Search the Community

Showing results for tags 'mill'.

-

I'm in the market to upgrade my workshop. I have several kit boats under my belt, and being retired I am spending more time in the workshop. I'm currently finishing up on the Pen Duick and eyeing a Shrimp boat next. I have been using a Dremel drill press to drill small holes in 1/8 or 1/16 brass strips. I have not been happy with the results. The drill bit can bounce around on the brass, and there is too much play with the unit when I switch it on which causes me to try to realign the work piece after the power is on. I solved some of these issues by using a on/off foot pedal, and using tape on top of the brass to help steady the drill bit on contact. But I'm still itching for an upgrade. I do not have an XY table, and I have never used a Mill or a Lathe (yet). I do see myself wanting to try Mill/Lathe capabilities sometime in the future as I grow my skills in modeling. I have been looking in to Vanda-Lay industries tools for the Dremel as an option. I could get their Acra Mill Plus with all the attachments for around $450 + tax and shipping. This would give me a Mill, Drill Press, and Lathe. As well as XY and Z control. Or I could start with the Drill Press Plus with Vice, and Drill Press table for around $215. But I wouldn't have XY precision (I'm not sure I need that), and no Mill or Lathe. Their products look good, but they are based on a Dremel which may be an issue with precision, but it could be good enough for an average modeler. I'm OK spending up to $500, but not interested in getting up in the $1000+ high end micro tools. The boss would not approve. I could start with the drill setup now and ask Santa for a Mill or Lathe down the road. Does anybody have a recommendation? I have also considered the Micro Mark 3 speed Drill Press for $300 when I add the XY table, Proxxon TBM 115 for around $315 with a XY table, or the Proxxon MF70 Mill at $400 which include XY I think. I also could go cheap with a Euro Tool DRL300 from Amazon for $115. I suspect some will say get the Proxxon Mill for $400, but to date I only use a drill and the mill looks awkward for mostly drilling. Thanks for your thoughts, Bill

- 9 replies

-

- Vanda-Lay Industries

- Drill Press

-

(and 2 more)

Tagged with:

-

Hi to everyone, I know there are already several similar topics however I have not been able to find an answer on this specific issue. I am currently looking for buying a desktop mill and noticed that most of you are using the Sherline mills. Unfortunately they’re not available in Europe so I would have to ship it from the US and import it in EU. This could be quite expensive so I am looking for alternatives. I’ve been looking for the small mills like the Optimum BF16 Vario. Does anyone has experience with such desktop mills in ship modelling? Are they accurate enough? They are quite heavier then the Sherline or some Proxxon mills so I presume I could use it also for some other milling requirements which is of course an advantage... Any help/advice on this one would be much appreciated. Thanks! Rok

-

Hi All I have been getting very interested in these little machines recently. Only really for fine wood milling. You see a lot of them across ebay and Amazon, pretty much all of the home market ones seem to come from China. They are three axis, USB linked, approx. A4 table size and come with a software package. And the prices are very good. But that is as far as I have got, in a lot of respects they seem too good to be true. Has anybody got any experience of using one? Or even seen one in action. I would like to understand a lot more - build quality, spares availability, ease of programming, reliability etc etc Nick

-

All, I have a couple questions. I have been granted permission to purchase a mill. I have decided on a Sherline 5400. Where has everyone purchased their equipment? Directly from Sherline? An authorized dealer? Obviously I'm looking to get the best deal I can. Also which does everyone prefer, imperial or metric? I don't want to start a debate, but just looking as to which direction everyone goes and why. What about DRO (Digital Read Out) seems like it would be a nice feature to have. What about CNC, I've never used CNC before and for what I will be using the mill for it doesn't really seem to be an option I would really need right now. Any guidance would be appreciated. Thanks Shawn

-

Homemade mini Lathe by Aluminium Alloy Parts and Tools: 1 pcs Aluminium Alloy Profile 650 mm x 80 mm x 40 mm. 4 pcs Aluminium Alloy 6061 120 mm x 80 mm x 12 mm 2 pcs Aluminium Alloy 6061 150 mm x 80 mm x 12 mm Mini Lathe Chuck, Head Drll, Motor Sew Machine, and few time holiday http://www.youtube.com/watch?v=lJC6q7f7yPY http://www.youtube.com/watch?v=DsRVrV95x4A http://www.youtube.com/watch?v=Jrl629jmEkA http://www.youtube.com/watch?v=mPqJ0y9FV5Q http://www.youtube.com/watch?v=H42UeDIShfM More Step by Step and More Homemade Lathe DIY Mill Miling CNC Router here:

-

- HomemadeCNC

- DIY

-

(and 2 more)

Tagged with:

-

Homemade Vertical Mill Router by Aluminium Alloy Profile very easy and cheap Parts and Tools: 4 or 6 or 8 SCS10UU 20 mm Linear Ball Bearing Motion Bearing CNC 2 x 300 mm 20 mm Linear Rails 2 x 400 mm 20 mm Linear Rails 2 pcs Aluminium Alloy Profile 400 mm x 80 mm 2 pcs Aluminium Alloy Profile 300 mm x 80 mm Aluminium Alloy 6061 400 mm x 120 mm x 12 mm. Aluminium Alloy 6061 400 mm x 800 mm x 12 mm. Linear shaft 20 mm x 400 mm aixs Linear shaft 20 mm x 300 mm aixs Linear Rail Shaft Support XYZ Table 1 pcs 25mm Linear Ball Bearing CNC http://www.youtube.com/watch?v=0mR3zOTjpX0 http://www.youtube.com/watch?v=UsXL6rAY6JE http://www.youtube.com/watch?v=JvQjrDDpivw http://www.youtube.com/watch?v=zoJwyPsdMWY More Step by Step and More Homemade Lathe DIY Mill Miling CNC Router here:

-

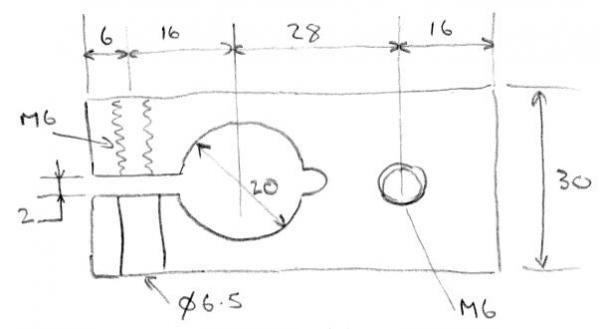

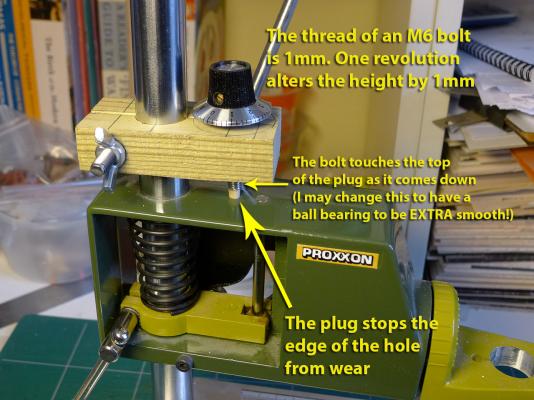

I was thinking about how to modify my Proxxon MB 140 drill stand to have a reasonably accurate vertical feed so I could use it as a mill. So I did a web search on 'Proxxon stand modification' and after several pages of results I came across this modification by a guy called Stu who posted it in a Railway Modellers' forum. I asked him for the details, and he very kindly provided the following plan: He made his block out of Perspex, but I have never worked with Perspex before, so I thought I'd try it with an old piece of pine that was lying around. This wood one works fine and I thought I'd share the results with the forum because there has been such a lot of interest in mills. However, I have ordered a block of 100mm square Perspex to make another one because I have a feeling the screw threads will last longer. The following is a picture of the original stand before modification: The following are the tools I used together with the block of wood ready cut (the very cheap drill stand I used to cut the 20mm and other holes with my large drill is not shown): As you will note, this is not an expensive modification once you have the drill stand, tap wrench and spade bit -- all of which would be useful for many other jobs. There are a couple of changes I made to Stu's original plan: 1. The tightening bolt at the back is not threaded into the block. Instead I drilled a 6mm hole and it closes with a simple wing nut. 2. Rather than driving the 'height' bolt directly on to the top of the stand, I cut off the tip of an old chopstick, put a layer of CA glue on the end to stop it fragmenting when the bolt comes into contact, and use it as a plug in the M5 hole left by the depth stop screw (which is removed when the stand is used as a mill). As you will find out when you try this, the dimensions are not critical. The stand's post is 19.8mm, and because the diameter of the flat bit was 20mm, a good slit is needed in the block to give enough clearance for the sides to flex. 2mm is just fine when you put a 6mm hole across it for the M6 bolt with the wing nut. You'll note that the slit I made on the other side of the hole for the stand looks as though it reaches into the hole for the depth bolt. This is actually the bottom end of the circular saw cut, which is much shallower on the other side of the block. When I make the next one out of Perspex I'll file it out instead. I did also buy a shielded ball bearing for the bamboo plug but it works so well without the ball bearing that I'll leave it out until it proves necessary. In practice it seems accurate. One turn of the knob gives a 1mm change in height because the M6 bolt has a thread spacing of 1mm -- so that suits the knob I bought from Maplin very nicely indeed! I hope this is as useful for others as it has been for me. Once I receive my Perspex block I'll post pictures of that as well. Tony

-

I'd like throw out a few questions I have about milling bits: 1) I'm looking for a US or Canadian vendor that sells milling bits that are reasonably priced and decent quality. Who do you recommend? Completely understand you get what you pay for, esp. when it comes to tools, so am looking for a decent balance between price and quality. 2) For our hobby, what size milling bits do you tend to use the most? Flat or round nose? 3) Which is the best way to go: 2- or 4-flute bits? 4) Is HSS the most versatile? I'm thinking at this point more of my milling will be with wood, but maybe some light metal work later on. 5) Would love to hear additional suggestions, recommendations, and ideas! Right now I'm looking at using the bits with my Proxxon drill press x-y table (will use collets when milling), but will eventually step up to a proper mill--most likely a Sherline. Thanks for your help and input! Jay

- 17 replies

-

- Mill

- Milling Machine

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.