrott. Leaning toward Tucker's statement, I started the 3D model of the IX gun tube, and while trying to discern the pivot carriage from the Miami photo, went ahead making the tube and the Marsilly carriage. Of all the Naval guns of the American Civil War, the IX Dahlgren on a Marsilly carriage, and the XI Dahlgren on it's designed for it pivot carriage, are the easiest to find data and images for. The IX was modeled in just a couple of hours. I'm doing these as static models, so I'm not concerned with wheels turning, or guns elevating. I printed 4 of the guns, 2 for the Lane with 2 spares, in 1:96. In the 1870's, Constellation was a training ship and armed with 8 of these guns, so I printed one at 1:36 for my intended display. In my drawing software, using the photo as a reference; I scaled the tube in the photo to the length of the actual IX tube and traced the carriage to get the right proportions, since I didn't have a measured drawing like I did the for Constellation's 10 inch shell-gun pivot. The slide is that from the XI Dahlgren carriage. Once modeled, I printed one off for the Lane. This one wasn't on my list of Constellation guns, so I didn't need to print one in 1:36. The Lane, still needed the 24# howitzer, which I had usable data for; and a 30# Parrott pivot. Constellation, during the Civil War got a 30# Parrott forward, and a 20# Parrott aft, to replace the 10 inch pivots that were removed in 1859. I managed to find drawings online for the 20 and 30 from the Navy's Bureau of Ordnance that made sure I had the tubes accurate. Years ago I visited the Constellation and met with the folks running the "restoration." One of the things they showed me was a drawing of a 30# Parrott on a pivot carriage. I was modeling Constellation as she was in 1856, so didn't figure I needed plans for a gun she got in 1862; but I took some photos of the drawing anyway. Now it turns out I did need them, and just had to find those photos. Once found, it turns out I had good data for the carriage itself, but not much for the slide. In the mean time, I got started on the 24 pounders. Using the gun tube from the boat-howitzer, I scaled it to the size of the 24# version, and scaled my reference image to that to get the proportions right. Then I printed 4 of them in 1:96 for the Lane. When the 3D model of the 30# Parrott was done, I printed it in 1:96; and since Constellation had one, in 1:36. One the guns for the Lane were all printed, I boxed them up and mailed them off. I cranked out two guns that made up Constellation's original broadside; the 8 inch shell gun, and the 32# gun and printed them in 1:36 scale. I now had 4 of 11 types of gun Constellation had, printed. While posting the STL for all these guns on Thingiverse, I got a request for something a bit off the track. -

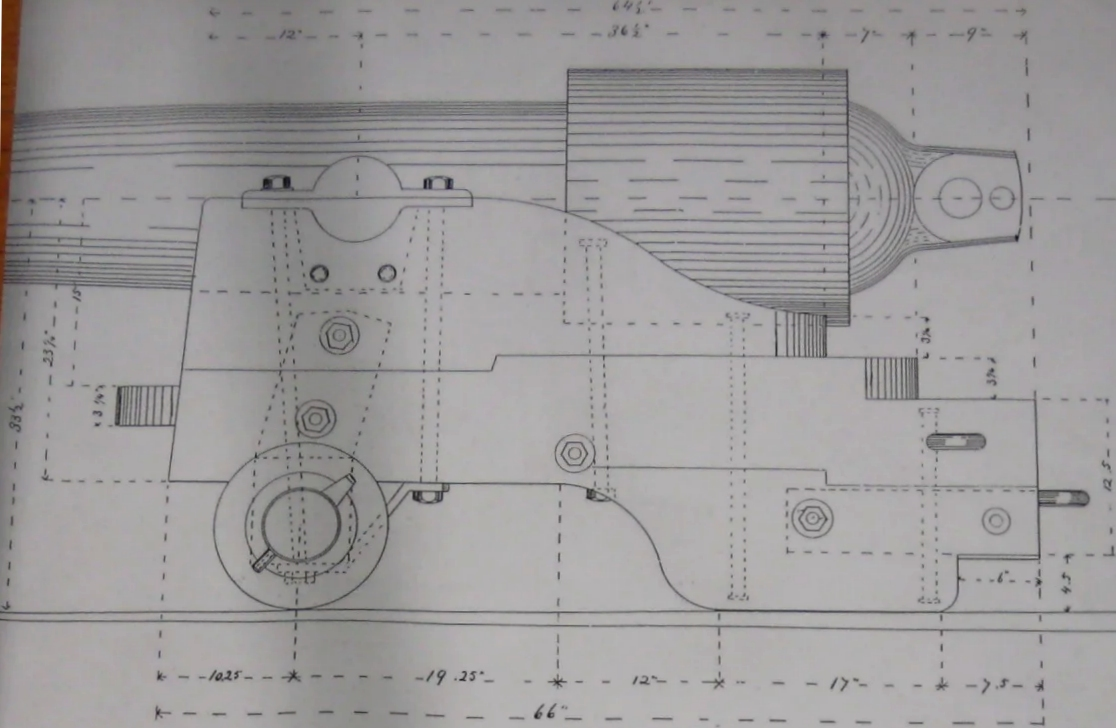

When 3D printing became available to me, I went to work on creating 3D models of the parts I'd need for my models (all linked in my signature below). Even before 3D printing was "a thing" I started a model in Anim8or* of Constellation's pivot guns. Just a basic model at first, but when I actually got a 3D printer, details were added to the model. I had built the basic model in wood with the intention of learning photo-etch to detail them. 3D printing negated that entirely. The guns were modeled to a plans for the 10 inch shell-gun pivots for Mississippi that were acquired from the National Archives in College Park Maryland. (click the pic to see full-size)... It took a couple of tries, but I managed to get a pair of pivot guns that if not perfect prints, were usable, and with more and better detail than I could have managed by hand. The next gun needed for Constellation was the boat-howitzer for her launch. Working mainly from the images in Boat Armament in the US Navy 1856, and any drawings and photos I could find online, I based my model on an existing boat-gun located in Fairfax Virginia with iron wheels. Despite the spindly looking nature of the gun's field carriage, it was actually quite a fun model to make; lots of circles. Once printed, and painted, it took it's place in Constellation's launch. Much later I felt the wooden wheeled version was probably more appropriate for Constellation in 1856, so I added a set of wood wheels to the model howitzer. Since I didn't model Constellation's gundeck, I didn't need to make the 16 8 inch shell-guns and 4 32# guns that would require. I did model a 6# gun in 1:20 scale for Pride of Baltimore, and started on 18# Blomefields and 32# carronades for Macedonian. But that's getting off-topic... * Anim8or is free 3D modeling software that I used back at the turn-of-the-century to make 3D models for a WWI flight sim/game. I use it today because I'm used to it after two+ decades, though either it or I aren't capable of doing some of things I want/need to do. I can't recommend it to complete novices, but It's still available at anim8or.com.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.