Search the Community

Showing results for tags 'proxxon'.

-

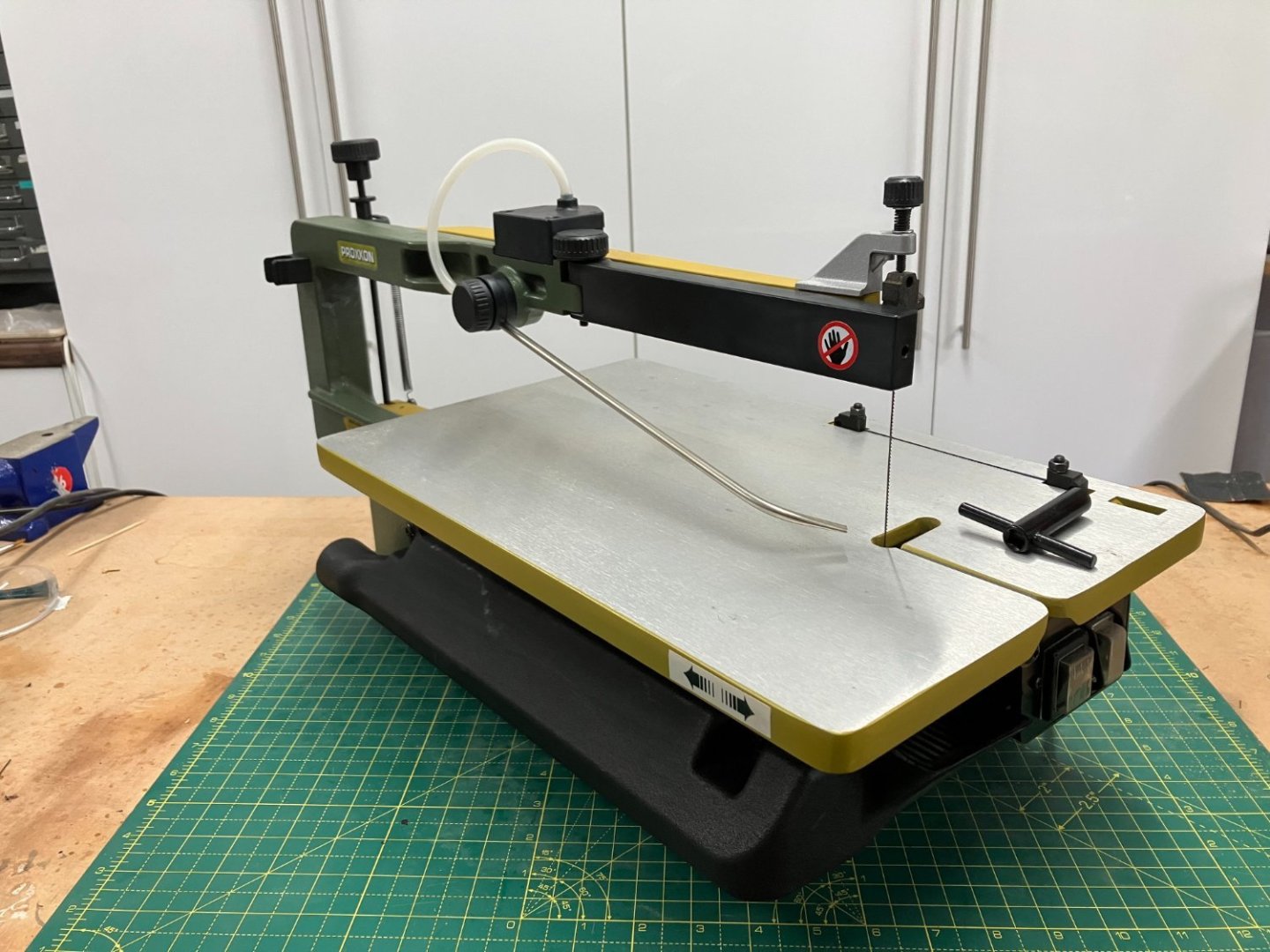

We are planning to move to a retirement village later this year and I won't be taking my larger workshop tools with me. I've already put my larger lathe and mill on ebay, but would much rather my modelling equipment went to a Forum member (I'm also listing my oscillating bobbin sander). I'm hanging on to smaller tools and in a funny sort of way I'm looking forward to going back to a simpler way of modelling. This is Proxxon's top of the range scroll saw and does everything you could want such a machine to do. I've used it quite a bit but it's still in perfect working order and comes with a set of coarse, medium and fine blades. I particularly like the handy slot on the table that keeps the blade holders exactly the right distance apart as you fit the blade. The saw currently retails for around £450 and I would be happy for it to go to a Forum member for £300. The saw is heavy (20kgs) so will need to be collected in person, from Worksop in North Nottinghamshire. Derek

-

Hello Gents! Got a sweet deal on a Proxxon DB250 wood lathe, so I pulled the trigger on this unit with the 3 jaw chuck while I save up for a Sherline (which you guys really sold me!). Are there any tips/tricks/mods that can be performed to improve function/added value? Would love to see what you guys can come up with... already saw a stainless steel mod for the tool rest, so this one seems a no brainer to perform... bugger, more stable tool rest. Please, let me know what can be done to improve the unit. Thanks! Jorge

- 11 replies

-

- db250

- mini lathe

-

(and 1 more)

Tagged with:

-

One of my favourite tools is the small proxxon drill press. The manual suggests every 10 hours of operation to lubricate the bearings but does not specify what oil to use. I emailed Proxxon and this was the reply: The TBM 220 drill press may be lubricated with a wide range oils, so we do not recommend any specific lubricant. Sewing machine oil is absolutely suitable. Maybe this will be of help to others. I am not sure what I will use, I think probably what ever car motor oil I can get my hands on. Vaddoc

-

Proxxon DB250 with three jaw chuck No longer required as I have gone to the dark side (plastic kits!), in excellent working order, complete in the box it came in with manual etc. The 3 jaw chuck was purchased later (about £30.00) and makes life so much easier. One of the two chuck keys was lost early on, but anything will serve, I used a small screwdriver. I haven't actually costed the postal price, as I'm lazy (it'll be about a tenner - in the UK) and hoping the purchaser might want to pick it up (UK - SK17 6DU). On Amazon currently it costs £136.00 and the chuck £41.00. Both yours for £90.00 plus postage How can you not want it! Bryan

-

hello friends! i just boat the Disc sander TG 125/E and i can say that tool is from the category : "Must have" a very good quality there is degrees guide and the table also can move with degrees guide (beside the ruler !) i just want to ask if some one has this tool and if he know about alternative for sandpapers Because for that tool you need a spacial sand paper that cam with sticker best regards! Michael.

-

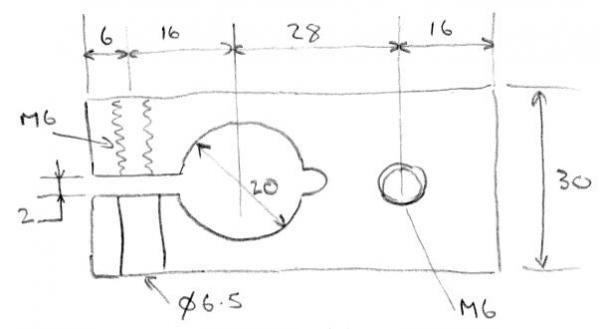

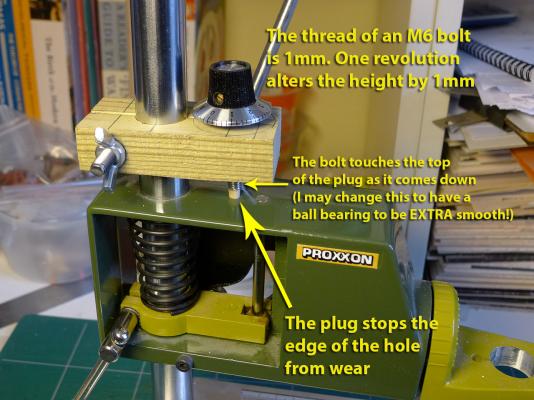

I was thinking about how to modify my Proxxon MB 140 drill stand to have a reasonably accurate vertical feed so I could use it as a mill. So I did a web search on 'Proxxon stand modification' and after several pages of results I came across this modification by a guy called Stu who posted it in a Railway Modellers' forum. I asked him for the details, and he very kindly provided the following plan: He made his block out of Perspex, but I have never worked with Perspex before, so I thought I'd try it with an old piece of pine that was lying around. This wood one works fine and I thought I'd share the results with the forum because there has been such a lot of interest in mills. However, I have ordered a block of 100mm square Perspex to make another one because I have a feeling the screw threads will last longer. The following is a picture of the original stand before modification: The following are the tools I used together with the block of wood ready cut (the very cheap drill stand I used to cut the 20mm and other holes with my large drill is not shown): As you will note, this is not an expensive modification once you have the drill stand, tap wrench and spade bit -- all of which would be useful for many other jobs. There are a couple of changes I made to Stu's original plan: 1. The tightening bolt at the back is not threaded into the block. Instead I drilled a 6mm hole and it closes with a simple wing nut. 2. Rather than driving the 'height' bolt directly on to the top of the stand, I cut off the tip of an old chopstick, put a layer of CA glue on the end to stop it fragmenting when the bolt comes into contact, and use it as a plug in the M5 hole left by the depth stop screw (which is removed when the stand is used as a mill). As you will find out when you try this, the dimensions are not critical. The stand's post is 19.8mm, and because the diameter of the flat bit was 20mm, a good slit is needed in the block to give enough clearance for the sides to flex. 2mm is just fine when you put a 6mm hole across it for the M6 bolt with the wing nut. You'll note that the slit I made on the other side of the hole for the stand looks as though it reaches into the hole for the depth bolt. This is actually the bottom end of the circular saw cut, which is much shallower on the other side of the block. When I make the next one out of Perspex I'll file it out instead. I did also buy a shielded ball bearing for the bamboo plug but it works so well without the ball bearing that I'll leave it out until it proves necessary. In practice it seems accurate. One turn of the knob gives a 1mm change in height because the M6 bolt has a thread spacing of 1mm -- so that suits the knob I bought from Maplin very nicely indeed! I hope this is as useful for others as it has been for me. Once I receive my Perspex block I'll post pictures of that as well. Tony

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpg.6fd4c1b78768bb3efd745ab810936005.jpg)