Search the Community

Showing results for tags 'lugger'.

-

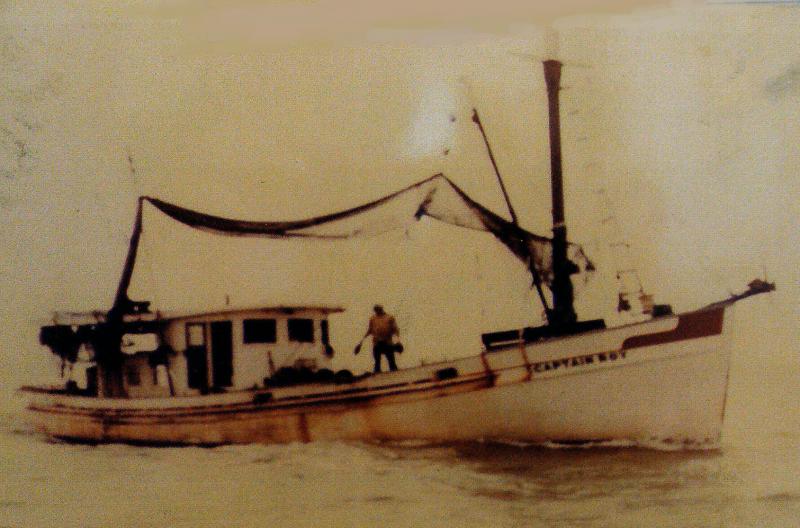

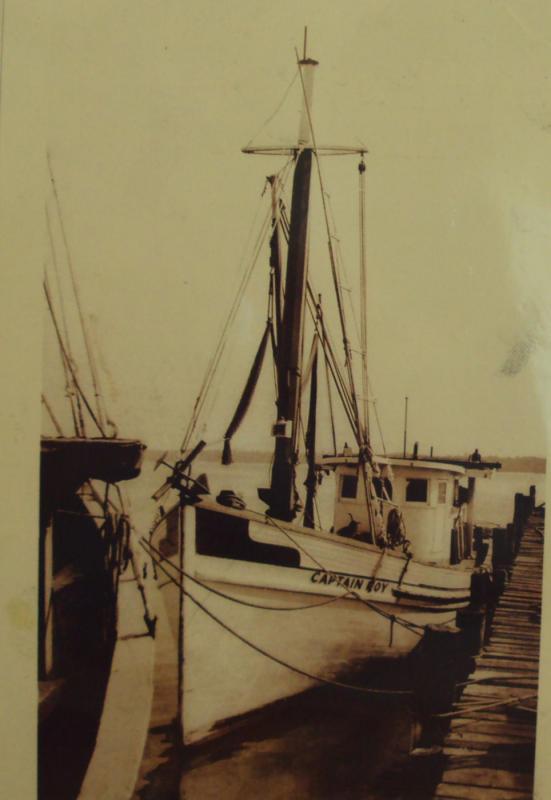

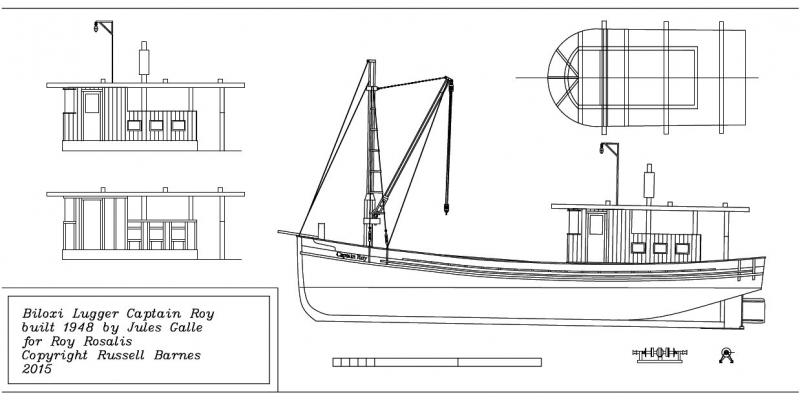

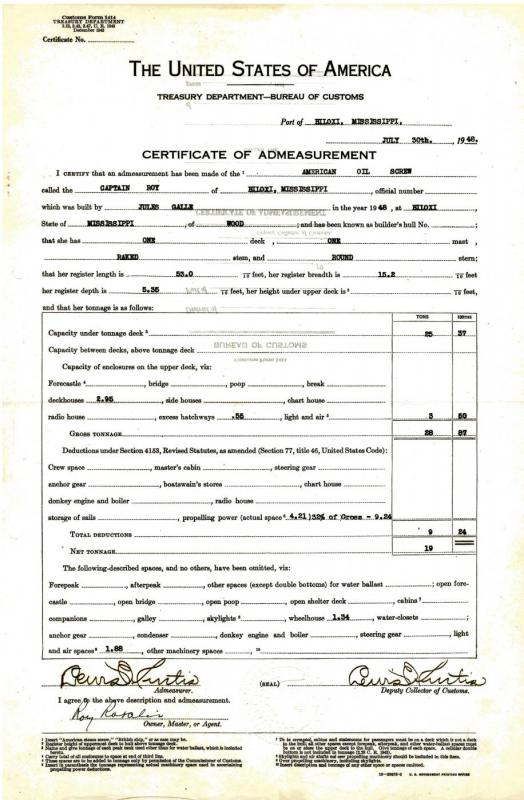

Hello everyone. I am starting a new project. This is a 1/48 scale scratch built model of a Biloxi lugger named Captain Roy, built in 1948 by local builder Jules Galle'. This was one of two identical luggers he built that year for Roy Rosalis, owner of Biloxi Canning Co. The other boat was named Boston Bill. I have used tonnage admeasurement data and photographs to reconstruct the lines and details for this model. Here are two photographs; one is a rather poor copy, and a bow view. I also include the outboard view from my plans so you can see the finished model's appearance, and her original certificate of admeasurement showing her dimensions etc. Russ

- 420 replies

-

- shrimpboat

- lugger

-

(and 2 more)

Tagged with:

-

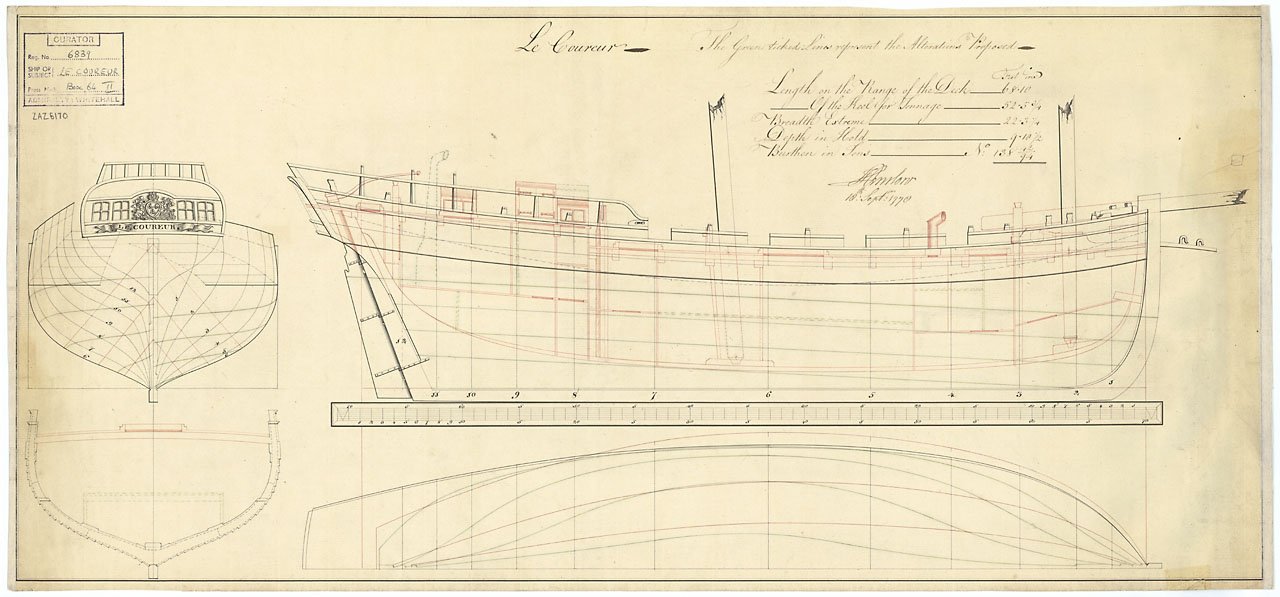

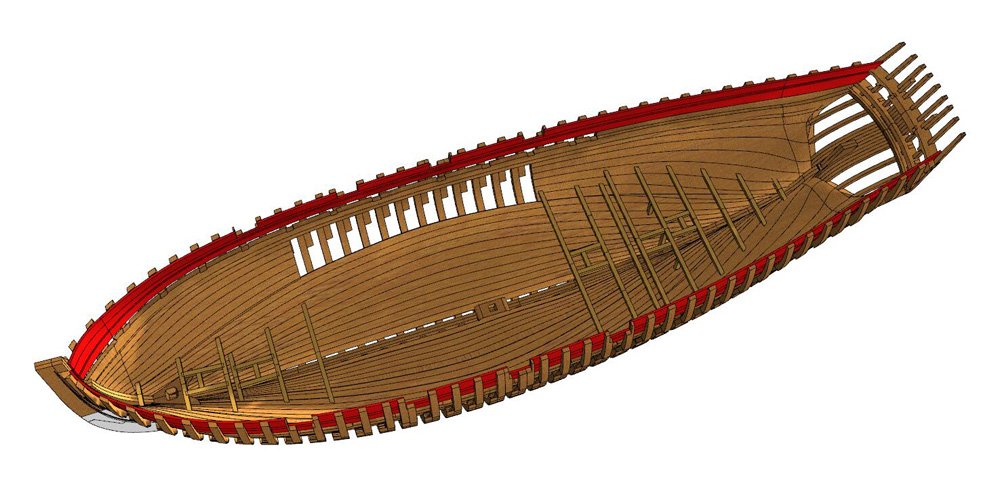

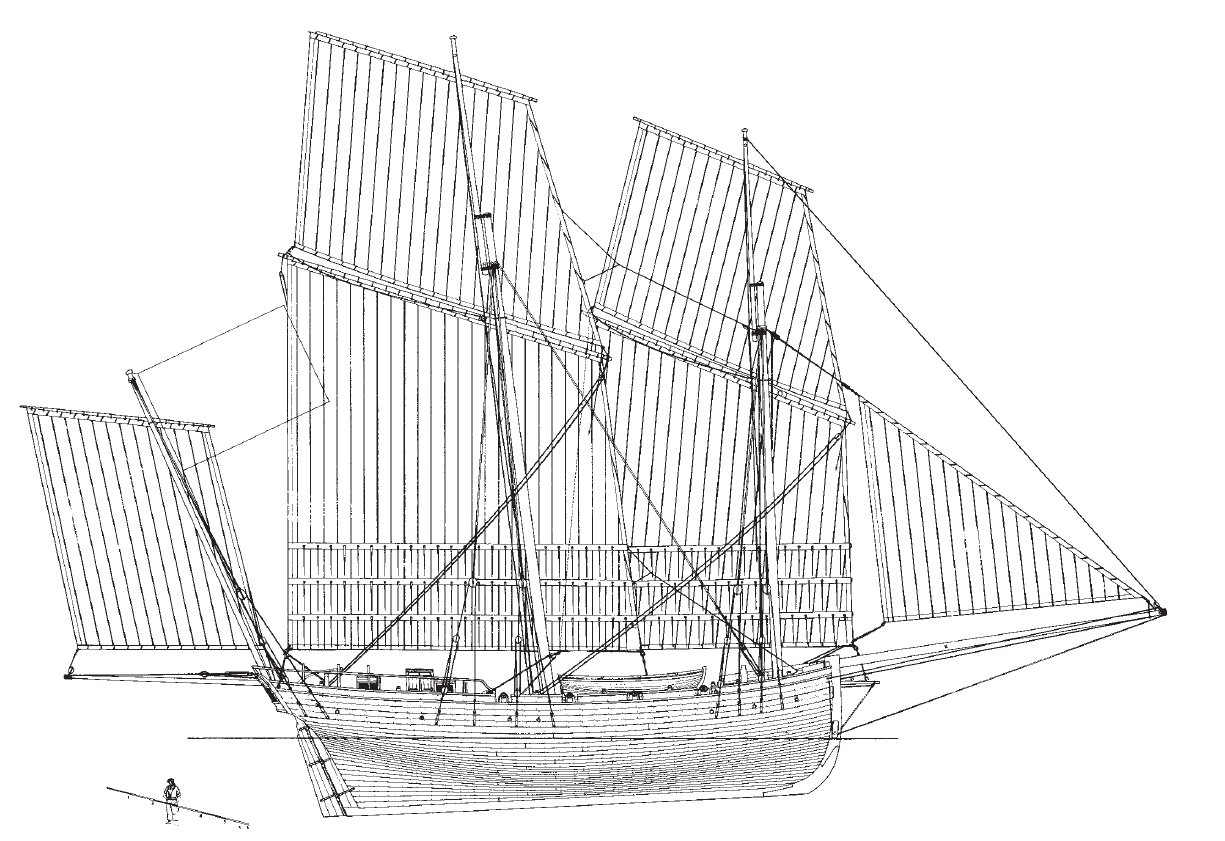

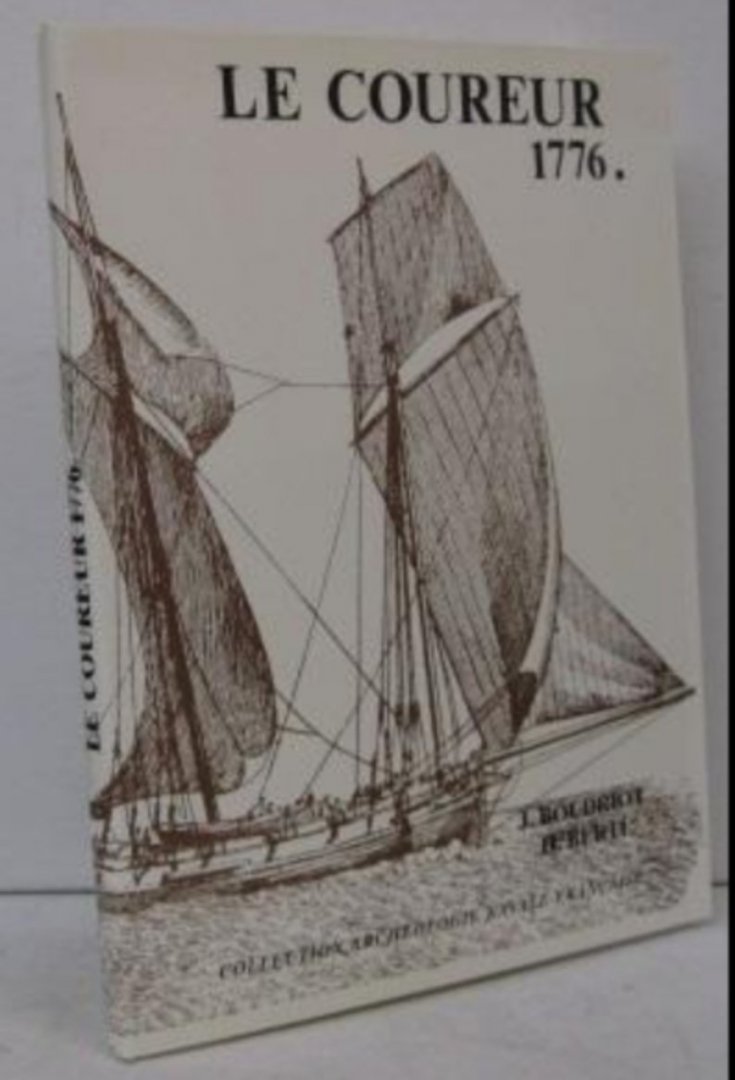

Hello model shipbuilders! Here is my latest build log. I started this project early last year and now I decided to share it with you. The build is based on Boudriot's monograph "Le Coureur". There were several things I found very interesting when I decided to build this model: the sail plan the clinker planking of the hull - I've never done one before and the acceptable size and complexity I plan to do a fully rigged model. Everything will be scratch built except the guns and the gun carriages which were bought from SyrenShipModelCompany.com

-

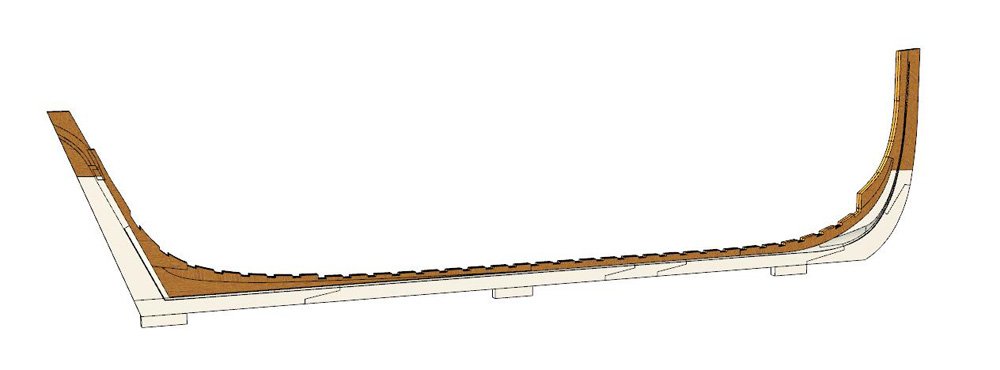

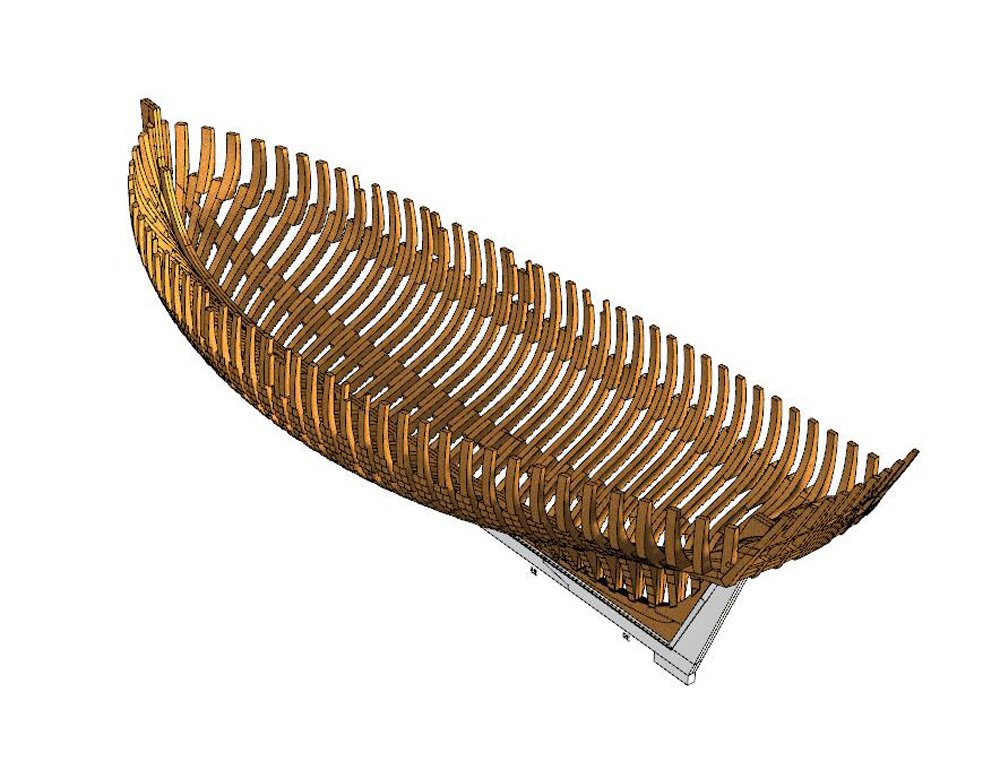

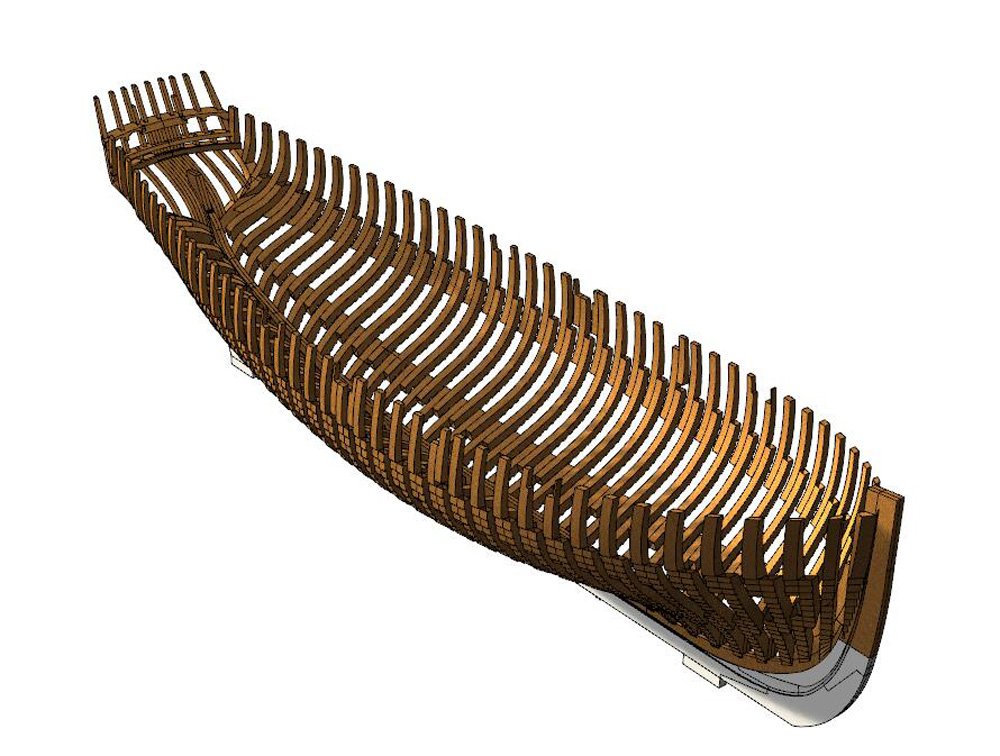

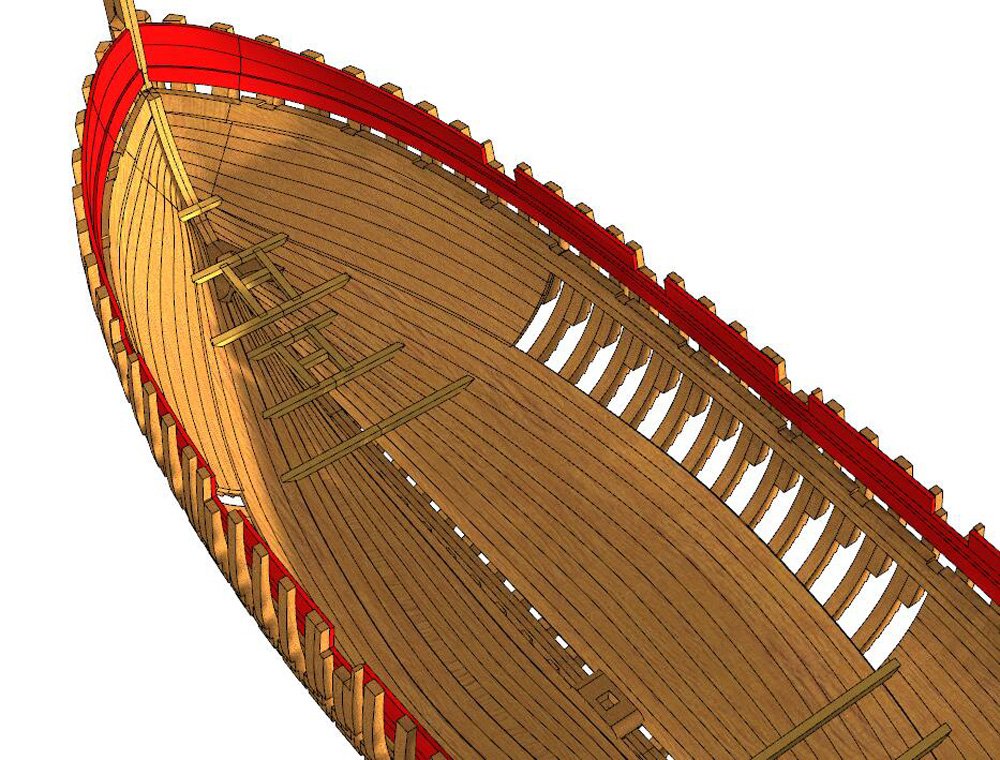

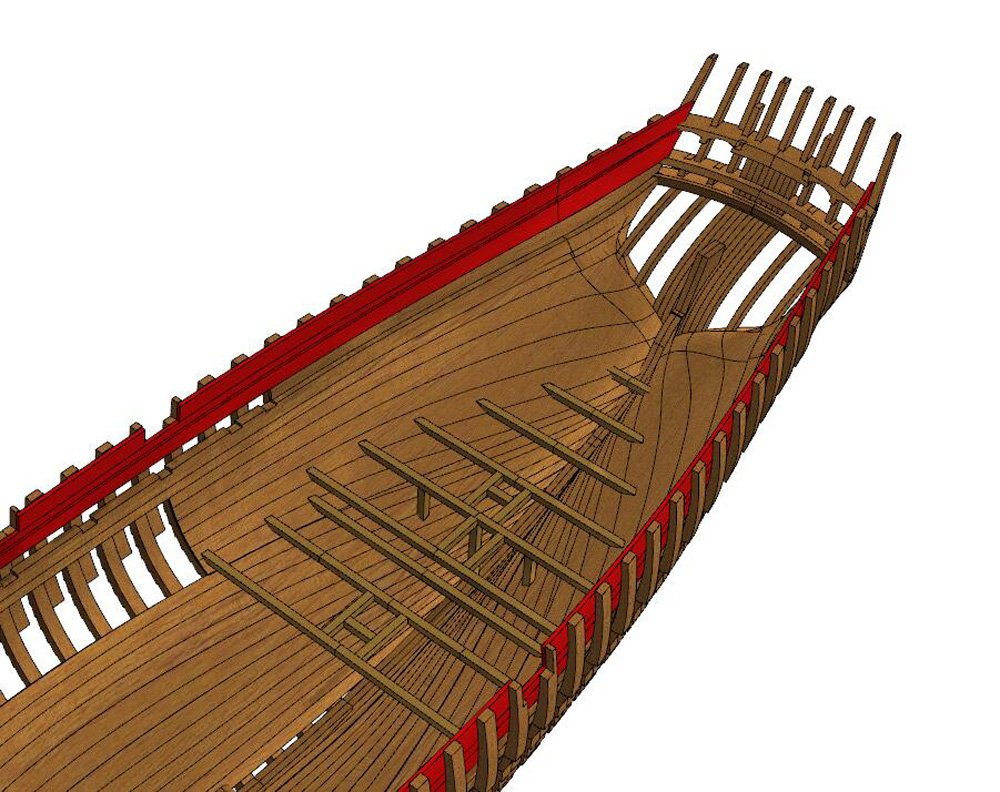

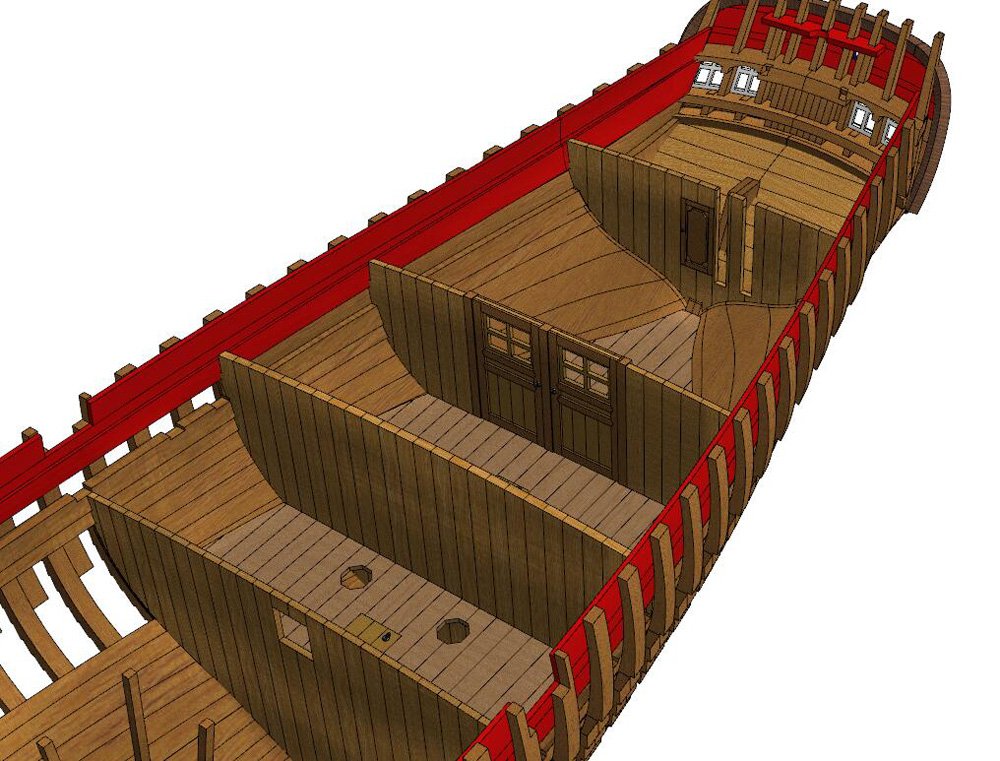

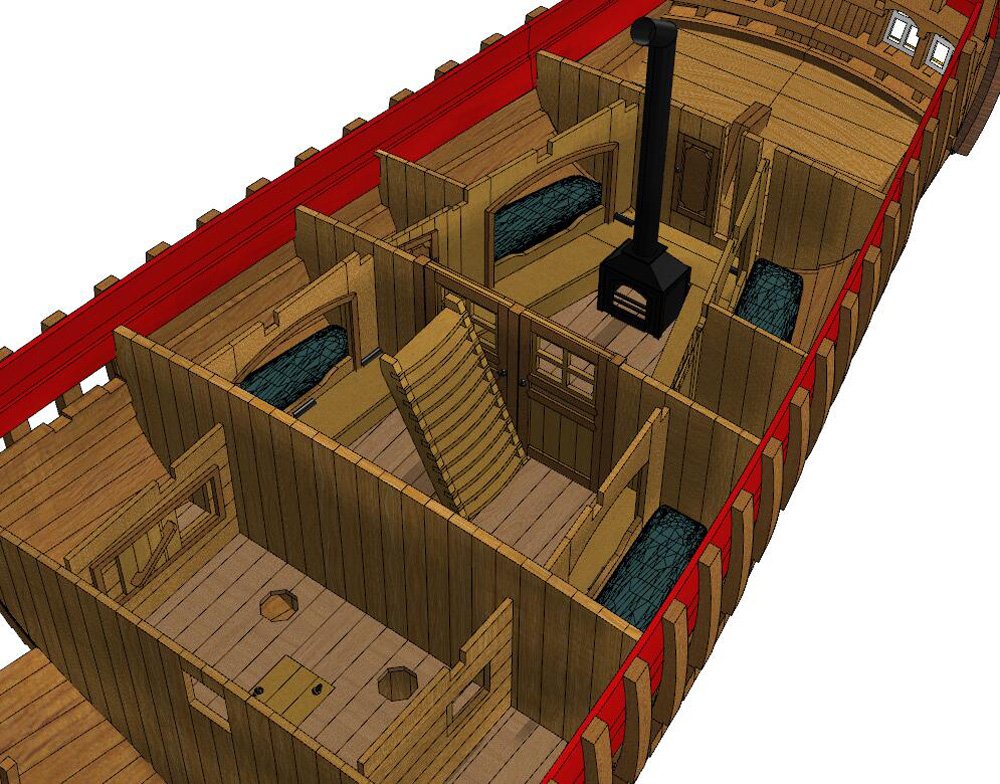

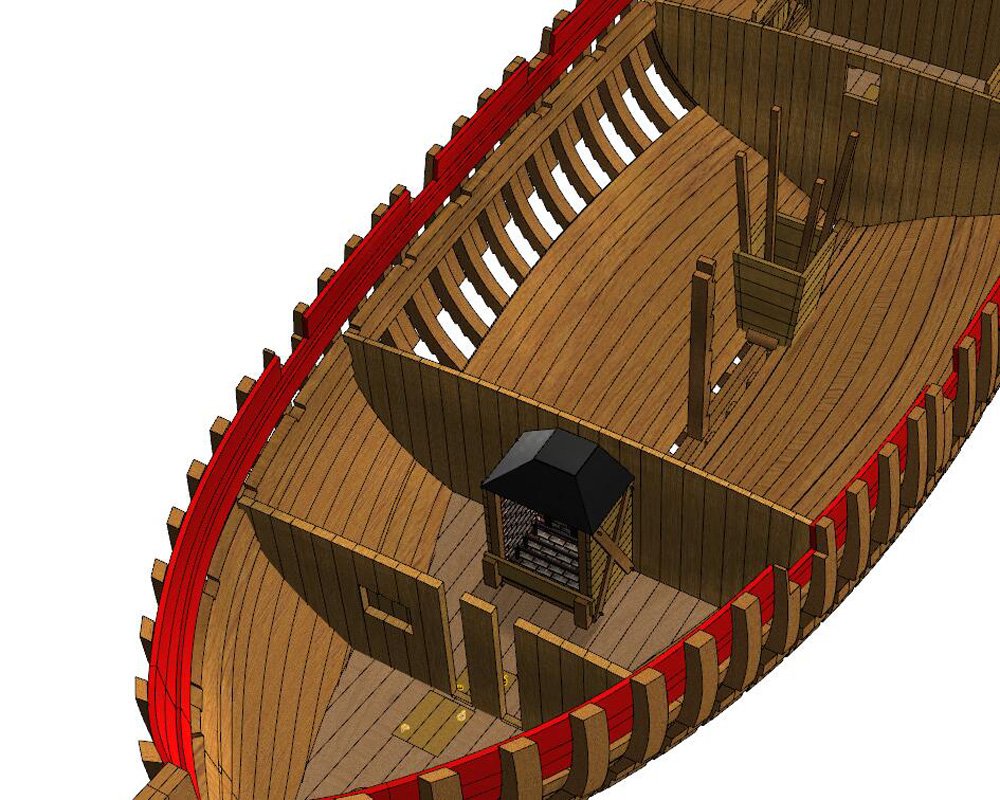

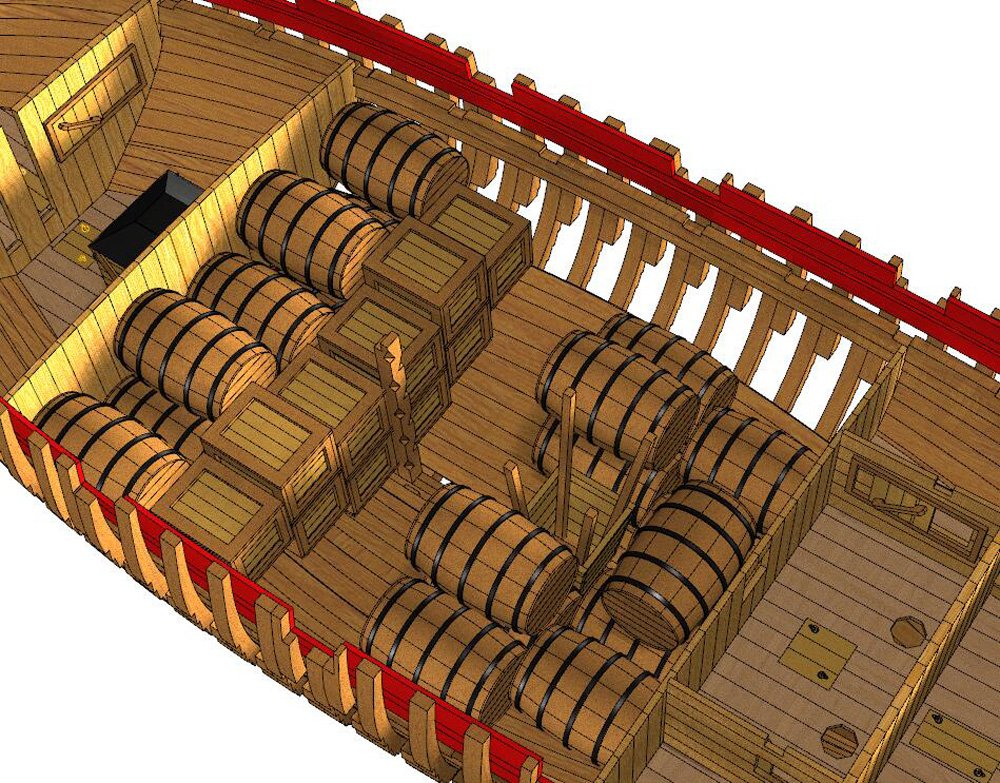

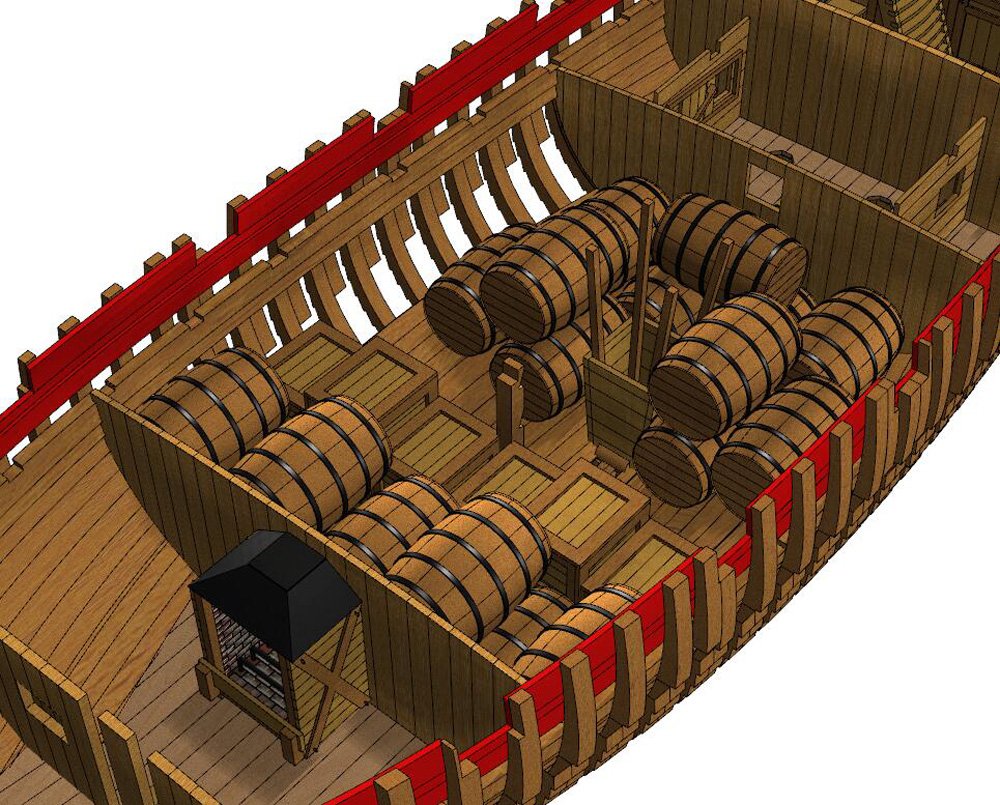

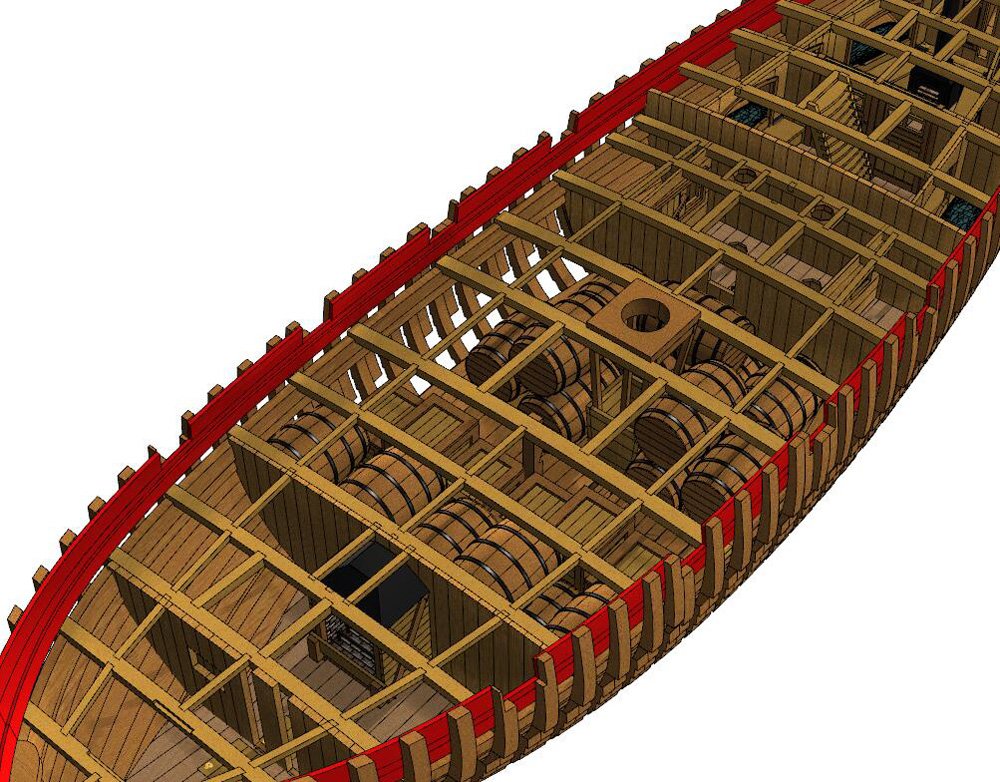

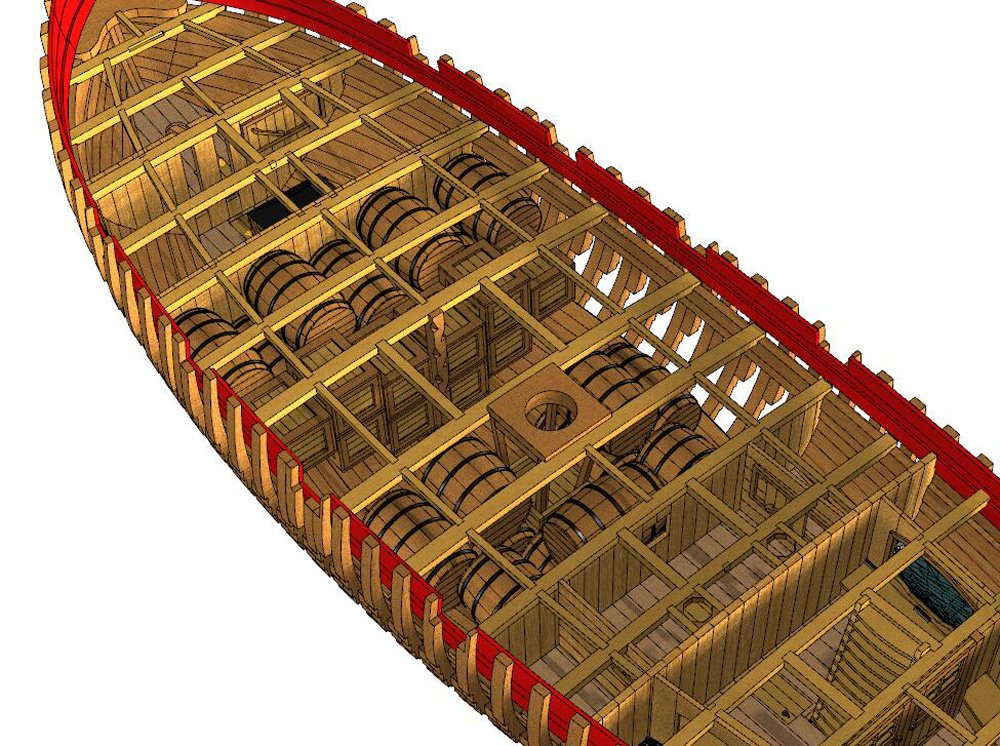

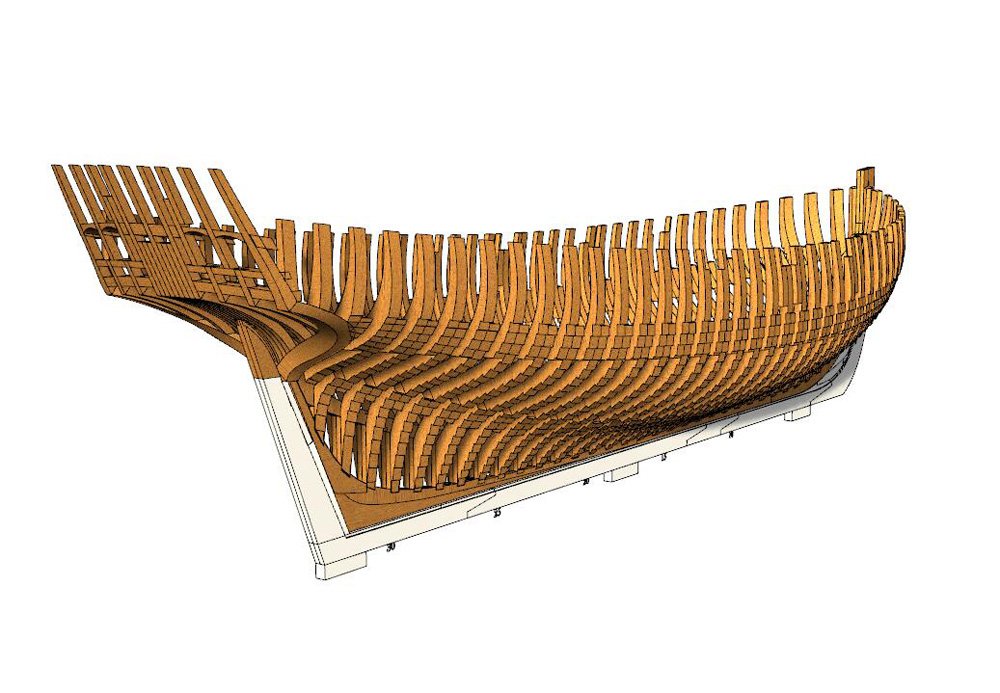

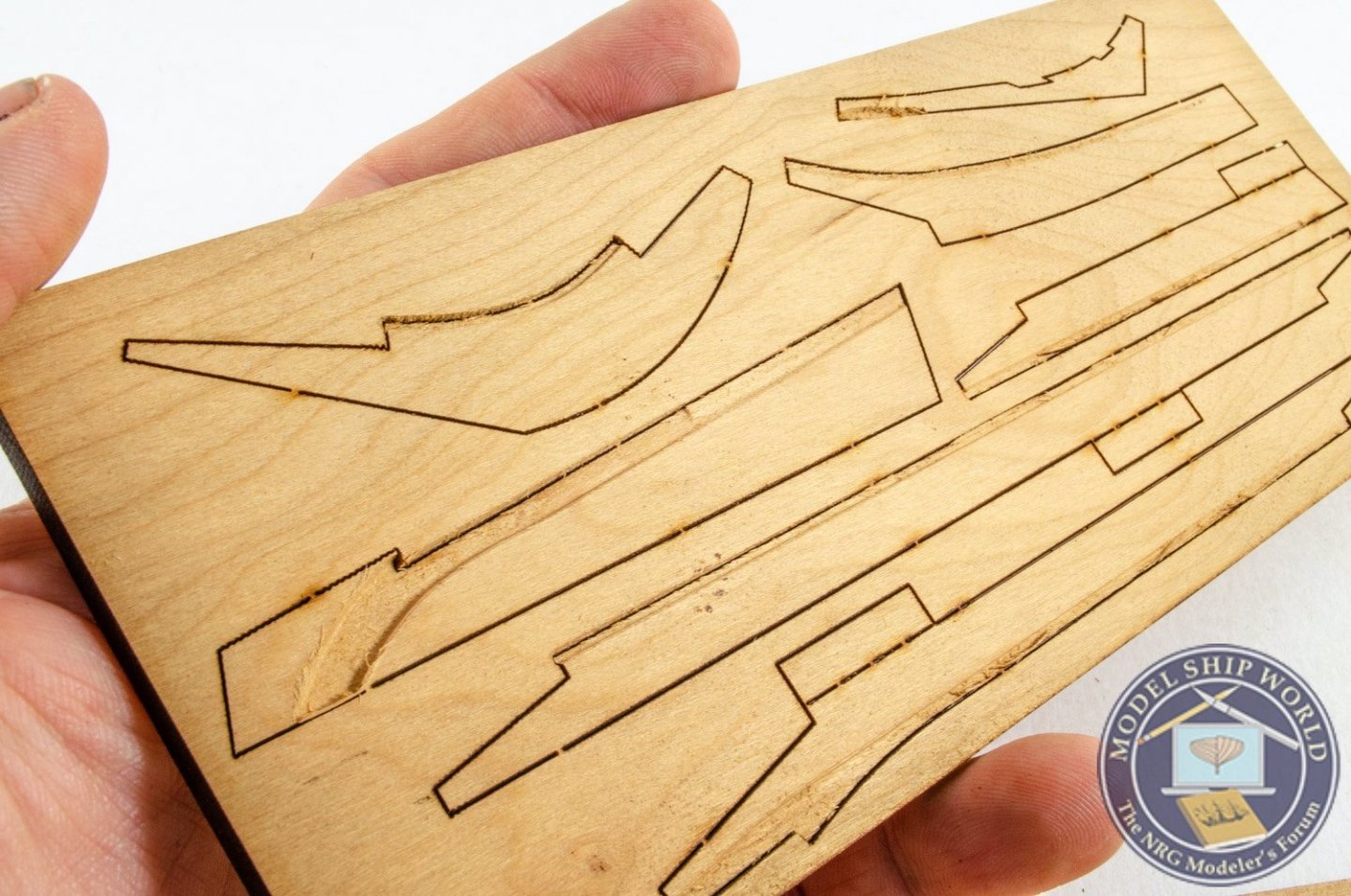

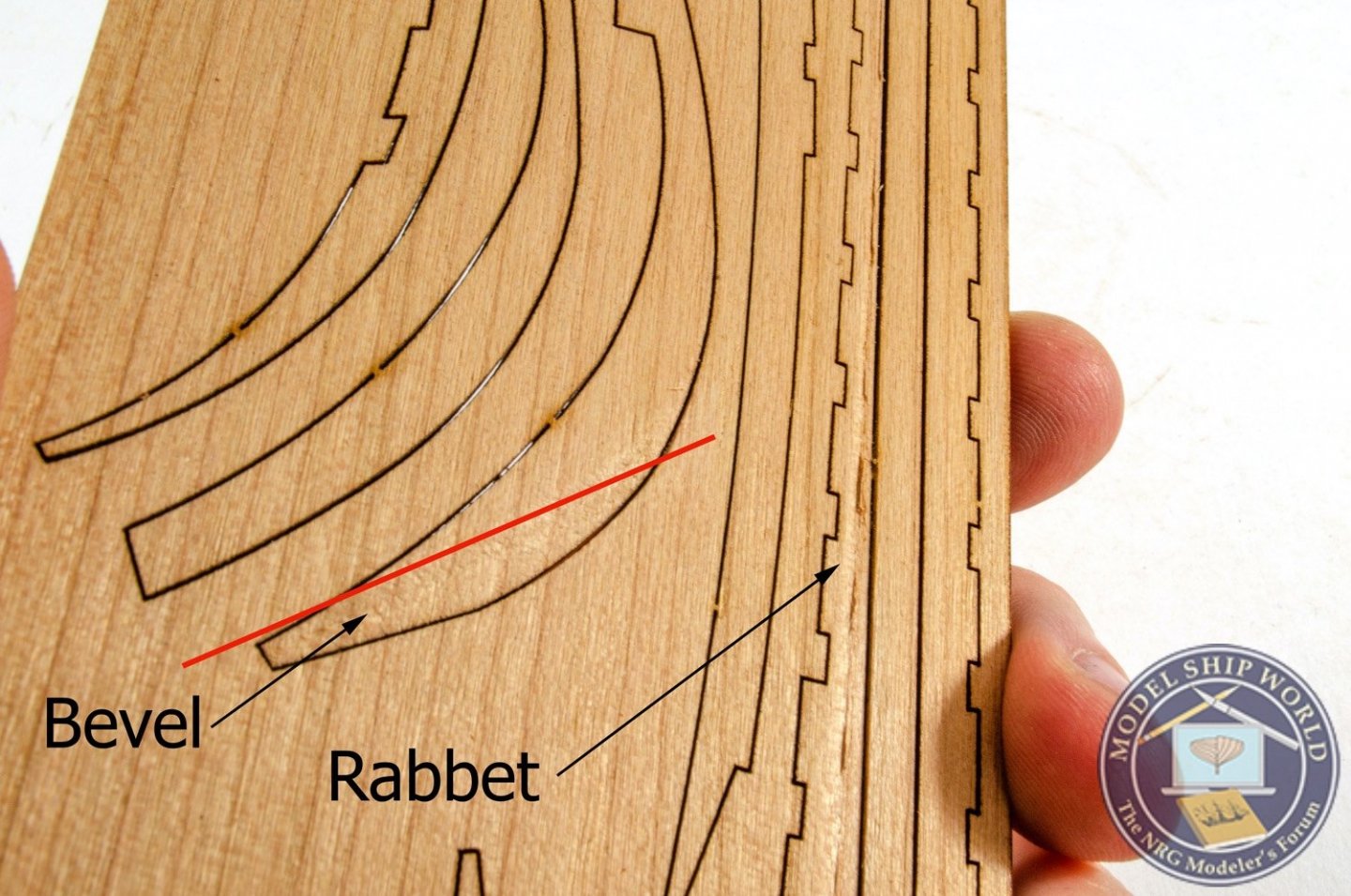

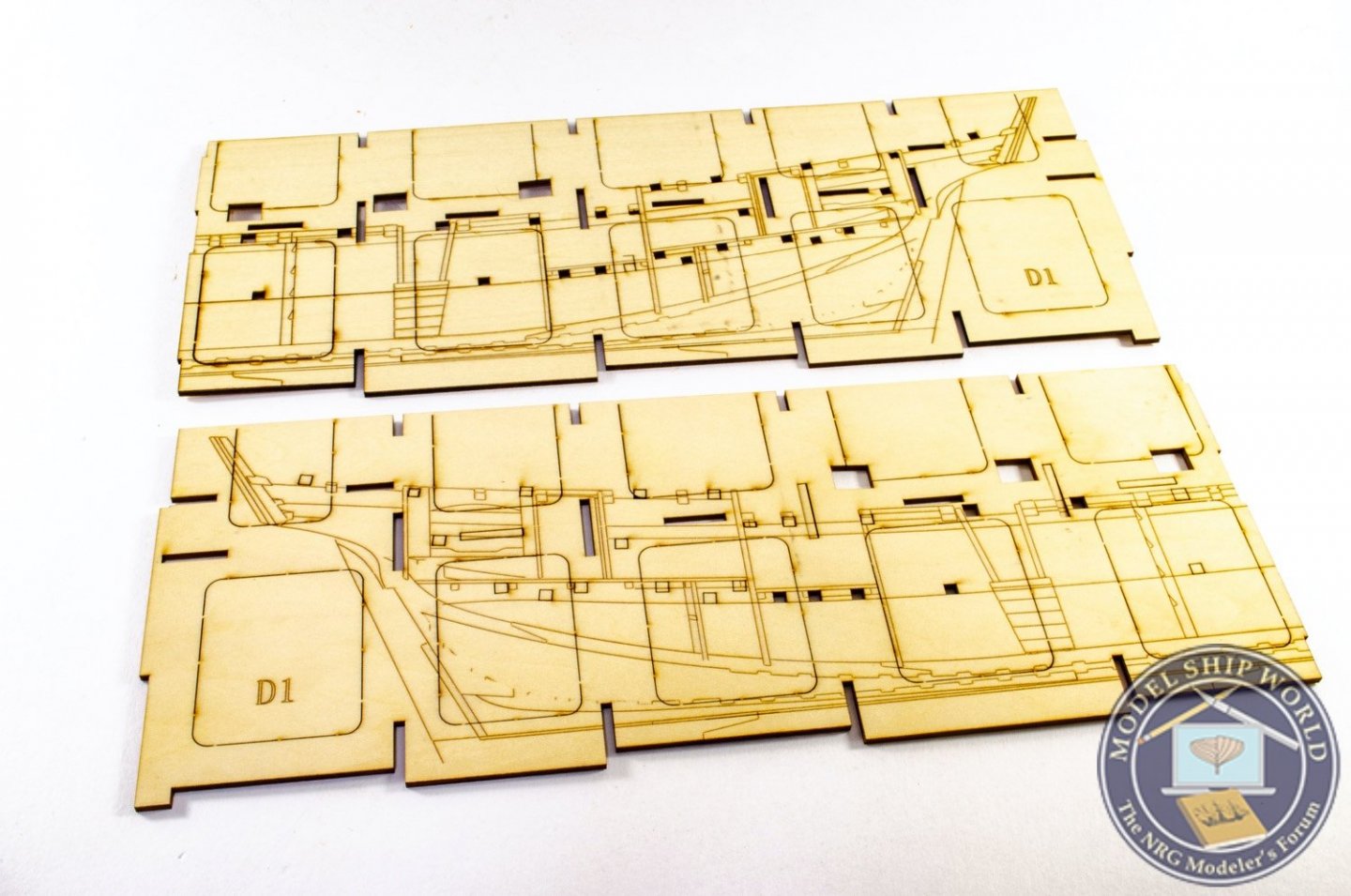

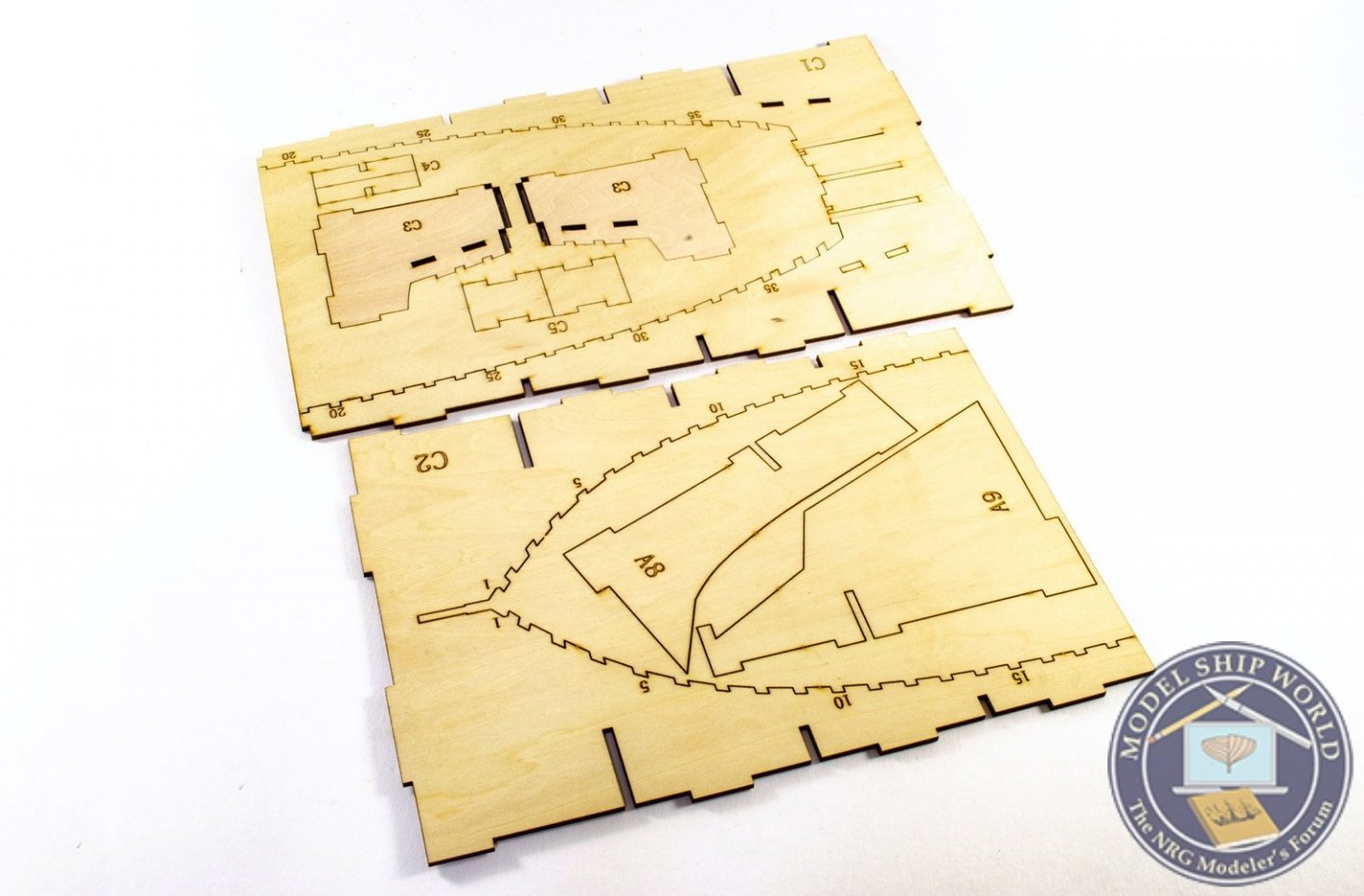

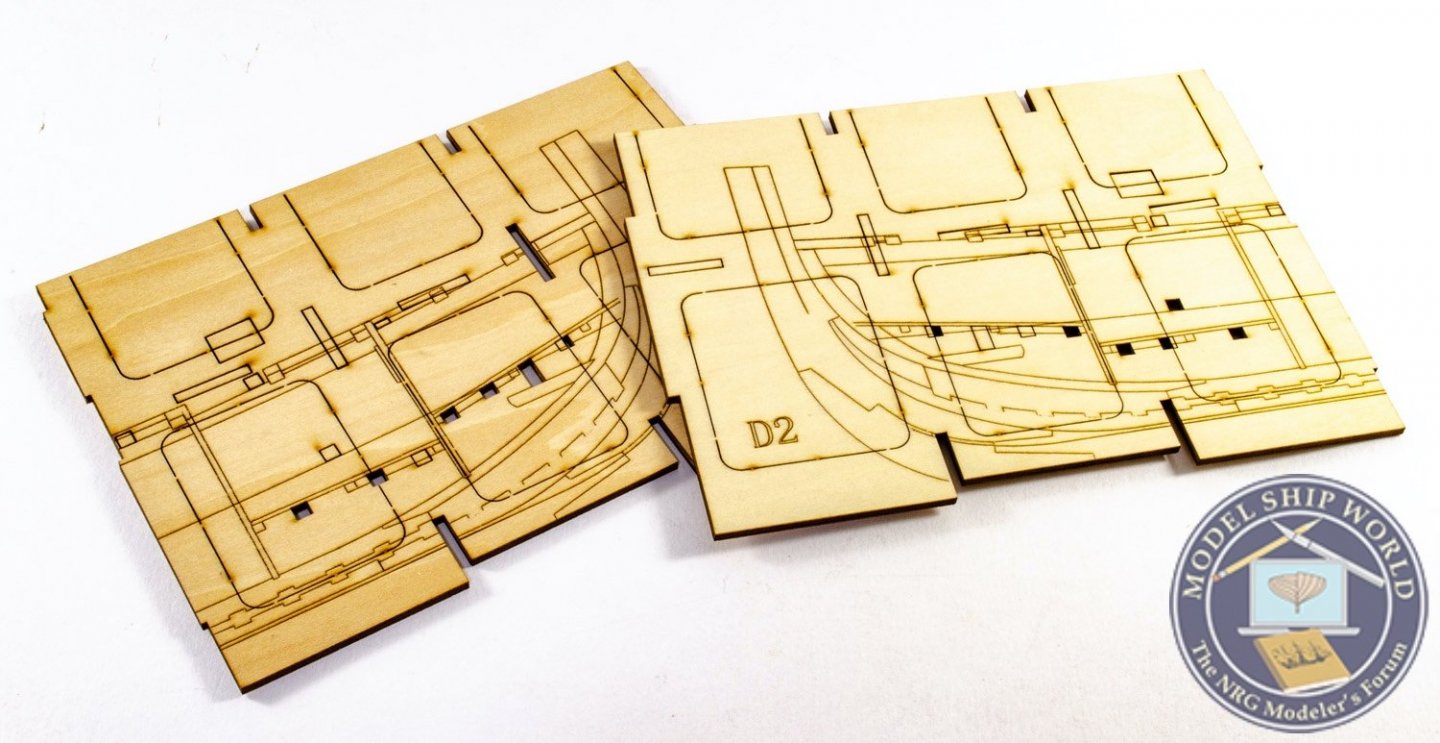

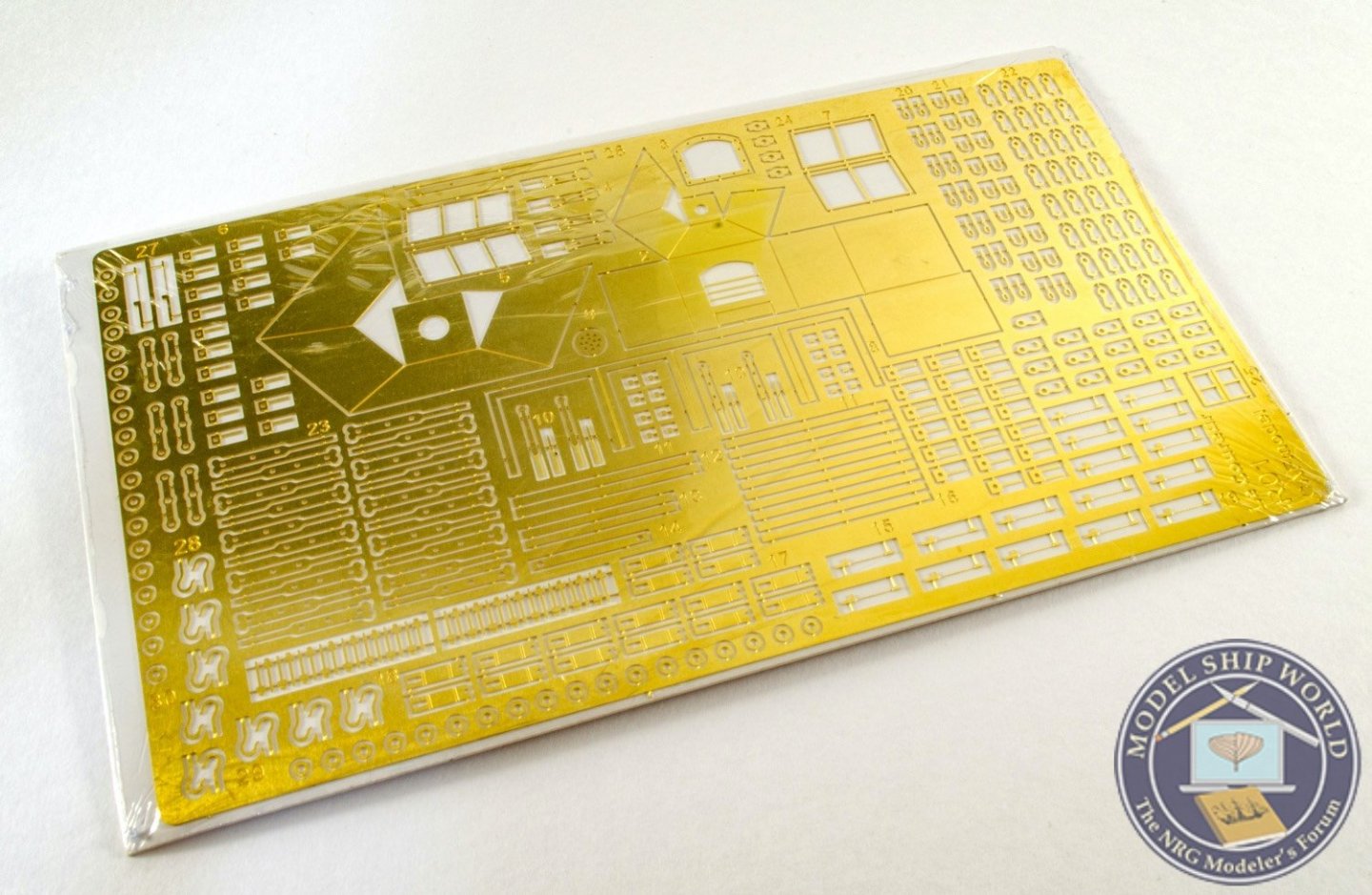

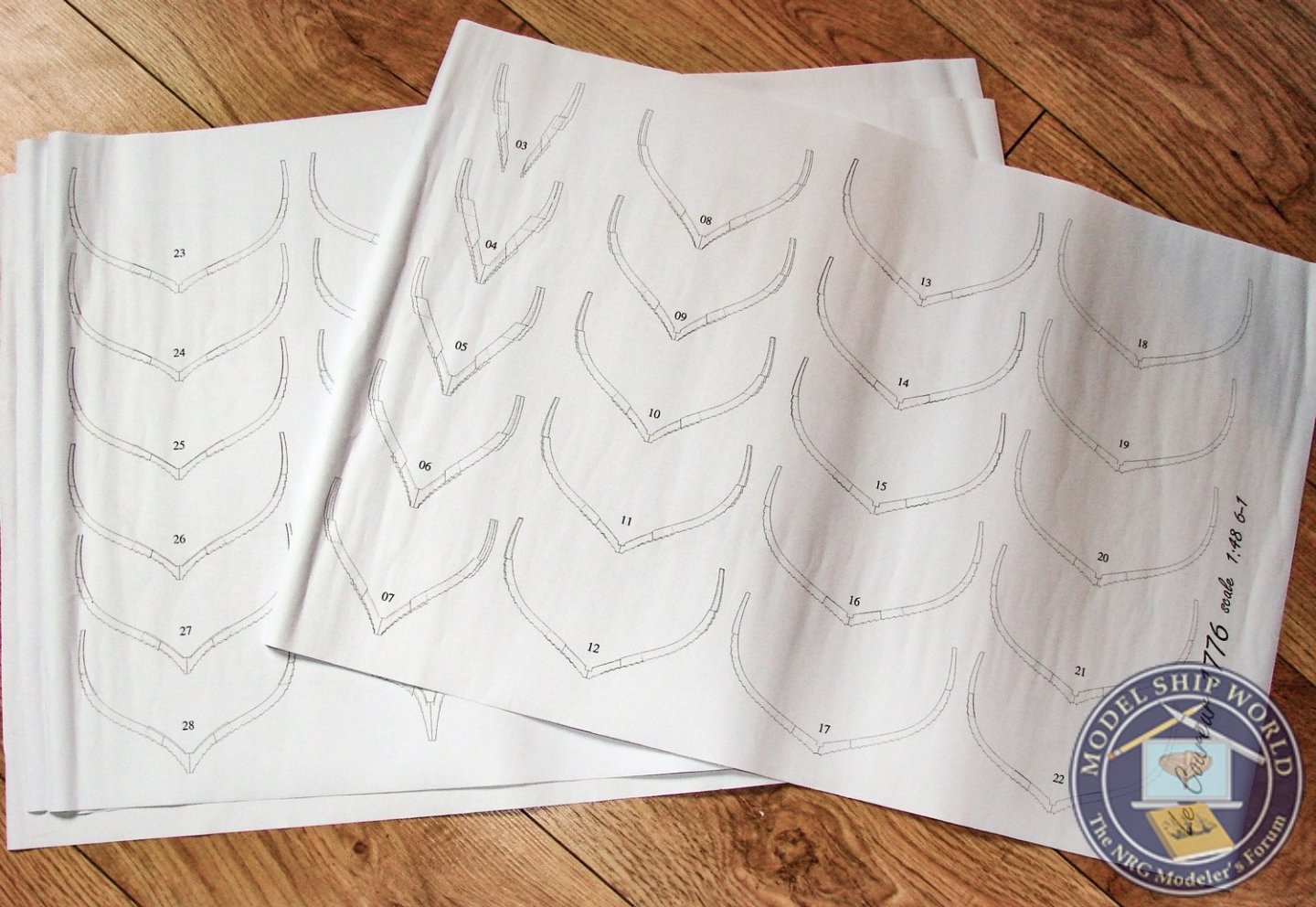

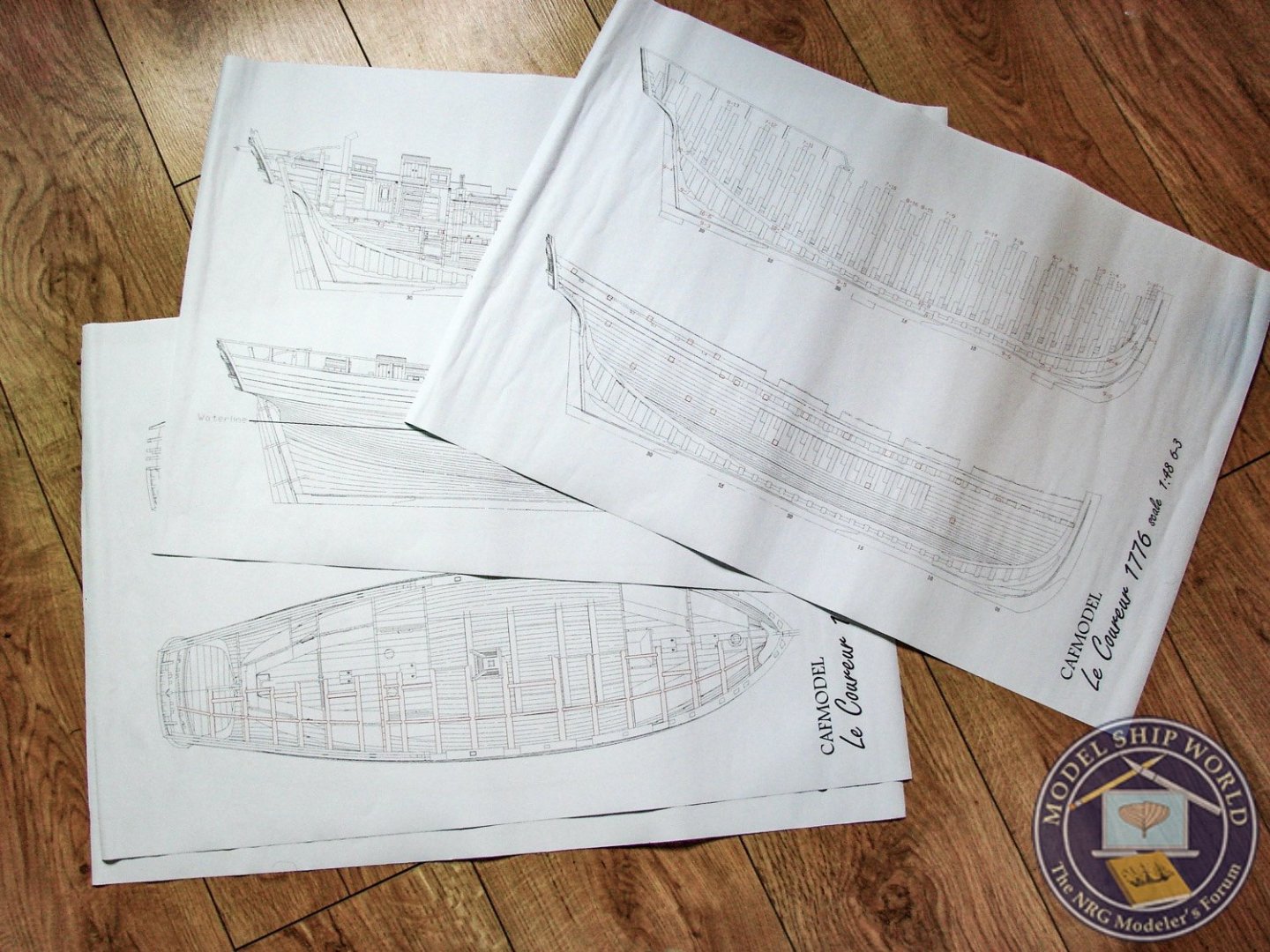

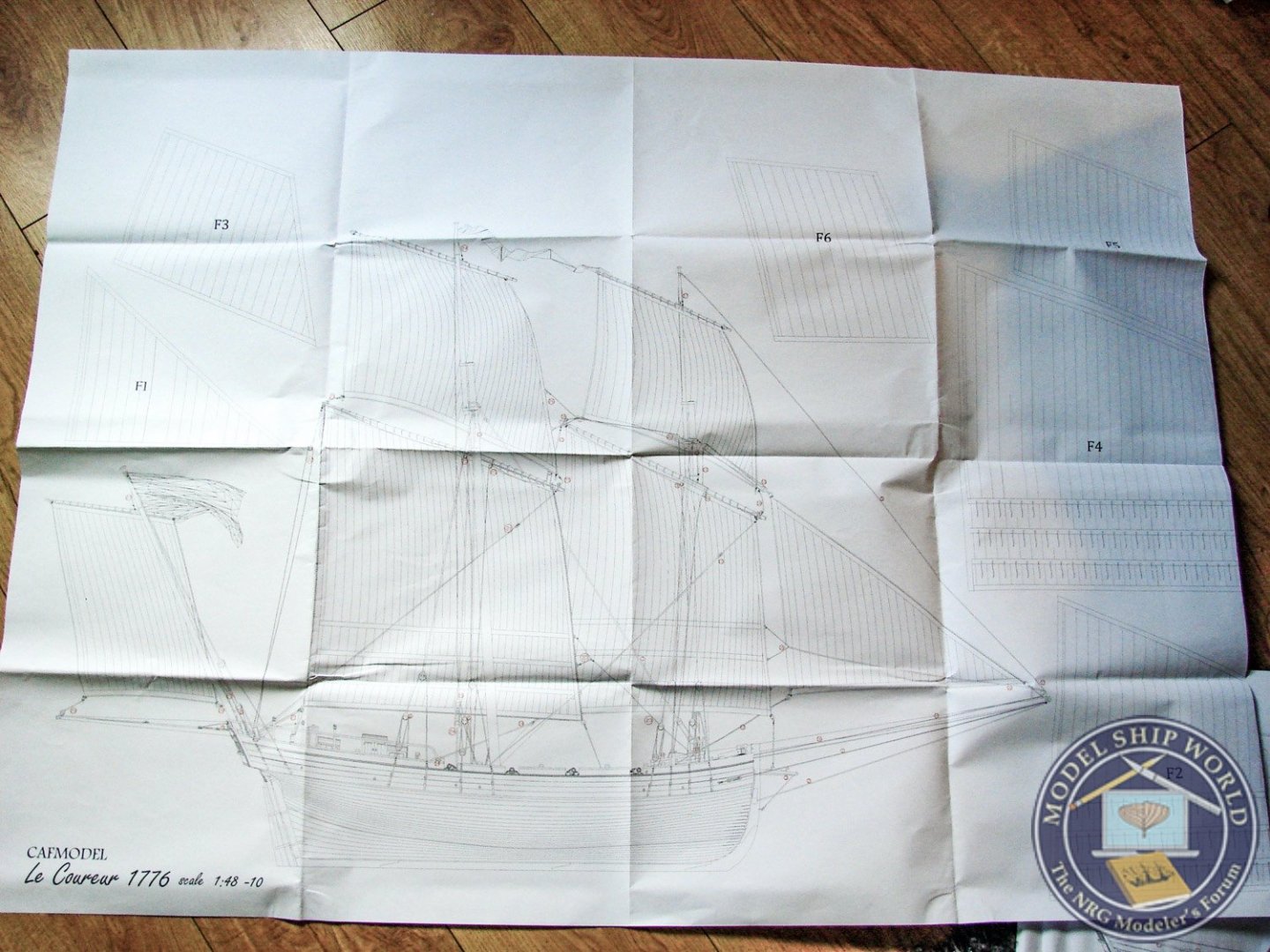

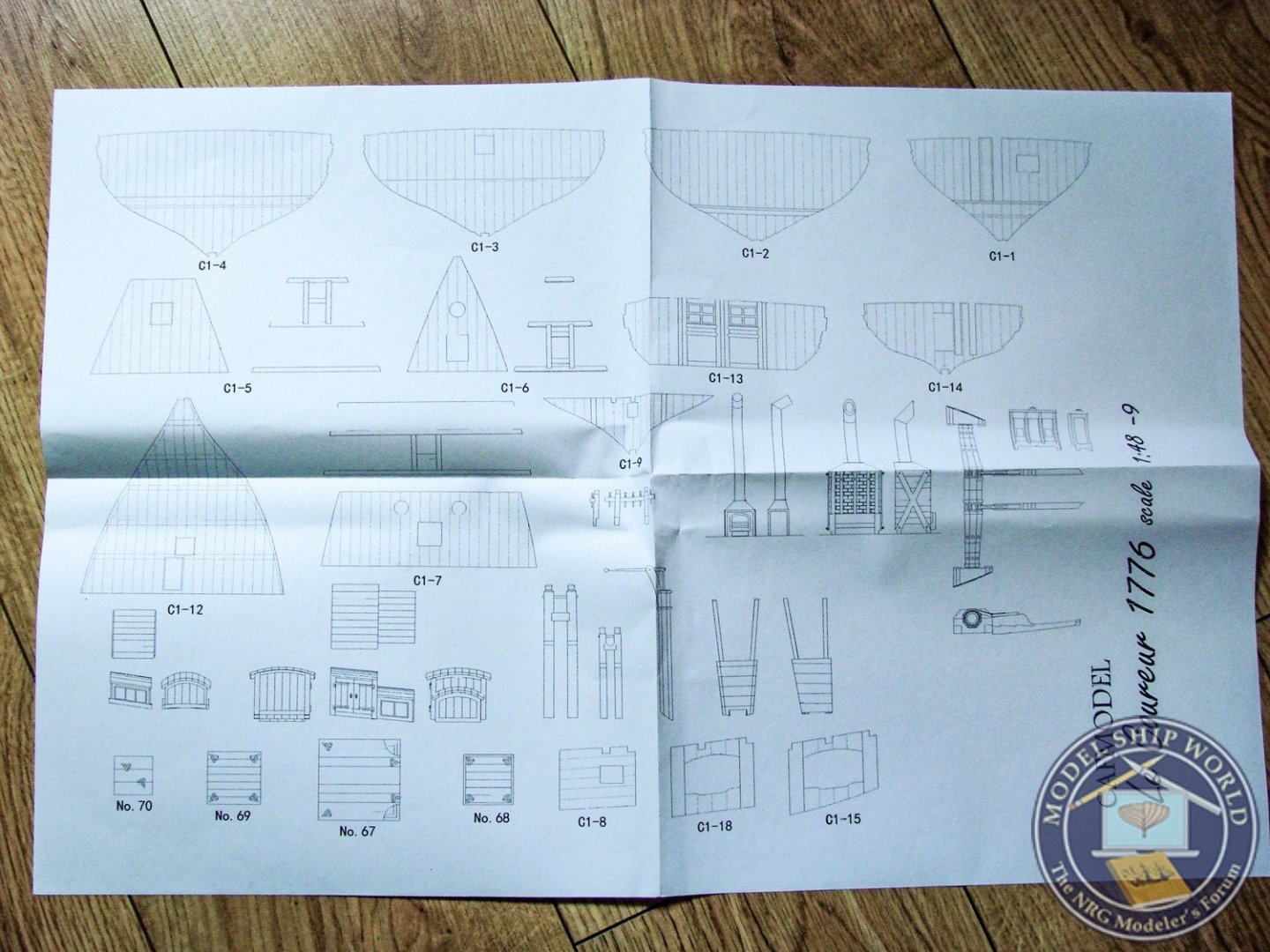

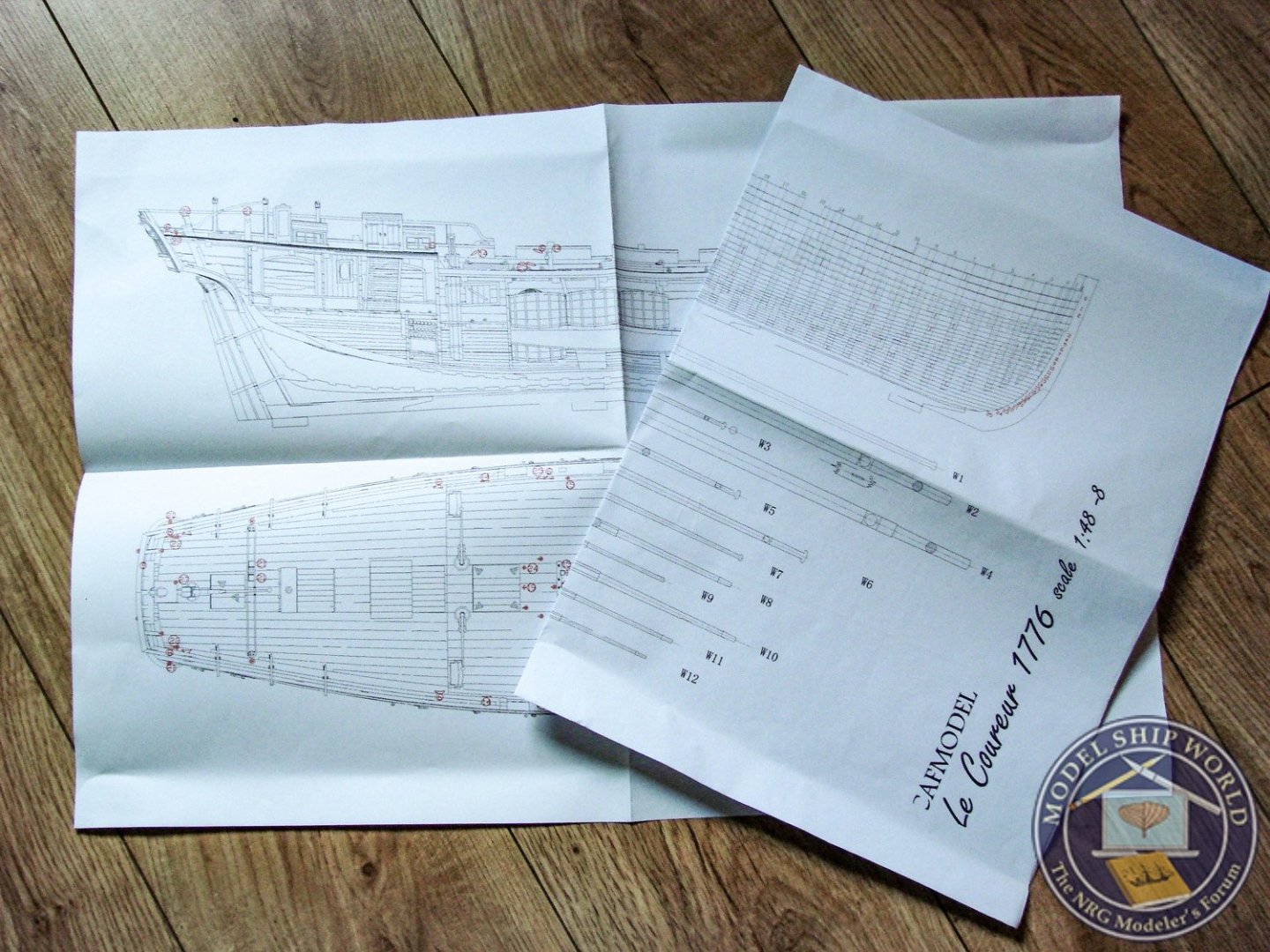

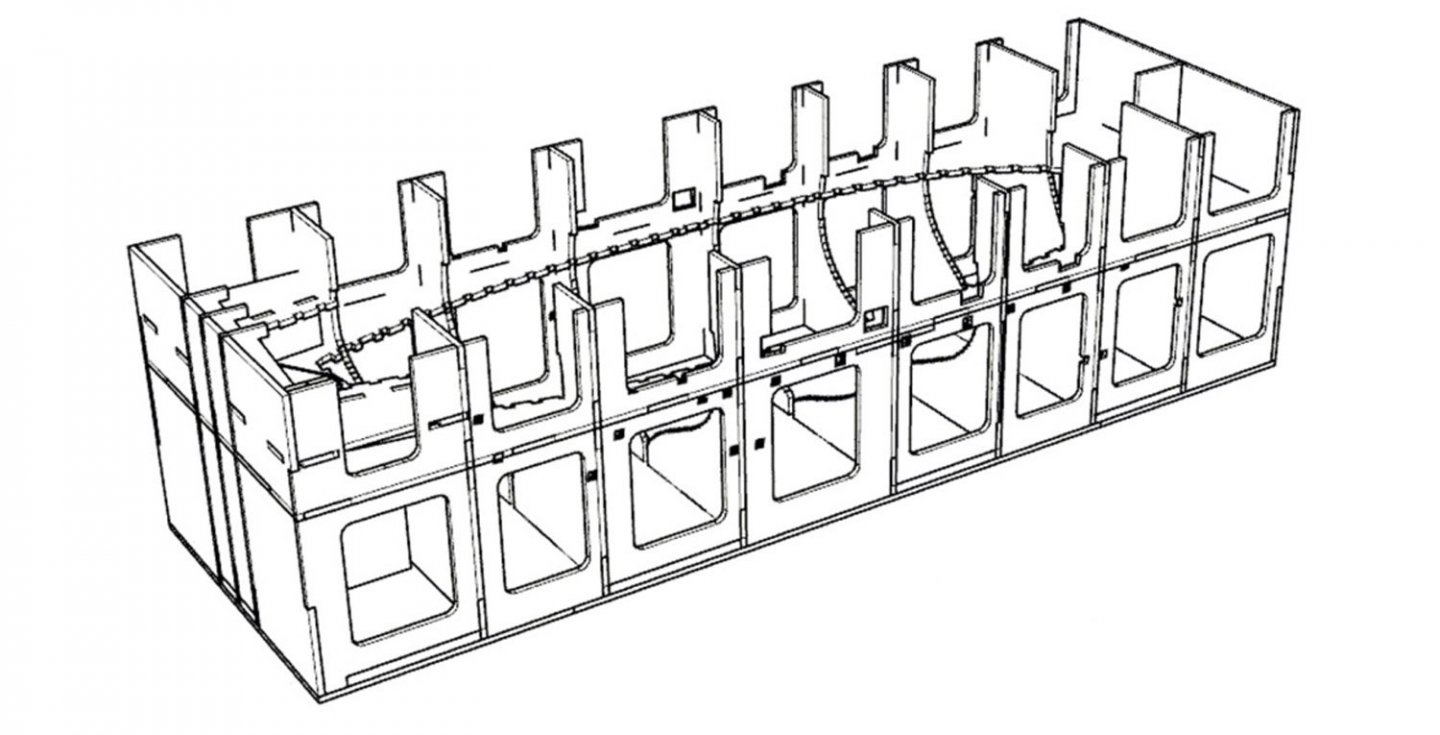

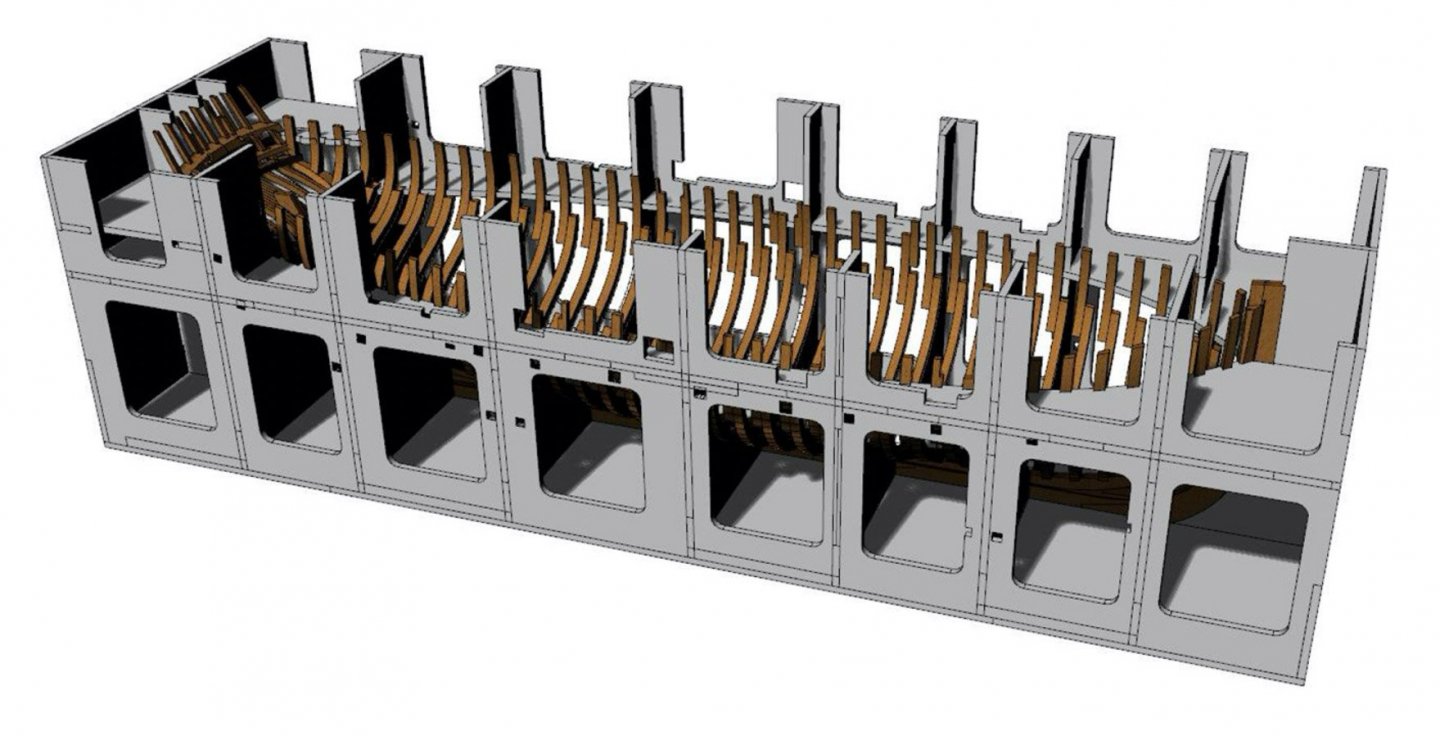

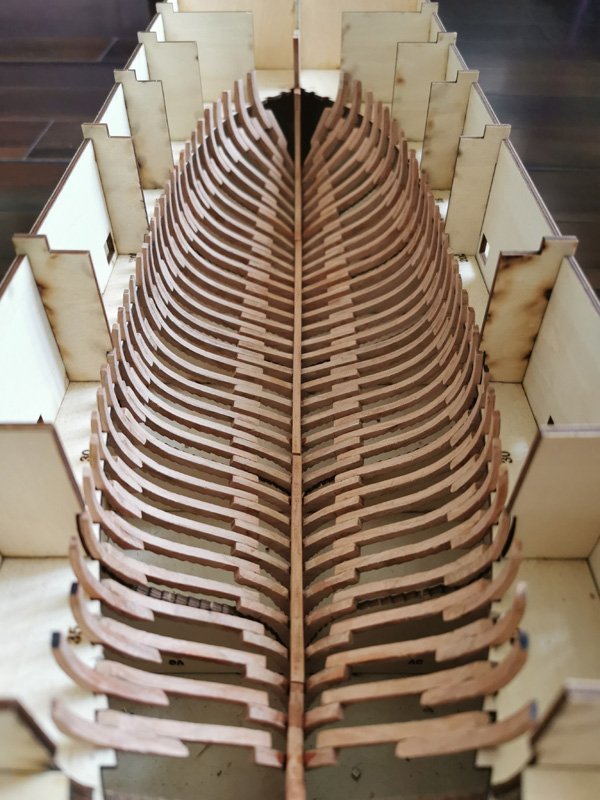

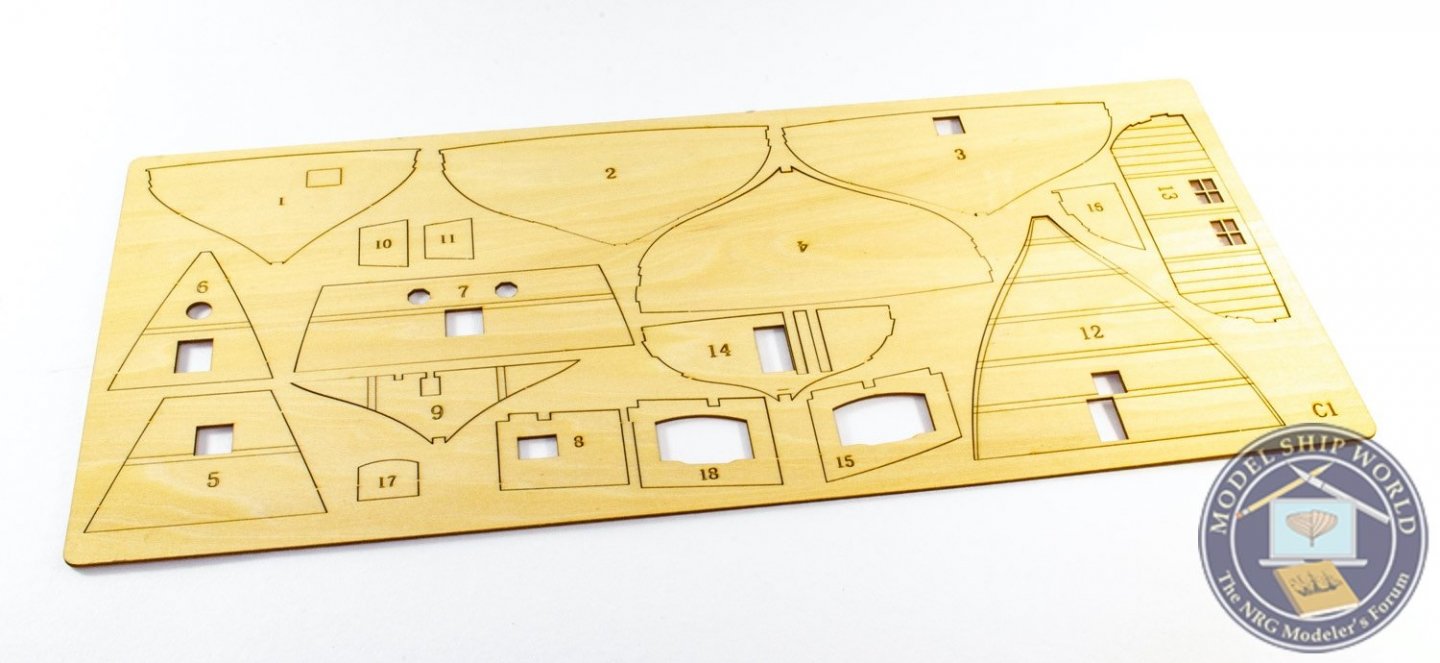

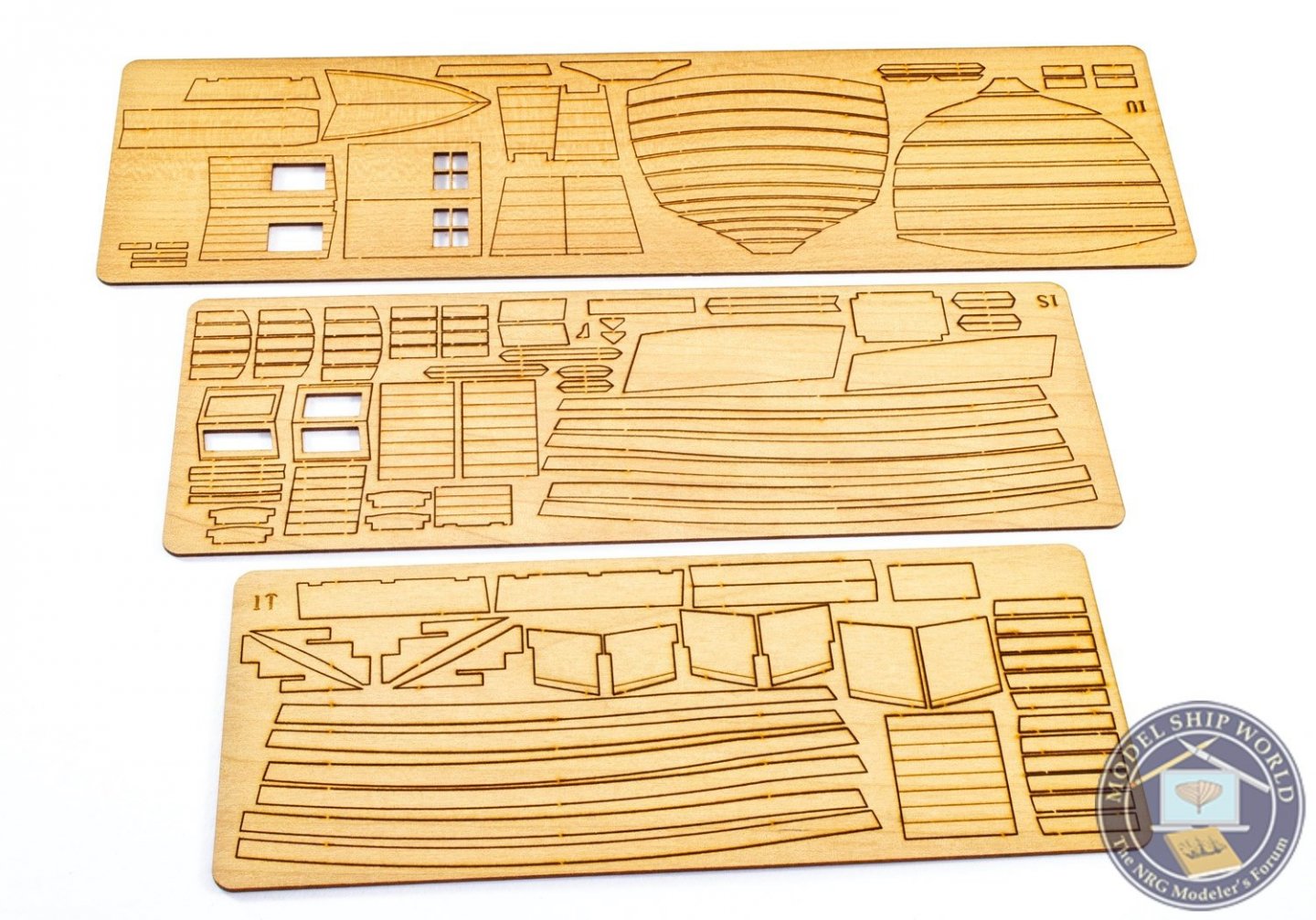

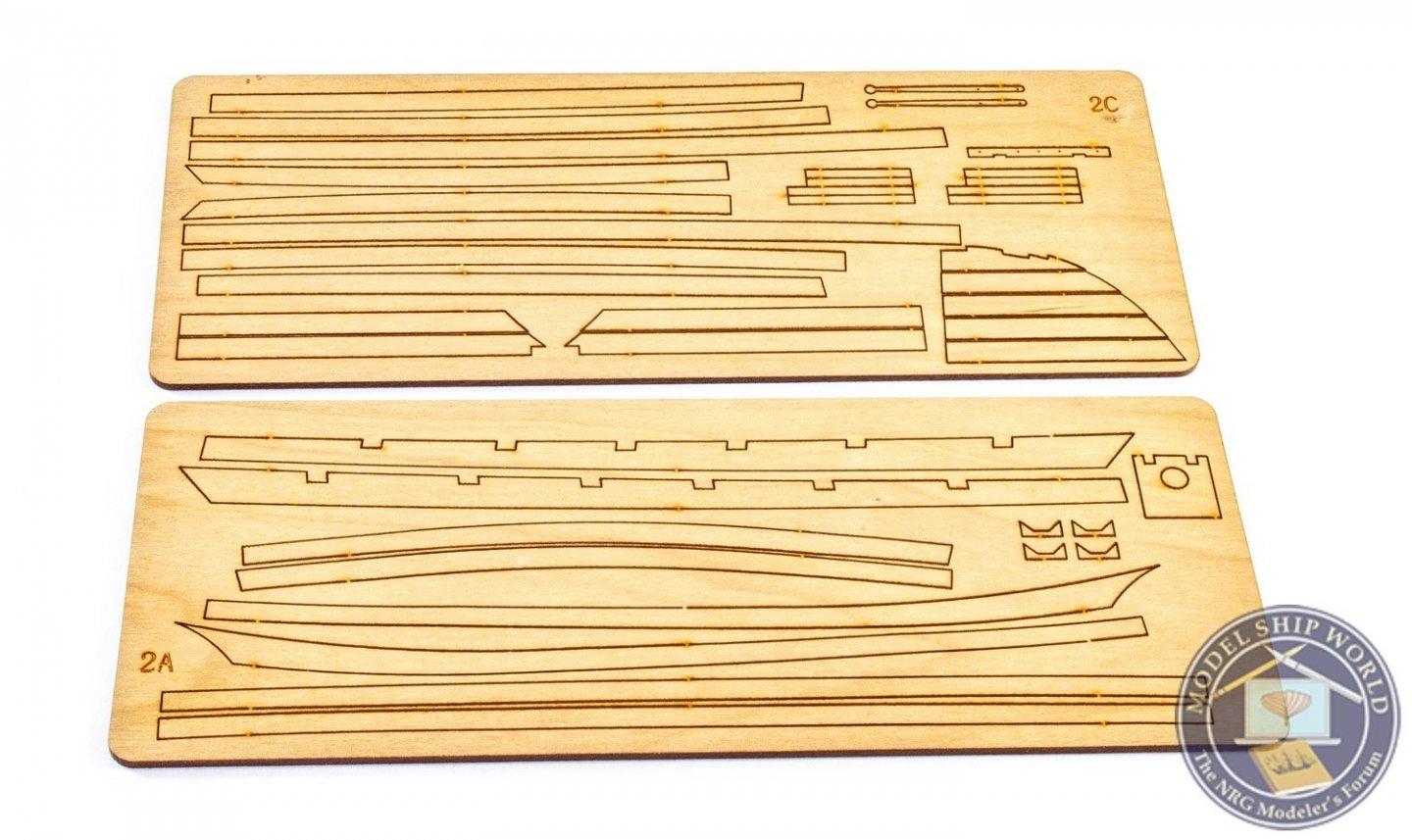

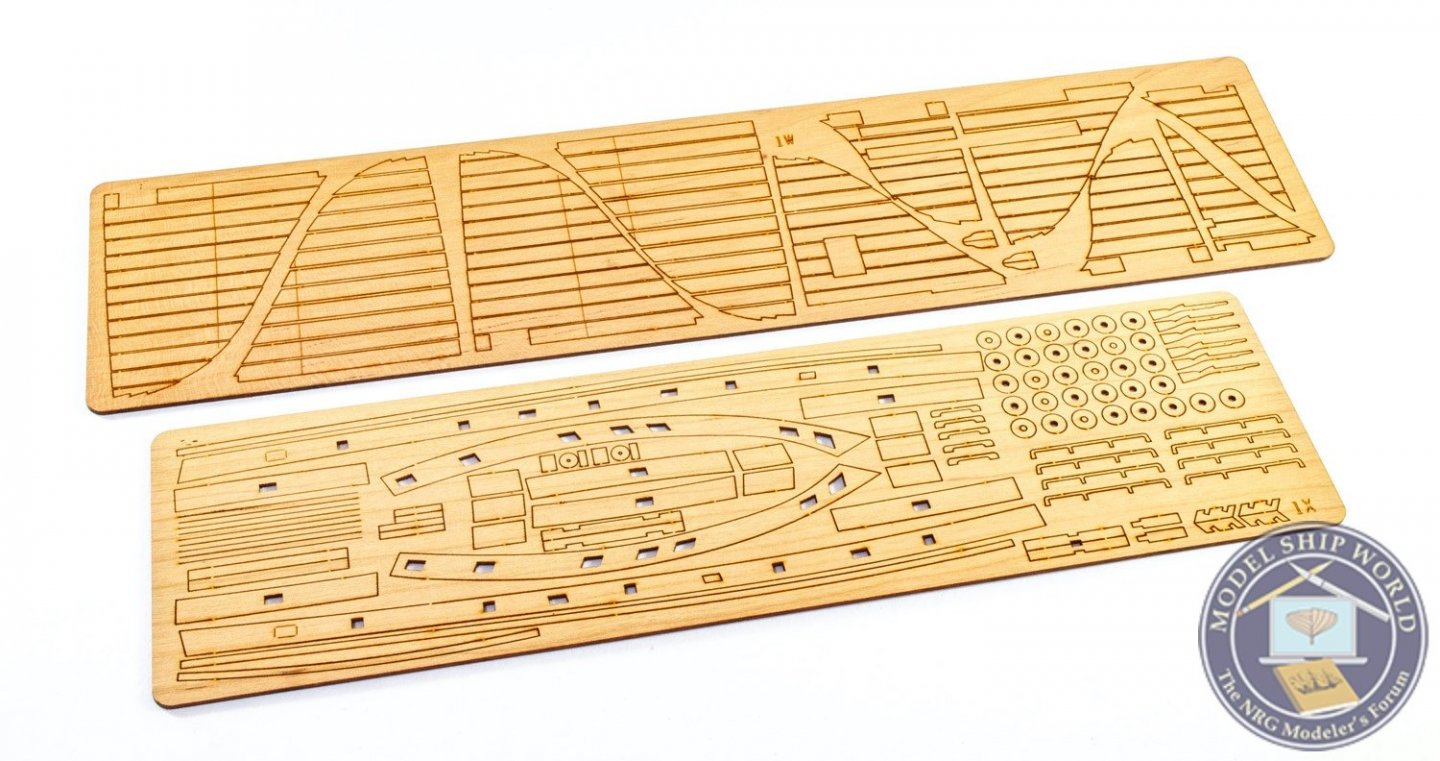

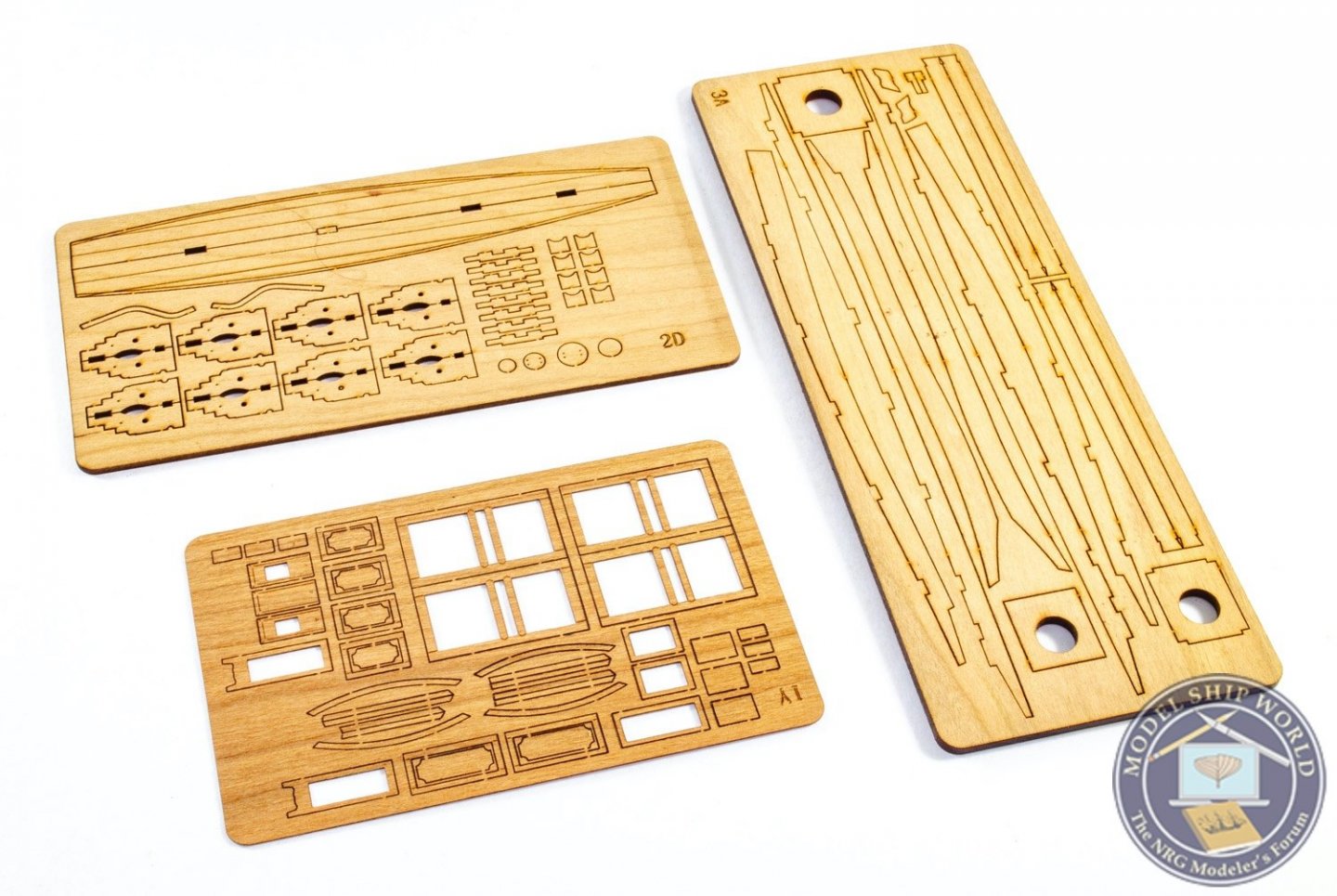

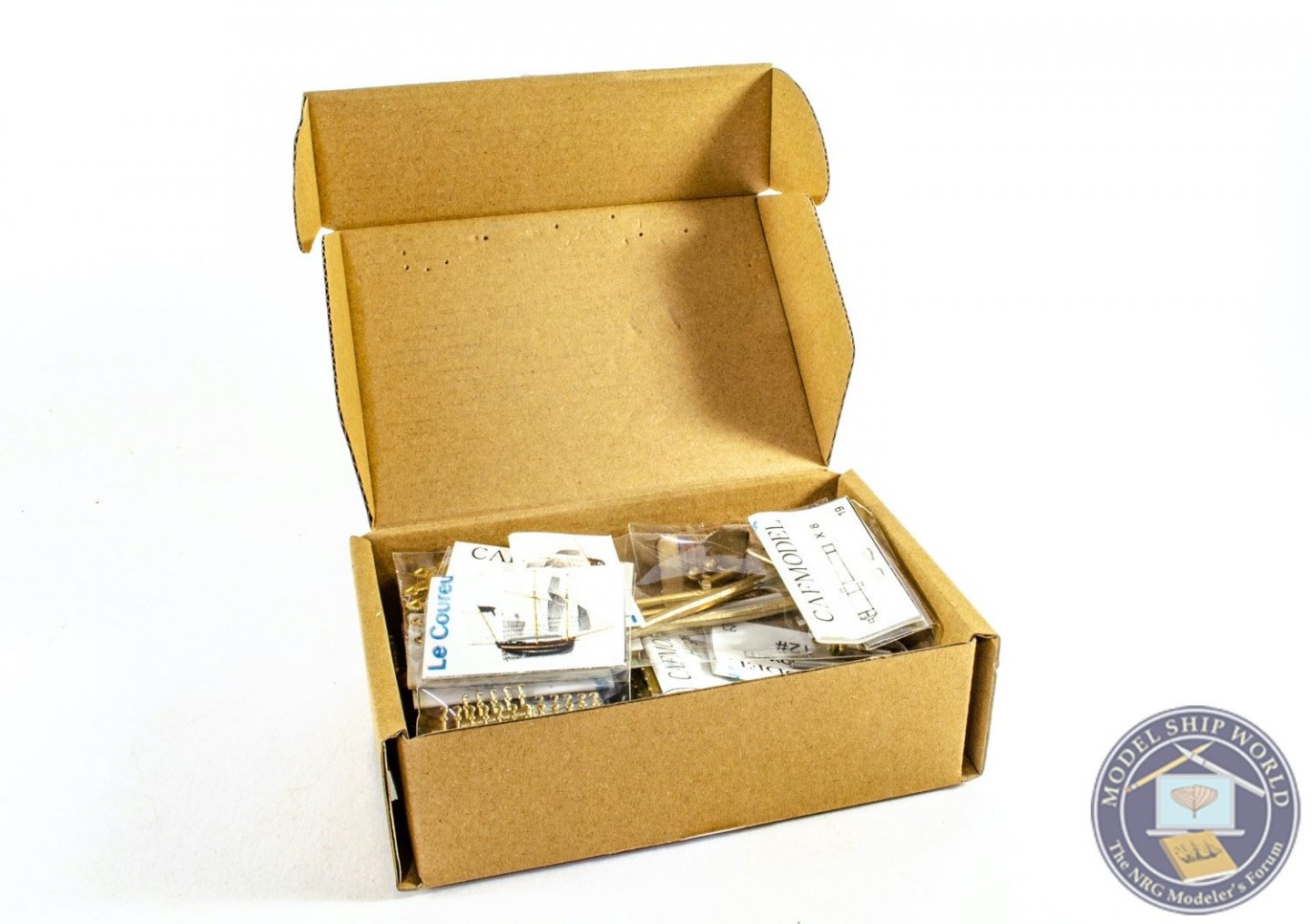

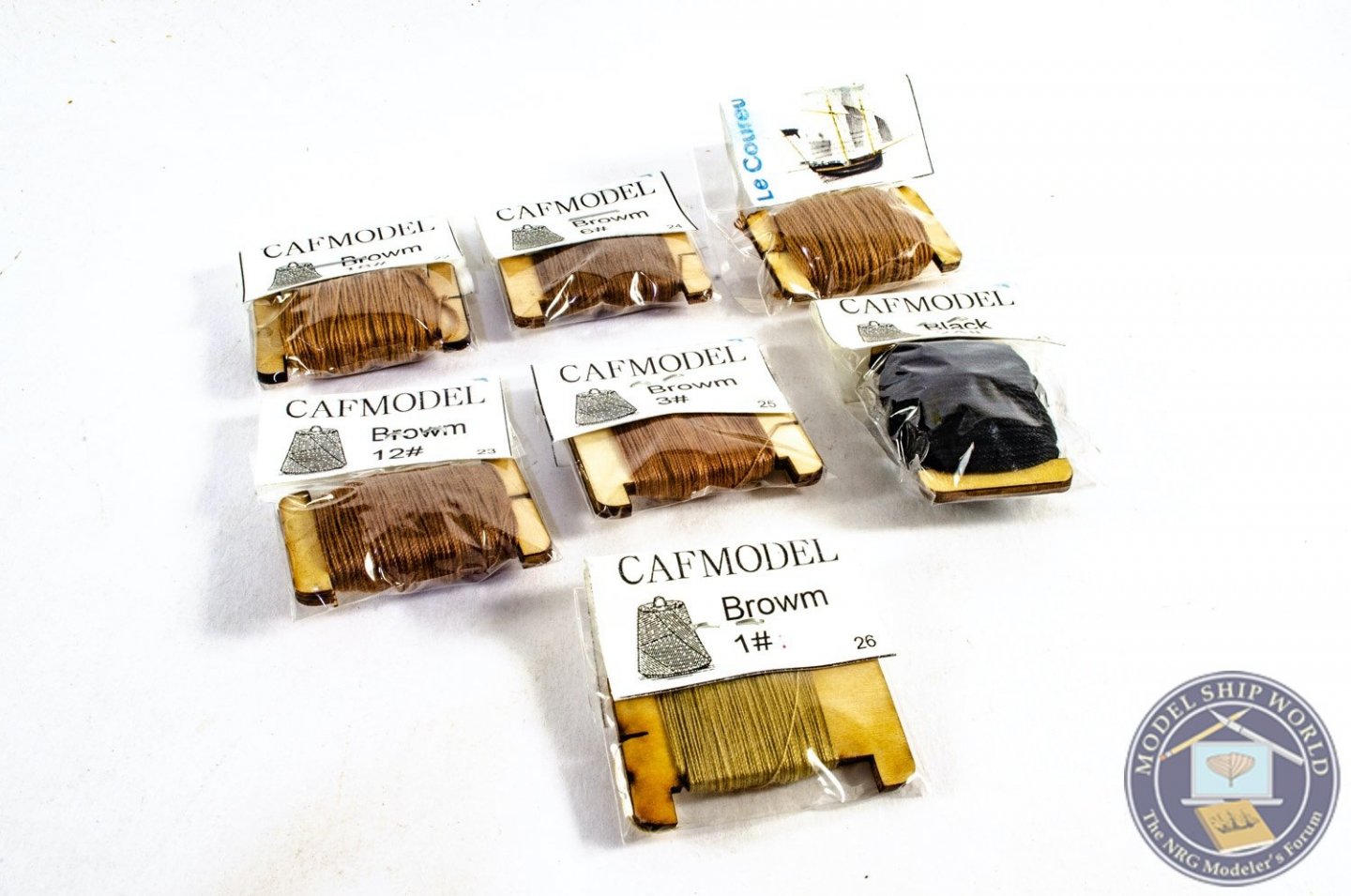

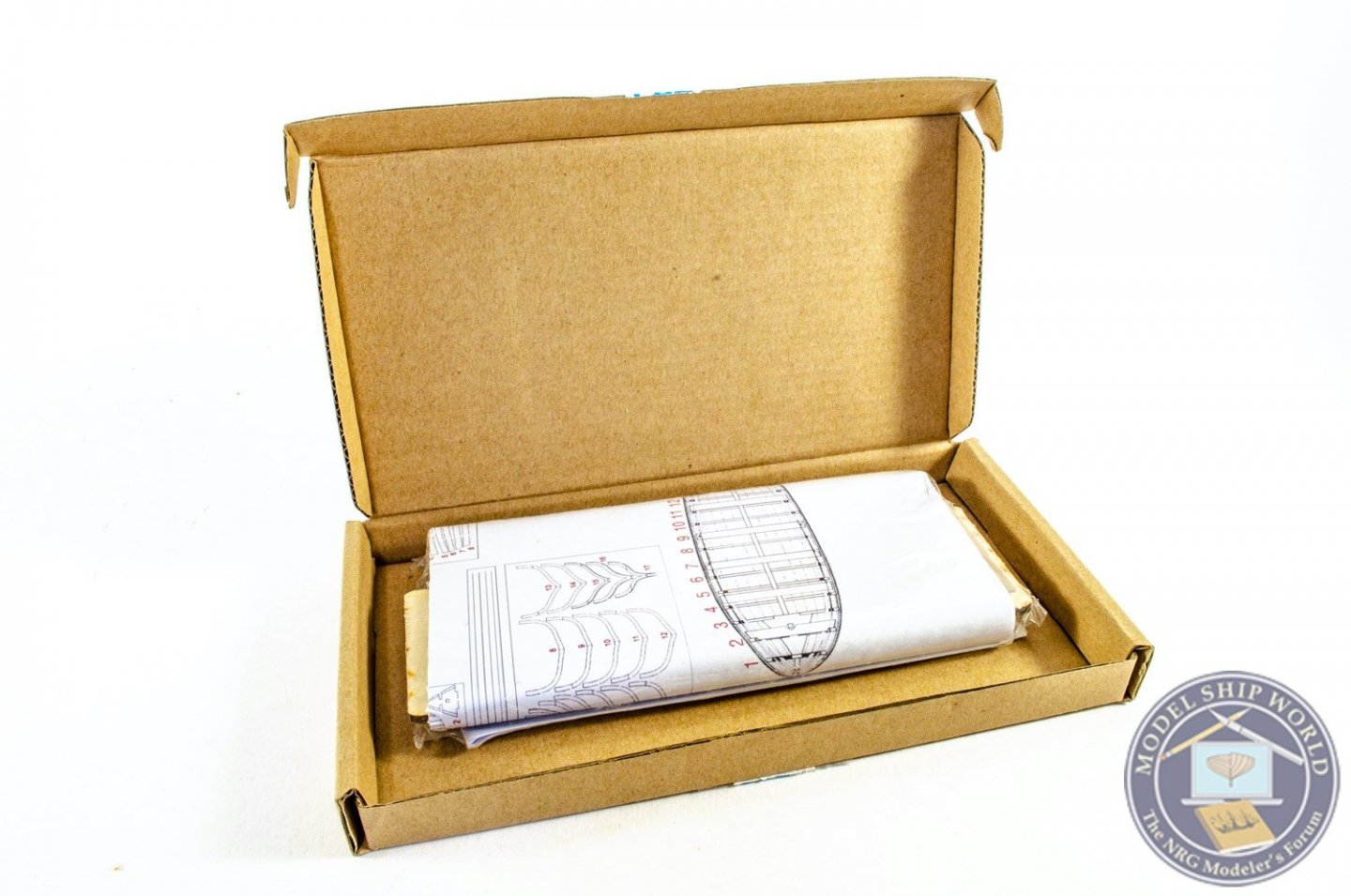

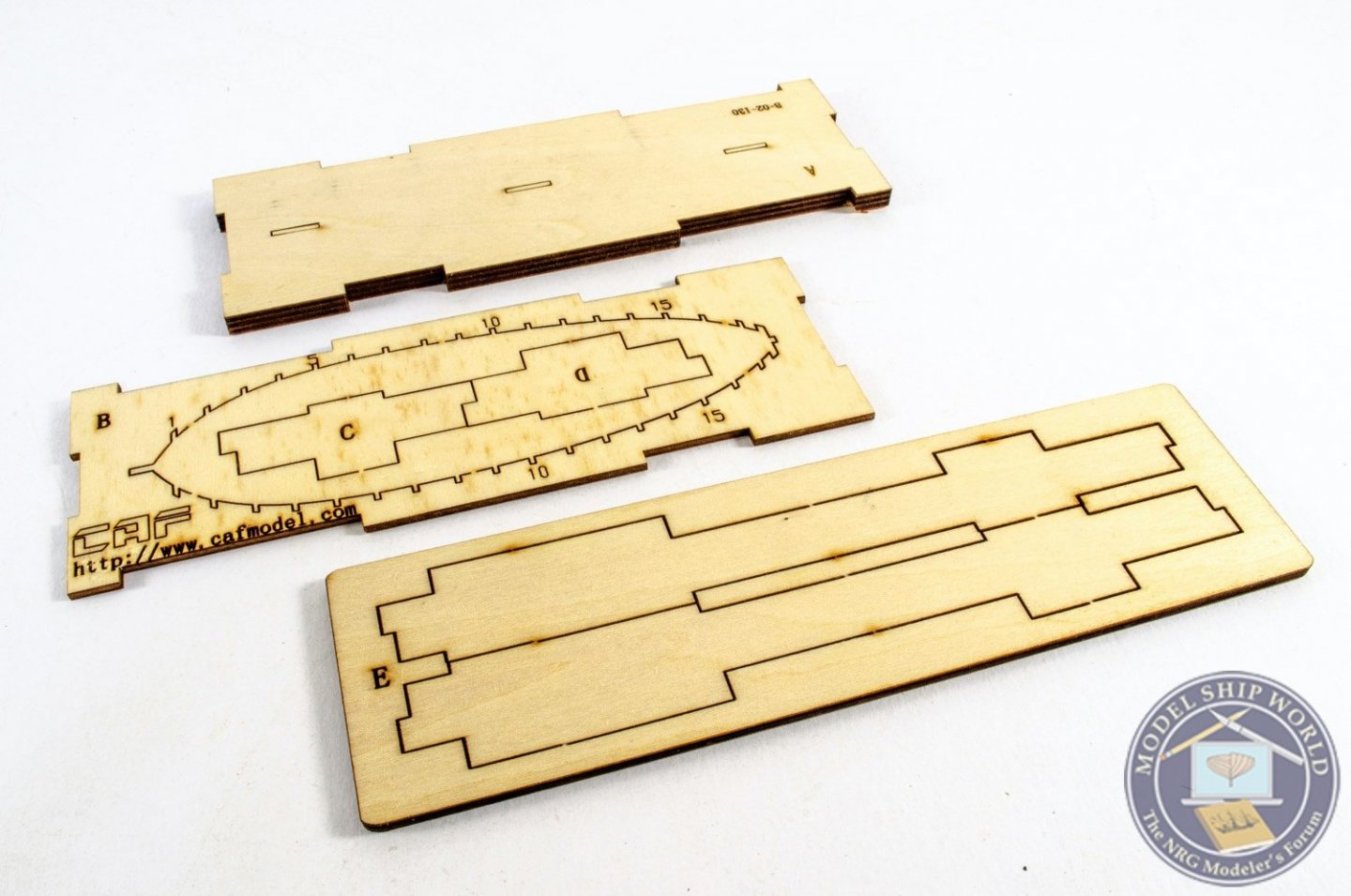

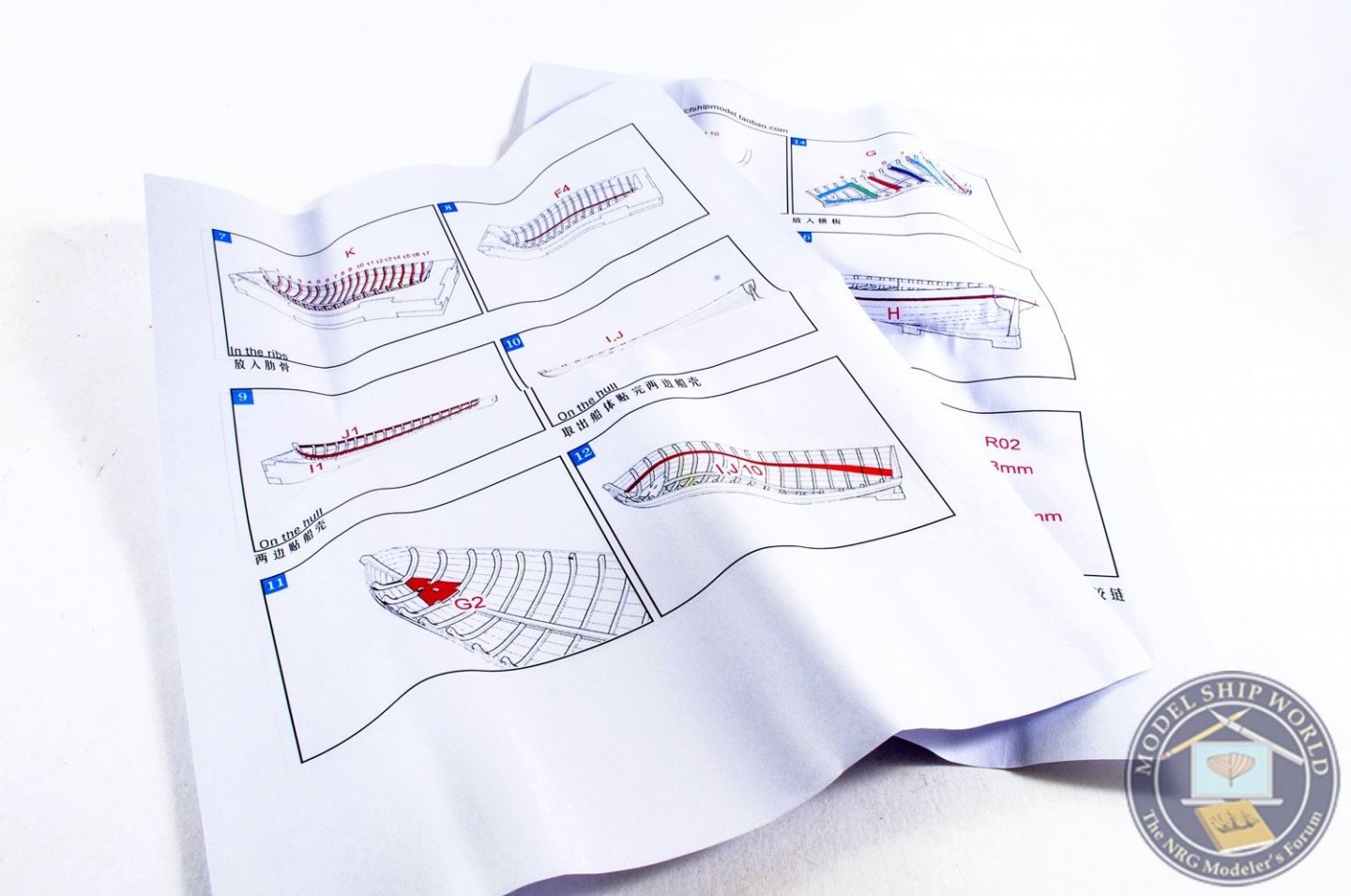

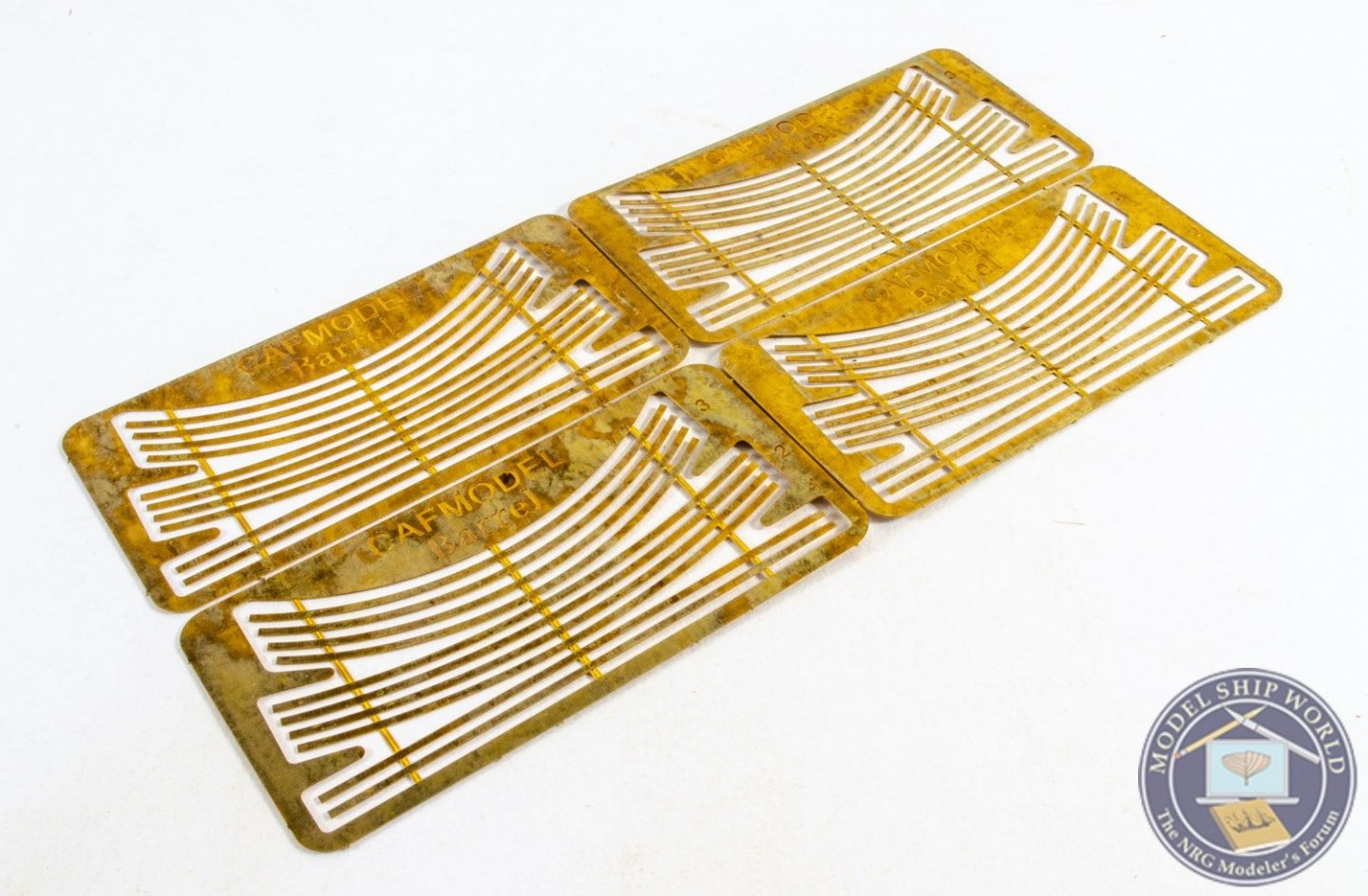

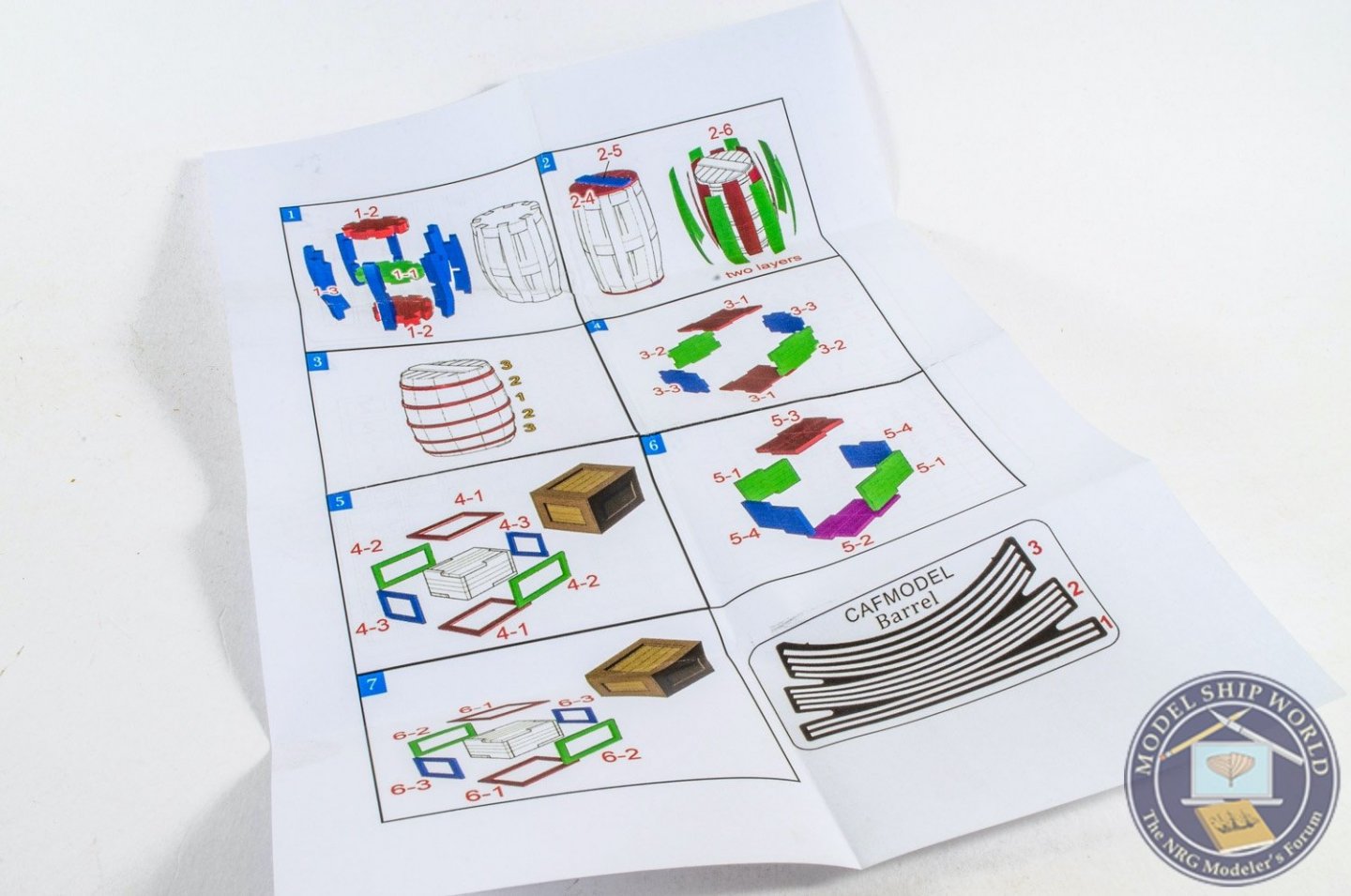

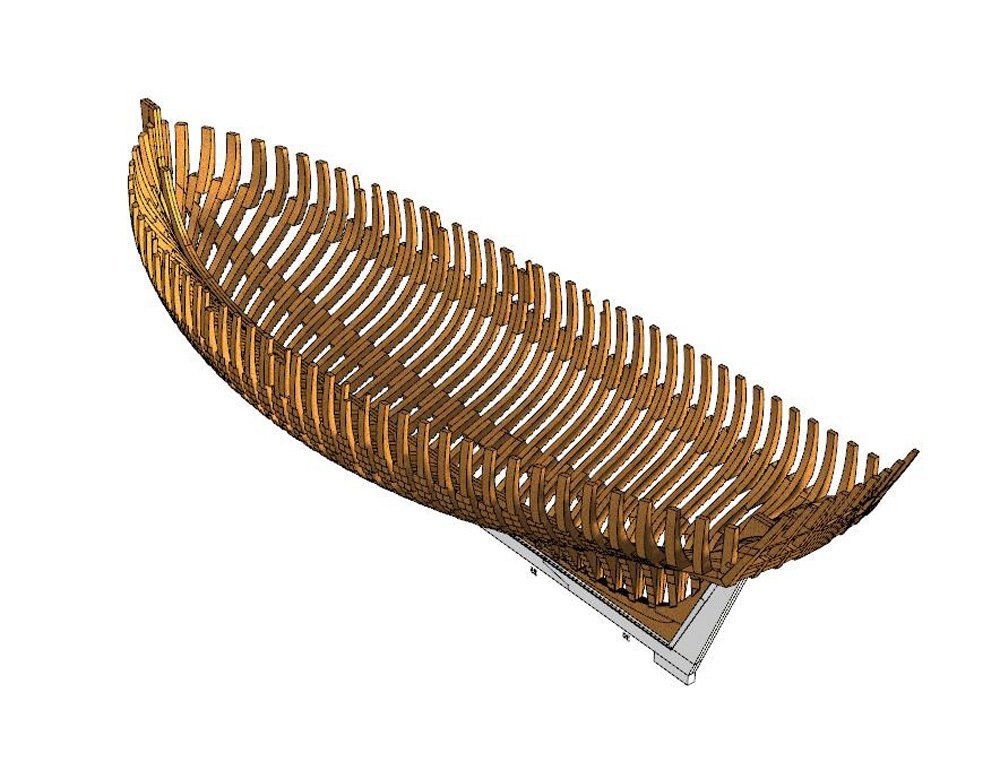

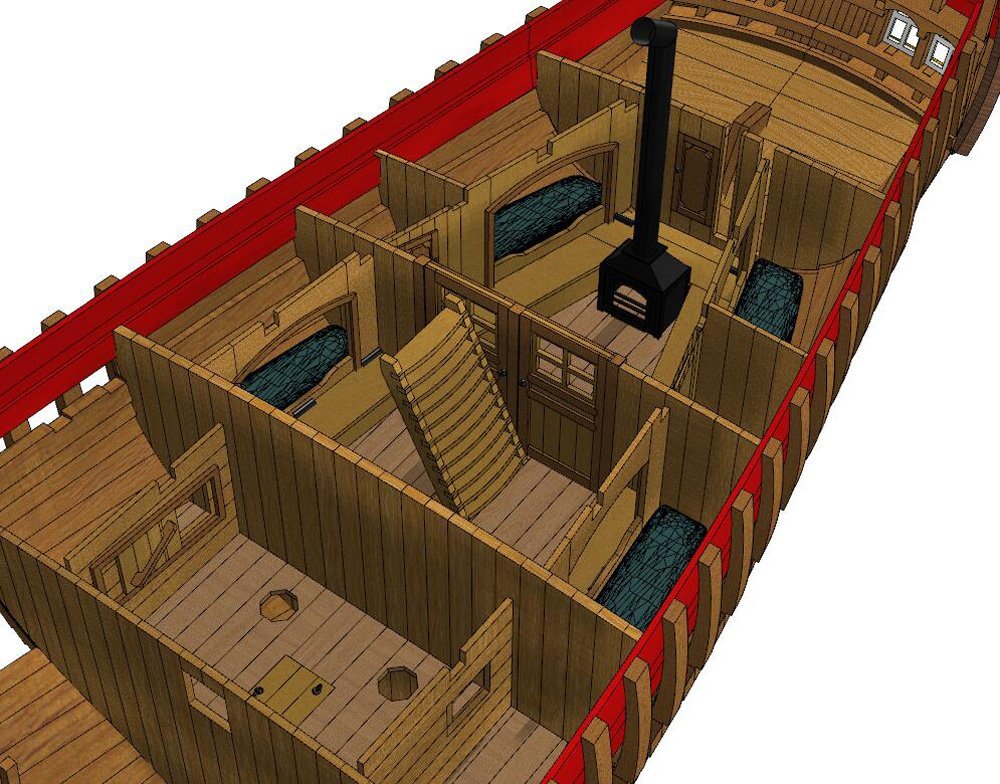

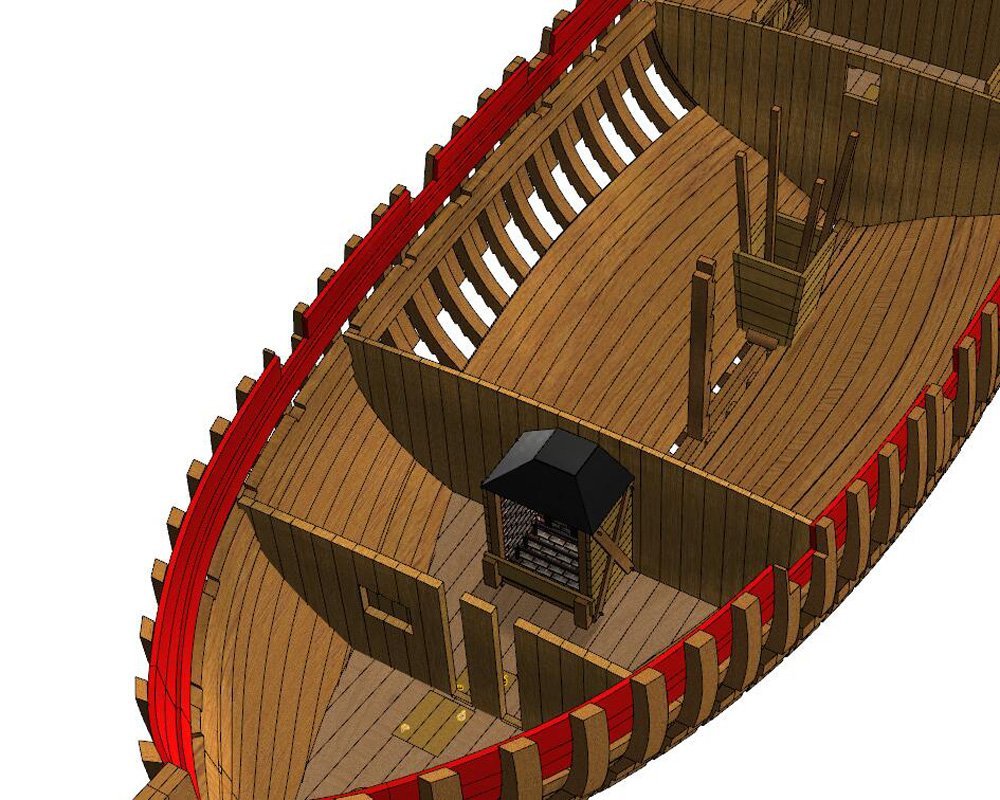

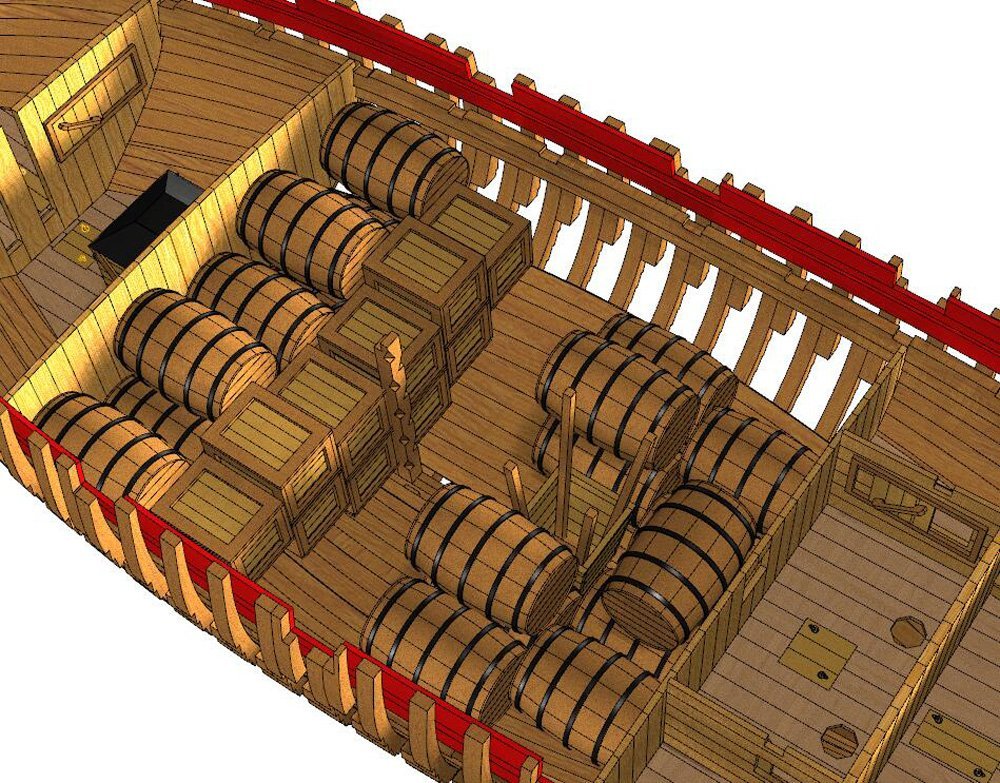

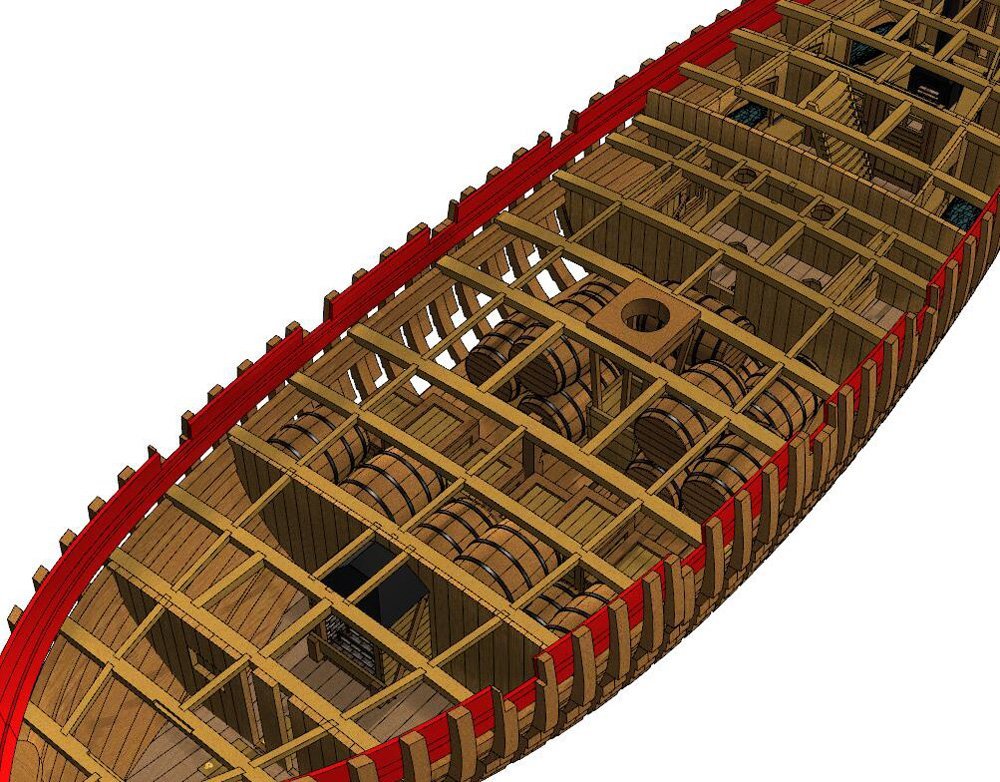

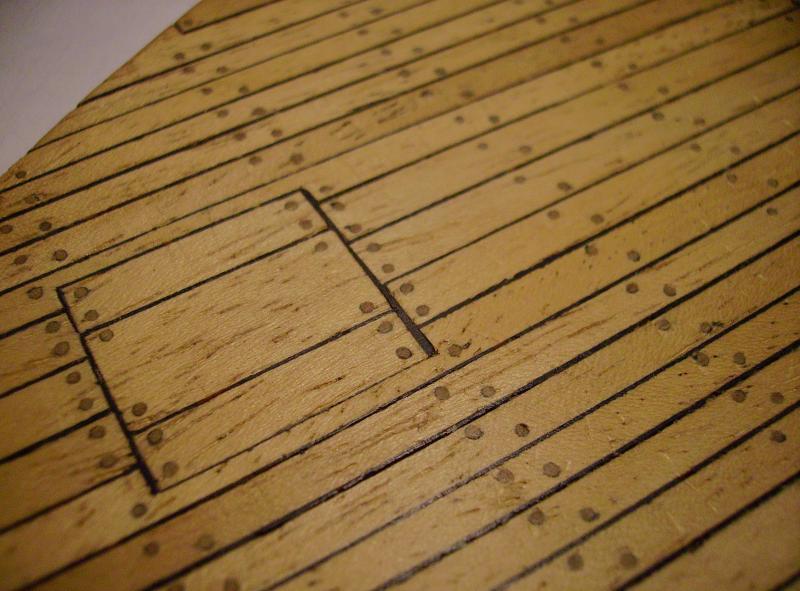

1:48 Le Coureur 1776 CAF Model Catalogue # SSL07 Available directly from CAF Model for $342USD plus shipping Le Coureur (1778) was a French lugger that Jacques and Daniel Denys built at Dunkirk and launched on 8 May 1776. HMS Alert, under the command of Lieutenant William George Fairfax, engaged and captured her on 17 June 1778, in advance of the declaration of war. In the engagement, Coureur, under the command of Enseigne de Rosily, had five men killed and seven wounded out of her crew of 50. Alert had four men wounded, two mortally. The British took Coureur into the Royal Navy under her existing name, as HMS Coureur. She was under the command of Lieutenant Christopher Major on 21 June 1780 when two American privateers, the Fortune and the Griffin, captured her outside Bonavista Bay after an action that cost her three men killed and four wounded. The Americans put Major and 30 of his men aboard Griffin, which fell prey the next day to HMS Fairy. Wikipedia The kit Le Coureur is split into two kits, Parts 1 & 2. To make things a little easier to understand here, this article will look at the contents of each individual box. Each box is a shallow, corrugated affair with a lid flap and folding edge with tabs that lock everything closed. Each box is also very full of material, so much so that when removing items to review, I had the devil’s own work in trying to get it all back in there! Still, that’s certainly nothing to complain about. Instruction manuals are nicely printed and in clear plastic sleeves, and the plans and photo-etch are also nicely packaged. All parts are also sheathed in a sealed plastic covering to stop anything moving about in transit. In the main photo, please ignore the inclusion of the Salamandre cutter. This is separate and will be reviewed soon. Pack 1 There are items within Pack 1 which pertain to Pack 2, such as side view plans with the interior, photo-etch etc. but for the sake of this article, we’ll look at them here as this is where they were found. Pack 1 is essentially a kit which produces the building cradle and the hull framing/keel etc. That’s it. So, you won’t find any embellishments, cannon or other fittings in here. What you do get are numerous ply frames that build the cradle, complete with a side plan engraved on one side, plus twelve panels of laser-cut cherry parts. This looks very easy to build and of course provides all positive locations for the keel, frames and stern timbers. CAF recommend the cradle base parts are screwed down onto a plat surface. I’ll use some high quality blockboard when my time comes, as this was excellent for the flying models I used to build, many moons ago. The latter are produced with rounded edges, and I think this is because they needed to be able to flip the parts over to add the engraving to the opposite side, plus some CNC machining……yes, CNC on laser-cut sheets! I know it’s the first time I’ve ever encountered it. As far as the engravings go, these frame parts really do require it as they mark out the bevel for this clinker-planked hull. That’s why some sheets have the engraving on the reverse too. One thing you will see on the reverse is some heat scorching. This varies from sheet to sheet, but the one I show here is the worst of them. These parts will need to first be bevelled to the engraved lines before removing the char as we don’t want to lose the engravings by simply sanding the whole sheet first. There doesn’t appear to be any loss of surface material with this, so it should clean up just fine.Each panel of parts is clearly numbered, and the part numbers are referenced with a map of the panels that’s provided in the manual for Pack 1. So, you will have a part on panel 2, for example, shown as 02-8-a for part 8a. Very simple. All frames are constructed on the series of drawings which are supplied on the rolled-up sheets. As these frames are built from parts on top of parts, the drawings also show where the overlaying frame elements sit, and you’ll need a metal setsquare to confirm things before you commit to glue. All parts will also need to be bevelled before any frame construction. Some parts panels, as mentioned, also have some CNC machining. This is to create things like the rabbet on the keel, and the bevel for deadwood bearding line. The machining itself will need to be cleaned up to smooth it out, but the majority of the material is already removed for you, so just the cosmetics will be required. Taking of CNC machining, CAF also supply some stern parts which are fully machine-shaped. These just need cutting from the blocks they are a part of, and then cleaning up. As these are naturally verry complex shapes, it’s nice to see these prefabricated for the modeller. Also in this pack, but for use with Pack 2 are two photo-etch frets, produced in brass. The larger one contains everything you would imagine you need, such as hinges, stove parts etc. An acetate sheet is included for glazing the stern windows. Pack 2 This box is identical in size to that for Pack 1, and again, contains that much material that you’ll actually struggle to put it all back properly! All items, including fittings boxes, are wrapped in a single covering of clear film. Included here are three sheets of ply, four sheets of maple (deck), and over 35 sheets of cherry wood. Ply parts are included to modify the building jig as your model progresses, and also for a display stand, although I would be sorely tempted to use the parts as templates and build a display cradle from a more suitable material. The decks are supplied as individual planks, laser cut into the maple sheets, and in the layout order in which you will install them. That’s a nice touch. I expect the laser char between them could be a good caulk representation, but I’d need to test that first. When it comes to planking, CAF supply the materials to complete the whole hull interior and exterior. The exterior is clinker, and all planks are provided as laser-cut parts over a good many of the included sheets. The instructions clearly show how this much be approached. The tricky internal planks are a godsend, especially with the taper that’s required, so the inclusion of those is also very welcome. CAF’s approach to other planked areas also follows that of the decks, where a specific area is laser cut in the order of application. It’s a no-brainer! Other parts, where applicable, are also engraved with bevel lines. Not all parts are laser cut. Three parts panels are CNC cut. These also include machined notches, and they appear to be deck beams. There are TWO fittings boxes with Le Coureur, and they are brimming with parts. The first I look at contains pins, rings, chains, lead sheeting, rigging blocks, leather, cord, clay stove parts, and a myriad of machined wooden items. First of all, the rigging blocks are machined from a dark timber and are supplied in chains that you need to cut up and clean the block ends. The machined wooden parts include the capstan and hawse, stern windows and stern embellishments. Some of the latter looks a little rough when photographed, but actually looks perfectly fine to the eye. Some very fine sanding sticks could be used to tickle anything you aren’t too happy with. To remove these fragile parts, you need to grind the backs of them over some medium abrasive paper, and they will be released. The second parts box contains numerous metal fittings. I’m not sure if these are brass or bronze, but the casting is excellent. The cannon emblems are very nice, but I was unable to get a clear pic on the bare metal. Other metal parts include anchors, hooks, triangular eyelets, hinges etc. Also in this box are various spools of rigging cord, and these also look very good quality. I was lucky enough to receive the Le Coureur nameplate, carved in pear wood, as part of their initial free gift promotion. This isn’t now included, but is available from CAF for $15. Brass wire is supplied on a wooden spool. A bundle of strip wood and dowel is included and is of high quality. Lengths are identified for size. Sail cloth is also included, but you will need to make these yourself using the plans as reference. Manuals The manuals are very good, with English that is certainly easy enough to understand (having been proof-read and corrected by our very own Kerry Jang), and especially in context with the illustrations which have coloured elements to show what’s happening. The Pack 1’s 15-page manual focuses solely on the construction of the building cradle, preparation and assembly of the frames, and of course the basic building of the hull. Hull construction ends with the fitting of the keelson, and with the skeleton still within the building cradle. The manual supplied with Pack 2 is a thicker publication, with 50 pages. Here we see the external planking, interior of the hull being fitted out with interior planking, interior bulkheads for the various compartments, floor, cabinets, sleeping berths, stove etc. The hull is indeed fully detailed within. This model is also fully masted and rigged and this is all shown in superb detail, rope by rope, rigging block by rigging block. As with the previous manual, you will need to cross identify each part with the parts map in the back of this manual. Numerous sheets of plans are supplied either rolled up or folded, and in full size. The largest, showing rigging and masting, is printed in A0 size, so you'll need a large place to hang this up! Drawings are superbly done, and to my eye, look easy to understand, but then again, I am used to studying technical and engineering drawings. Cutter This type of cutter was very typical for the time, hence the reason for its inclusion with this kit. CAF have packed this into its own little box, and it presents a project in itself. As with the main hull, this is built up using a box jig into which seventeen individual frames sit on the keel, followed by the keelson. My only criticism of this is the use of ply for the frames. I feel these should’ve been made in cherry or preferable pear. All planks are laser cut into a thin veneer and need to be handled carefully. When built up, this should look a very attractive little addition to Le Coureur. Accessories This kit includes a small box containing barrels, crates, small crates, beds and also four crew. The barrel staves are produced in thin veneer, and photo-etch for the hoops. The crates are of simple construction and the parts look great with their laser engraving. Four resin crew figures are supplied too. Conclusion This is the first time I’ve seen a CAF kit ‘in the timber’, so to speak, and I very much like this release. Production quality is high and I think it sells for a very reasonable price for the amount of work and time you will invest in the build. CAF have tried to make the dark art (for some of us!) of POF, as simple as they can with engraving lines for bevelled frame parts, machined chamfers and also pre-cut planks. Still, this will be no walk in the park if you’ve never attempted such a project before, but CAF has done as much as possible to hold your metaphorical hand throughout the build. There is some clean-up required on the rear of some panels, to remove scorching, but this won’t be too difficult, and the inclusion of those machined stern timbers is a very nice touch. Kit fittings such as stove and cannon are also nicely cast and made, and the wooden barrel and crate set add an extra degree of life to the already nicely furnished hull interior. Of course, there’s those resin crew and beds too. In all, this is a very attractive and comprehensive kit of a very worthy subject. One beauty of this POF kit is that the frames have a natural spacing which means you can still the interior if you decide to leave a number of planks off the model. Head over to CAF Model and place your order. Looking forward to seeing some build logs of this on MSW. My sincere thanks to Tom at CAF Model for the kit reviewed here. To purchase, click the link at the top of the article.

-

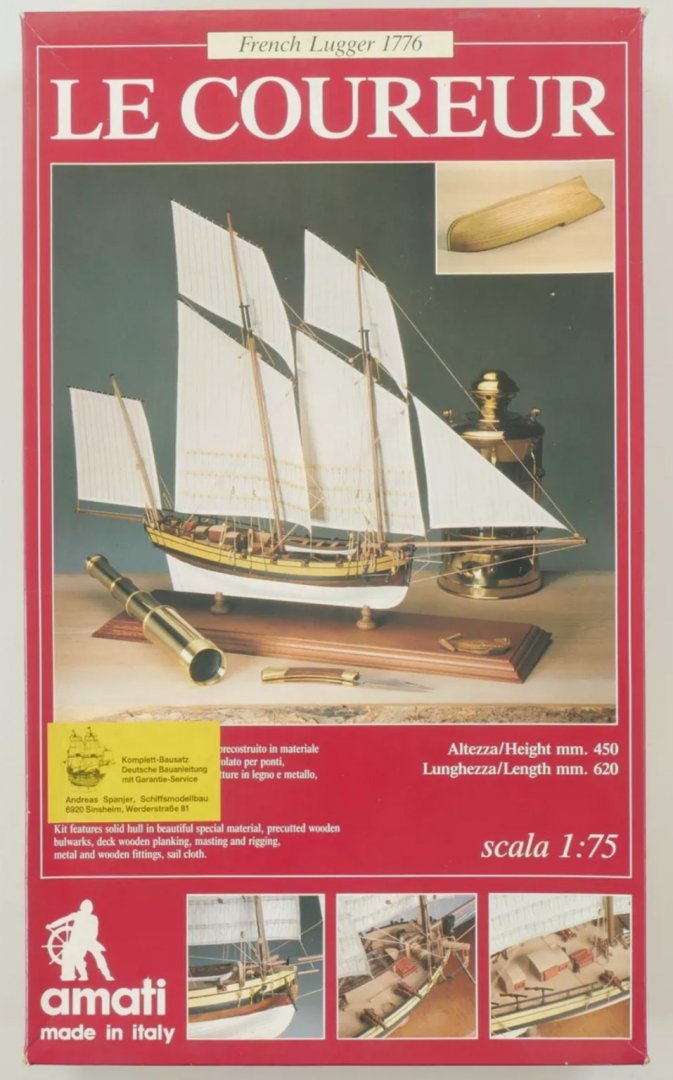

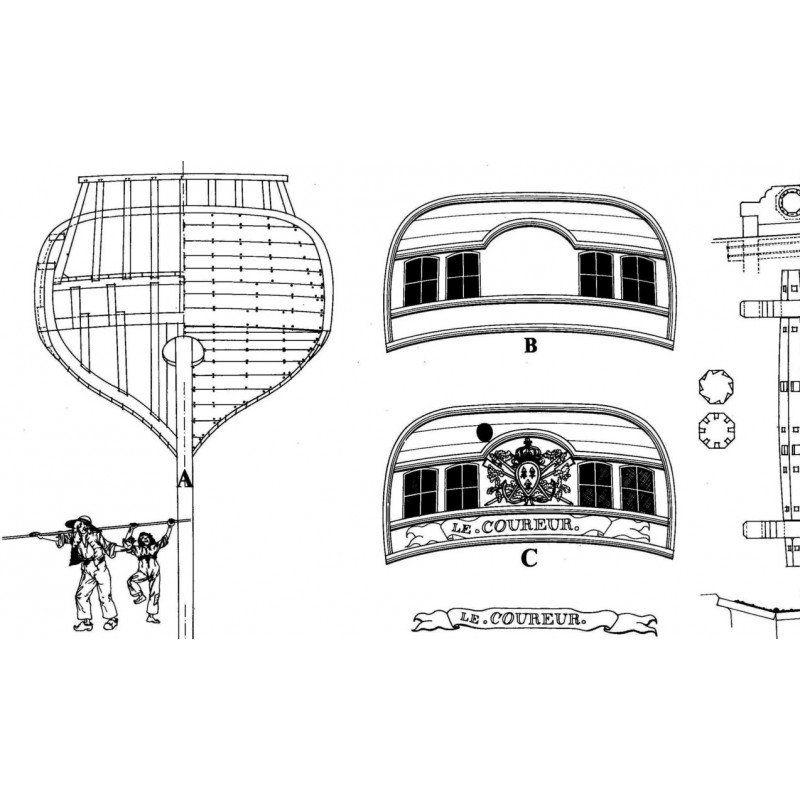

Hello friends of the shipmodel! Due to illness I have to drove back and more slowly. So I renewed my first non pure plastic kit of the COUREUR by Amati. I tortured this kit 25 years ago and lost it an increcibly unlucky accident on a removal - when a shelf fall on the model in its card box driving the masts through the hull. So I searched around for sources of further information. I am totaly aware that this model isn't the peak of the kits (and ordered an 1/48 wooden kit from Russia in the hope to get somthing more "qualitavily" better). I want to build this kit with your help and some support from the well known Ancre Monography by Berti & Boudriot. The Monography shows an interesting mixture of the RN changes (staircase superstructure) and the original French ship (1pounder handguns aft). I found a very very good build of the Shipyard card model in 1/96 from a Russian website: https://karopka.ru/community/user/18476/?MODEL=381160 Here the beautfull superered and I coloured and painted transom... ...and the Berti & Boudriot drawing to comparison of the details. As the hull is a massive block (of I do think to remember PolyUretan/ HardFoam?) there isn't very much to do without drilling the holes for the mast. As we all know we have to decide for a single solution of the prototype. Here the precaptured deck of the Shipyard card kit and the Russian superdetailling of the very same kit side by side (right). So I think about the story of the recaptured LE COUREUR so as the RN plans show but under the Pure Blance flag - using all the features Amati added to the kit. Does anybody has had any experience onto this kit and is able to tell a bit about some of its trabs and its sources of trouble? Hope you like it, HdS

-

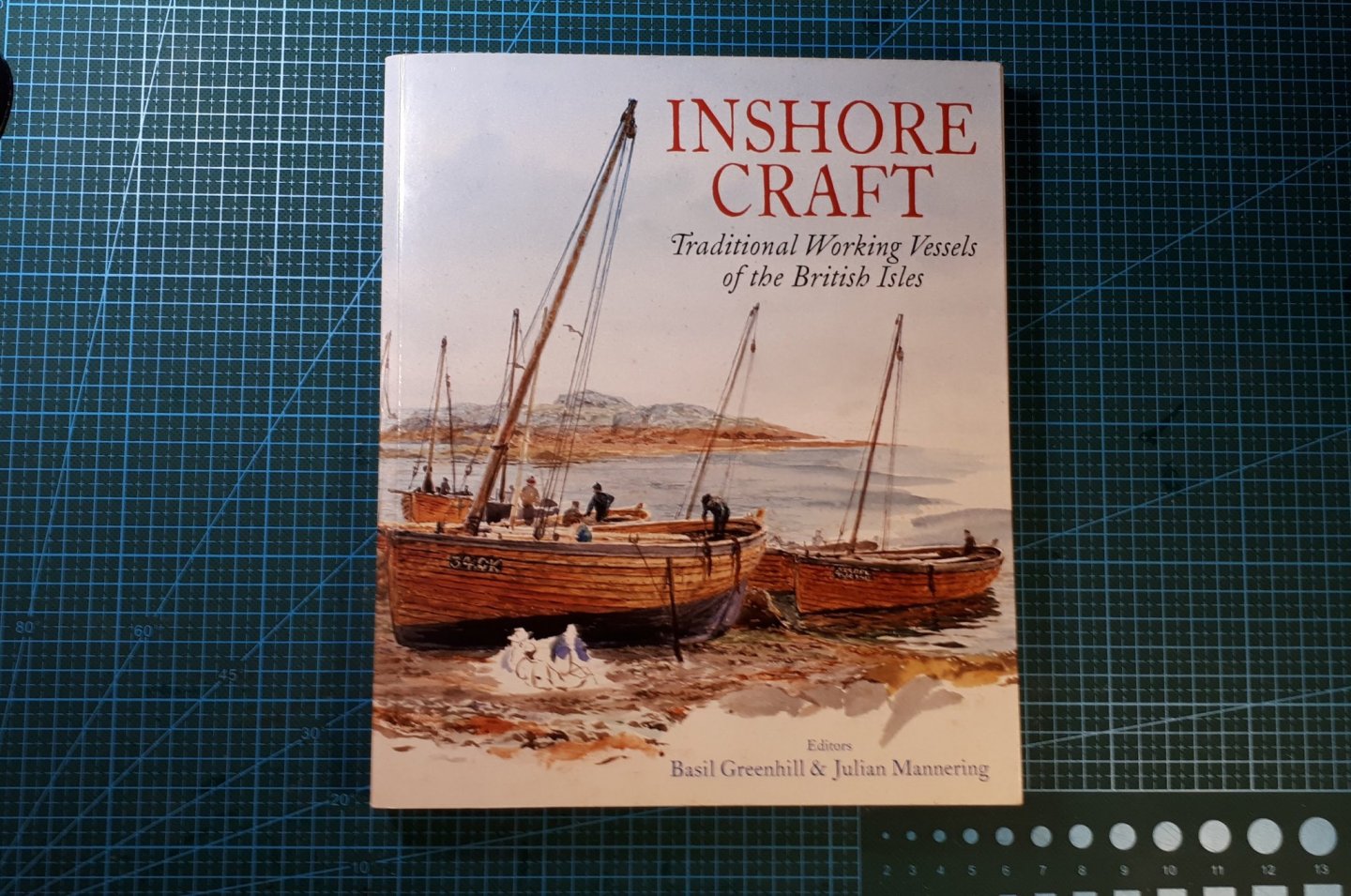

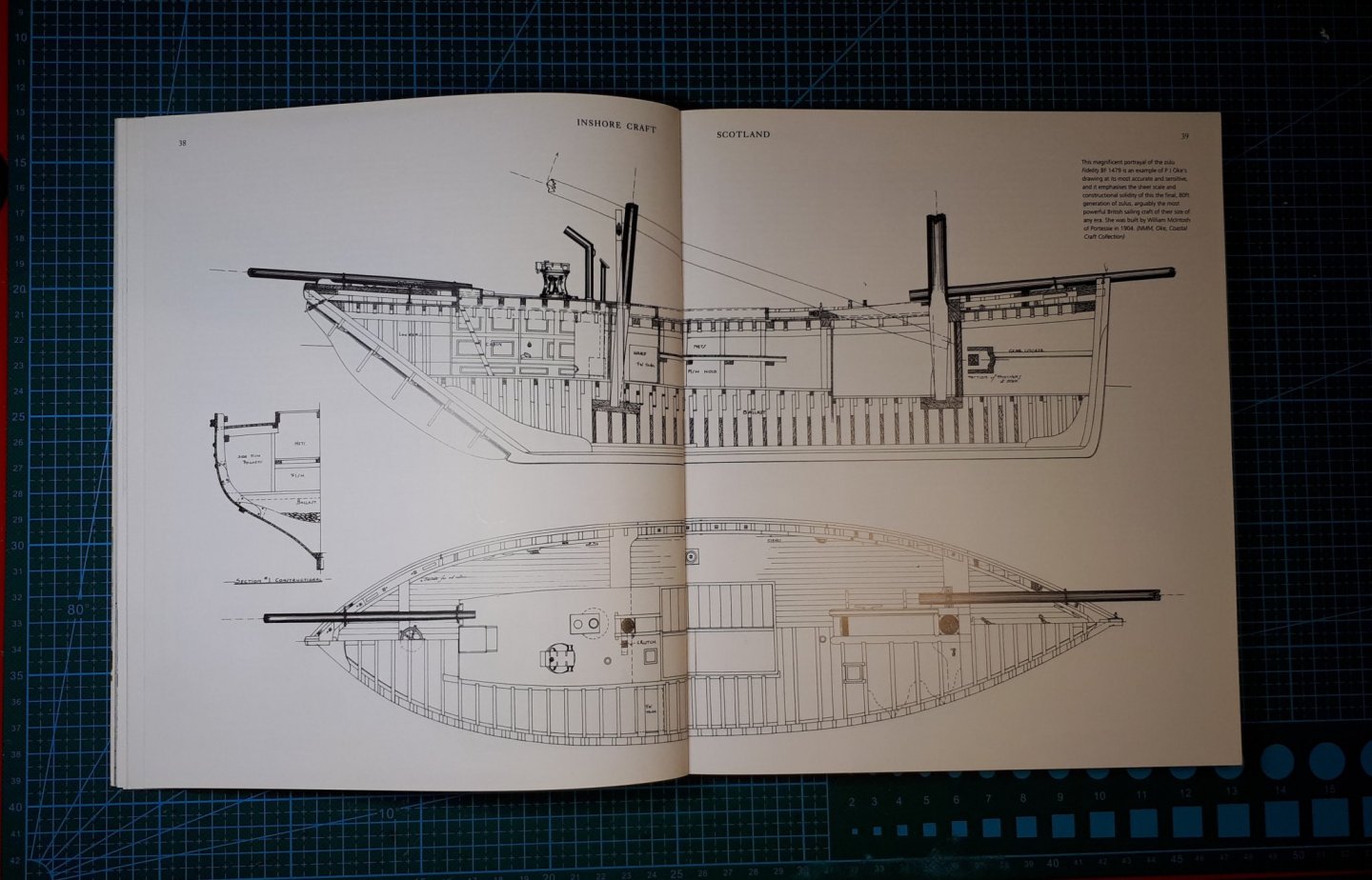

My current project is a lugger of the east coast of Scotland, a type of ship called Zulu, which was the most powerful and efficient sailboat for the herring sail fishery among those of its size in the British Isles. Its origin dates back to 1879, the year in which a Lossiemouth fisherman, William "Dad" Campbell, devised a radical design for his new boat for the capture of herring. He had the vertical bow of the fifie and the sloping stern of the skafie, and called this ship "Nonesuch." It was relatively small, with 16 m. of length and a keel length of 12 meters. This design, which provided a longer deck and a shorter keel, markedly improved the maneuverability of the boat and provided it with a good speed, characteristics that made it highly appreciated by herring fishing fleets, as they managed to reach promptly to the fishing grounds and return quickly with the catch. Due to these qualities, that type of vessel quickly became very popular throughout the Scottish east coast. The new type of vessel was baptized as a Zulu because of the war that was developing in South Africa at that time, in which Scottish soldiers fought, a war that was rejected by the population who thought they were fighting in an English conflict that, deep down, they were not concerned, which made their sympathies lean towards the Zulus. The Zulu ships were carvel built, instead of clinker built, which was the most common in those waters. They were provided with two masts carrying lug sails and a bow jib. The sails were heavy and difficult to maneuver, and the masts to carry them had to be very long and strong. In the Zulu of greater size, the masts came to be 18 m high in boats of 24 m in length. As the twentieth century approached, steam winches were introduced aboard, which made maneuvering sails and nets much easier for crews. However, and despite the success of its design, the life of the Zulu was quite short, since it was replaced by steam fisherboats after a brief existence of just over three decades.

-

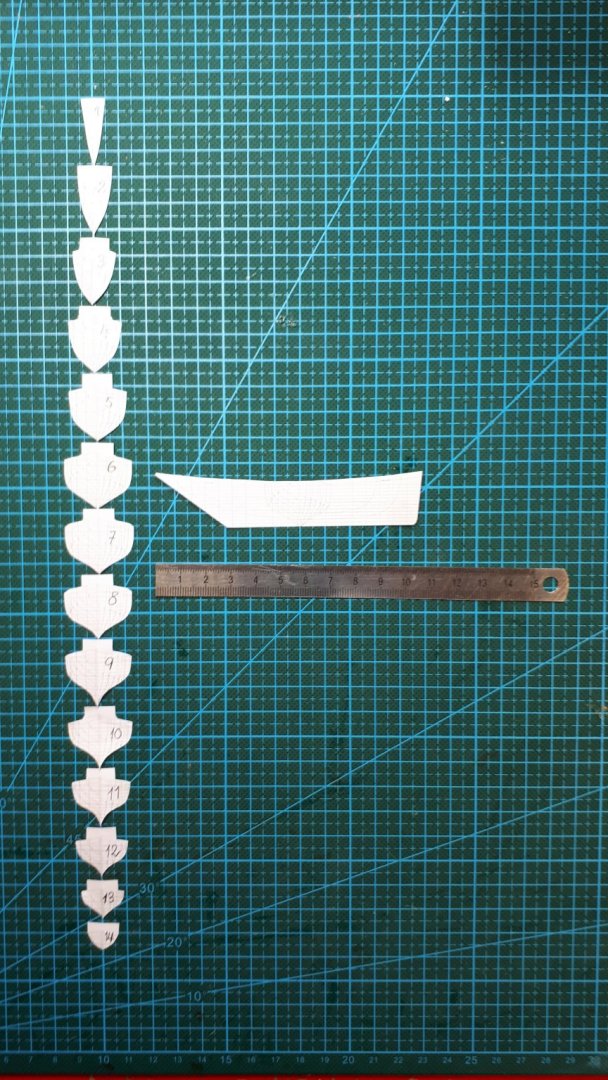

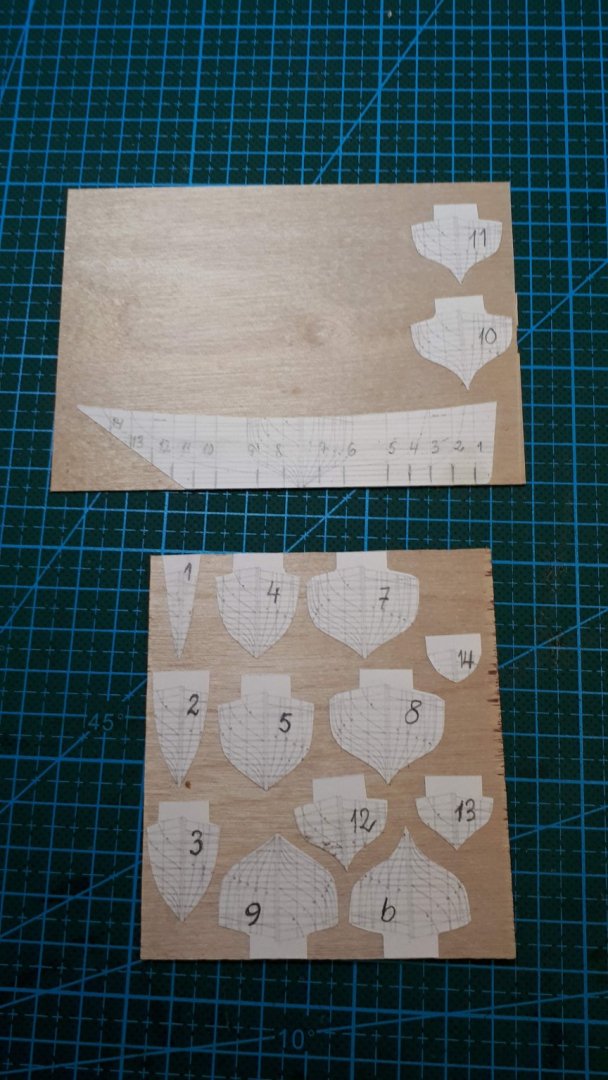

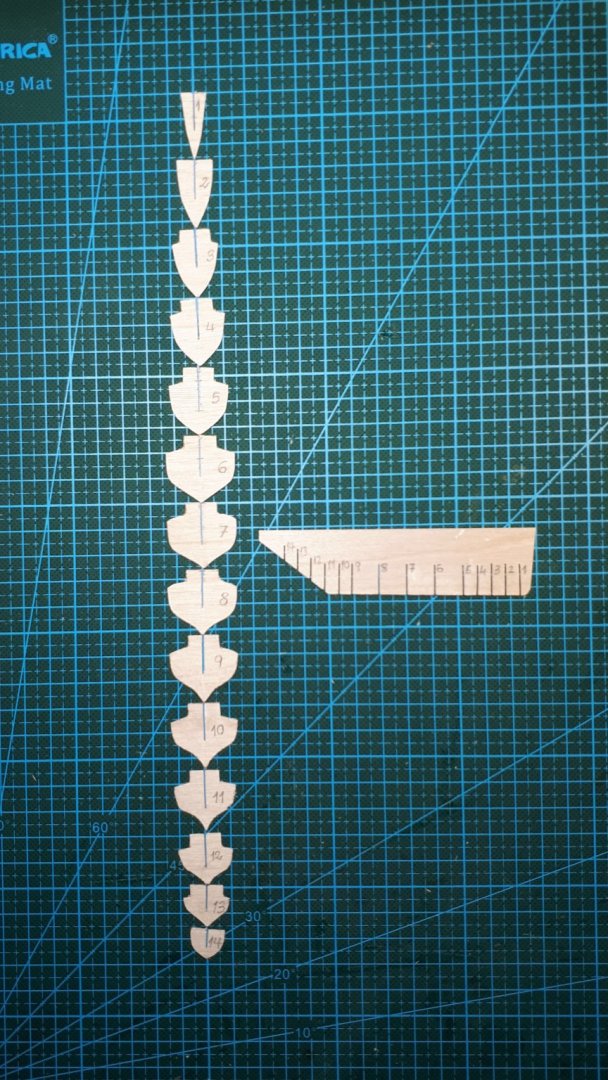

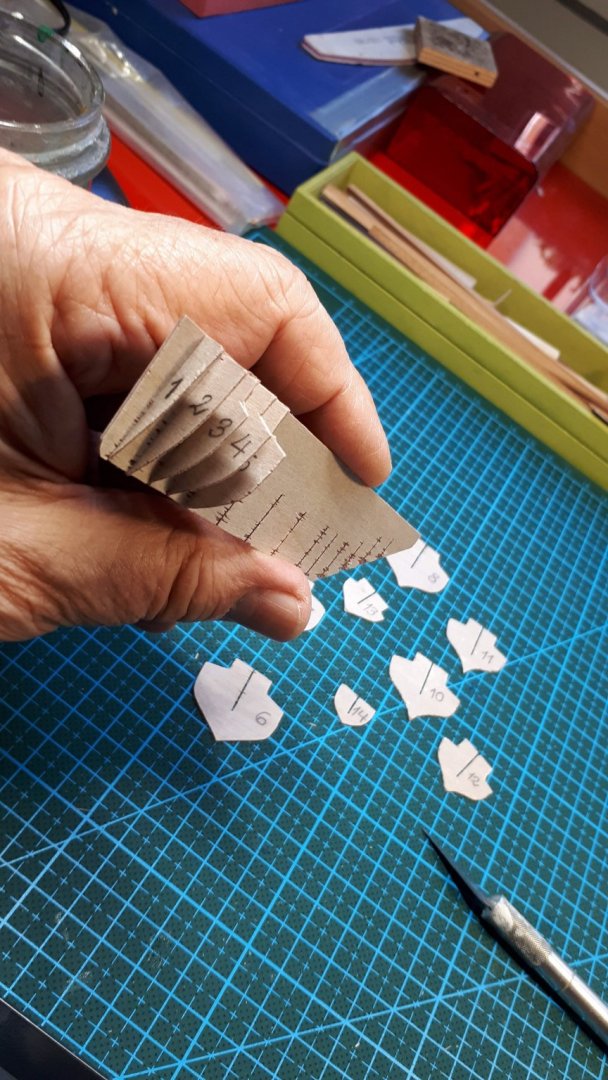

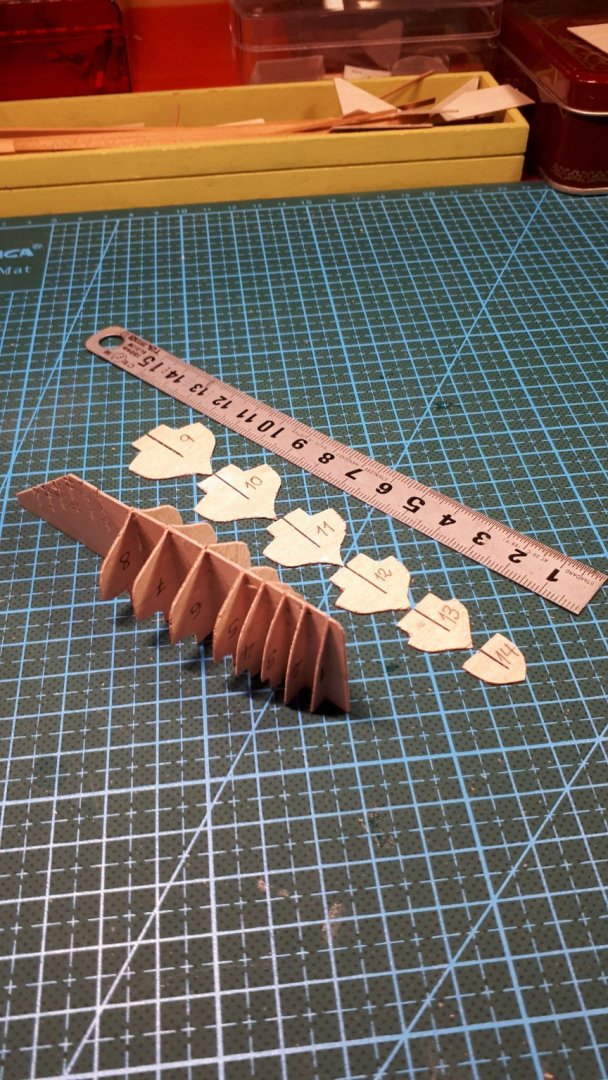

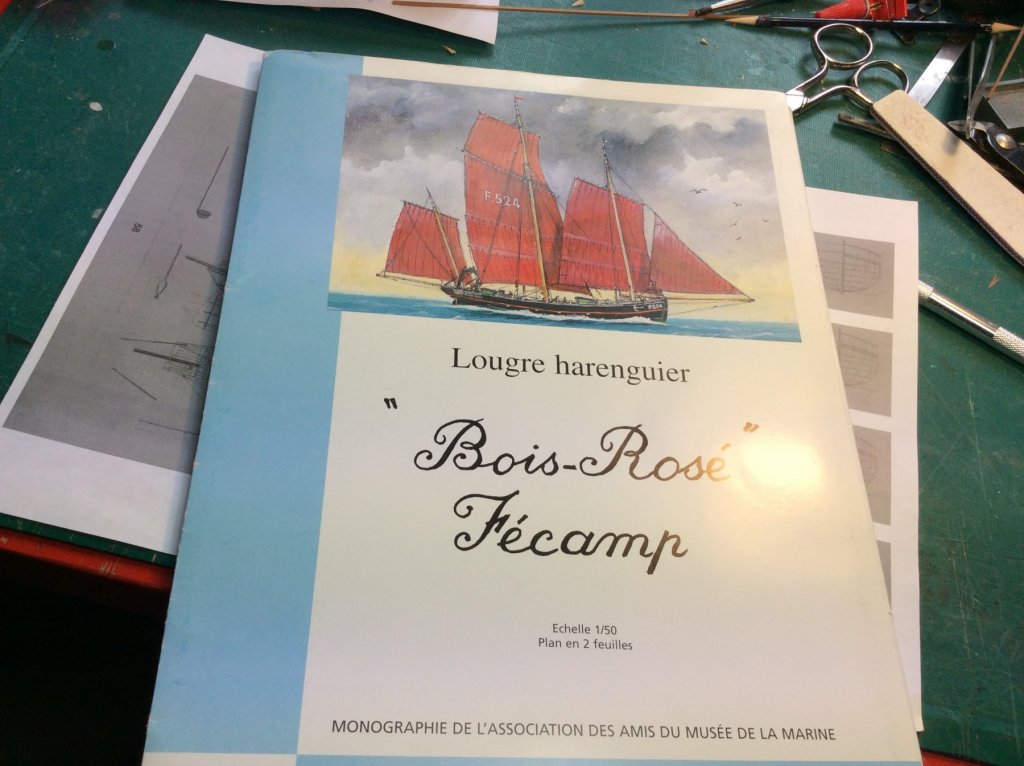

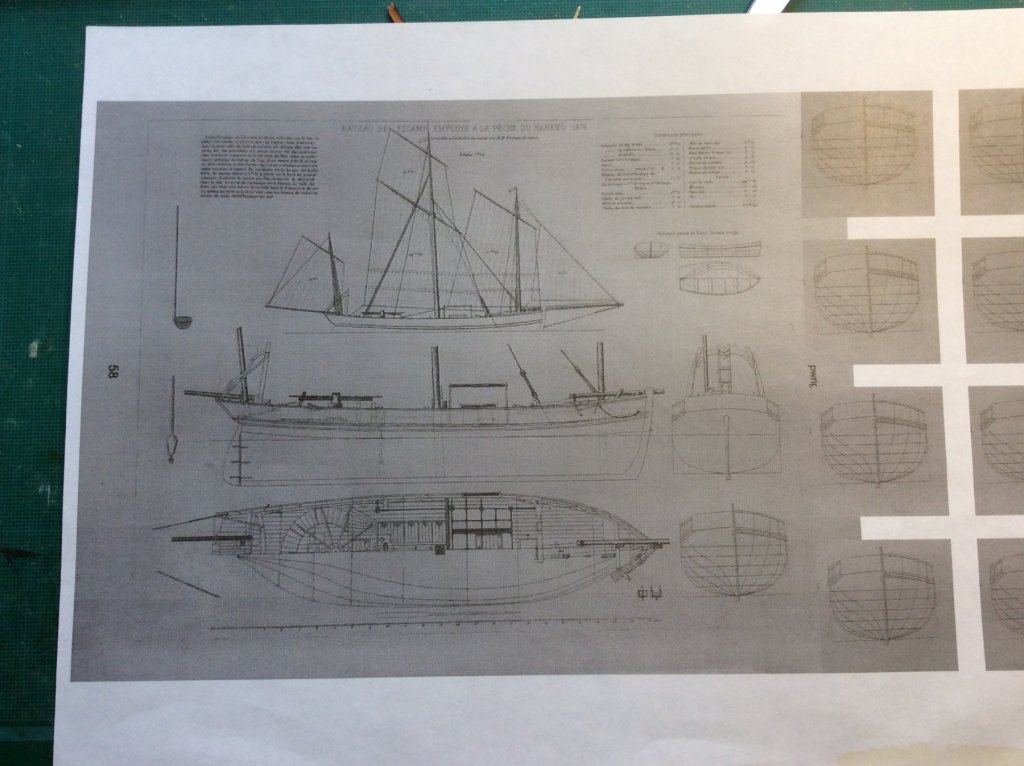

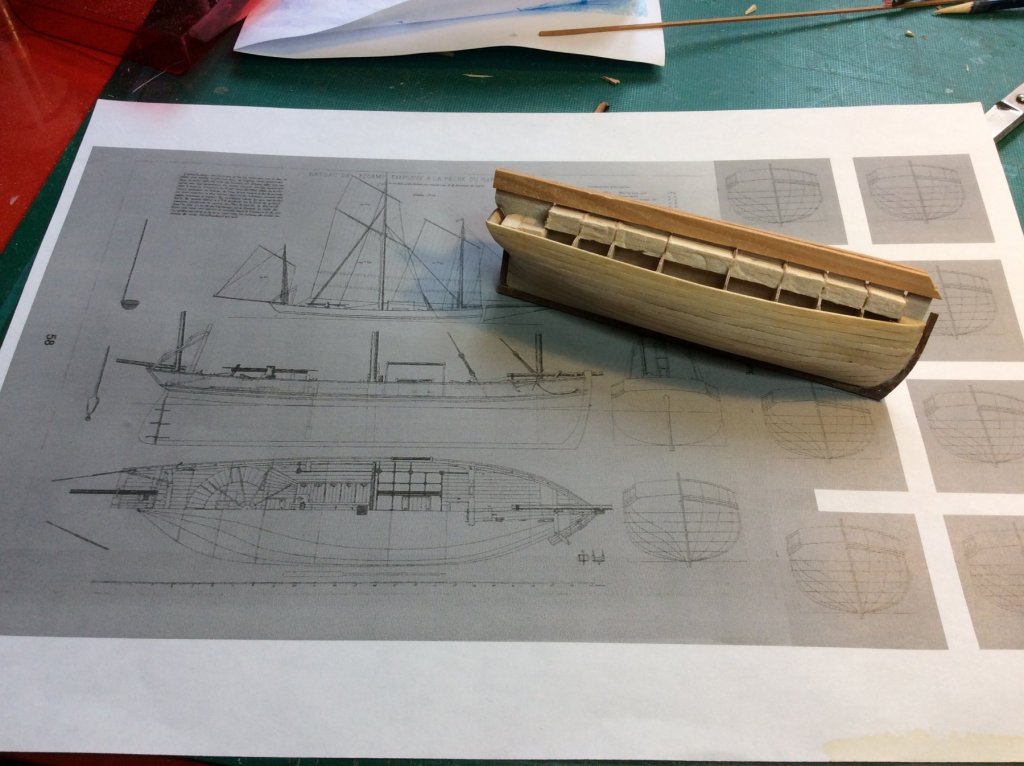

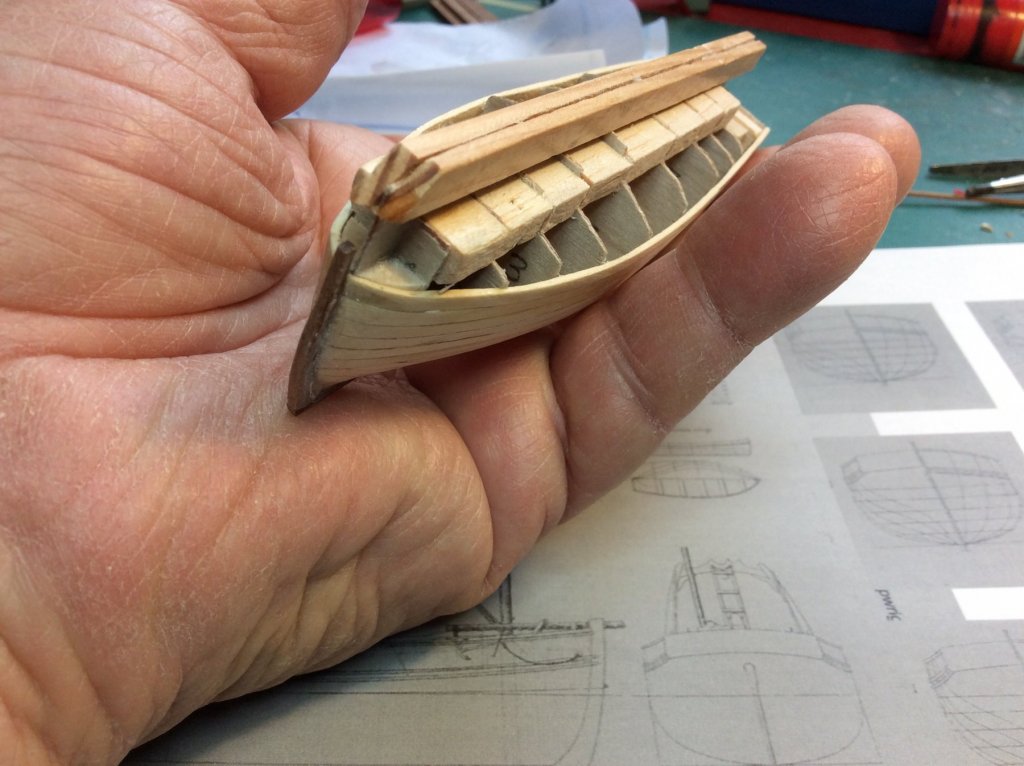

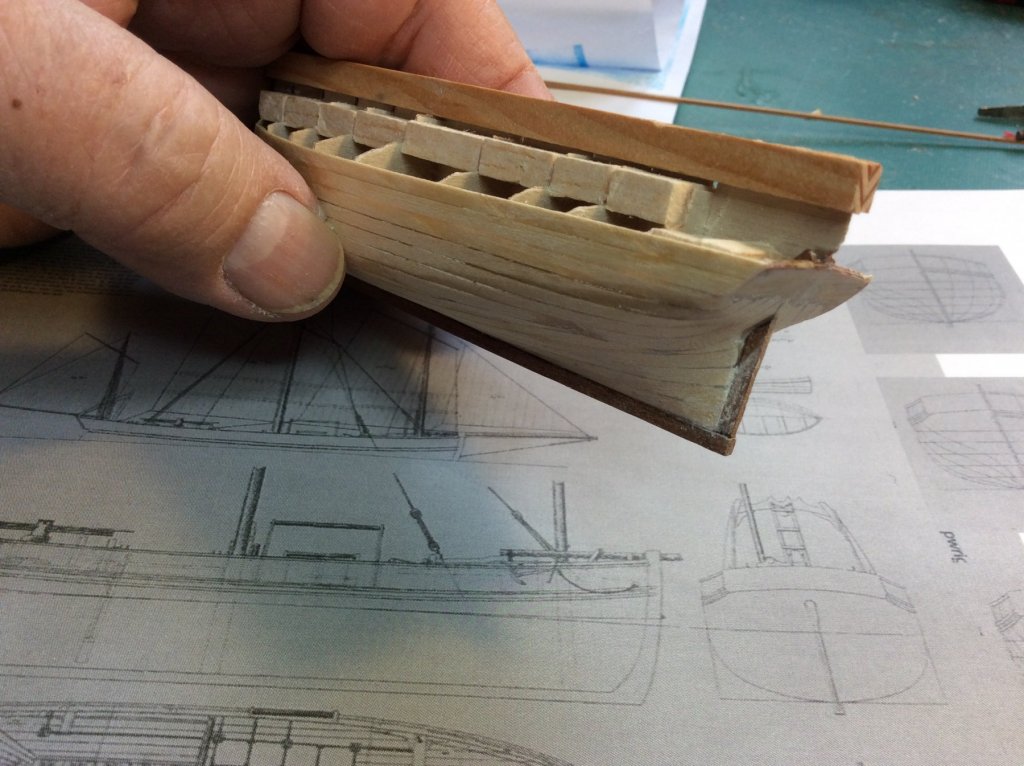

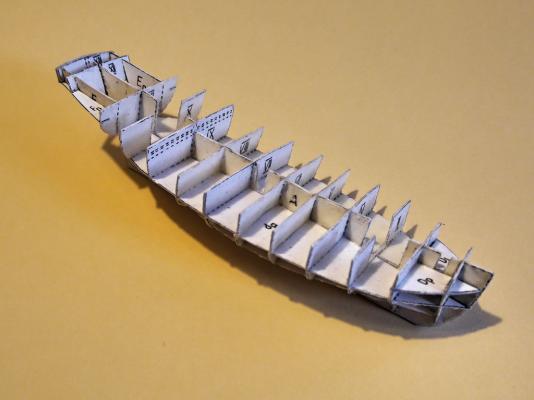

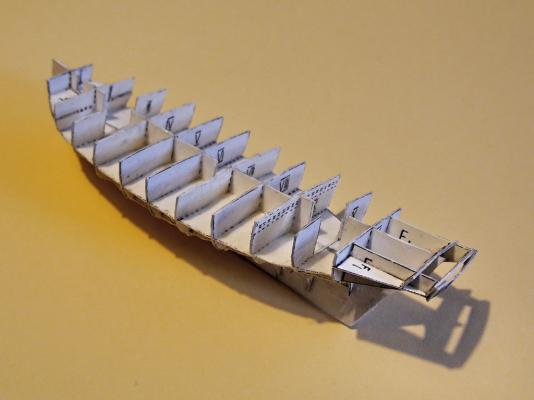

I start a new model for my collection. It is a "Lougre harenguier" by Fécamp, based on the plans in the collection "Souvenirs de Marine Conservés" by Admiral Paris and the monograph of the "Bois-Rosé" of the Association of Friends of the Navy Museum from Paris. The system that I follow for the construction of the hull is that of disposable frames. This system of disposable frames I already showed it in my previous Build Log of the Tartana de Liguria. I believe that the photographs clearly show what the process that I carry out. I started this model about ten days ago, and the last pictures show the current status of the work in progress.

-

A couple years ago, I came across pictures of a replica early 19th century lugger, the Grayhoud, from https://www.grayhoundluggersailing.co.uk/ . This type of rig is simply beautiful and looks fast standing still. The model I built is from plans from an early 20th century Biscay fishing lugger, but the rig is from Lennarth Peterson's Rigging Period Fore-and-Aft Craft, so is based on accurate early 19th century practice including shrouds with ratlines and cordage shrouds and stays rather than steel cable, for example. I also armed her with eight carronades. I found some plans thanks to lovely people from this forum, and built it over the last two years. I've been taking pictures of the process here and there, but I was kind of lazy so I didn't update a build log 😳. So here are some of my pictures with explanations of how the build went, and when I'm done setting up this log I'll post in the gallery. Thanks to everyone who helped me find those plans! Here are some reference photos first.

-

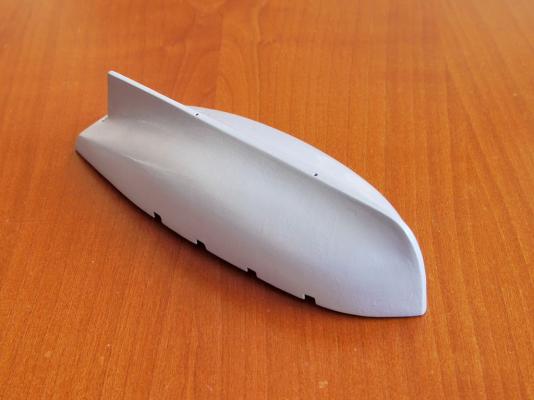

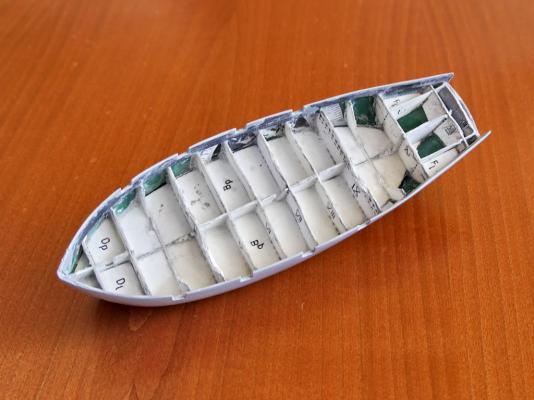

Another project.. Better to say a bit of experimenting Time ago I found the paper model for Le Coureur, and for the first I decided to made the hull, to see the lines and how do the paper works in this case. In meantime I found drawings from iconography, in small scale, but my intention is to made a small scale. As I started with LN in 1:120 (in fact 1:119) I decided that it will be my standard scale so reduced the drawings . I haven't the requested paper but used some envelopes and made some copies, glued together. For fast and straight gluing I use PVA glue and the iron for faster work. (also with iron prevent the elements to deforms due to the water from PVA glue) I made the skeleton and that was like a playing.. but the lines seemed nice so I decided to continue. But the hull made from paper wasn't too nice, many panels are deformed like on the real steel boats. So I fixed the paper with CA glue and then applied the mono-component car's putty (IMPA) which regularly is used on plastic modells Few repeating of sanding and applying the putty, final coat of liquid fine putty Mr Surfacer and sanding with paper 1000 to obtain clear surface. The next step will be the second layer of boat's hull, it will be done with styrene strips

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.