Search the Community

Showing results for tags 'Ship in bottle'.

-

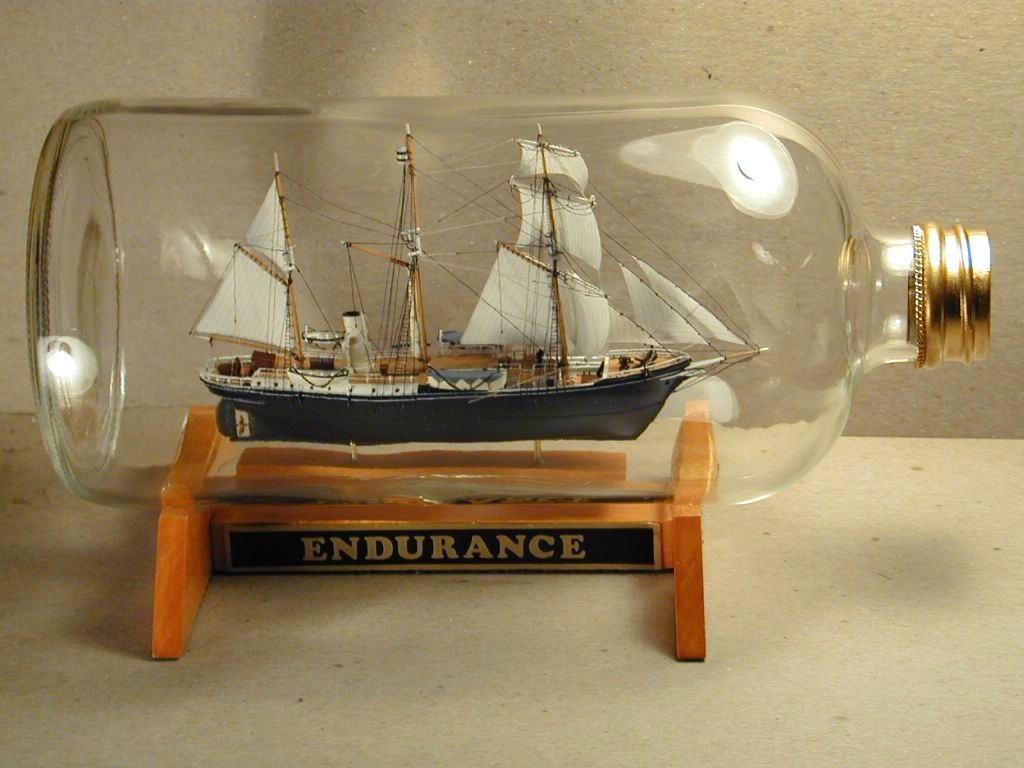

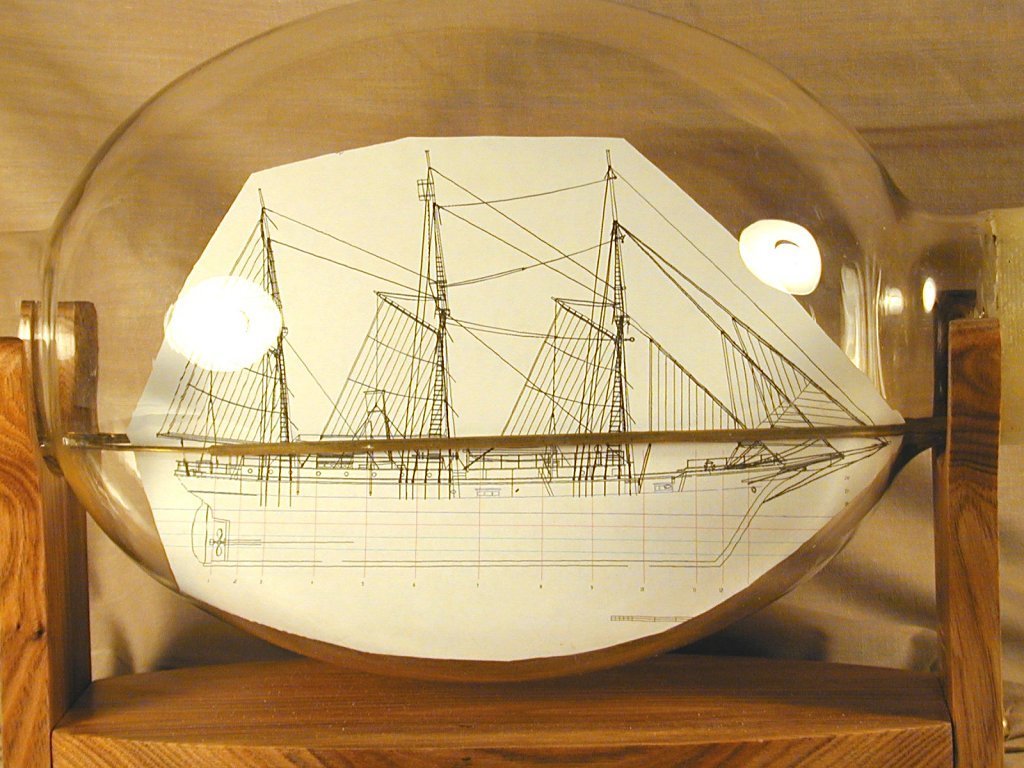

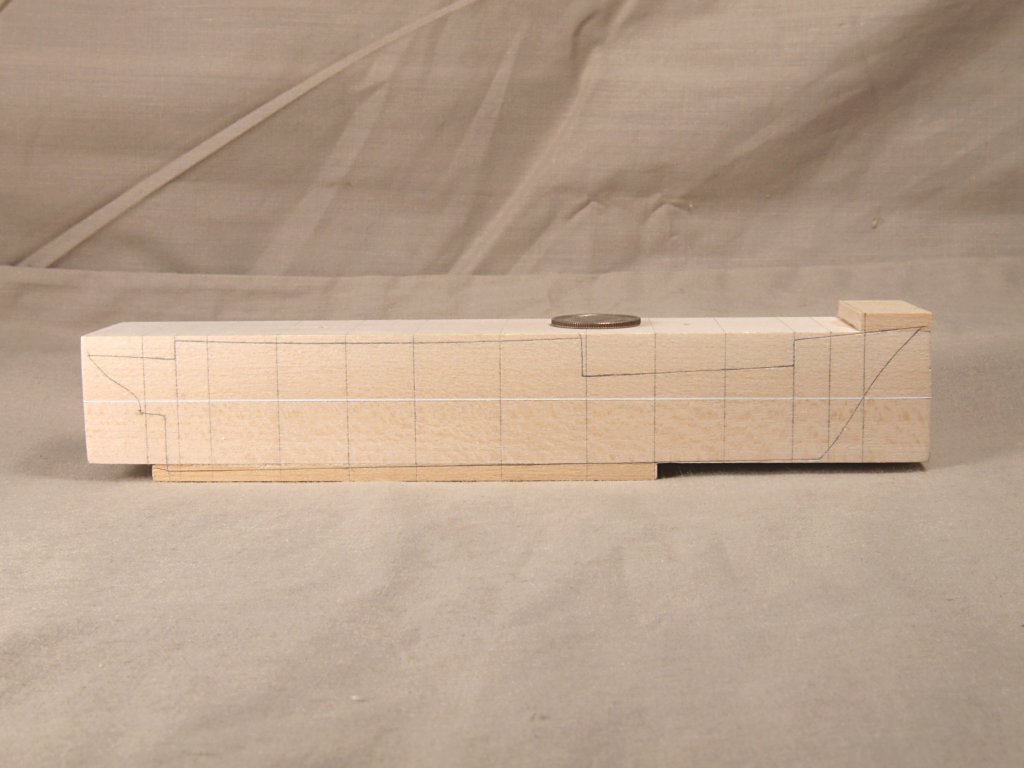

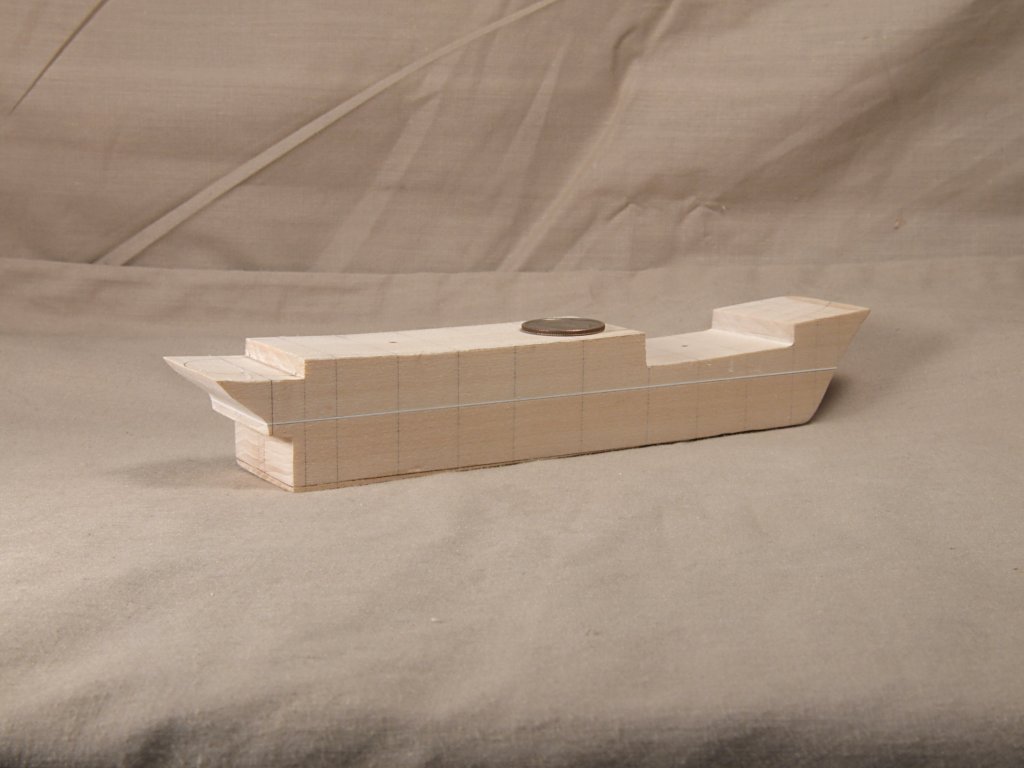

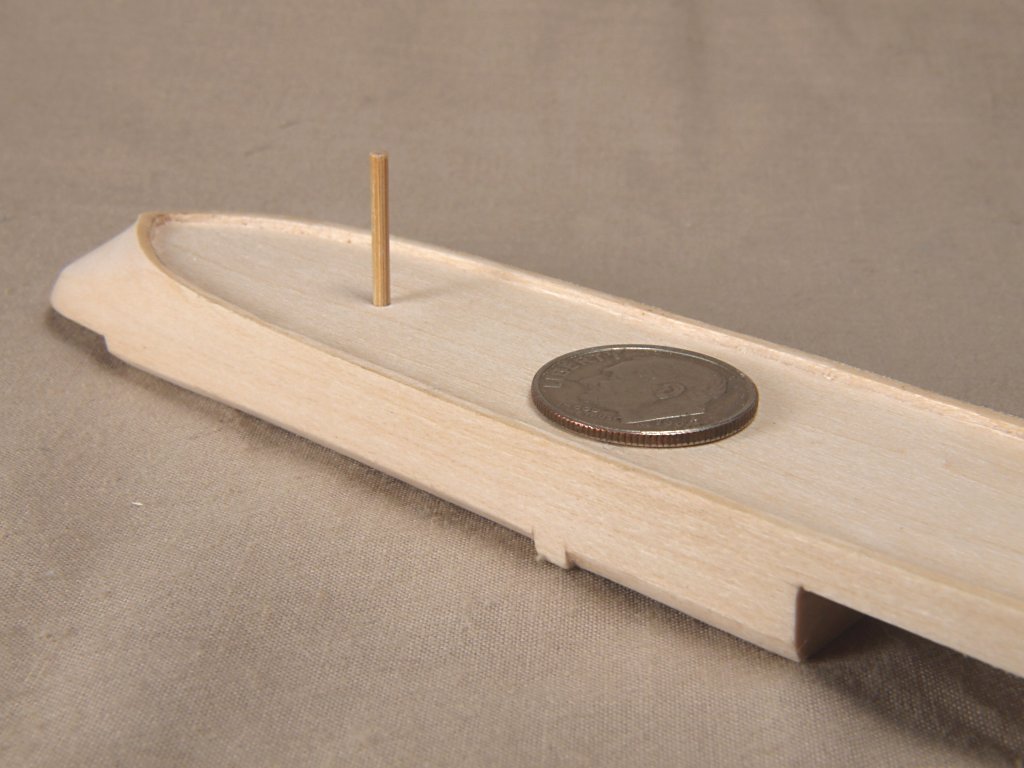

This is a log of the building of Endurance I constructed around 2001. A previous series of models were done at 1:350 as ship in bottle models. The first photo shows one of those. Most of this build log will be photographs taken while building the larger model, which was put into a sodium vapor light bulb with the end cut off. I will be happy to answer any questions. Endurance History The Polar Wooden Screw Yacht “Polaris” was built at the Framnaes shipyard in Norway, possibly in 1899. The Polaris was a 300-ton wooden barquentine, and never sailed under her maiden name. She was 144 feet long, built of planks of oak, and Norwegian fir up to two and one-half feet thick, and sheathed in greenheart, a wood so tough that it cannot be worked by conventional means. Polaris was built at a time in history when much of the world’s attention was focused on exploration of polar regions, both Arctic and Antarctic, with many expeditions from various countries attempting to reach the North and South Poles. One of the early explorers during this Heroic Age of exploration was Ernest Shackleton. In 1914 Shackleton proposed an expedition to cross the Antarctic continent, his expedition would require two vessels, one to take the men, equipment and the sled dogs to the Antarctic continent, and one to take men and supplies to the opposite side of the continent where they were to lay supply caches. Polaris was the vessel Shackleton purchased for the outward voyage, with an ex-sealing vessel, “Aurora” being obtained as the second vessel. He changed the name of Polaris to “Endurance”, after his family motto: “Fortitudine Vincimus - by endurance we conquer”. After much preparation, Endurance left her dock in London on August 1, 1914. The exact same day war was declared between many European nations, and World War I was begun. Endurance had not yet left British waters when the mobilization orders were sent out, so Shackleton offered his crew and ship for the British government's wartime use. The Admiralty decided that his Imperial Trans-Antarctic Expedition should proceed. Endurance set sail from Plymouth on August 8, 1914 on her voyage into history. Endurance sailed to Buenos Aires to pick up crew members and sled dogs and then sailed to South Georgia on November 5, spent a month re-provisioning while at this station and left Grytviken’s Cumberland Bay on December 5, 1914. Endurance sailed only two days before encountering the first pack ice. Endurance worked it’s way through pack ice for two weeks, passing many large ice bergs along the way. The ice and weather conditions worsened from about January 24 onward, and at times the crew would debark and attempt to chisel pathways themselves. By January 27, 1915 the ship was stuck fast in the ice. The fierce southern winter weather was causing further concern for all, as gales blew the pack ice into moving walls of destruction. The crew watched helplessly as huge chunks of some of the pack ice were moved and shoved into amazingly high stacks. In some cases the buildup of pressure would accumulate for a length of time causing massive ice movements in very little time when the pressure was finally released. For those living aboard Endurance it must have appeared all too clear what the gallant ship’s fate was going to be. The terrible winter weather continued for many more months. Endurance, and it’s crew, received both a great relief, followed by the worst moment in the voyage so far around the 10th of October. At that time the ice started to break up, and a new lane opened up that everyone thought had a chance of being navigated. This breakup was followed however by a severe wind, which piled the pack ice up beneath Endurance and lifted her above the water. The gallant ship was then heeled over on her port side by 30 degrees, before righting again when the pressure reduced. On Sunday October 24th Endurance was severely struck in the stern by no less than three pressure ridges of ice. The ship was listed over to starboard 8 degrees, and the stern post nearly twisted out of the hull. The vessel started leaking badly, and the steam engine had to be kept running to keep the pumps working. At 4:00 p.m., October 27, Endurance received a heavy blow, which knocked it’s stern higher, and completely tore away the rudder and stern post, the keel was ripped out and the water poured in. Shackleton and his crew lived on the ice nearby the Endurance for nearly one month before the ship met it’s final end. This came for Endurance on the evening of November 21, 1915, when the vessel rose by the stern and then slid down into the water. The Imperial Trans-Antarctic Expedition ended with the loss of Endurance, though Shackleton and his entire crew survived and were rescued. Ship In Light Bulb Model of “Endurance - Construction Ship in light bulb models have certain construction differences from static display models. The first consideration for construction of such a model is that the model, or it’s individual parts, must fit through the neck of the light bulb. For the Endurance model the type of construction used by this builder required that the finished upper hull of the model, including all masts, yards sails and all rigging lines, be able to be collapsed small enough to pass through the bulb opening. The lower hull and model base are separate pieces, that can be passed through the neck of the bulb individually. The base is then glued to the inside glass surface, then the lower hull is glued to the model base, the upper hull is then glued to the lower hull. A laminate block of basswood is made up and used to carve the hull. The upper hull is a single piece of the wood, the lower hull is three separate pieces glued together. The lower hull has a thin piece of wood in the center, flanked by two wider pieces, making the whole as wide as the upper hull piece. The two hull parts are held together by drilling a pair of holes, and tightly fitting bamboo pegs into the holes. At the time of making up this “hull block sandwich”, a sheet of styrene plastic is placed between the upper and lower hulls, representing the waterline of the hull. The hull shape is then carved out of this sandwich of basswood and plastic, using the thin center strip of the lower hull for the keel location and to mark the locations of the cross sections from the body plan. The styrene sheet waterline is also used as a guide for the templates made from cutting out individual cross sections from multiple prints of the body plan. This method of hull construction also allows the hull to be separated to make painting of the hull of the model easier. An air brush was used to apply the paint, and a protective sealer coat, to the hull parts. The scale of the model is 1:400, so some of the smaller detail trim was simplified. In order to make the upper hull small enough to fit through the bulb opening, the superstructure must be built in such a way that it is able to be collapsed. In order to do this, the masts have hidden hinges built into them. This allows them to pivot backwards, lowering their tops and all the sails and yards attached to them. All the square sails, and yards, on the fore mast must be attached to the mast in such a way that they can rotate parallel to the mast along the length of the hull, so that they too will fit through the opening in the light bulb. The Endurance model’s hidden hinges are carved into the masts by making a lower piece that has a two pronged “forked” top that fits around a single center stem on the lower end of the upper mast piece. A simple drawn down bamboo pin is then inserted into a hole drilled through the center of the overlap, where the upper mast piece fits into the fork of the lower mast piece. This allows the masts to break at a point well above the deck of the model, which was critical with the cabin structure directly behind the fore mast. All the spars for the Endurance model were made from glued laminates of maple veneer. The resulting glued joint helps to strengthen the thinner spars, allowing the necessary rigging line holes to be drilled without splitting them. Pieces of veneers of maple are glued together, then strips are cut from them. The strips are then “spin-sanded” down to nearly their largest diameter, by chucking them into a Dremel moto-tool and using folded sandpaper pinched around the spinning mast blanks. Final sizing and shaping of the spars is done by hand sanding. Any necessary holes in a spar are drilled before the hand sanding, when the spars are a bit larger in diameter. This laminate structure for the masts made it much simpler to carve the necessary parts of the hidden hinges in them. Most of the rigging lines on the Endurance model are working, or control, lines that are used to bring the masts up into their raised positions. Control rigging lines are also used to pull all the sails, booms and gaffs into correct position after the masts are raised. Most of the control rigging lines are rigged and worked the same as the actual running rigging lines on the real vessel.. All control rigging lines run through holes in the bulwarks, a fife or pin rail, the bowsprit or some other spars, before finally passing through the hull at the deck or other location. The control lines pass through the hull into a hollowed area carved into the underside of the upper hull. This allows the lines to pass forward from their entry point and out through the hawse holes on either side of the bow. The model was assembled inside the light bulb, with the ends of all the control rigging lines left outside the bulb. Several rubber bands are then wrapped around the lines and the neck of the bulb. This keeps the lines taught after they are tightened to pull the various parts of the model into proper final position. At every accessible point that a control line passes through a spar, a rail or the deck of the hull, a tiny amount of glue is applied to hold the line in place, once the lines are taught. When all the glue had dried, the excess control rigging lines were cut off as close to the hawse holes as possible. The small amount of these lines that remained were stuffed back inside the hollowed area beneath the upper hull.

-

Has any one threaded the sails on for this kit? According to the diagram in the instructions, it looks as though they are threaded on the ends.

- 1 reply

-

- ship in bottle

- hannah

-

(and 2 more)

Tagged with:

-

I've been doing some research and interviewing some older ship in bottle builders and thought I'd open this discussion up on this forum. I'm gathering information on how some of the first ships in bottle were built in hopes of using the same materials tools and techniques and documenting the experience through a build log and my blog. It seems to me a lot of this information is fading in time or at the very least hard to find. I'd like to contribute another source to make it that much easier to find and keep it alive. Here's what I have so far. Wood used was mainly pine. While not used for actual ships it had a lot of other purposes and was widely available. Hulls were often thinner then what would be scale. Segmented hulls were not often if ever done in older ship in bottles. I have heard of old ships in bottles being made from bone as well. Masts and yards were made from either splintered wood or match sticks. Both would have likely been sanded down with dry sharkskin. Glue was made from different fish parts boiled down. There's youtube videos on this I'd have to dig around for them again though. Thin thread may have been hard to find but wax from candles could have been used to strengthen pieces enough to use. Don Hubbard had a thought that Baleen from whales could have been used for thread but there's no way to know for sure. Sails were not common among old ship in bottles because they were harder to do. Usually the ship was just shown with the bare yards. When it was done they used paper or some times wood shavings. Sea is tricky and I think it depends on the time period. Michael Bardet suggested that seas were made of wood in old ship in bottles. I've seen some of the old ships he restores, some as old as 1895, and have seen how that was done. His work is incredible I highly suggest seeing it. http://michel.bardet.pagesperso-orange.fr/indexa.htm Other methods for sea was some kind of putty with pigment in it. Don Hubbard theorizes that green copper oxide could have been used as well. As far as bottles I found an interesting idea from an article by Louis Norton. He says that most alcohol would have been transported in wood barrels on sailing ships so the bottles used were more likely medicine or spice bottles. I wouldn't doubt that a sailor would keep a clear liquor bottle he picked up in port though. Most of the old bottles I've seen have mostly been wine bottles. I've looked around a little bit in regards to tools. Sailors definitely had knives and this would have been a primary tool. Other things I found were surgical scissors and Sail Awls. Tweezers or forceps could have been carved out of wood. I'm not sure yet on drills. Don Hubbard uses a technique where you sand down a needle and use it as a drill. This may have been the tool used. Shark skin for sand paper. From what I can tell sailors were quiet resourceful. Just about anything and everything could have been used. I'm sure there's ideas I haven't thought of or possibly books I don't know about. If you have any ideas please post them.

- 2 replies

-

- Ship in Bottle

- Bottle

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.